ASTM F2298-03(2009)e1

(Test Method)Standard Test Methods for Water Vapor Diffusion Resistance and Air Flow Resistance of Clothing Materials Using the Dynamic Moisture Permeation Cell (Withdrawn 2015)

Standard Test Methods for Water Vapor Diffusion Resistance and Air Flow Resistance of Clothing Materials Using the Dynamic Moisture Permeation Cell (Withdrawn 2015)

SIGNIFICANCE AND USE

The water vapor transport properties of textile materials are of considerable importance in determining the comfort properties of clothing systems. Water vapor transport through porous textiles may occur due to both diffusion (driven by vapor concentration differences) and convection (driven by gas pressure differences).

For air permeable porous materials, a very small pressure gradient can produce large convective flows through the pores in the structure. In many standard water vapor permeability test methods, when used for materials with high air permeability, slight variations in pressure gradient across a specimen will greatly influence the measured water vapor transport properties. Therefore, the water vapor transport properties of the porous and non-porous textile materials cannot be directly compared when the method has no provision for controlling the pressure gradient. This test method determines the diffusion and convection properties from the same test and generates data that allows direct comparison of the results obtained between materials.

SCOPE

1.1 This test method covers the measurement of the moisture vapor transport and gas flow properties of fabrics, membranes, and membrane laminates used for protective materials.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covered the measurement of the moisture vapor transport and gas flow properties of fabrics, membranes, and membrane laminates used for protective materials.

Formerly under the jurisdiction of Committee F23 on Personal Protective Clothing and Equipment, this test method was withdrawn in February 2015. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F2298 − 03(Reapproved 2009)

Standard Test Methods for

Water Vapor Diffusion Resistance and Air Flow Resistance

of Clothing Materials Using the Dynamic Moisture

Permeation Cell

This standard is issued under the fixed designation F2298; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Reapproved with editorial changes in February 2009.

1. Scope 3.1.2 water vapor transmission rate, n— the steady water

vapor flow in unit time through unit area of a material, under

1.1 This test method covers the measurement of the mois-

specific conditions of temperature and humidity at each sur-

ture vapor transport and gas flow properties of fabrics,

face.

membranes, and membrane laminates used for protective

materials.

4. Summary of Test Methods

1.2 The values stated in SI units are to be regarded as the

4.1 The testing outlined in this standard consists of measur-

standard.

ingtheamountofwatervaportransportacrossaspecimen.The

1.3 This standard does not purport to address all of the

water vapor transport properties can be measured in a pure

safety concerns, if any, associated with its use. It is the

diffusion mode and in a diffusion/convection mode.

