ASTM B709-04(2009)

(Specification)Standard Specification for Iron-Nickel-Chromium-Molybdenum Alloy (UNS N08028)* Plate, Sheet, and Strip

Standard Specification for Iron-Nickel-Chromium-Molybdenum Alloy (UNS N08028)* Plate, Sheet, and Strip

ABSTRACT

This specification covers solution-annealed UNS N08028 iron-nickel-chromium-molybdenum alloy plates, sheets, and strips. In preparing the materials, the final heat treatment should be a solution-anneal which can be followed by minor cold working such as flattening or temper rolling. The recommended solution-anneal consists of heating to a minimum temperature and rapid cooling.

SCOPE

1.1 This specification covers iron-nickel-chromium-molybdenum alloy (UNS N08028)* plate, sheet, and strip in the solution-annealed condition.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B709 −04(Reapproved 2009)

Standard Specification for

Iron-Nickel-Chromium-Molybdenum Alloy (UNS N08028)

Plate, Sheet, and Strip

This standard is issued under the fixed designation B709; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope not limited to those specified in Ordering Information Section

in Specification B906.

1.1 This specification covers iron-nickel-chromium-

molybdenum alloy (UNS N08028)* plate, sheet, and strip in

4. General Requirements

the solution-annealed condition.

4.1 Material furnished under this specification shall con-

1.2 The values stated in inch-pound units are to be regarded

form to the applicable requirements of the current edition of

as standard. The values given in parentheses are mathematical

Specification B906, unless otherwise specified herein.

conversions to SI units that are provided for information only

and are not considered standard.

5. Materials and Manufacture

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5.1 Heat Treatment—The final heat treatment shall be a

responsibility of the user of this standard to become familiar solution-anneal. Minor cold working such as flattening or

with all hazards including those identified in the appropriate

temper rolling may be performed after the final solution

Material Safety Data Sheet (MSDS) for this product/material annealing treatment.

as provided by the manufacturer, to establish appropriate

NOTE 1—This recommended solution-anneal consists of heating to a

safety and health practices, and determine the applicability of

minimum temperature of 1975°F (1080°C) and cooling rapidly to room

regulatory limitations prior to use.

temperature.

2. Referenced Documents

6. Chemical Composition

2.1 ASTM Standards:

6.1 The material sampled in accordance with 10.2 shall

B880 Specification for General Requirements for Chemical

conform to the composition limits prescribed in Table 1.

Check Analysis Limits for Nickel, Nickel Alloys and

6.2 If a product analysis is subsequently made, the material

Cobalt Alloys

shall conform to the composition limits with the product

B906 Specification for General Requirements for Flat-

analysis variation prescribed Specification B880.

