ASTM E595-93(1999)

(Test Method)Standard Test Method for Total Mass Loss and Collected Volatile Condensable Materials from Outgassing in a Vacuum Environment

Standard Test Method for Total Mass Loss and Collected Volatile Condensable Materials from Outgassing in a Vacuum Environment

SCOPE

1.1 This test method covers a screening technique to determine volatile content of materials when exposed to a vacuum environment. Two parameters are measured: total mass loss (TML) and collected volatile condensable materials (CVCM). An additional parameter, the amount of water vapor regained (WVR), can also be obtained after completion of exposures and measurements required for TML and CVCM.

1.2 This test method describes the test apparatus and related operating procedures for evaluating the mass loss of materials being subjected to 125°C at less than 7 X 10-3 Pa (5 X 10 -5 torr) for 24 h. The overall mass loss can be classified into noncondensables and condensables. The latter are characterized herein as being capable of condensing on a collector at a temperature of 25°C.

Note 1—Unless otherwise noted, the tolerance on 25 and 125°C is ± 1°C and on 23°C is ± 2°C. The tolerance on relative humidity is ± 5%.

1.3 Many types of organic, polymeric, and inorganic materials can be tested. These include polymer potting compounds, foams, elastomers, films, tapes, insulations, shrink tubings, adhesives, coatings, fabrics, tie cords, and lubricants. The materials may be tested in the "as-received" condition or prepared for test by various curing specifications.

1.4 This test method is primarily a screening technique for materials and is not necessarily valid for computing actual contamination on a system or component because of differences in configuration, temperatures, and material processing.

1.5 The criteria used for the acceptance and rejection of materials shall be determined by the user and based upon specific component and system requirements. Historically, TML of 1.00% and CVCM of 0.10% have been used as screening levels for rejection of spacecraft materials.

1.6 The use of materials that are deemed acceptable in accordance with this test method does not ensure that the system or component will remain uncontaminated. Therefore, subsequent functional, developmental, and qualification tests should be used, as necessary, to ensure that the material's performance is satisfactory.

1.7 This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 595 – 93 (Reapproved 1999)

Standard Test Method for

Total Mass Loss and Collected Volatile Condensable

Materials from Outgassing in a Vacuum Environment

This standard is issued under the fixed designation E 595; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope subsequent functional, developmental, and qualification tests

should be used, as necessary, to ensure that the material’s

1.1 This test method covers a screening technique to deter-

performance is satisfactory.

mine volatile content of materials when exposed to a vacuum

1.7 This standard does not purport to address all of the

environment. Two parameters are measured: total mass loss

safety concerns associated with its use. It is the responsibility

(TML) and collected volatile condensable materials (CVCM).

of the user of this standard to establish appropriate safety and

An additional parameter, the amount of water vapor regained

health practices and determine the applicability of regulatory

(WVR), can also be obtained after completion of exposures

limitations prior to use.

and measurements required for TML and CVCM.

1.2 This test method describes the test apparatus and related

2. Referenced Documents

operating procedures for evaluating the mass loss of materials

−3 −5 2.1 ASTM Standards:

being subjected to 125°C at less than 7 3 10 Pa (5 3 10

E 177 Practice for Use of the Terms Precision and Bias in

torr) for 24 h. The overall mass loss can be classified into

ASTM Test Methods

noncondensables and condensables. The latter are character-

2.2 ASTM Adjuncts:

ized herein as being capable of condensing on a collector at a

Micro VCM Detailed Drawings

temperature of 25°C.

NOTE 1—Unless otherwise noted, the tolerance on 25 and 125°C is 3. Terminology

61°C and on 23°C is 62°C. The tolerance on relative humidity is 65%.