responsibility of the user of this standard to establish appro-

4.2 Two test methods are presented in this standard:

priate safety and health practices and determine the applica-

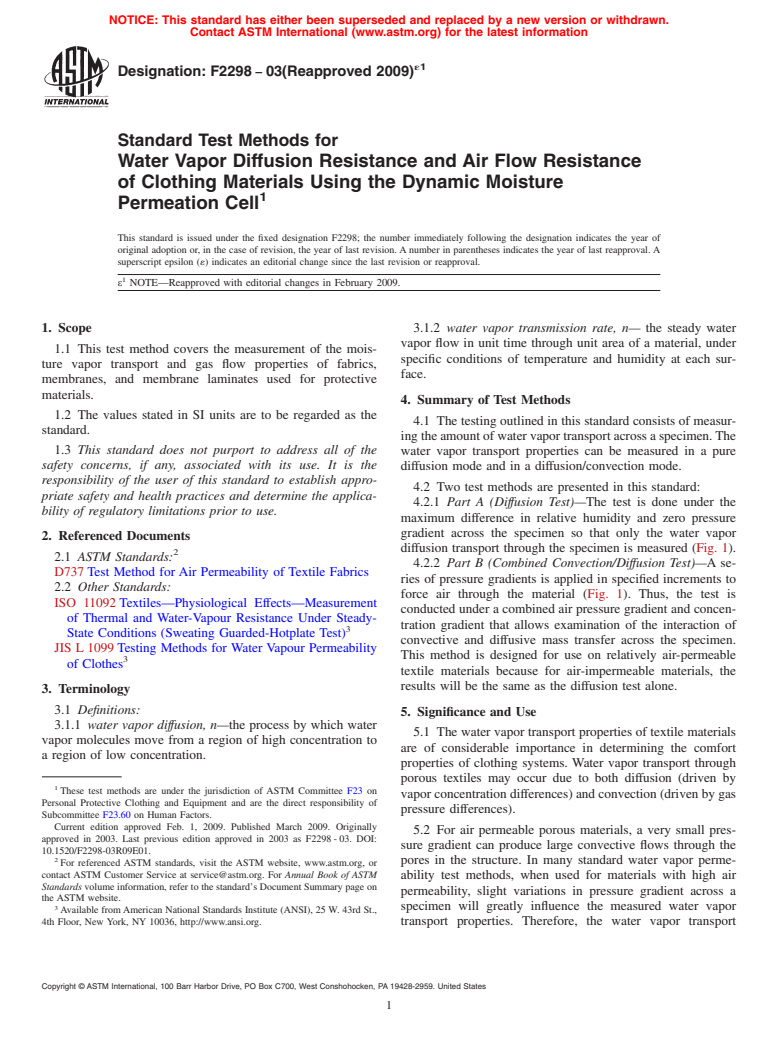

4.2.1 Part A (Diffusion Test)—The test is done under the

bility of regulatory limitations prior to use.

maximum difference in relative humidity and zero pressure

gradient across the specimen so that only the water vapor

2. Referenced Documents

diffusion transport through the specimen is measured (Fig. 1).

2.1 ASTM Standards:

4.2.2 Part B (Combined Convection/Diffusion Test)—A se-

D737Test Method for Air Permeability of Textile Fabrics

ries of pressure gradients is applied in specified increments to

2.2 Other Standards:

force air through the material (Fig. 1). Thus, the test is

ISO 11092Textiles—Physiological Effects—Measurement

conducted under a combined air pressure gradient and concen-

of Thermal and Water-Vapour Resistance Under Steady-

tration gradient that allows examination of the interaction of

State Conditions (Sweating Guarded-Hotplate Test)

convective and diffusive mass transfer across the specimen.

JIS L 1099Testing Methods for Water Vapour Permeability

This method is designed for use on relatively air-permeable

of Clothes

textile materials because for air-impermeable materials, the

results will be the same as the diffusion test alone.

3. Terminology

3.1 Definitions:

5. Significance and Use

3.1.1 water vapor diffusion, n—the process by which water

5.1 The water vapor transport properties of textile materials

vapor molecules move from a region of high concentration to

are of considerable importance in determining the comfort

a region of low concentration.

properties of clothing systems. Water vapor transport through

porous textiles may occur due to both diffusion (driven by

These test methods are under the jurisdiction of ASTM Committee F23 on

vaporconcentrationdifferences)andconvection(drivenbygas

Personal Protective Clothing and Equipment and are the direct responsibility of

pressure differences).

Subcommittee F23.60 on Human Factors.

Current edition approved Feb. 1, 2009. Published March 2009. Originally

5.2 For air permeable porous materials, a very small pres-

approved in 2003. Last previous edition approved in 2003 as F2298-03. DOI:

sure gradient can produce large convective flows through the

10.1520/F2298-03R09E01.

pores in the structure. In many standard water vapor perme-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ability test methods, when used for materials with high air

Standards volume information, refer to the standard’s Document Summary page on

permeability, slight variations in pressure gradient across a

the ASTM website.