Rolled Nickel and Nickel Alloys Plate, Sheet, and Strip

E8/E8M Test Methods for Tension Testing of Metallic Ma-

7. Mechanical Properties

terials

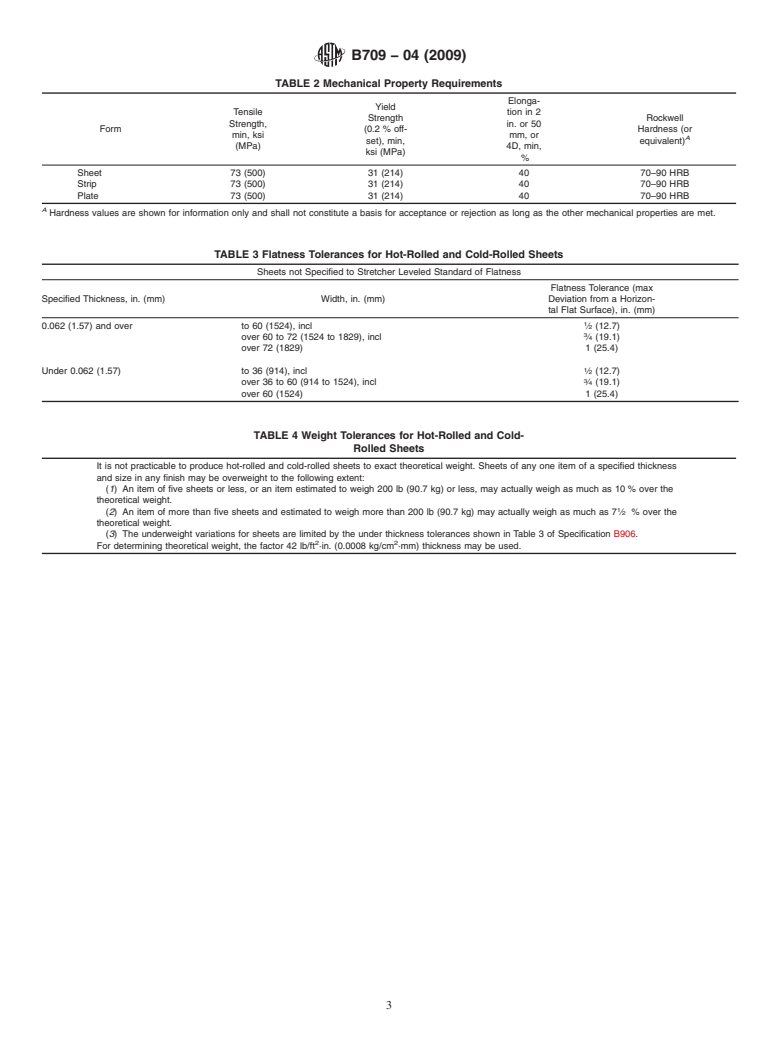

7.1 The material shall conform to the requirements as to the

3. Ordering Information

mechanical property prescribed in Table 2.

3.1 It is the responsibility of the purchaser to specify all

requirements that are necessary for material ordered under this 8. Dimensions and Permissible Variations

specification. Examples of such requirements include, but are

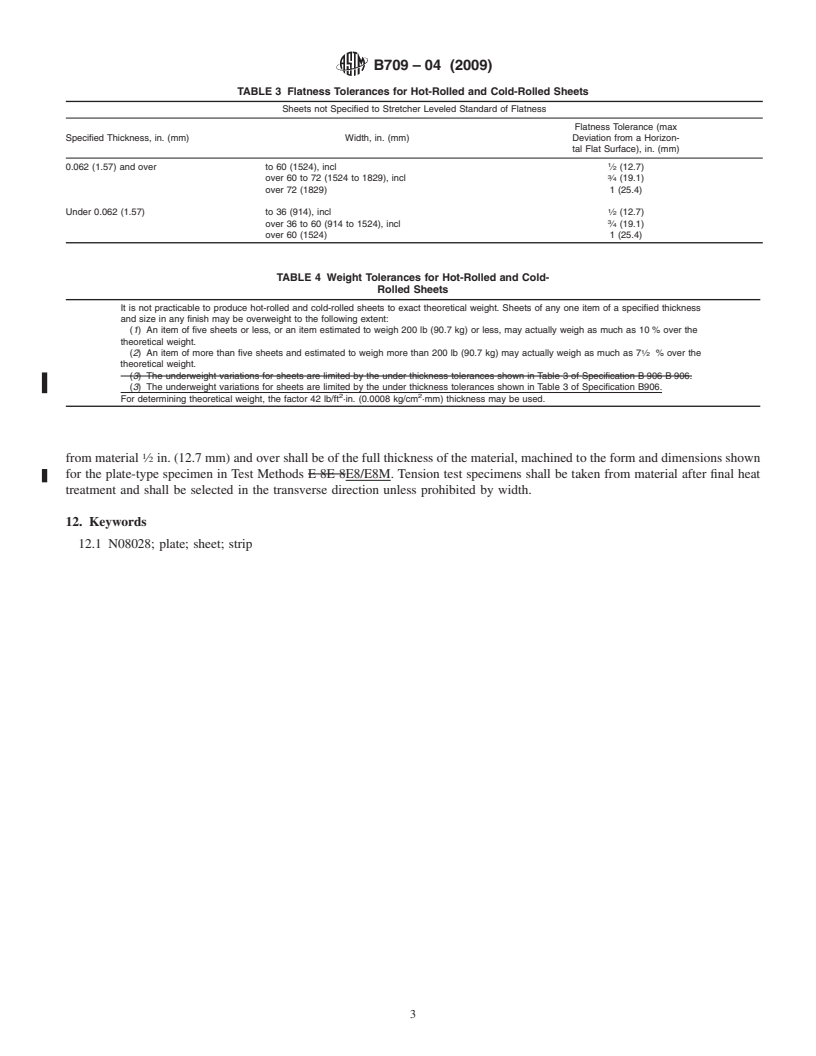

8.1 Sheet—Material furnished under this specification shall

conformtotheapplicablerequirementsofthecurrenteditionof

Specification B906, except as specified in Table 3 and Table 4.