3.1 Definitions:

1.3 Many types of organic, polymeric, and inorganic mate-

3.1.1 collected volatile condensable material, CVCM—the

rials can be tested. These include polymer potting compounds, quantity of outgassed matter from a test specimen that con-

foams, elastomers, films, tapes, insulations, shrink tubings,

denses on a collector maintained at a specific constant tem-

adhesives, coatings, fabrics, tie cords, and lubricants. The perature for a specified time. CVCM is expressed as a

materials may be tested in the “as-received” condition or

percentage of the initial specimen mass and is calculated from

prepared for test by various curing specifications. the condensate mass determined from the difference in mass of

1.4 This test method is primarily a screening technique for

the collector plate before and after the test.

materials and is not necessarily valid for computing actual

3.1.2 total mass loss, TML—total mass of material out-

contamination on a system or component because of differ- gassed from a specimen that is maintained at a specified

ences in configuration, temperatures, and material processing.

constant temperature and operating pressure for a specified

1.5 The criteria used for the acceptance and rejection of time. TML is calculated from the mass of the specimen as

materials shall be determined by the user and based upon

measured before and after the test and is expressed as a

specific component and system requirements. Historically, percentage of the initial specimen mass.

TML of 1.00 % and CVCM of 0.10 % have been used as

3.1.3 water vapor regained, WVR—the mass of the water

screening levels for rejection of spacecraft materials. vapor regained by the specimen after the optional recondition-

1.6 The use of materials that are deemed acceptable in

ing step. WVR is calculated from the differences in the

accordance with this test method does not ensure that the specimen mass determined after the test for TML and CVCM

system or component will remain uncontaminated. Therefore,

and again after exposure to a 50 % relative humidity atmo-

sphere at 23°C for 24 h. WVR is expressed as a percentage of

the initial specimen mass.

This test method is under the jurisdiction of ASTM Committee E-21 on Space

Simulation and Applications of Space Technology and is the direct responsibility of

Subcommittee E21.05 on Contamination. Annual Book of ASTM Standards, Vol 14.02.

Current edition approved June 15, 1993. Published August 1993. Originally Available from ASTM Headquarters, 100 Barr Harbor Dr., PO Box C700, West

published as E 595 – 77. Last previous edition E 595 – 90. Conshohocken, PA 19428–2959. Order Adjunct ADJE0505.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 595

4. Summary of Test Method foregoing operations are conducted. Three specimen compart-

ments can serve as controls and three can be used for each type

4.1 This microvolatile condensable system was developed

of material being tested. The total time required for specimens

from an earlier system for determination of macrovolatile

requiring no prior preparation is approximately 4 days. The

condensables that required much larger samples and a longer

equipment should be calibrated at least once a year by using

test.

previously tested materials as test specimens.

4.2 The test specimen is exposed to 23°C and 50 % relative

4.6 The apparatus may be oriented in any direction as long

humidity for 24 h in a preformed, degreased container (boat)