3 specimen will greatly influence the measured water vapor

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. transport properties. Therefore, the water vapor transport

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F2298 − 03 (2009)

FIG. 1 Overview of the Test Methods

properties of the porous and non-porous textile materials test and generates data that allows direct comparison of the

cannotbedirectlycomparedwhenthemethodhasnoprovision

results obtained between materials.

for controlling the pressure gradient. This test method deter-

mines the diffusion and convection properties from the same

´1

F2298 − 03 (2009)

6. Sampling and Preparation of Test Specimens flows of a saturated and a dry nitrogen stream. The test

apparatus requires four mass flow controllers. Two controllers

6.1 Sampling:

adjustthedryandsaturatednitrogengasstreamstothetopflow

6.1.1 Laboratory Sample—Take test specimens that are

cell, and two controllers adjust the dry and wet nitrogen gas

believedtoberepresentativeofthesampletobetestedandfree

streamstothebottomflowcell.Themassflowcontrollersshall

ofabnormaldistortions.Thesamplemaybeapieceoffabricor

be controlled at an accuracy of 6 1% of full scale, with a

a garment.

response time of less than 5 s, unless stated otherwise in the

6.1.2 If the material is of nonsymmetrical construction, the

data report. Electronic mass flow controllers usually indicate

two faces shall be designated by distinguishing marks.

flow rate in terms of volumetric flow rates at standard

6.2 Sample Preparation:

conditions of 0°C and atmospheric pressure. The actual volu-

6.2.1 Cut three specimens from each laboratory sample.

metricflowrateattheactualtesttemperaturecanbecalculated

6.2.2 Specimen Size—Use specimens larger than the area of

from the mass flow rate, the temperature, and the pressure of

the opening in the clamping plate so that the test area is

the actual flow.

covered completely.

7.2.2 Channel Power Supply and Readout, controls and

displays the flow meters and controllers. The display accuracy

7. Test Apparatus

of the channel readout shall be within 6 0.2% 6 1 digit,

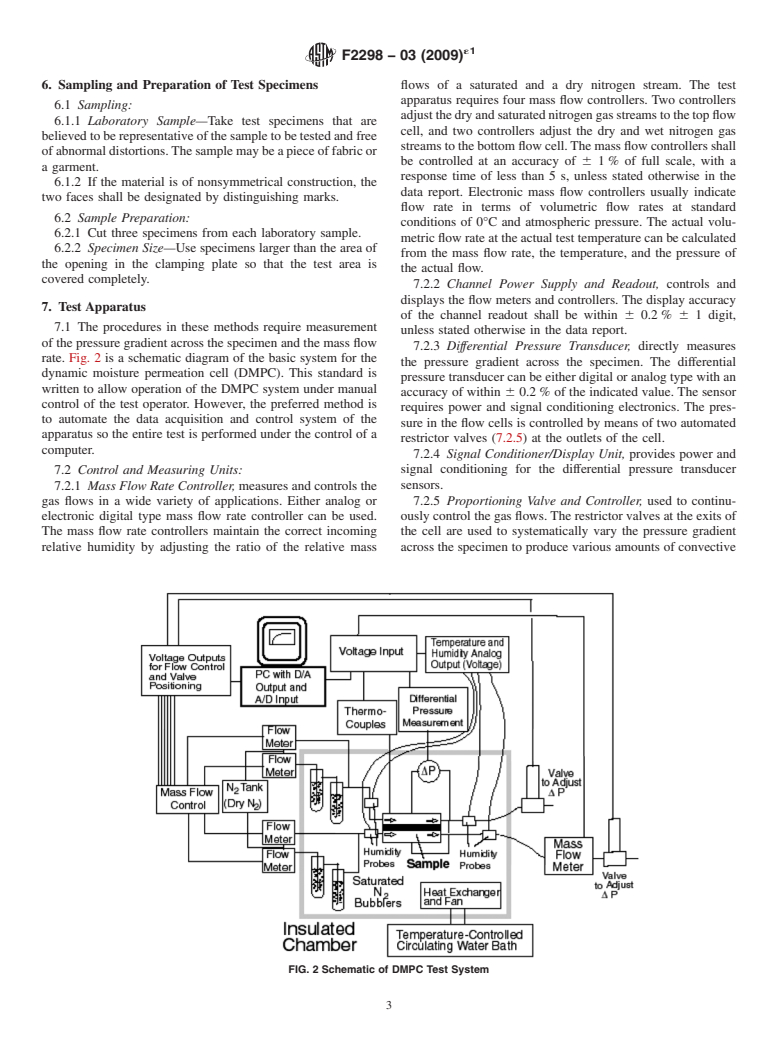

7.1 The procedures in these methods require measurement

unless stated otherwise in the data report.