This specification is under the jurisdiction of ASTM Committee B02 on

8.2 Cold-Rolled Strip—Material furnished under this speci-

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.07 on Refined Nickel and Cobalt and Their Alloys.

fication shall conform to the applicable requirements of the

Current edition approved April 15, 2009. Published April 2009. Originally

current edition of Specification B906, except as specified in

approved in 1982. Last previous edition approved in 2004 as B709 – 98 (2004).

Tables 5-7.

DOI: 10.1520/B0709-04R09.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

8.3 Plate—Material furnished under this specification shall

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

conformtotheapplicablerequirementsofthecurrenteditionof

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Specification B906.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B709−04 (2009)

TABLE 1 Chemical Requirements

purchase order additional material of adequate size to provide

Element Composition, % sample coupons for inspection purposes.

Ni 29.5 to 32.5

A 10. Number of Tests and Retests

Fe remainder

Cr 26.0 to 28.0

10.1 In the case of sheet or strip supplied in coil form, two

Mo 3.0 to 4.0

or more tension tests (one from each end of each coil), and one

C, max 0.030

Si, max 1.00

or more hardness tests shall be made on specimens taken from

Mn, max 2.50

each end of the coil. When material is supplied in flatsheet, flat

P, max 0.030

strip, or plate, one tension and one or more hardness tests shall

S, max 0.030

Cu 0.6 to 1.4

be made on each 100 or less sheets, strips, or plates of the same

A

Determined arithmetically by difference. lot. When specified, one corrosion test shall be conducted for

each lot.

10.2 If any specimens selected to represent any lot fail to

meet any of the test requirements, the material represented by

9. Sampling

such specimens may be retested. If there is valid reason to

believe the result is not representative, the material may be

9.1 Sampling for Chemical Analysis, Mechanical Testing,

re-reannealed and retested.

and Corrosion Testing shall be performed in accordance with

Specification B906, except as specified herein:

11. Specimen Preparation

9.1.1 Plate—A lot of plate for testing and inspection pur-

11.1 Tension test specimens from material under ⁄2 in. (12.7

poses shall consist of the products resulting from the rolling of

mm) in thickness shall be of the full thickness of the material

one heat of material in the same condition and specified

and machined to the form and dimensions shown for the

thickness, solution annealed by the same practice, but in no

sheet-type specimen in Test Methods E8/E8M. Tension test

case more than 25 000 lb (11 340 kg).

specimens from material ⁄2 in. (12.7 mm) and over shall be of

9.1.2 Sheet and Strip—Alot of sheet or strip for testing and

the full thickness of the material, machined to the form and

inspection purposes shall consist of material from one heat in

dimensions shown for the plate-type specimen inTest Methods

the same form (sheet or strip), condition, finish, and specified

E8/E8M. Tension test specimens shall be taken from material

thickness, solution-annealed by the same practice but in no

after final heat treatment and shall be selected in the transverse

case more than 25 000 lb (11 340 kg).

direction unless prohibited by width.

9.2 Sampling for Mechanical Tests:

12. Keywords

9.2.1 When samples are to be taken after delivery, the

purchaser of material ordered to cut lengths may request on the 12.1 N08028; plate; sheetstrip

B709−04 (2009)

TABLE 2 Mechanical Property Requirements

Elonga-

Yield

Tensile tionin2

Strength Rockwell

Strength, in.or50

Form (0.2 % off- Hardness (or

min, ksi mm, or

A

set), min, equivalent)

(MPa) 4D, m

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B709–98 Designation: B 709 – 04 (Reapproved 2009)

Standard Specification for

Iron-Nickel-Chromium-Molybdenum Alloy (UNS N08028)*

Plate, Sheet, and Strip

This standard is issued under the fixed designation B 709; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers iron-nickel-chromium-molybdenum alloy (UNS N08028)* plate, sheet, and strip in the

solution-annealed condition.