as the configuration shown in Fig. 1 is maintained and bulk

that has been weighed. After this exposure, the boat and

material does not fall from the sample holder nor obstruct the

specimen are weighed and put in one of the specimen com-

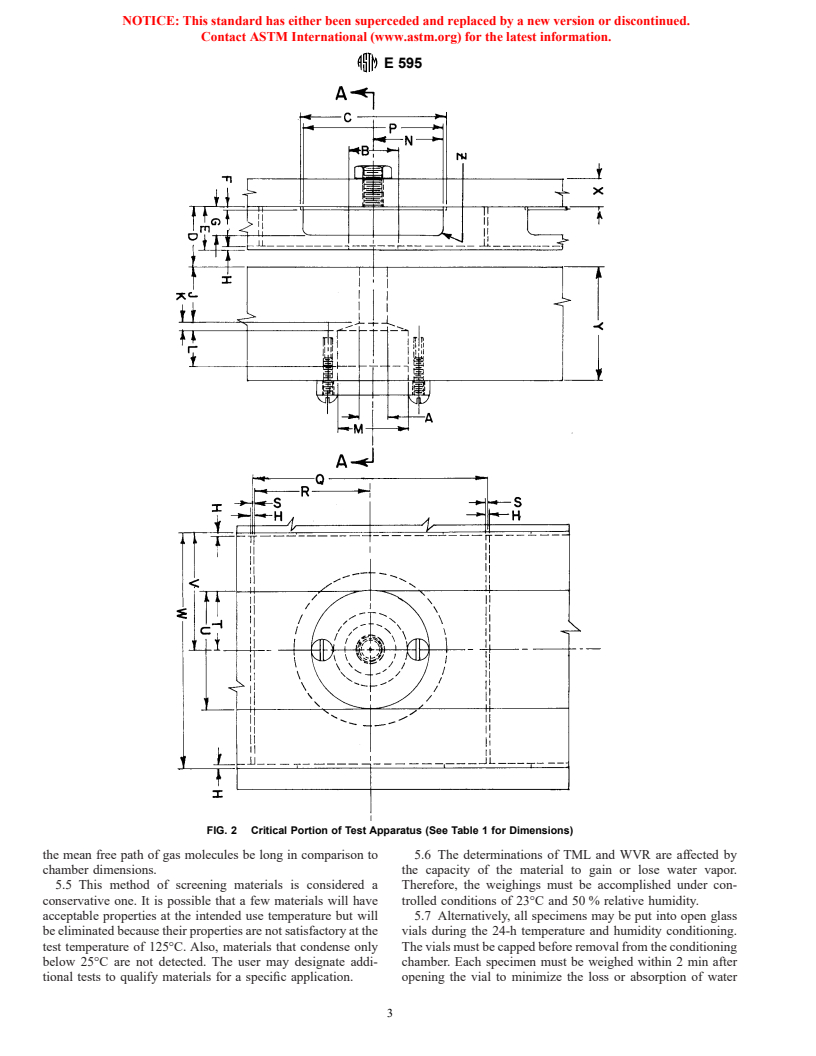

gas-exit hole. The dimensions for critical components given in

partments in a copper heating bar that is part of the test

Fig. 2 and Table 1 are provided so that apparatus constructed

apparatus. The copper heating bar can accommodate a number

for the purpose of this test may provide uniform and compa-

of specimens for simultaneous testing. The vacuum chamber in

rable results.

which the heating bar and other parts of the test apparatus are

placed is then sealed and evacuated to a vacuum of at least

−3 −5 5. Significance and Use

7 3 10 Pa (5 3 10 torr). The heating bar is used to raise the

5.1 This test method evaluates, under carefully controlled

specimen compartment temperature to 125°C. This causes

conditions, the changes in the mass of a test specimen on

vapor from the heated specimen to stream from the hole in the

exposure under vacuum to a temperature of 125°C and the

specimen compartment. A portion of the vapor passes into a

mass of those products that leave the specimen and condense

collector chamber in which some vapor condenses on a

on a collector at a temperature of 25°C.

previously-weighed and independently temperature-controlled,

5.2 Comparisons of material outgassing properties are valid

chromium-plated collector plate that is maintained at 25°C.

at 125°C sample temperature and 25°C collector temperature

Each specimen compartment has a corresponding collector

only. Samples tested at other temperatures may be compared

chamber that is isolated from the others by a compartmented

only with other materials which were tested at that same

separator plate to prevent cross contamination. After 24 h, the

temperature.

test apparatus is cooled and the vacuum chamber is repressur-

5.3 The measurements of the collected volatile condensable

ized with a dry, inert gas. The specimen and the collector plates

material are also comparable and valid only for similar

are weighed. From these results and the specimen mass

collector geometry and surfaces at 25°C. Samples have been

determined before the vacuum exposure, the percentage TML

tested at sample temperatures from 50 to 230°C and at collector

and percentage CVCM are obtained. Normally, the reported

temperatures from 1 to 30°C by this test technique. Data taken

values are an average of the percentages obtained from three

at nonstandard conditions must be clearly identified and should

samples of the same material.

not be compared with samples tested at 125°C sample tem-

NOTE 2—It is also possible to conduct infrared and other analytical tests

perature and 25°C collector temperature.

on the condensates in conjunction with mass-loss tests. Sodium chloride

5.4 The simulation of the vacuum of space in this test

flats may be used for infrared analysis. These flats are nominally 24 mm

method does not require that the pressure be as low as that

(1 in.) in diameter by 3.2 mm (0.125 in.) thick and are supported edgewise

−12

in a metal holder that fits into the collector plate receptacle. On completion encountered in interplanetary flight (for example, 10 Pa

−14

of the test, the flats are placed into an infrared salt flat holder for

(10 torr)). It is sufficient that the pressure be low enough that

examination by an infrared spectrophotometer. As an alternative method,

the condensate may be dissolved from the metallic collector, the solvent

evaporated, and the residue deposited on a salt flat for infrared tests.