ofthepressuregradientacrossthespecimenandthemassflow

7.2.3 Differential Pressure Transducer, directly measures

rate. Fig. 2 is a schematic diagram of the basic system for the

the pressure gradient across the specimen. The differential

dynamic moisture permeation cell (DMPC). This standard is

pressuretransducercanbeeitherdigitaloranalogtypewithan

written to allow operation of the DMPC system under manual

accuracy of within 6 0.2% of the indicated value. The sensor

control of the test operator. However, the preferred method is

requires power and signal conditioning electronics. The pres-

to automate the data acquisition and control system of the

sure in the flow cells is controlled by means of two automated

apparatus so the entire test is performed under the control of a

restrictor valves (7.2.5) at the outlets of the cell.

computer.

7.2.4 Signal Conditioner/Display Unit, provides power and

signal conditioning for the differential pressure transducer

7.2 Control and Measuring Units:

sensors.

7.2.1 Mass Flow Rate Controller,measuresandcontrolsthe

gas flows in a wide variety of applications. Either analog or 7.2.5 Proportioning Valve and Controller, used to continu-

electronic digital type mass flow rate controller can be used. ouslycontrolthegasflows.Therestrictorvalvesattheexitsof

The mass flow rate controllers maintain the correct incoming the cell are used to systematically vary the pressure gradient

relative humidity by adjusting the ratio of the relative mass across the specimen to produce various amounts of convective

FIG. 2 Schematic of DMPC Test System

´1

F2298 − 03 (2009)

flows across the specimen. The valves shall withstand the 7.3.1 Flow Cell Unit, consists of two identical flow cell

maximumpressureinthetestcellduringthetest.Insteadofthe segmentsmadeofplastic,glass,orothermaterialsthatwillnot

electronicpressuregaugesandautomatedrestrictorvalves,itis corrodeanddonotabsorbmoisture.Eachcellsegmentconsists

acceptable to use analog differential pressure gauges in a of a flow cell and a sample clamping plate.The size of the cell

variety of different full scale ranges, and manual needle or can be as large as practical, so as the size of the duct. The

orifice metering valves at the gas flow exit of the cells to typical size of the duct in each flow cell segment is 0.025 m

control the pressure gradient across the test specimen. wide, 0.13 m long, and 0.0050 m high. The entrance length of

7.2.6 Electronic Mass Flow Meter and Power Supply, con- the nitrogen gas must be long enough to get a stable fully

nects one of the exits of the flow cells (bottom cell) and the developed flow. At 2000 cm /min gas flow rate, more than

proportioning valve. The mass flow meter directly measures 0.002misrequiredfortheductlengthfromthegasentranceto

and displays the mass flow rate with a response time of within the sample, and from the specimen to the gas exit. The typical

5s. duct length is about 0.003 to 0.007 m. Each flow cell segment

7.2.7 Humidity Measurement Instrument,measurestherela- shall have ports for flow inlet and outlet in both ends of the

tive humidity of the incoming and the outgoing gas flows.The flow cell segment, and a port for differential pressure measure-

relativehumidityoftheincominggasflowisdirectlymeasured ment on the front top of the flow cell segment. A specimen is

with the humidity sensor. Relative humidity can be measured held in-between the two flow cell segments (Fig. 3).

in different ways, such as a condensation type dew point

7.3.2 Specimen Clamping Plate, can be made of plastic,

hygrometer, capacitance type relative humidity probe, or gas

metal, or steel, and attached to the flow cell segments by using

chromatography. Capacitance type humidity probe is recom-

a sealing agent or mounting bolts. The thickness of clamping

-5

mendedbecauseitprovidessmallsizeandafastresponsetime.

plate shall be5×10 m (0.5 mm). The hole opening in the

The relative humidity probes shall have a measurement accu-

clamping plate that determines the test area of the specimen

racy of 6 3% R.H. over the range in use, unless stated in the

shall have the size of 0.05 m long by 0.02 m wide (0.001 m ).

report.

