ASTM D5444-08

(Test Method)Standard Test Method for Mechanical Size Analysis of Extracted Aggregate

Standard Test Method for Mechanical Size Analysis of Extracted Aggregate

SIGNIFICANCE AND USE

This test method is used to determine the grading of aggregates extracted from bituminous mixtures. The results are used to determine compliance of the particle size distribution with applicable specifications requirements, and to provide necessary data for control of the production of various aggregates to be used in bituminous mixtures.

SCOPE

1.1 This test method covers a procedure for determination of the particle size distribution of fine and coarse aggregates extracted from bituminous mixtures using sieves with square openings.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5444 − 08

StandardTest Method for

1

Mechanical Size Analysis of Extracted Aggregate

This standard is issued under the fixed designation D5444; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Significance and Use

1.1 This test method covers a procedure for determination 3.1 This test method is used to determine the grading of

aggregatesextractedfrombituminousmixtures.Theresultsare

of the particle size distribution of fine and coarse aggregates

extracted from bituminous mixtures using sieves with square used to determine compliance of the particle size distribution

with applicable specifications requirements, and to provide

openings.

necessary data for control of the production of various aggre-

1.2 The values stated in SI units are to be regarded as the

gates to be used in bituminous mixtures.

standard. The values given in parentheses are for information

only.

4. Apparatus

1.3 This standard does not purport to address all of the

4.1 Balances,orscales,readableto0.1gandaccurateto0.1

safety concerns, if any, associated with its use. It is the

g or 0.1% of the test load, whichever is greater, at any point

responsibility of the user of this standard to establish appro-

within the range of use.

priate safety and health practices and determine the applica-

4.2 Sieves, with square openings, mounted on substantial

bility of regulatory limitations prior to use.

frames constructed in a manner that will prevent the loss of

materials during sieving. Suitable sieve sizes shall be selected

2. Referenced Documents

to furnish the information required by the specifications

2

2.1 ASTM Standards:

coveringthematerialtobetested.Thewovenwireclothsieves

C670Practice for Preparing Precision and Bias Statements shall conform to the requirements of Specification E11.

for Test Methods for Construction Materials

4.3 Mechanical Sieve Shaker—If used, it shall impart a

D2172Test Methods for Quantitative Extraction of Bitumen

vertical,orlateralandvertical,motiontothesieve,causingthe

From Bituminous Paving Mixtures

particles thereon to bounce and turn so as to present different

D6307TestMethodforAsphaltContentofHot-MixAsphalt

orientations to the sieving surface. The sieving action shall be

by Ignition Method

such that the criterion for adequacy of sieving described in 6.8

E11Specification forWovenWireTest Sieve Cloth andTest

is met in a reasonable time period.

Sieves

4.4 Oven, of appropriate size, capable of maintaining a

3

2.2 AASHTO Standard:

uniform temperature of 110 6 5°C (230 6 9°F).

AASHTO Test Method T30 Mechanical Analysis of Ex-

4.5 Container—A pan or vessel of a size sufficient to

tracted Aggregate

contain the sample covered with water and to permit vigorous

agitation without loss of any of the sample or water.

1

5. Sample

This test method is under the jurisdiction of ASTM Committee D04 on Road

and Paving Materials and is the direct responsibility of Subcommittee D04.51 on

5.1 The sample shall consist of the entire sample of aggre-

Aggregate Tests.

gate from Test Method D2172 or Test Method D6307.

Current edition approved Dec. 1, 2008. Published December 2008. Originally

5.1.1 Aggregate extracted by the ignition method in Test

approved in 1993. Last previous edition approved in 2005 as D5444–05. DOI:

10.1520/D5444-08.

Method D6307 shall not be used for gradation analysis if the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

correction factor obtained in Test Method D6307 is greater

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

than 1.0 (see Note 1).

