ASTM D6556-17

(Test Method)Standard Test Method for Carbon Black—Total and External Surface Area by Nitrogen Adsorption

Standard Test Method for Carbon Black—Total and External Surface Area by Nitrogen Adsorption

SIGNIFICANCE AND USE

4.1 This test method is used to measure the total and external surface area of carbon blacks based on multipoint nitrogen adsorption. The NSA measurement is based on the B.E.T. theory and it includes the total surface area, inclusive of micropores, pore diameters less than 2 nm (20 Å). The external surface area, based on the statistical thickness method (STSA), is defined as the specific surface area that is accessible to rubber.

4.2 CTAB Surface Area (formerly Test Method D3765) has been withdrawn. The CTAB value may be estimated from the STSA value using Eq 1. The equation is based on a linear regression of the STSA and CTAB measured values of the SRB 5 standards.

SCOPE

1.1 This test method covers the determination of the total surface area by the Brunauer, Emmett, and Teller (B.E.T. NSA) theory of multilayer gas adsorption behavior using multipoint determinations and the external surface area based on the statistical thickness surface area method.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. (The minimum safety equipment should include protective gloves, sturdy eye and face protection).

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6556 − 17

Standard Test Method for

Carbon Black—Total and External Surface Area by Nitrogen

1

Adsorption

This standard is issued under the fixed designation D6556; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3765Test Method for Carbon Black—CTAB (Cetyltrim-

ethylammonium Bromide) Surface Area (Withdrawn

1.1 This test method covers the determination of the total

3

2007)

surfaceareabytheBrunauer,Emmett,andTeller(B.E.T.NSA)

D4483Practice for Evaluating Precision for Test Method

theory of multilayer gas adsorption behavior using multipoint

StandardsintheRubberandCarbonBlackManufacturing

determinations and the external surface area based on the

Industries

statistical thickness surface area method.

3. Summary of Test Method

1.2 The values stated in SI units are to be regarded as the

3.1 The total and external surface areas are measured by

standard. The values given in parentheses are for information

evaluating the amount of nitrogen adsorbed, at liquid nitrogen

only.

temperature, by a carbon black at several partial pressures of

1.3 This standard does not purport to address all of the

nitrogen. The adsorption data is used to calculate the NSAand

safety concerns, if any, associated with its use. It is the

STSA values.

