ASTM F2929-13

(Specification)Standard Specification for Crosslinked Polyethylene (PEX) Tubing of 0.070 in. Wall and Fittings for Radiant Heating Systems up to 75 psig

Standard Specification for Crosslinked Polyethylene (PEX) Tubing of 0.070 in. Wall and Fittings for Radiant Heating Systems up to 75 psig

ABSTRACT

This specification establishes the requirements for 0.070 in. wall thickness crosslinked polyethylene (PEX) tubing that is outside diameter controlled, and intended for non-potable radiant heating applications for pressures up to 75 psig. It covers requirements and test methods for material, workmanship, dimensions, burst pressure, hydrostatic sustained pressure, bent-tube hydrostatic pressure, environmental stress cracking, stabilizer functionality, excessive temperature and degree of crosslinking, as well as requirements for tubing markings.

SCOPE

1.1 This specification covers 0.070 in. wall thickness crosslinked polyethylene (PEX) tubing that is outside diameter controlled, and intended for non-potable radiant heating applications for pressures up to 75 psig in sizes 5/8 NTS (nominal tubing size) and 7/8 NTS. This specification also includes fittings that are specifically designed for this 0.070 in.-wall PEX tubing. Only 75-psig relief valves shall be used with this tubing. Included in this specification are requirements and test methods for material, workmanship, dimensions, burst pressure, hydrostatic sustained pressure, environmental stress cracking, stabilizer functionality, bent-tube hydrostatic pressure, excessive temperature and degree of crosslinking. Requirements for tubing markings are also given. This tubing does not have an oxygen diffusion barrier layer and shall not be used in systems that require a barrier layer. This tubing is not intended for field bending at temperatures above 120ºF (49ºC).

1.2 The text of this specification references notes, footnotes, and appendixes, which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 7, of this specification:This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2929 −13 An American National Standard

Standard Specification for

Crosslinked Polyethylene (PEX) Tubing of 0.070 in. Wall and

Fittings for Radiant Heating Systems up to 75 psig

This standard is issued under the fixed designation F2929; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Stainless Steel Tubing for General Service

A276 Specification for Stainless Steel Bars and Shapes

1.1 This specification covers 0.070 in. wall thickness cross-

A312/A312M Specification for Seamless, Welded, and

linked polyethylene (PEX) tubing that is outside diameter

Heavily Cold Worked Austenitic Stainless Steel Pipes

controlled, and intended for non-potable radiant heating appli-

5 B16/B16M Specification for Free-Cutting Brass Rod, Bar

cations for pressures up to 75 psig in sizes ⁄8 NTS (nominal

7 and Shapes for Use in Screw Machines

tubing size) and ⁄8 NTS. This specification also includes

B61 Specification for Steam or Valve Bronze Castings

fittings that are specifically designed for this 0.070 in.-wall

B62 Specification for Composition Bronze or Ounce Metal

PEX tubing. Only 75-psig relief valves shall be used with this

Castings

tubing. Included in this specification are requirements and test

B140/B140M Specification for Copper-Zinc-Lead (Red

methods for material, workmanship, dimensions, burst

Brass or Hardware Bronze) Rod, Bar, and Shapes

pressure, hydrostatic sustained pressure, environmental stress

cracking, stabilizer functionality, bent-tube hydrostatic B283 Specification for Copper and Copper-Alloy Die Forg-

ings (Hot-Pressed)

pressure, excessive temperature and degree of crosslinking.

Requirements for tubing markings are also given. This tubing B371/B371M Specification for Copper-Zinc-Silicon Alloy

doesnothaveanoxygendiffusionbarrierlayerandshallnotbe Rod

used in systems that require a barrier layer. This tubing is not

B584 Specification for Copper Alloy Sand Castings for

intended for field bending at temperatures above 120ºF (49ºC). General Applications

B967/B967M Specification for Copper-Zinc-Tin-Bismuth

1.2 The text of this specification references notes, footnotes,

Alloy Rod, Bar and Wire

and appendixes, which provide explanatory material. These

D618 Practice for Conditioning Plastics for Testing

notesandfootnotes(excludingthoseintablesandfigures)shall

D792 Test Methods for Density and Specific Gravity (Rela-

not be considered as requirements of the specification.

tive Density) of Plastics by Displacement

1.3 The values stated in inch-pound units are to be regarded

D1505 Test Method for Density of Plastics by the Density-

as standard. The values given in parentheses are mathematical

Gradient Technique

conversions to SI units that are provided for information only

D1598 Test Method for Time-to-Failure of Plastic Pipe

and are not considered standard.

