ASTM F2181-14

(Specification)Standard Specification for Wrought Seamless Stainless Steel Tubing for Surgical Implants

Standard Specification for Wrought Seamless Stainless Steel Tubing for Surgical Implants

ABSTRACT

This specification covers the requirements for three compositions of wrought seamless stainless steel tubing for the manufacture of surgical implants. Materials shall be tested and shall conform to chemical composition, metallurgical requirements, and mechanical properties. Materials and manufacture are also detailed.

SCOPE

1.1 This specification covers the requirements for five compositions of wrought seamless stainless steel tubing for the manufacture of surgical implants. Material shall conform to the applicable requirements of Specifications F138, F1314, F1586, F2229, or F2581. This specification addresses those product variables that differentiate wrought seamless tubing from the bar and wire product forms covered in these specifications.

1.2 This specification applies to cold finished, straight length tubing from 3 to 34 mm [0.125 to 1.315 in.] nominal outside diameter (OD) and 0.5 mm [0.020 in.] and greater nominal wall thickness.

1.3 The specifications in 2.1 are referred to as the ASTM material standard(s) in this specification.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2181 −14

Standard Specification for

Wrought Seamless Stainless Steel Tubing for Surgical

1

Implants

This standard is issued under the fixed designation F2181; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Stainless Steel Alloy Bar and Wire for Surgical Implants

(UNS S20910)

1.1 This specification covers the requirements for five

F1586 Specification for Wrought Nitrogen Strengthened

compositions of wrought seamless stainless steel tubing for the

21Chromium—10Nickel—3Manganese—

manufactureofsurgicalimplants.Materialshallconformtothe

2.5Molybdenum Stainless Steel Alloy Bar for Surgical

applicable requirements of Specifications F138, F1314, F1586,

Implants (UNS S31675)

F2229,or F2581. This specification addresses those product

F2229 Specification for Wrought, Nitrogen Strengthened

variables that differentiate wrought seamless tubing from the

23Manganese-21Chromium-1Molybdenum Low-Nickel

bar and wire product forms covered in these specifications.

Stainless Steel Alloy Bar and Wire for Surgical Implants

1.2 This specification applies to cold finished, straight

(UNS S29108)

length tubing from 3 to 34 mm [0.125 to 1.315 in.] nominal

F2581 Specification for Wrought Nitrogen Strengthened

outside diameter (OD) and 0.5 mm [0.020 in.] and greater

11Manganese-17Chromium-3Molybdenum Low-Nickel

nominal wall thickness.

Stainless Steel Alloy Bar and Wire for Surgical Implants

(UNS S29225)

1.3 The specifications in 2.1 are referred to as the ASTM

material standard(s) in this specification. 2.2 ASTM Standards:

A262 Practices for Detecting Susceptibility to Intergranular

1.4 The values stated in either SI units or inch-pound units

Attack in Austenitic Stainless Steels

are to be regarded separately as standard. The values stated in

A269 Specification for Seamless and Welded Austenitic

each system may not be exact equivalents; therefore, each

Stainless Steel Tubing for General Service

system shall be used independently of the other. Combining

A632 Specification for Seamless and Welded Austenitic

values from the two systems may result in nonconformance

Stainless Steel Tubing (Small-Diameter) for General Ser-

with the standard.

vice

E29 Practice for Using Significant Digits in Test Data to

2. Referenced Documents

Determine Conformance with Specifications

2

2.1 ASTM Material Standards:

F2257 Specification for Wrought Seamless or Welded and

F138 Specification for Wrought 18Chromium-14Nickel-

Drawn 18 Chromium-14Nickel-2.5Molybdenum Stainless

2.5Molybdenum Stainless Steel Bar andWire for Surgical

Steel Small Diameter Tubing for Surgical Implants (UNS

Implants (UNS S31673)

S31673)

F1314 Specification for Wrought Nitrogen Strengthened 22

IEEE/ASTM SI 10 American National Standard for Use of

Chromium–13 Nickel–5 Manganese–2.5 Molybdenum

theInternationalSystemofUnits(SI):TheModernMetric

System

3

1

This specification is under the jurisdiction of ASTM Committee F04 on

2.3 ISO Standards:

Medical and Surgical Materials and Devices and is the direct responsibility of

ISO 5832-1 Implants for Surgery—Metallic Materials—Part

Subcommittee F04.12 on Metallurgical Materials.