responsibility of the user of this standard to establish appro-

4. Significance and Use

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

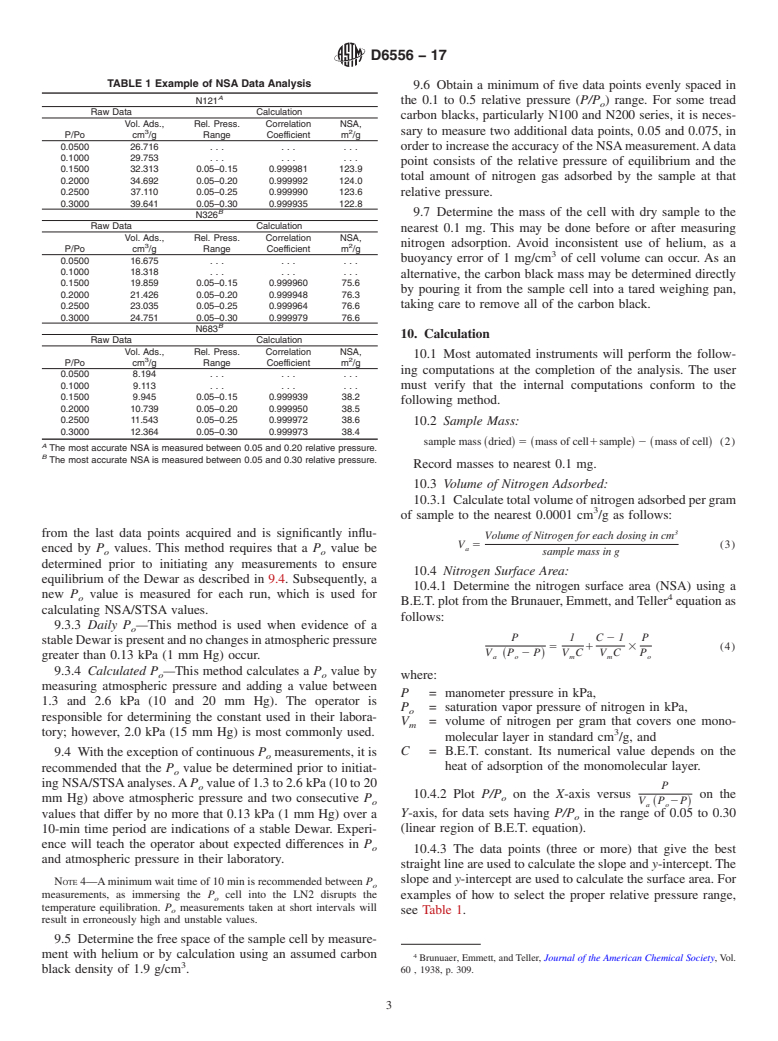

4.1 This test method is used to measure the total and

(The minimum safety equipment should include protective

external surface area of carbon blacks based on multipoint

gloves, sturdy eye and face protection).

nitrogen adsorption. The NSA measurement is based on the

B.E.T.theoryanditincludesthetotalsurfacearea,inclusiveof

1.4 This international standard was developed in accor-

micropores,porediameterslessthan2nm(20Å).Theexternal

dance with internationally recognized principles on standard-

surfacearea,basedonthestatisticalthicknessmethod(STSA),

ization established in the Decision on Principles for the

is defined as the specific surface area that is accessible to

Development of International Standards, Guides and Recom-

rubber.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. 4.2 CTAB SurfaceArea (formerly Test Method D3765) has

been withdrawn. The CTAB value may be estimated from the

STSA value using Eq 1. The equation is based on a linear

2. Referenced Documents

regressionoftheSTSAandCTABmeasuredvaluesoftheSRB

2

2.1 ASTM Standards:

5 standards.

D1799 Practice for Carbon Black—Sampling Packaged

CTAB 5STSA*1.017012.6434 (1)

Shipments

D1900Practice for Carbon Black—Sampling Bulk Ship-

5. Apparatus

ments

5.1 MultipointStatic-VolumetricGasAdsorptionApparatus,

with Dewar flasks and all other accessories required for

operation.

1

This test method is under the jurisdiction ofASTM Committee D24 on Carbon

5.2 Sample Cells, that when attached to the adsorption

Black and is the direct responsibility of Subcommittee D24.21 on Carbon Black

Surface Area and Related Properties. apparatus, will maintain isolation of the sample from the

–5 3

Current edition approved Oct. 1, 2017. Published November 2017. Originally

atmosphere equivalent to a helium leak rate of <10 cm /min,

approved in 2000. Last previous edition approved in 2016 as D6556–16. DOI:

per atmosphere of pressure difference.

10.1520/D6556-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6556 − 17

5.3 Balance, Analytical, with 0.1 mg sensitivity. fromtheheatsourceandcontinuetheflowofpurginggasuntil

it is ready for analysis.

5.4 Heating Mantle or Equivalent, capable of maintaining a

8.4.5 Go directly to Section 9 and continue the remaining

temperature of 300 6 10°C.

steps of the procedure.

5.5 Oven, Gravity Convection, capable of maintaining a

8.5 Vacuum Degassing:

temperature of 125 6 10°C.

8.5.1 With the apparatus at atmospheric pressure, place the

6. Reagents

sample cell containing the carbon black onto the degassing

apparatus.

6.1 Liquid Nitrogen, 98% or higher purity.

8.5.2 Begin the degassing procedure as appropri

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6556 − 16 D6556 − 17

Standard Test Method for

Carbon Black—Total and External Surface Area by Nitrogen

1

Adsorption

This standard is issued under the fixed designation D6556; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the total surface area by the Brunauer, Emmett, and Teller (B.E.T. NSA) theory

of multilayer gas adsorption behavior using multipoint determinations and the external surface area based on the statistical

thickness surface area method.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. (The minimum safety equipment should include protective gloves, sturdy eye

and face protection).

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D1799 Practice for Carbon Black—Sampling Packaged Shipments

D1900 Practice for Carbon Black—Sampling Bulk Shipments

3

D3765 Test Method for Carbon Black—CTAB (Cetyltrimethylammonium Bromide) Surface Area (Withdrawn 2007)

D4483 Practice for Evaluating Precision for Test Method Standards in the Rubber and Carbon Black Manufacturing Industries