Under Constant Internal Pressure

1.4 The following safety hazards caveat pertains only to the

D1599 Test Method for Resistance to Short-Time Hydraulic

test methods portion, Section 7, of this specification:This

Pressure of Plastic Pipe, Tubing, and Fittings

standard does not purport to address all of the safety concerns,

D1600 Terminology forAbbreviatedTerms Relating to Plas-

if any, associated with its use. It is the responsibility of the user

tics

of this standard to establish appropriate safety and health

D2122 Test Method for Determining Dimensions of Ther-

practices and determine the applicability of regulatory limita-

moplastic Pipe and Fittings

tions prior to use.

D2765 Test Methods for Determination of Gel Content and

Swell Ratio of Crosslinked Ethylene Plastics

2. Referenced Documents

D2837 Test Method for Obtaining Hydrostatic Design Basis

2.1 ASTM Standards:

forThermoplasticPipeMaterialsorPressureDesignBasis

A269 Specification for Seamless and Welded Austenitic

for Thermoplastic Pipe Products

D3895 Test Method for Oxidative-Induction Time of Poly-

olefins by Differential Scanning Calorimetry

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

E18 Test Methods for Rockwell Hardness of Metallic Ma-

Piping Systems and is the direct responsibility of Subcommittee F17.61 on Water.

terials

Current edition approved May 1, 2013. Published June 2013. DOI: 10.1520/

F2929–13 F412 Terminology Relating to Plastic Piping Systems

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2929−13

F2657 Test Method for Outdoor Weathering Exposure of hydrostatic design basis (HDB) times the design factor (DF)

Crosslinked Polyethylene (PEX) Tubing for water. For this standard, the design factor is equal to 0.50.

2.2 ANSI Standard:

HDS 5HDB 3DF

B36.10 Standards Dimensions of Steel Pipe (IPS)

5HDB 30.05 ~For this s tandard!

2.3 Federal Standard:

(1)

FED-STD-123 Marking for Shipment (Civil Agencies)

3.2.3 hydrostatic design basis (HDB)—one of a series of

2.4 Military Standard:

established stress values (specified in Test Method D2837) for

MIL-STD-129 Marking for Shipment and Storage

4 a plastic compound obtained by categorizing the long-term

2.5 ISO Standards:

hydrostatic strength determined in accordance with Test

ISO 1167 Thermoplastics pipes, fittings and assemblies for

Method D2837.

theconveyanceoffluids--Determinationoftheresistance

3.2.3.1 Discussion—A listing of HDB and HDS values are

to internal pressure -- Part 1: General method

contained in PPI publication PPI TR–4.

ISO R 161-1690 Pipes of Plastic Materials for the Transport

3.2.4 pressure rating (PR)—the estimated maximum water

of Fluids (Outside Diameters and Nominal Pressures) Part

pressure the tube is capable of withstanding continuously with

1, Metric Series

ahighdegreeofcertaintythatfailureofthetubewillnotoccur.

2.6 PPI Standards:

5 7

3.2.4.1 Discussion—If both ⁄8 NTS and ⁄8 NTS tubing are

PPI TR-3 Policies and Procedures for Developing Recom-

used in the same system, the pressure rating of the system is

mended Hydrostatic Design Basis (HDB), Strength De-

limited to the pressure rating of the ⁄8 NTS tubing.

sign Basis (SDB), Pressure Design Basis (PDB) and

Minimum Required Strength (MRS) Ratings for Thermo-

3.2.5 relation between dimensions, hydrostatic design

plastic Piping Materials or Pipe

stress, and pressure rating—the following expression, com-

PPI TR-4 PPI Listing of Hydrostatic Design Basis (HDB),

monly known as the ISO equation, 6 is used in this specifica-

Strength Design Basis (SDB), Pressure Design Basis

tion to relate dimensions, hydrostatic design stress, and pres-

(PDB) and Minimum Required Strength (MRS) Ratings

sure rating:

for Thermoplastic Piping Materials or Pipe

2S⁄P 5 D ⁄ t 2 1

~ !

O

or

3. Terminology

2S⁄P 5 R 21 (2)

3.1 Definitions—Definitions are in accordance with Termi-

nology F412, and abbreviations are in accordance with Termi-

where:

nologyD1600,unlessotherwisespecified.Theabbreviationfor

S = hydrostatic design stress, psi (MPa),

crosslinked polyethylene is PEX.

P = pressure rating, psi (or MPa),

D = average outside diameter, in. (mm),

3.2 Definitions of Terms Specific to This Standard:

O

t = minimum wall thickness, in. (mm), and

3.2.1 crosslinked polyethylene, n—molecular polyethylene

R = dimension ratio, DR.

chains chemically connected through irradiation with high-

energy electron beams, or chemical agents such as organic

3.2.6 tubing material designation code—The tubing mate-

peroxides or silanes. rial designation code shall consist of the abbreviation for the

type of plastic (PEX) followed by four Arabic digits that

3.2.2 hydrostatic design stress (HDS), n—the estimated

describe short-term properties in accordance with applicable

maximum tensile stress the material is capable of withstanding

ASTM standards and as shown in Table 1.

continuously with a high degree of certainty that failure of the

3.2.6.1 Discussion—The first digit is for chlorine resistance,

tube will not occur.This stress is circumferential when internal

which is not applicable for radiant tubing applications, but is

hydrostatic water pressure is applied. The HDS is equal to the

mentioned here for information purposes.