1.2The values stated in inch-pound units are to be regarded as the standard.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data

Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and

determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

B 880 SpecificationforGeneralRequirementsforChemicalCheckAnalysisLimitsforNickel,NickelAlloysandCobaltAlloys

E8Test Methods forTensionTesting of Metallic Materials Specification for General Requirements for Chemical CheckAnalysis

Limits for Nickel, Nickel Alloys and Cobalt Alloys

E10Test Method for Brinell Hardness of Metallic Materials B 906 Specification for General Requirements for Flat-Rolled

Nickel and Nickel Alloys Plate, Sheet, and Strip

E18Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials

E29Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E38Methods for Chemical Analysis of Nickel-Chromium and Nickel-Chromium-Iron Alloys

E55Practice for Sampling Wrought Nonferrous Metals and Alloys for Determination of Chemical Composition

E140Hardness Conversion Tables for Metals

E1473Test Methods for ChemicalAnalysis of Nickel, Cobalt, and High-TemperatureAlloys 8/E 8M Test Methods for Tension

Testing of Metallic Materials

3. Terminology

3.1Definitions of Terms Specific to This Standard:

3.2The terms of plate, sheet, and strip as used in this specification are described as follows:

3.3plate—material 0.187 in. (4.76 mm) and over in thickness and over 10 in. (254 mm) in width.

3.4sheet—material under 0.187 in. (4.75 mm) in thickness and over 24 in. (610 mm) in width.

3.5strip—material under 0.187 in. (4.75 mm) in thickness and under 24 in. (610 mm) in width.

4.Ordering Information

4.1It is the responsibility of the purchaser to specify all requirements that are necessary for the safe and satisfactory performance

of material ordered under this specification. Examples of such requirements include, but are not limited to the following:

4.1.1Quantity (weight or number of pieces),

4.1.2Name of material or UNS N08028,

This specification is under the jurisdiction of ASTM Committee B-2B02 on Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee B02.07 on

Refined Nickel and Cobalt and Their Alloys.

Current edition approved Oct. 10, 1998. Published November 1998. Originally published as B709–82. Last previous edition B709–93.

*New designation in accordance with ASTME 527 and SAEJ1086, Practice for Numbering Metals and Alloys (UNS).

Current edition approved April 15, 2009. Published April 2009. Originally approved in 1982. Last previous edition approved in 2004 as B 709 – 98 (2004).

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 02.04.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 709 – 04 (2009)

4.1.3Form (plate, sheet, or strip),

4.1.4Dimensions,

4.1.5Type of edge required (for strip only, see 8.4),

4.1.6Finish (Section 9)—For sheet ordered with No. 4 finish, specify whether one or both sides are to be polished,

4.1.7ASTM designation and year of issue,

4.1.8Marking—State if metal die identification is required on plate ⁄4 in. (6.35 mm) or thicker (Section 17),

4.1.9Certification or Test Reports—State if certification or test reports are required (Section 16), and

4.1.10Source Inspection—State if inspection is required (Section 14).

3.1 It is the responsibility of the purchaser to specify all requirements that are necessary for material ordered under this

specification. Examples of such requirements include, but are not limited to those specified in Ordering Information Section in

Specification B 906.

4. General Requirements

4.1 Material furnished under this specification shall conform to the applicable requirements of the current edition of

Specification B 906, unless otherwise specified herein.

5. Materials and Manufacture

5.1 Heat Treatment—Thefinalheattreatmentshallbeasolution-anneal.Minorcoldworkingsuchasflatteningortemperrolling

may be performed after the final solution annealing treatment.

NOTE 1—This recommended solution-anneal consists of heating to a minimum temperature of 1975°F (1080°C) and cooling rapidly to room

temperature.

6. Chemical Composition

6.1 The material sampled in accordance with 11.210.2 shall conform to the composition limits prescribed in Table 1.

6.2 If a product analysis is subsequently made, the material shall conform to the composition limits with the product analysis

variation prescribed Specification B 880.

7. Mechanical Properties

7.1 The material shall conform to the requirements as to the mechanical property prescribed in Table 2.

8. Dimensions and Permissible Variations

8.1 Sheet—The material referred to as sheet shall conform to the variations in dimensions prescribed in Tables 3-8, inclusive.

—Material furnished under this specification shall conform to the applicable requirements of the current edition of Specification

B 906, except as specified in Table 3 and Table 4.

8.2 Cold-Rolled Strip—The material referred to as cold-rolled strip shall conform to the permissible variations in dimensions

prescribed in Tables 9-12 inclusive. —Material furnished under this specification shall conform to the applicable requirements of

the current edition of Specification B 906, except as specified in Tables 5-7.

8.3 Plate—The material referred to as plate shall conform to the permissible variations in dimensions prescribed in Tables

13-19, inclusive.