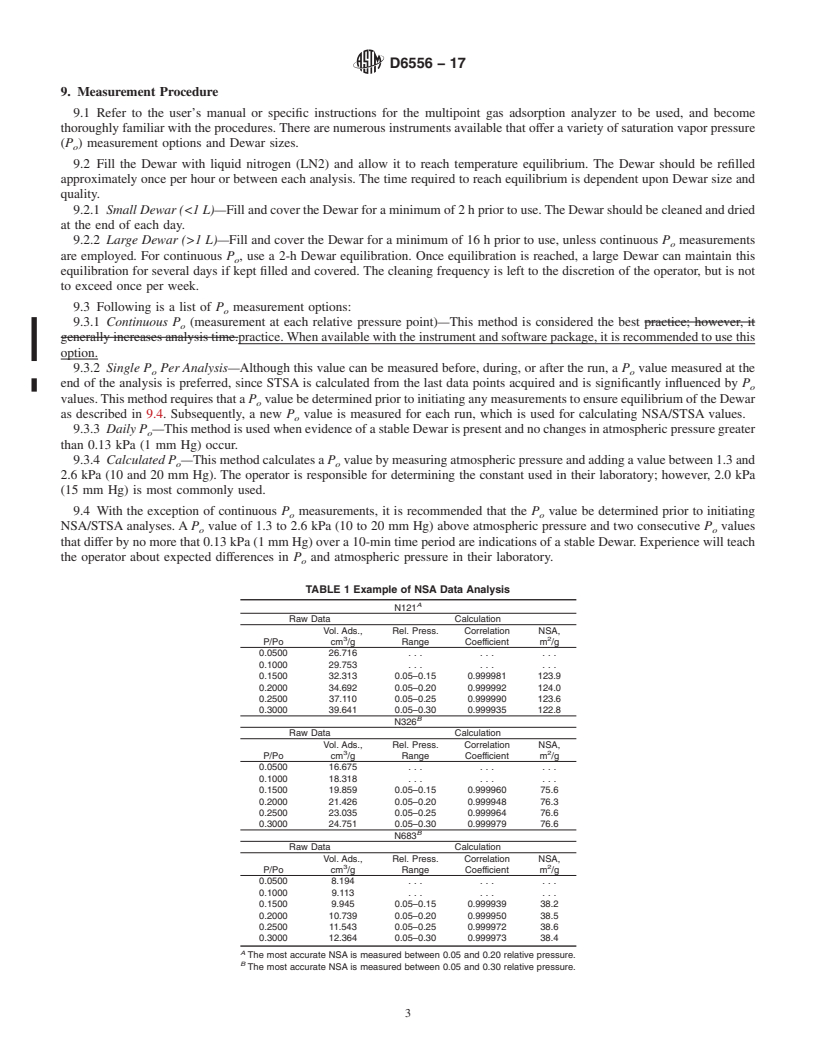

3. Summary of Test Method

3.1 The total and external surface areas are measured by evaluating the amount of nitrogen adsorbed, at liquid nitrogen

temperature, by a carbon black at several partial pressures of nitrogen. The adsorption data is used to calculate the NSA and STSA

values.

4. Significance and Use

4.1 This test method is used to measure the total and external surface area of carbon blacks based on multipoint nitrogen

adsorption. The NSA measurement is based on the B.E.T. theory and it includes the total surface area, inclusive of micropores,

pore diameters less than 2 nm (20 Å). The external surface area, based on the statistical thickness method (STSA), is defined as

the specific surface area that is accessible to rubber.

4.2 CTAB Surface Area (formerly Test Method D3765) has been withdrawn. The CTAB value may be estimated from the STSA

value using Eq 1. The equation is based on a linear regression of the STSA and CTAB measured values of the SRB 5 standards.

CTAB 5 STSA*1.017012.6434 (1)

1

This test method is under the jurisdiction of ASTM Committee D24 on Carbon Black and is the direct responsibility of Subcommittee D24.21 on Carbon Black Surface

Area and Related Properties.

Current edition approved Jan. 1, 2016Oct. 1, 2017. Published February 2016November 2017. Originally approved in 2000. Last previous edition approved in 20142016

as D6556 – 14.D6556 – 16. DOI: 10.1520/D6556-16.10.1520/D6556-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6556 − 17

5. Apparatus

5.1 Multipoint Static-Volumetric Gas Adsorption Apparatus, with Dewar flasks and all other accessories required for operation.

5.2 Sample Cells, that when attached to the adsorption apparatus, will maintain isolation of the sample from the atmosphere

–5 3

equivalent to a helium leak rate of <10 cm /min, per atmosphere of pressure difference.

5.3 Balance, Analytical, with 0.1 mg sensitivity.

5.4 Heating Mantle or Equivalent, capable of maintaining a temperature of 300 6 10°C.

5.5 Oven, Gravity Convection, capable of maintaining a temperature of 125 6 10°C

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.