ASTM C714-23

(Guide)Standard Guide for Thermal Diffusivity of Carbon and Graphite by Thermal Pulse Method

Standard Guide for Thermal Diffusivity of Carbon and Graphite by Thermal Pulse Method

SIGNIFICANCE AND USE

5.1 Thermal diffusivity is an important property required for such purposes as design applications under transient heat flow conditions, determination of safe operating temperature, process control, and quality assurance.

5.2 The flash method is used to measure values of thermal diffusivity (α) of a wide range of solid materials. It is particularly advantageous because of the simple specimen geometry, small specimen size requirements, rapidity of measurement, and ease of handling materials having a wide range of thermal diffusivity values over a large temperature range with a single apparatus. The short measurement times involved reduce the chances of contamination and change of specimen properties due to exposure to high temperature environments.

5.3 Thermal diffusivity results in many cases can be combined with values for specific heat (Cp) and density (ρ) to derive thermal conductivity (λ) from the relation λ = αCpρ. For guidance on converting thermal diffusivity to thermal conductivity, refer to Practice C781.

5.4 This test method described in this guide can be used to characterize graphite for design purposes.

5.5 Test Method E1461 is a more detailed form of this test method described in this guide and has applicability to much wider ranges of materials, applications, and temperatures.

SCOPE

1.1 This guide covers the determination of the thermal diffusivity of carbons and graphite at temperatures up to 500 °C. It is applicable only to small easily fabricated specimens. Thermal diffusivity values in the range from 0.04 cm2/s to 2.0 cm2/s are readily measurable by this guide; however, for the reason outlined in Section 7, for materials outside this range this guide may not be applicable.

1.2 Units—The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C714 − 23

Standard Guide for

Thermal Diffusivity of Carbon and Graphite by Thermal

1

Pulse Method

This standard is issued under the fixed designation C714; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Terminology

1.1 This guide covers the determination of the thermal 3.1 Definitions:

diffusivity of carbons and graphite at temperatures up to 3.1.1 For definitions of terms used in this guide, refer to

500 °C. It is applicable only to small easily fabricated speci-

Terminology D4175.

2

mens. Thermal diffusivity values in the range from 0.04 cm /s

3.1.2 thermal conductivity, n—the rate at which heat passes

2

to 2.0 cm /s are readily measurable by this guide; however, for

through a material, expressed as the amount of heat that flows

the reason outlined in Section 7, for materials outside this

per unit time through a unit area with a temperature gradient of

range this guide may not be applicable.

one degree per unit distance.

1.2 Units—The values stated in SI units are to be regarded 3.1.3 thermal diffusivity, n—a measure of the ability of a

as the standard. No other units of measurement are included in

material to conduct thermal energy relative to its ability to store

this standard. thermal energy; it is equal to the thermal conductivity divided

by density and specific heat capacity at constant pressure.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Summary of Guide

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

4.1 A high-intensity short-duration thermal pulse from a

mine the applicability of regulatory limitations prior to use.

flash lamp is absorbed on the front surface of a specimen; and

1.4 This international standard was developed in accor-

the rear surface temperature change as a function of time is

dance with internationally recognized principles on standard-

recorded. The pulse raises the average temperature of the

ization established in the Decision on Principles for the

specimen only a few degrees above its initial value. The

Development of International Standards, Guides and Recom-

ambient temperature of the specimen is controlled by a furnace

mendations issued by the World Trade Organization Technical

or cryostat. Thermal diffusivity is calculated from the specimen

Barriers to Trade (TBT) Committee.

thickness and the time required for the temperature of the back

3

surface to rise to one half of its maximum value (1).