8.4Edges for Cold-Rolled Strip—The various types of edges procurable shall be as follows:

8.4.1No. 1. Edge— Rolled edge, contour as specified.

8.4.2No. 3 Edge—An edge produced by slitting.

8.4.3No. 5 Edge—Approximately square edge produced by rolling or filing, or both, after slitting. —Material furnished under

this specification shall conform to the applicable requirements of the current edition of Specification B 906.

9. Workmanship, Finish, and Appearance

9.1The material shall be free of injurious imperfections and shall correspond to the designated finish as described as follows:

TABLE 1 Chemical Requirements

Element Composition, %

Ni 29.5 to 32.5

A

Fe remainder

Cr 26.0 to 28.0

Mo 3.0 to 4.0

C, max 0.030

Si, max 1.00

Mn, max 2.50

P, max 0.030

S, max 0.030

Cu 0.6 to 1.4

A

Determined arithmetically by difference.

B 709 – 04 (2009)

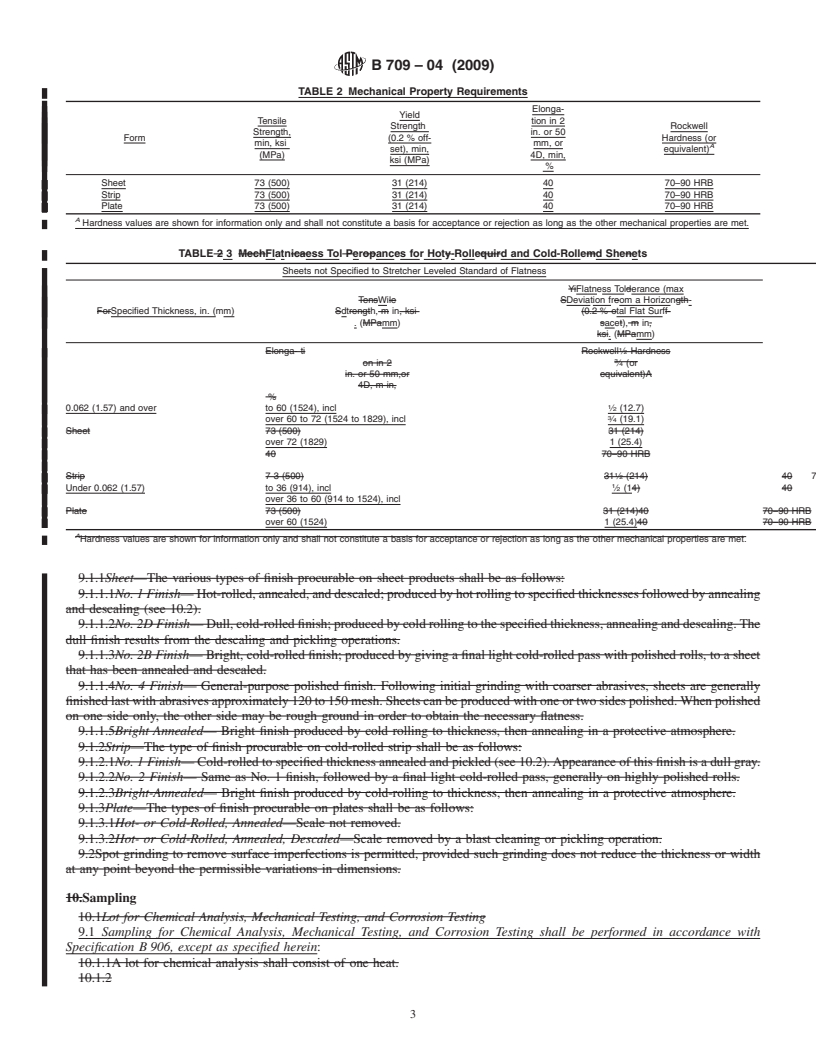

TABLE 2 Mechanical Property Requirements

Elonga-

Yield

Tensile tionin2

Strength Rockwell

Strength, in.or50

Form (0.2 % off- Hardness (or

min, ksi mm, or

A

set), min, equivalent)

(MPa) 4D, min,

ksi (MPa)

%

Sheet 73 (500) 31 (214) 40 70–90 HRB

Strip 73 (500) 31 (214) 40 70–90 HRB

Plate 73 (500) 31 (214) 40 70–90 HRB

A

Hardness values are shown for information only and shall not constitute a basis for acceptance or rejection as long as the other mechanical properties are met.