3.2.6.2 Discussion—The second digit is for demonstrated

UVresistance of PEX material when tested in accordance with

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org.

Test Method F2657. For radiant heating, it shall be one of the

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

classificationdigitsfromTable1forthenominalexposuretime

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

period from Table 1 of Test Method F2657 where the UV-

dodssp.daps.dla.mil.

exposed samples meet the requirement of 7.10 Stabilizer

Available from International Organization for Standardization (ISO), 1, ch. de

la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org.

Functionality. The UV resistance shall be demonstrated on

Available from Plastics Pipe Institute (PPI), 105 Decker Court, Suite 825,

representative pipe samples for the original validation of pipe

Irving, TX 75062, http://www.plasticpipe.org.

TABLE 1 PEX Tubing Material Designation Code Cells

Property Standard 0 1 2 3 6 8

Chlorine Resistant Not applicable . . . . .

Minimum UV Not tested or rated 1 month 3 months 6 months . .

Resistance

HDS for water at . . . . 630 800

73°F, psi

F2929−13

made from a particular PEX material, that material being the 5.2.2 Machined Brass—Machined brass fittings shall be

combination of PEX resin and its additive system. made from material meeting the requirements of one of the

following:

3.2.6.3 Discussion—The last two digits are the hydrostatic

(1) Specification B16/B16M, Copper Alloy UNS No.

design stress for water at 73°F (23°C) in units of 100 psi with

C36000,

any decimal figures dropped. Where the hydrostatic design

(2) Specification B140/B140M copper alloy UNS No.

stress code contains less than two figures, a zero is used before

C31400,

the number. Thus, a complete material designation code for

(3) Specification B371/B371M Copper Alloy UNS No.

PEX tubing shall consist of the three letters “PEX” and four

C69300, or

digits.

(4) Specification B967/B967M copper alloy UNS No.

3.2.7 0.070 in. wall radiant heating system—PEX tubing

C49260 or C49340.

with a 0.070 in. thickness, and corresponding fittings designed

5.2.3 Forged Brass—Forged brass fittings shall be made

for 0.070 in. wall tubing, used for radiant heating applications.

from material meeting the requirements of Specification B283,

Copper Alloy UNS Nos. C27450, C35330, C36500, C37700,

4. Tubing Classification

C46400, C48600, C49260, C49340, or C69300.

5.2.4 Stainless Steel—Stainless steel fittings shall be made

4.1 General—This specification covers tubing for 0.070 in.

from material meeting requirements of one of the following:

wall radiant heating that is classified using the tubing material

(1) Specification A312/A312M, stainless steel alloy 304,

designation code for PEX tubing.

304L, 316 or 316L, (UNS Nos. S30400, S30403, S31600 or

S31603),

5. Materials

(2) Specification A269, stainless steel alloy 304, 304L,

5.1 Tubing—Crosslinked polyethylene tubing, meeting the

316, 316L(UNS Nos. S30400, S30403, S31600 or S31603), or

requirements of this specification, is primarily defined by

(3) Specification A276, Stainless steel alloy 304, 401L,

means of three criteria, namely, (1) nominal density, (2) degree

316, or 316L(UNS Nos. S30400, S30403, S31600 or S31603)

of crosslinking, and (3) long-term strength tests. There is a

strong correlation between nominal density and results of

6. Requirements

short-term strength tests.

6.1 Workmanship—The tubing shall be homogeneous

5.1.1 Basic Materials—PEX tubing shall be made from

throughout and free of visible cracks, holes, foreign inclusions,

polyethylene compounds, which have been crosslinked by

or other defects. The pipe shall be as uniform as commercially

peroxides, Azo compounds, or silane compounds in extrusion,

practicable in color, opacity, density, and other physical prop-

or by electron beam after extrusion, or by other means such

erties.