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

5.2 The size of the test sample shall be governed by the

3

Available from American Association of State Highway and Transportation

nominal maximum aggregate size and shall conform to the

Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

http://www.transportation.org.

mass requirements shown in Table I.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

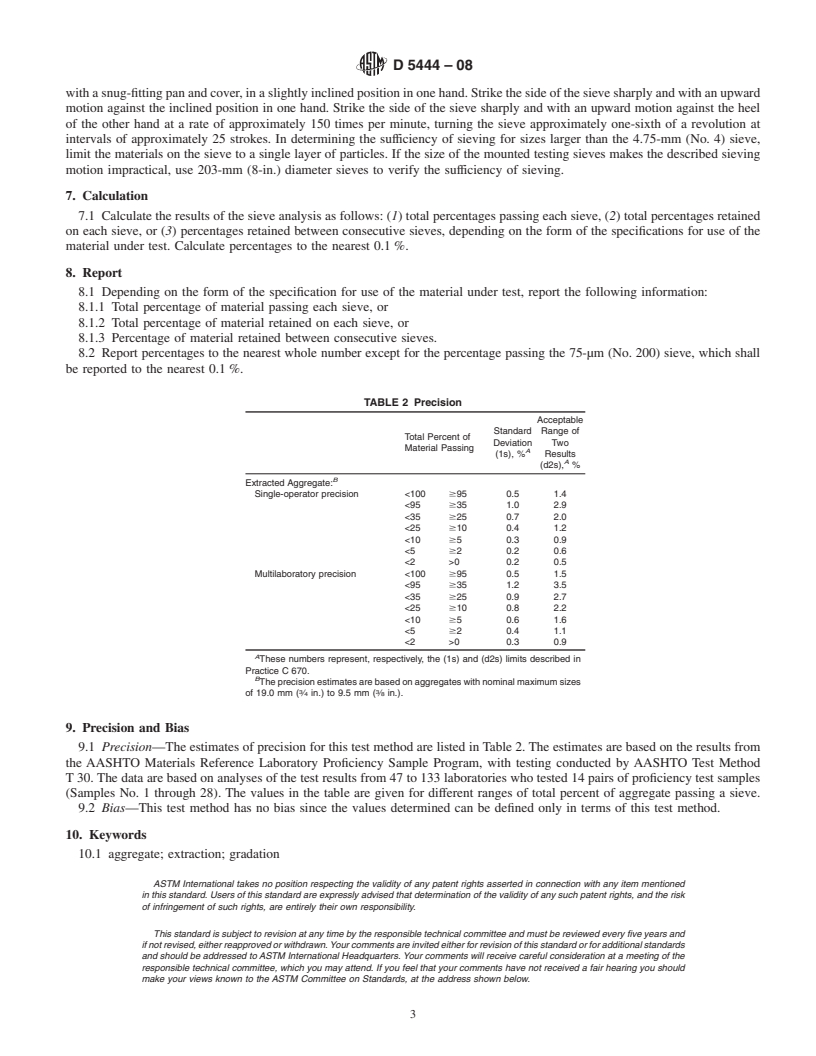

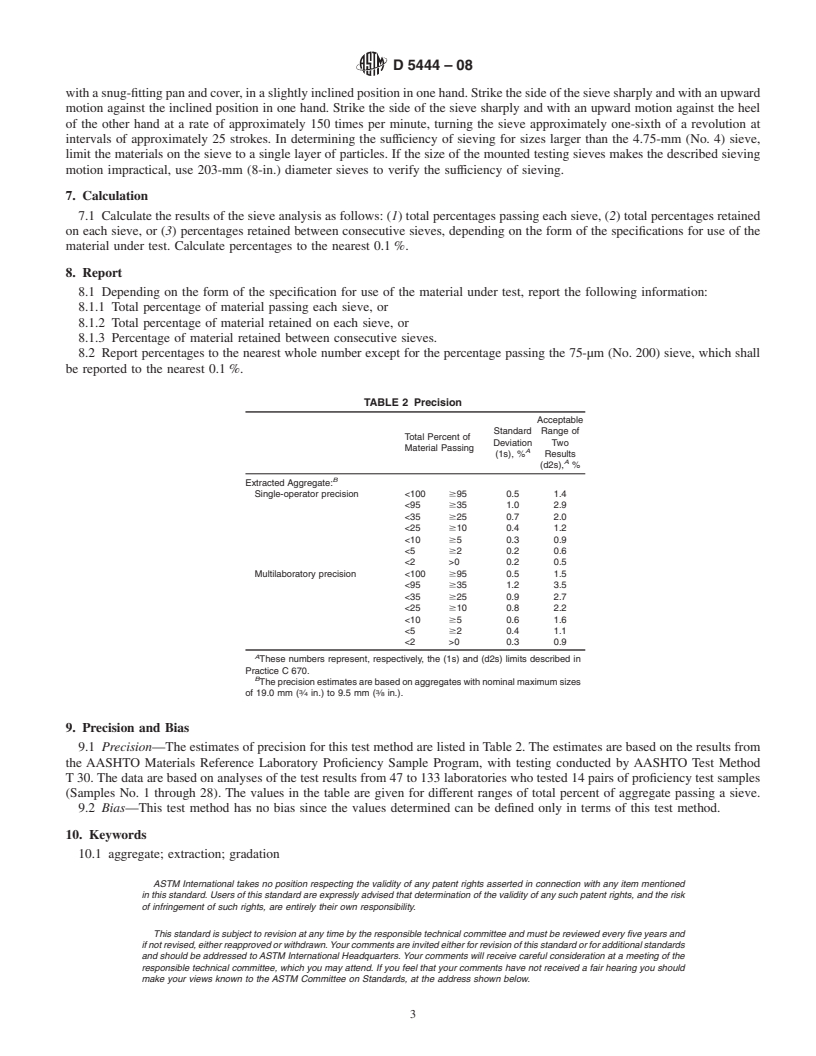

D5444 − 08

TABLE 1 Size of Sample

6.5 Thensievetheaggregateoversievesofthevarioussizes

Minimum Mass of required by the specification covering the mixture, including

Sample, kg

the 75-µm sieve. Record the weight of material passing each

4.75 (No. 4) 0.5

sieve and retained on the next and the amount passing the

3

9.5 ( ⁄8 in.) 1

75-µm sieve. The summation of these various weights must

1

12.5 ( ⁄2 in.) 1.5

3

19.0 ( ⁄

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5444–05 Designation:D5444–08

Standard Test Method for

1

Mechanical Size Analysis of Extracted Aggregate

This standard is issued under the fixed designation D 5444; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thistestmethodcoversaprocedurefordeterminationoftheparticlesizedistributionoffineandcoarseaggregatesextracted

from bituminous mixtures using sieves with square openings.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C 670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

D 2172 Test Methods for Quantitative Extraction of Bitumen fromFrom Bituminous Paving Mixtures

D 6307 Test Method for Asphalt Content of Hot-Mix Asphalt by Ignition Method