Sodium chloride flats shall not be used for CVCM determinations.

4.3 After the specimen has been weighed to determine the

TML, the WVR can be determined, if desired, as follows: the

specimen is stored for 24 h at 23°C and 50 % relative humidity

to permit sorption of water vapor. The specimen mass after this

exposure is determined. From these results and the specimen

mass determined after vacuum exposure, the percentage WVR

is obtained.

4.4 Two or three empty specimen chambers in the heater bar

and collector plates on the cold bar, selected for each test at

random, can be used as controls to ensure that uniform

cleaning procedures have been followed after each test.

4.5 A typical test apparatus can have 24 specimen chambers

with 24 associated collector plates so that a number of

specimens of different types can be tested each time the

Muraca, R. F., and Whittick, J. S., “Polymers for Spacecraft Applications.” SRI

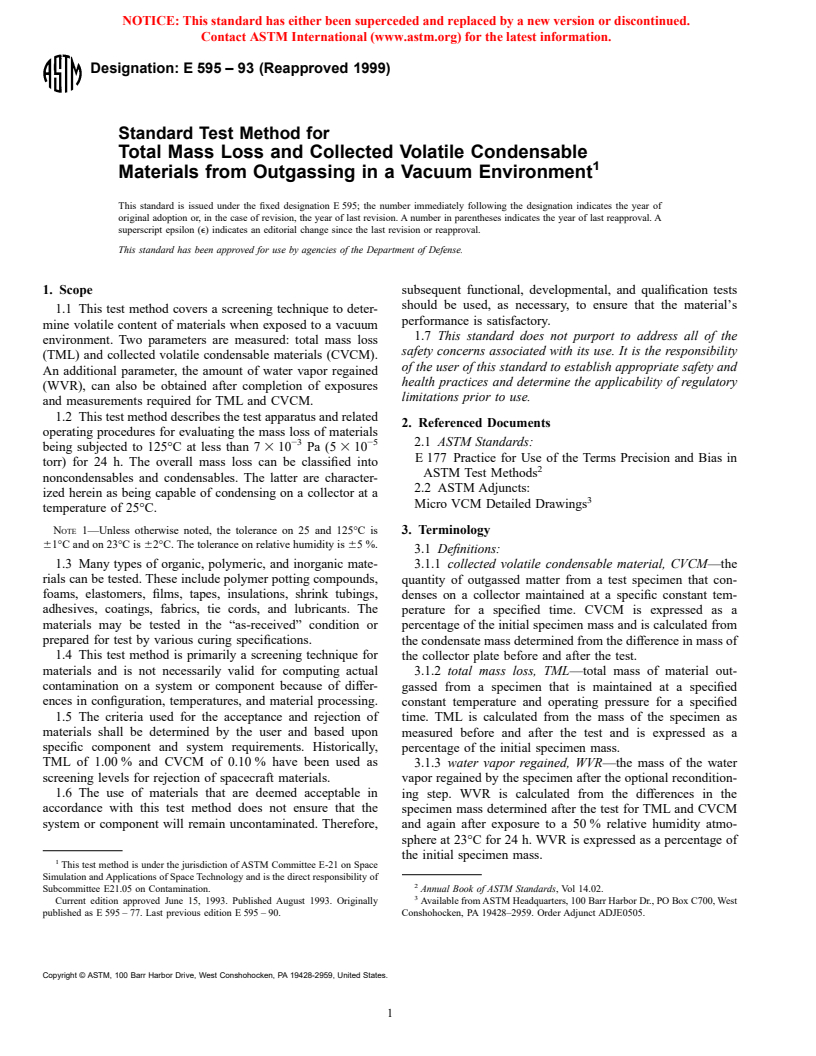

Project ASD-5046, NASA CR-89557, N67-40270, Stanford Research Institute, FIG. 1 Schematic of Critical Portion of Test Apparatus (Section

September 1967. A-A of Fig. 2)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 595

FIG. 2 Critical Portion of Test Apparatus (See Table 1 for Dimensions)

the mean free path of gas molecules be long in comparison to 5.6 The determinations of TML and WVR are affected by

chamber dimensions. the capacity of the material to gain or lose water vapor.