2. Referenced Documents

2

4.2 The critical factors in this guide are:

2.1 ASTM Standards:

1

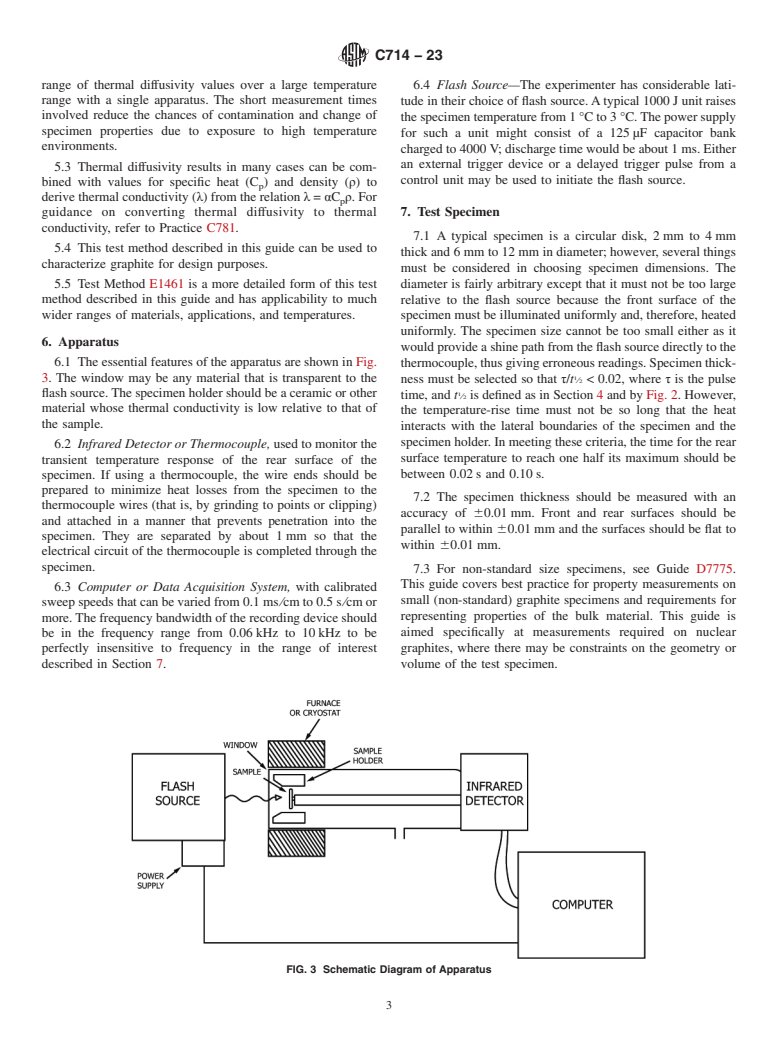

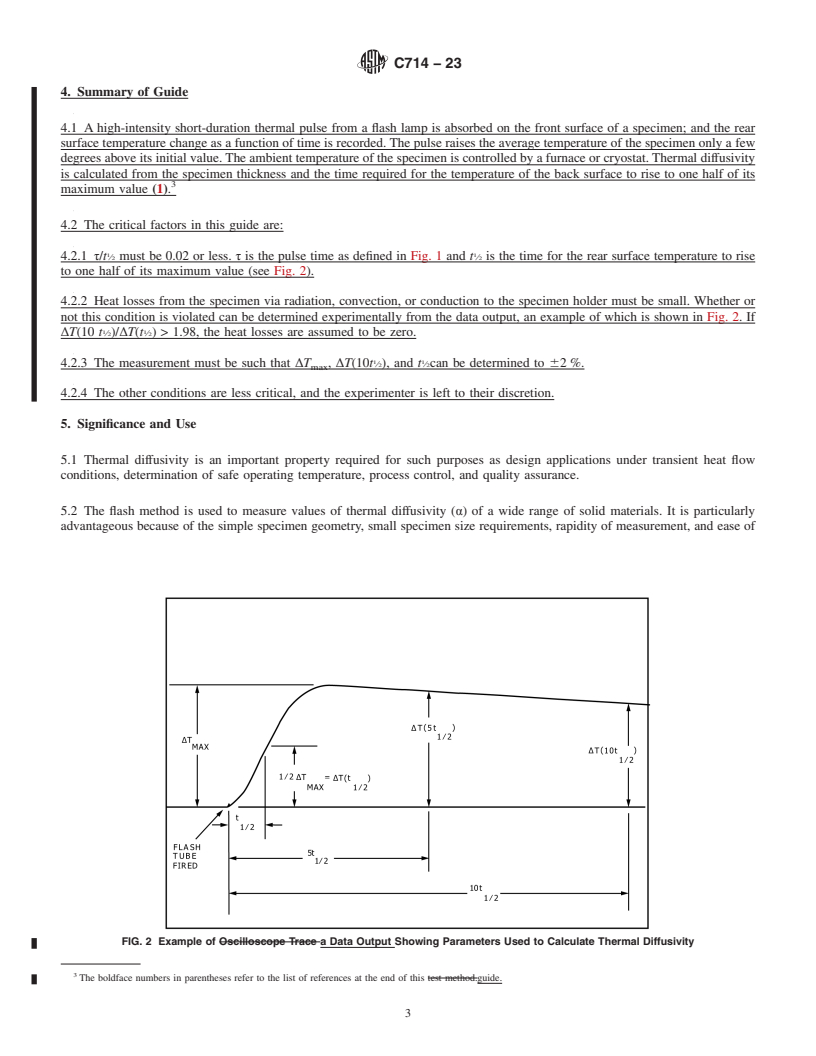

4.2.1 τ/t ⁄2 must be 0.02 or less. τ is the pulse time as defined

C781 Practice for Testing Graphite Materials for Gas-Cooled

1

in Fig. 1 and t ⁄2 is the time for the rear surface temperature to

Nuclear Reactor Components

rise to one half of its maximum value (see Fig. 2).