E11 Specification for Wire Cloth and Sieves for Testing Purposes

3

2.2 AASHTO Standard:

AASHTO Test Method T 30Mechanical Analysis of Extracted Aggregate Mechanical Analysis of Extracted Aggregate

3. Significance and Use

3.1 This test method is used to determine the grading of aggregates extracted from bituminous mixtures. The results are used

to determine compliance of the particle size distribution with applicable specifications requirements, and to provide necessary data

for control of the production of various aggregates to be used in bituminous mixtures.

4. Apparatus

4.1 Balances, or scales, readable to 0.1 g and accurate to 0.1 g or 0.1 % of the test load, whichever is greater, at any point within

the range of use.

4.2 Sieves, with square openings, mounted on substantial frames constructed in a manner that will prevent the loss of materials

during sieving. Suitable sieve sizes shall be selected to furnish the information required by the specifications covering the material

to be tested. The woven wire cloth sieves shall conform to the requirements of Specification E 11.

4.3 MechanicalSieveShaker—If used, it shall impart a vertical, or lateral and vertical, motion to the sieve, causing the particles

thereon to bounce and turn so as to present different orientations to the sieving surface. The sieving action shall be such that the

criterion for adequacy of sieving described in 6.8 is met in a reasonable time period.

4.4 Oven, of appropriate size, capable of maintaining a uniform temperature of 110 6 5°C (230 6 9°F).

4.5 Container—A pan or vessel of a size sufficient to contain the sample covered with water and to permit vigorous agitation

without loss of any of the sample or water.