TABLE 2 3 MechFlatnicaess Tol Peropances for Hoty-Rollequird and Cold-Rollemd Shenets

Sheets not Specified to Stretcher Leveled Standard of Flatness

YiFlatness Tolderance (max

TensWile SDeviation freom a Horizongth-

ForSpecified Thickness, in. (mm) Sdtrength, m in, ksi (0.2 % otal Flat Surff-

. (MPamm) sacet), m in,

ksi. (MPamm)

Elonga- ti Rockwell ⁄2 Hardness

on in 2 ⁄4 (or

in. or 50 mm,or equivalent)A

4D, m in,

%

0.062 (1.57) and over to 60 (1524), incl ⁄2 (12.7)

over 60 to 72 (1524 to 1829), incl ⁄4 (19.1)

Sheet 73 (500) 31 (214)

over 72 (1829) 1 (25.4)

40 70–90 HRB

Strip 7 3 (500) 31 ⁄2 (214) 40 7

Under 0.062 (1.57) to 36 (914), incl ⁄2 (14) 40

over 36 to 60 (914 to 1524), incl

Plate 73 (500) 31 (214)40 70–90 HRB

over 60 (1524) 1 (25.4)40 70–90 HRB

A

Hardness values are shown for information only and shall not constitute a basis for acceptance or rejection as long as the other mechanical properties are met.

9.1.1Sheet—The various types of finish procurable on sheet products shall be as follows:

9.1.1.1No. 1 Finish—Hot-rolled,annealed,anddescaled;producedbyhotrollingtospecifiedthicknessesfollowedbyannealing

and descaling (see 10.2).

9.1.1.2No. 2D Finish—Dull,cold-rolledfinish;producedbycoldrollingtothespecifiedthickness,annealinganddescaling.The

dull finish results from the descaling and pickling operations.

9.1.1.3No. 2B Finish— Bright, cold-rolled finish; produced by giving a final light cold-rolled pass with polished rolls, to a sheet

that has been annealed and descaled.

9.1.1.4No. 4 Finish— General-purpose polished finish. Following initial grinding with coarser abrasives, sheets are generally

finishedlastwithabrasivesapproximately120to150mesh.Sheetscanbeproducedwithoneortwosidespolished.Whenpolished

on one side only, the other side may be rough ground in order to obtain the necessary flatness.

9.1.1.5Bright Annealed— Bright finish produced by cold rolling to thickness, then annealing in a protective atmosphere.

9.1.2Strip—The type of finish procurable on cold-rolled strip shall be as follows:

9.1.2.1No. 1 Finish— Cold-rolled to specified thickness annealed and pickled (see 10.2).Appearance of this finish is a dull gray.

9.1.2.2No. 2 Finish— Same as No. 1 finish, followed by a final light cold-rolled pass, generally on highly polished rolls.

9.1.2.3Bright-Annealed— Bright finish produced by cold-rolling to thickness, then annealing in a protective atmosphere.

9.1.3Plate—The types of finish procurable on plates shall be as follows:

9.1.3.1Hot- or Cold-Rolled, Annealed—Scale not removed.

9.1.3.2Hot- or Cold-Rolled, Annealed, Descaled—Scale removed by a blast cleaning or pickling operation.

9.2Spot grinding to remove surface imperfections is permitted, provided such grinding does not reduce the thickness or width

at any point beyond the permissible variations in dimensions.

10.Sampling

10.1Lot for Chemical Analysis, Mechanical Testing, and Corrosion Testing

9.1 Sampling for Chemical Analysis, Mechanical Testing, and Corrosion Testing shall be performed in accordance with

Specification B 906, except as specified herein:

10.1.1A lot for chemical analysis shall consist of one heat.

10.1.2

B 709 – 04 (2009)

TABLE 3 4 ThicknWessight Tolerances for Hot-Rolled and Cold-

Cold-Rolled Sheets

Specified Thickness, in. (mm)

Toler an ce,ov erand under, in. ( mm)

It is not practicable to produce hot-rolled and cold-rolled sheets to exact theoretical weight. Sheets of any one item of a specified thickness and size in any finish mm)

ay be overweight to the following

extent:

O ver 0.145t o less th an0.187 (3.68 t o less th an 4.76)

(1) An item of five sheets or less, or an item estimated to weigh 200 lb (90.7 kg) or less, may actually weigh as much as 10 % over the theoretical weight.76)

0.014 (0.36) may actually weigh as much as 7 ⁄2 % over the theoretical weight.