D4175 Terminology Relating to Petroleum Products, Liquid

4.2.2 Heat losses from the specimen via radiation,

Fuels, and Lubricants

convection, or conduction to the specimen holder must be

D7775 Guide for Measurements on Small Graphite Speci-

small. Whether or not this condition is violated can be

mens

determined experimentally from the data output, an example of

E1461 Test Method for Thermal Diffusivity by the Flash

1 1

which is shown in Fig. 2. If ΔT(10 t ⁄2 )/ΔT(t ⁄2 ) > 1.98, the heat

Method

losses are assumed to be zero.

1

1 4.2.3 The measurement must be such that ΔT , ΔT(10t ⁄2 ),

This guide is under the jurisdiction of ASTM Committee D02 on Petroleum

max

1

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom-

and t ⁄2 can be determined to 62 %.

mittee D02.F0 on Manufactured Carbon and Graphite Products.

4.2.4 The other conditions are less critical, and the experi-

Current edition approved Oct. 1, 2023. Published October 2023. Originally

menter is left to their discretion.

approved in 1972. Last previous edition approved in 2017 as C714 – 17. DOI:

10.1520/C0714-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The boldface numbers in parentheses refer to the list of references at the end of

the ASTM website. this guide.

*A Summary of Changes section appears at the end of this s

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C714 − 17 C714 − 23

Standard Test Method Guide for

Thermal Diffusivity of Carbon and Graphite by Thermal

1

Pulse Method

This standard is issued under the fixed designation C714; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method guide covers the determination of the thermal diffusivity of carbons and graphite at temperatures up to

500 °C. It requires only ais applicable only to small easily fabricated specimen.specimens. Thermal diffusivity values in the range

2 2

from 0.04 cm /s to 2.0 cm /s are readily measurable by this test method; guide; however, for the reason outlined in Section 7, for

materials outside this range this test method may require modification. guide may not be applicable.

1.2 Units—The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this

standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and healthsafety, health, and environmental practices and determine

the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C781 Practice for Testing Graphite Materials for Gas-Cooled Nuclear Reactor Components

D4175 Terminology Relating to Petroleum Products, Liquid Fuels, and Lubricants

D7775 Guide for Measurements on Small Graphite Specimens

E1461 Test Method for Thermal Diffusivity by the Flash Method

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this guide, refer to Terminology D4175.

3.1.2 thermal conductivity, n—the rate at which heat passes through a material, expressed as the amount of heat that flows per unit

time through a unit area with a temperature gradient of one degree per unit distance.

1

This test method guide is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.F0 on Manufactured Carbon and Graphite Products.

Current edition approved May 1, 2017Oct. 1, 2023. Published May 2017October 2023. Originally approved in 1972. Last previous edition approved in 20152017 as

C714 – 05 (2015).C714 – 17. DOI: 10.1520/C0714-17.10.1520/C0714-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C714 − 23

3.1.3 thermal diffusivity, n—a measure of the ability of a material to conduct thermal energy relative to its ability to store thermal

energy; it is equal to the thermal conductivity divided by density and specific heat capacity at constant pressure.

4. Summary of Test Method

4.1 A high-intensity short-duration thermal pulse from a flash lamp is absorbed on the front surface of a specimen; and the rear

surface temperature change as a function of time is observed on an oscilloscope. The pulse raises the average temperature of the

specimen only a few degrees above its initial value. The ambient temperature of the specimen is controlled by a furnace or cryostat.

Thermal diffusivity is calculated from the specimen thickness and the time required for the temperature of the back surface to rise

3

to one half of its maximum value (1).

4.2 The critical factors in this test method are:

1 1

4.2.1 τ/t ⁄2 must be 0.02 or less. τ is the pulse time as defined in Fig. 1 and t ⁄2 is the time for the rear surface temperature to rise

to one half of its maximum value (see Fig. 2).

4.2.2 Heat losses from the specimen via radiation, convection, or conduction to the specimen holder m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.