5. Sample

5.1 The sample shall consist of the entire sample of aggregate from Test Method D 2172 or Test Method D 6307.

1

This test method is under the jurisdiction ofASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.51 onAggregate

Tests.

Current edition approved Feb.Dec. 1, 2005.2008. Published February 2005.December 2008. Originally approved in 1993. Last previous edition approved in 19982005 as

D5444–98.D 5444 – 05.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from the American Association of State Highway and Transportation Officials, 444 N. Capitol St., N.W., Washington, DC 20001.

3

Available from American Association of State Highway and Transportation Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5444–08

TABLE 1 Size of Sample

Minimum Mass of

Sample, kg

4.75 (No. 4) 0.5

3

9.5 ( ⁄8 in.) 1

1

12.5 ( ⁄2 in.) 1.5

3

19.0 ( ⁄4 in.) 2

25.0 (1 in.) 3

1

37.5 (1 ⁄2 in.) 4

5.1.1 Aggregate extracted by the ignition method in Test Method D 6307

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5444–05 Designation:D5444–08

Standard Test Method for

1

Mechanical Size Analysis of Extracted Aggregate

This standard is issued under the fixed designation D 5444; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thistestmethodcoversaprocedurefordeterminationoftheparticlesizedistributionoffineandcoarseaggregatesextracted

from bituminous mixtures using sieves with square openings.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C 670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

D 2172 Test Methods for Quantitative Extraction of Bitumen fromFrom Bituminous Paving Mixtures

D 6307 Test Method for Asphalt Content of Hot-Mix Asphalt by Ignition Method

E11 Specification for Wire Cloth and Sieves for Testing Purposes

3

2.2 AASHTO Standard:

AASHTO Test Method T 30Mechanical Analysis of Extracted Aggregate Mechanical Analysis of Extracted Aggregate

3. Significance and Use

3.1 This test method is used to determine the grading of aggregates extracted from bituminous mixtures. The results are used

to determine compliance of the particle size distribution with applicable specifications requirements, and to provide necessary data

for control of the production of various aggregates to be used in bituminous mixtures.

4. Apparatus

4.1 Balances, or scales, readable to 0.1 g and accurate to 0.1 g or 0.1 % of the test load, whichever is greater, at any point within

the range of use.

4.2 Sieves, with square openings, mounted on substantial frames constructed in a manner that will prevent the loss of materials

during sieving. Suitable sieve sizes shall be selected to furnish the information required by the specifications covering the material

to be tested. The woven wire cloth sieves shall conform to the requirements of Specification E 11.

4.3 MechanicalSieveShaker—If used, it shall impart a vertical, or lateral and vertical, motion to the sieve, causing the particles

thereon to bounce and turn so as to present different orientations to the sieving surface. The sieving action shall be such that the

criterion for adequacy of sieving described in 6.8 is met in a reasonable time period.

4.4 Oven, of appropriate size, capable of maintaining a uniform temperature of 110 6 5°C (230 6 9°F).

4.5 Container—A pan or vessel of a size sufficient to contain the sample covered with water and to permit vigorous agitation

without loss of any of the sample or water.

5. Sample

5.1 The sample shall consist of the entire sample of aggregate from Test Method D 2172 or Test Method D 6307.

1

This test method is under the jurisdiction ofASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.51 onAggregate

Tests.

Current edition approved Feb.Dec. 1, 2005.2008. Published February 2005.December 2008. Originally approved in 1993. Last previous edition approved in 19982005 as

D5444–98.D 5444 – 05.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from the American Association of State Highway and Transportation Officials, 444 N. Capitol St., N.W., Washington, DC 20001.

3

Available from American Association of State Highway and Transportation Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5444–08

TABLE 1 Size of Sample

Minimum Mass of

Sample, kg

4.75 (No. 4) 0.5

3

9.5 ( ⁄8 in.) 1

1

12.5 ( ⁄2 in.) 1.5

3

19.0 ( ⁄4 in.) 2

25.0 (1 in.) 3

1

37.5 (1 ⁄2 in.) 4

5.1.1 Aggregate extracted by the ignition method in Test Method D 6307

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.