(2) An item of more than five sheets and estimated to weigh more than 200 lb (90.7 kg) may actually weigh as much as 7 ⁄2 % over the theoretical weight.

Ov er 0.130to 0.145 (3.30to 3.68),inclerances shown in Table 3 of Specification B 906.

(3) The underweight variations for sheets are limited by the under thickness tolerances shown in Table 3 of Specification B 906.

0.012 (0.30)

Over 0.114 to 0.130 (2.90 to 0.010 (0.25)

3.30), incl

Over 0.114 tFo 0.130 (2.90 to 0.010 (0.25)

3.30), incl

Over 0.098to 0.114 (2.49 to 2.90), 0.009 (0.23)

incl

Over deto 0.114 (2.49 to 2.90), 0.009 (0.23)

incl

Over 0.083 to 0.098 (2.11 to 0.008 (0.20)

2.49),incl

Overmincl 0.008 (0.20)

Over 0.072 to 0.083 (1.83 to 0.007 (0.18)

2.11),incl

Over 0.058to 0.072 (1.47 to

1.83),incl0.006 (0.15)

Ovg theoretical0.006 (0.15)

Over 0.040to 0.058 (1.02 to 1.47), 0.005 (0.13)

incl

Ov weight, incl 0.005 (0.13)

Over 0.026to 0.0 40 (0.66 to

1.02), inc l0.004 (0.10)

Ov the factor 42 l0.004 (0.10)

26 (0.41 to 0.66),

Over 0.016to 0.0 incl 0.003 (0.08)

Over 0.016b/ft ·incl 0. (0.08)

Over0.007 to 0.016 (0.18 to 0.41), 0.002 (0.05)Over 0.005 to 0.007 (0.13 to 0.18),incl 0.0015

incl

Over008 kg/cl 0.00m ·mm) thicl 0kness may be u

0.005 (0.13) 0.001 (0.03)

9.1.1 Plate—Alot of plate for testing and inspection purposes shall consist of the products resulting from the rolling of one heat

of material in the same condition and specified thickness, solution annealed by the same practice, but in no case more than 25 000

lb (11 340 kg).

10.1.3

9.1.2 Sheet and Strip—A lot of sheet or strip for testing and inspection purposes shall consist of material from one heat in the

same form (sheet or strip), condition, finish, and specified thickness, solution-annealed by the same practice but in no case more

than 25 000 lb (11 340 kg).

10.2Sampling of Chemical Analysis:

10.2.1A representative sample shall be taken from each lot during pouring or subsequent processing.

10.2.2Product analysis, if performed, shall be wholly the responsibility of the purchaser.

10.3

9.2 Sampling for Mechanical Tests:

10.3.1A sample of the material to provide test specimens for mechanical tests shall be taken from such a location in each lot

as to be representative of that lot.

10.3.2When samples are to be taken after delivery, the purchaser of material ordered to cut lengths may request on the purch

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B 709–04 Designation: B709 – 04 (Reapproved 2009)

Standard Specification for

Iron-Nickel-Chromium-Molybdenum Alloy (UNS

N08028)*N08028) Plate, Sheet, and Strip

This standard is issued under the fixed designation B709; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers iron-nickel-chromium-molybdenum alloy (UNS N08028)* plate, sheet, and strip in the

solution-annealed condition.

1.2The values stated in inch-pound units are to be regarded as the standard.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data

Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and

determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

B880 Specification for General Requirements for Chemical CheckAnalysis Limits for Nickel, NickelAlloys and CobaltAlloys

B906 Specification for General Requirements for Flat-Rolled Nickel and Nickel Alloys Plate, Sheet, and Strip

E88/E8M Test Methods for Tension Testing of Metallic Materials

3. Ordering Information

3.1 It is the responsibility of the purchaser to specify all requirements that are necessary for material ordered under this

specification. Examples of such requirements include, but are not limited to those specified in Ordering Information Section in

Specification B 906.B906.

4. General Requirements

4.1 Material furnished under this specification shall conform to the applicable requirements of the current edition of

Specification B 906, B906, unless otherwise specified herein.

5. Materials and Manufacture

5.1 Heat Treatment—Thefinalheattreatmentshallbeasolution-anneal.Minorcoldworkingsuchasflatteningortemperrolling

may be performed after the final solution annealing treatment.