that the tubing meets the performance requirements of Section

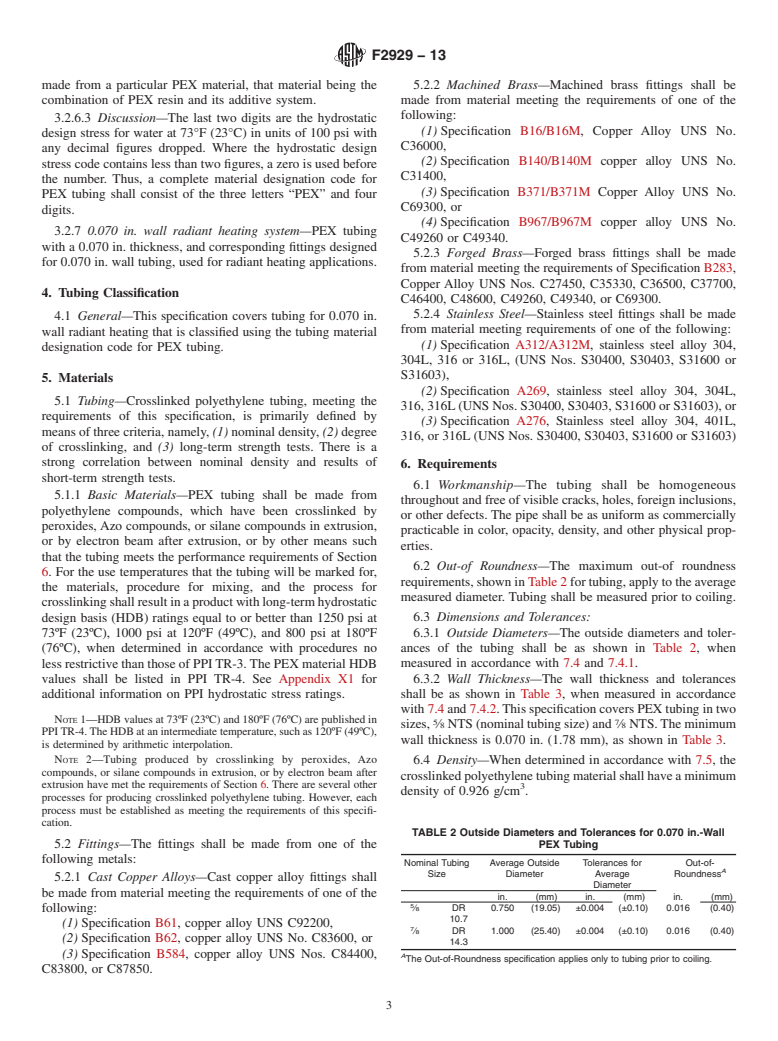

6.2 Out-of Roundness—The maximum out-of roundness

6. For the use temperatures that the tubing will be marked for,

requirements,showninTable2fortubing,applytotheaverage

the materials, procedure for mixing, and the process for

measured diameter. Tubing shall be measured prior to coiling.

crosslinkingshallresultinaproductwithlong-termhydrostatic

design basis (HDB) ratings equal to or better than 1250 psi at 6.3 Dimensions and Tolerances:

73ºF (23ºC), 1000 psi at 120ºF (49ºC), and 800 psi at 180ºF 6.3.1 Outside Diameters—The outside diameters and toler-

(76ºC), when determined in accordance with procedures no ances of the tubing shall be as shown in Table 2, when

less restrictive than those of PPITR-3.The PEX material HDB measured in accordance with 7.4 and 7.4.1.

values shall be listed in PPI TR-4. See Appendix X1 for 6.3.2 Wall Thickness—The wall thickness and tolerances

additional information on PPI hydrostatic stress ratings. shall be as shown in Table 3, when measured in accordance

with7.4and7.4.2.ThisspecificationcoversPEXtubingintwo

NOTE 1—HDB values at 73ºF (23ºC) and 180ºF (76ºC) are published in

5 7

sizes, ⁄8NTS(nominaltubingsize)and ⁄8NTS.Theminimum

PPITR-4.TheHDBatanintermediatetemperature,suchas120ºF(49ºC),

wall thickness is 0.070 in. (1.78 mm), as shown in Table 3.

is determined by arithmetic interpolation.

NOTE 2—Tubing produced by crosslinking by peroxides, Azo

6.4 Density—When determined in accordance with 7.5, the

compounds, or silane compounds in extrusion, or by electron beam after

crosslinkedpolyethylenetubingmaterialshallhaveaminimum

extrusion have met the requirements of Section 6. There are several other

density of 0.926 g/cm .

processes for producing crosslinked polyethylene tubing. However, each

process must be established as meeting the requirements of this specifi-

cation.

TABLE 2 Outside Diameters and Tolerances for 0.070 in.-Wall

5.2 Fittings—The fittings shall be made from one of the PEX Tubing

following metals:

Nominal Tubing Average Outside Tolerances for Out-of-

A

Size Diameter Average Roundness

5.2.1 Cast Copper Alloys—Cast copper alloy fittings shall

Diameter

be made from material meeting the requirements of one of the

in. (mm) in. (mm) in. (mm)

⁄8 DR 0.750 (19.05) ±0.004 (±0.10) 0.016 (0.40)

following:

10.7

(1) Specification B61, copper alloy UNS C92200,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.