5.5 This method of screening materials is considered a Therefore, the weighings must be accomplished under con-

conservative one. It is possible that a few materials will have trolled conditions of 23°C and 50 % relative humidity.

acceptable properties at the intended use temperature but will 5.7 Alternatively, all specimens may be put into open glass

be eliminated because their properties are not satisfactory at the vials during the 24-h temperature and humidity conditioning.

test temperature of 125°C. Also, materials that condense only The vials must be capped before removal from the conditioning

below 25°C are not detected. The user may designate addi- chamber. Each specimen must be weighed within 2 min after

tional tests to qualify materials for a specific application. opening the vial to minimize the loss or absorption of water

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 595

TABLE 1 Test Apparatus Dimensions (See Fig. 2)

Letter mm Tolerance in. Tolerance Notes

A B

A 6.3 60.1 0.250 60.005 diameter

A B

B 11.1 60.1 0.438 60.005 diameter

A B

C 33.0 60.1 1.300 60.005 diameter

AC

D 13.45 60.10 0.531 60.005

AC

E 9.65 60.10 0.380 60.005

AC

F 0.65 60.10 0.026 60.005

C

G 7.1 60.3 0.50 60.01

A

H 0.75 60.10 0.030 60.05 stock size

A

J 12.7 60.3 0.500 60.010

1 1

K 1.6 60.8 ⁄16 6 ⁄32

7 1

L 8.0 60.8 ⁄16 6 ⁄32

M 16.0 60.1 0.625 60.005 cover plate must fit snugly

5 1

N 16.0 60.8 ⁄8 6 ⁄32

1 1

P 32.0 60.8 1 ⁄4 6 ⁄32

Q 50.0 60.8 2 6 ⁄32

R 25.5 60.8 1 6 ⁄32

S 0.4 60.3 0.015 60.010 half stock thickness

1 1

T 12.0 60.8 ⁄2 6 ⁄32

U 25.5 60.8 1 6 ⁄32

V 25.5 60.8 1 6 ⁄32

W 50.0 60.8 2 6 ⁄32

1 1

X 6.0 60.8 ⁄4 6 ⁄32

Y 25.0 60.8 1 6 ⁄32

1 1

Z 1.6 60.8 ⁄16 6 ⁄32 radius, typical

A

Critical dimensions that must be maintained for test results to be comparable.

B

Diameters must be concentric to 60.1 mm (60.005 in.) for test results to be comparable.

C

Dimensions include plating thickness. Satisfactory surfaces have been produced by making substrate surface finish, 1.6-μm RMS (63-μin. RMS), highly polished,

plated with electroless nickel, 0.0127 mm (0.0005 in.) thick, and finished with electroplated chromium, 0.0051 mm (0.0002 in.) thick.

vapor while exposed to an uncontrolled humidity environment. tended operation. Care must be taken to prevent backstreaming

While control of humidity is not necessary at this point, the of oil from vacuum or diffusion pumps into the vacuum

temperature for the weighing should be controlled at 23°C, the chamber.

same temperature prescribed for the 24-h storage test. 6.5 The controller thermocouple should be mechanically

attached to the heater bar or ring to prevent the thermocouple

6. Apparatus

from loosening over time. It is essential that the orifice of the

6.1 The apparatus used in the determination of TML and

sample heater and collector plate be aligned and checked

CVCM typically contains two resistance-heated copper bars. regularly. A good test of alignment and stability is to run the

Generally, each bar is 650 mm (25.5 in.) in length with a

same material in every sample chamber. The results should

25-mm (1-in.) square cross section and contains twelve speci- agree within the accuracy of the test per Section 11.

men chambers. The open section of each specimen chamber

7. Test Specimen

allows vapors from the specimen to pass through a hole into a

collector chamber where it impinges on a removable 7.1 Finished products (for example, elastomers, hardware,

chromium-plated collector plate maintained at 25°C through- and structural parts) are cut into small p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.