NOTE 1—This recommended solution-anneal consists of heating to a minimum temperature of 1975°F (1080°C) and cooling rapidly to room

temperature.

6. Chemical Composition

6.1 The material sampled in accordance with 10.2 shall conform to the composition limits prescribed in Table 1.

6.2 If a product analysis is subsequently made, the material shall conform to the composition limits with the product analysis

variation prescribed Specification B 880B880.

ThisspecificationisunderthejurisdictionofASTMCommitteeB02onNonferrousMetalsandAlloysandisthedirectresponsibilityofSubcommitteeB02.07onRefined

Nickel and Cobalt and Their Alloys.

Current edition approved Feb. 1, 2004. Published February 2004. Originally approved in 1982. Last previous edition approved in 1998 as B 709–98.

Current edition approved April 15, 2009. Published April 2009. Originally approved in 1982. Last previous edition approved in 2004 as B709 – 98 (2004). DOI:

10.1520/B0709-04R09.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B709 – 04 (2009)

TABLE 1 Chemical Requirements

Element Composition, %

Ni 29.5 to 32.5

A

Fe remainder

Cr 26.0 to 28.0

Mo 3.0 to 4.0

C, max 0.030

Si, max 1.00

Mn, max 2.50

P, max 0.030

S, max 0.030

Cu 0.6 to 1.4

A

Determined arithmetically by difference.

7. Mechanical Properties

7.1 The material shall conform to the requirements as to the mechanical property prescribed in Table 2.

8. Dimensions and Permissible Variations

8.1 Sheet—Material furnished under this specification shall conform to the applicable requirements of the current edition of

Specification B 906, B906, except as specified in TablesTable 3 and and Table 44.

8.2 Cold-Rolled Strip—Material furnished under this specification shall conform to the applicable requirements of the current

edition of Specification B 906, B906, except as specified in Tables 5-7.

8.3 Plate—Material furnished under this specification shall conform to the applicable requirements of the current edition of

Specification B 906.B906.

9. Sampling

9.1 Sampling for Chemical Analysis, Mechanical Testing, and Corrosion Testing shall be performed in accordance with

Specification B 906, B906, except as specified herein:

9.1.1 Plate—Alot of plate for testing and inspection purposes shall consist of the products resulting from the rolling of one heat

of material in the same condition and specified thickness, solution annealed by the same practice, but in no case more than 25 000

lb (11 340 kg).

9.1.2 Sheet and Strip—A lot of sheet or strip for testing and inspection purposes shall consist of material from one heat in the

same form (sheet or strip), condition, finish, and specified thickness, solution-annealed by the same practice but in no case more

than 25 000 lb (11 340 kg).

9.2 Sampling for Mechanical Tests:

9.2.1 When samples are to be taken after delivery, the purchaser of material ordered to cut lengths may request on the purchase

order additional material of adequate size to provide sample coupons for inspection purposes.

10. Number of Tests and Retests

10.1 In the case of sheet or strip supplied in coil form, two or more tension tests (one from each end of each coil), and one or

more hardness tests shall be made on specimens taken from each end of the coil. When material is supplied in flatsheet, flat strip,

or plate, one tension and one or more hardness tests shall be made on each 100 or less sheets, strips, or plates of the same lot.When

specified, one corrosion test shall be conducted for each lot.

10.2 If any specimens selected to represent any lot fail to meet any of the test requirements, the material represented by such

specimens may be retested. If there is valid reason to believe the result is not representative, the material may be re-reannealed

and retested.

11. Specimen Preparation

11.1 Tension test specimens from material under ⁄2 in. (12.7 mm) in thickness shall be of the full thickness of the material and

machined to the form and dimensions shown for the sheet-type specimen in Test Methods E 8E 8E8/E8M. Tension test specimens

TABLE 2 Mechanical Property Requirements

Elonga-

Yield

Tensile tionin2

Strength Rockwell

Strength, in.or50

Form (0.2 % off- Hardness (or

min, ksi mm, or

A

set), min, equivalent)

(MPa) 4D, min,

ksi (MPa)

%

Sheet 73 (500) 31 (214) 40 70–90 HRB

Strip 73 (500) 31 (214) 40 70–90 HRB

Plate 73 (500) 31 (214) 40 70–90 HRB

A

Hardness values are shown for information only and shall not constitute a basis for acceptance or rejection as long as the other mechanical properties are met.

--------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.