Aspecimenmustbebiggerthantheholeofaclampingplateto

7.2.8 Temperature Measurement Instrument—The tempera-

cover the clamping plate completely.

ture measurement sensor shall measure the temperature within

7.3.3 Clamping System,preventsleakageofthenitrogengas

6 0.1°C with a time constant not exceeding 1 min. The

through the test cell unit. The sealing other than the clamping

temperature measurement shall be made at the same place as

force provided by the mounting bolts is unnecessary for most

the humidity measurement.

thinmaterialssuchaslaminatedandwoventextilematerials.If

7.3 Moisture Permeation Cell: there is any leakage from the edges of the specimen, special

FIG. 3 Typical Dimensions of the Specimen Holder for the DMPC

´1

F2298 − 03 (2009)

sealing methods such as molten wax, curable sealant, rubber valve or orifice, with a differential pressure sensor connected

sealing gaskets may be required. across the valve or orifice, which is connected to the output of

7.3.4 Bubblers, used to saturate nitrogen gas in water. a mass flow controller. Appropriate sizing of the needle valve

Bubblers of 500 mL or 1000 mL are appropriate for this test. or orifice opening, and the pressure transducer range, will give

The first bubbler completes the primary saturation of the gas a measured pressure gradient across the valve or orifice which

stream. The second bubbler ensures full saturation, and brings is indicative of whether each mass flow controller set at a

the gas stream back to deviation from the test temperature that particular flow is actually delivering identical gas flow rates.

may have occurred due to evaporative cooling in the first

8.3 Humidity Calibration—Requirements for humidity cali-

bubbler. The saturated and the dry nitrogen gas controlled by

bration will also depend on the humidity measurement system

separate mass flow meters shall merge into one gas tube and

selected for the test. Humidity calibration procedures may be

enter to the top flow cell. The ratio of dry and saturated

supplied by the manufacturer for the specific instrument, or

nitrogen gas determines the relative humidity in the flow cell.

may not be necessary for a high-accuracy system such as a gas

An identical set of two flow controllers and bubblers are

chromatograph, infrared diode laser sensor, or a chilled-mirror

neededtocontroltherelativehumidityofthebottomflowcell.

dew point hygrometer.

7.3.5 Data Acquisition System—It is possible to conduct the

8.4 Reference Material Calibration—Before starting test

tests manually by reading the outputs from the relative humid-

withaspecimen,conductatestwithareferencematerialunder

itymeasurementdevices,flowmeters,andpressuretransducers

the condition specified in 9.2. An expanded polytetrafluoreth-

and performing the necessary calculations. However, it is

ylene (ePTFE) film is used as a reference material for the

recommended to conduct the tests under the control of a

system. The ePTFE membranes are microporous and

computertoautomatethetasksofdatacollectionandcontrolof

hydrophobic, thus vapor transport takes place only through the

the mass flow controllers and valves.

interconnectedairspacesofthemembrane.Theydonotchange

7.4 Materials:

the transport properties as a function of membrane water

7.4.1 Reference Material, required for the calibration to

content or test conditions.

check the instrument before testing. Use microporous ex-

8.4.1 Test Conditions—Use the test conditions directed in

panded polytetrafluorethylene (ePTFE) membrane as a refer-

9.1.

ence material.

8.4.2 Place an ePTFE film in between the top and the

7.4.2 Nitrogen Gas, pure nitrogen gas with technical grade

bottom flow cell segments.

of 99% is used.

8.4.3 Follow the same procedures in 9.2.2 – 9.2.4.

8.4.4 Calculate total water vapor diffusion resistance Rdtot

8. Calibration Procedures

described in 9.3.

8.1 Threecalibrationproceduresmaybenecessary.Thefirst

8.4.5 The water vapor diffusion

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.