1: Wrought Stainless Steel

Current edition approved Oct. 1, 2014. Published January 2015. Originally

ISO 5832-9 Implants for Surgery—Metallic Materials—Part

approved in 2002. Last previous edition approved 2009 as F2181 – 09. DOI:

10.1520/F2181-14.

9: Wrought High Nitrogen Stainless Steel

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

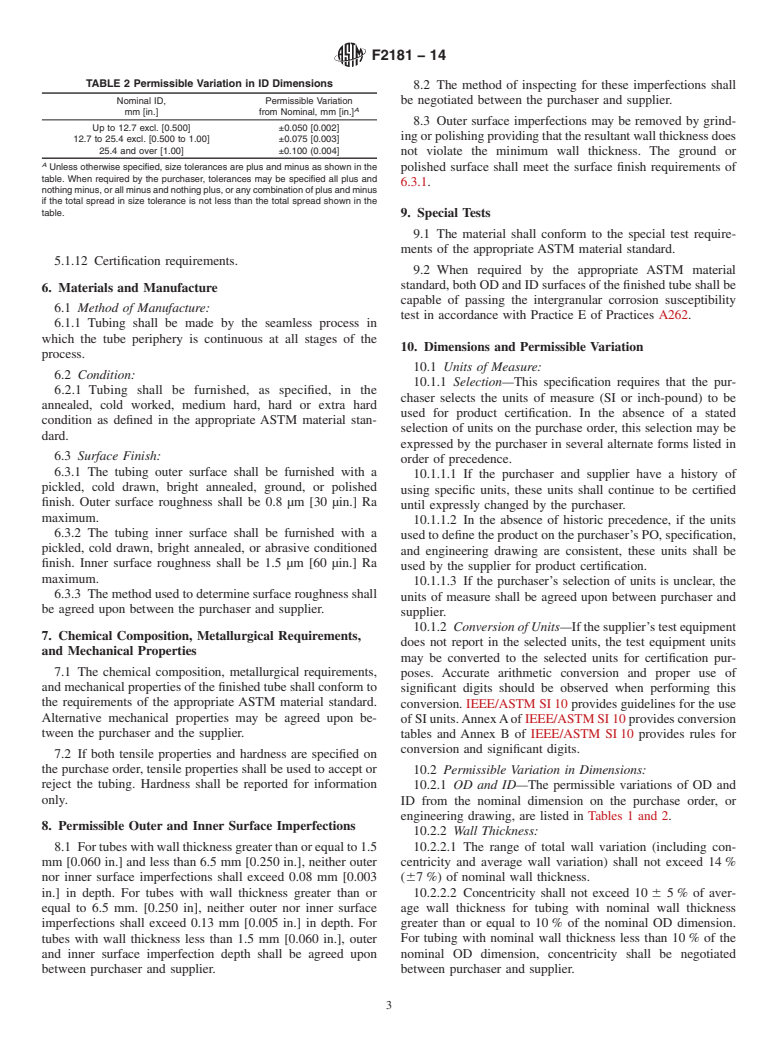

F2181−14

ISO 9001 Quality Management System—Requirements 3.1.9 sample maximum wall thickness—the largest indi-

ISO13485 Medicaldevices-Qualitymanagementsystems- vidual wall thickness measurement taken around the circum-

Requirements for regulatory purposes ference on any one transverse cross section of a single sample

4

of tube.

2.4 ASME Standard:

ASMEY14.5.1M Mathematical Definition of Dimensioning

3.1.10 sample minimum wall thickness—the smallest indi-

and Tolerancing Principles

vidual wall thickness measurement taken around the circum-

ference on any one transverse cross se

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2181 − 09 F2181 − 14

Standard Specification for

Wrought Seamless Stainless Steel Tubing for Surgical

1

Implants

This standard is issued under the fixed designation F2181; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers the requirements for five compositions of wrought seamless stainless steel tubing for the

manufacture of surgical implants. Material shall conform to the applicable requirements of Specifications F138, F1314, F1586,

F2229, or F2581. This specification addresses those product variables that differentiate wrought seamless tubing from the bar and

wire product forms covered in these specifications.

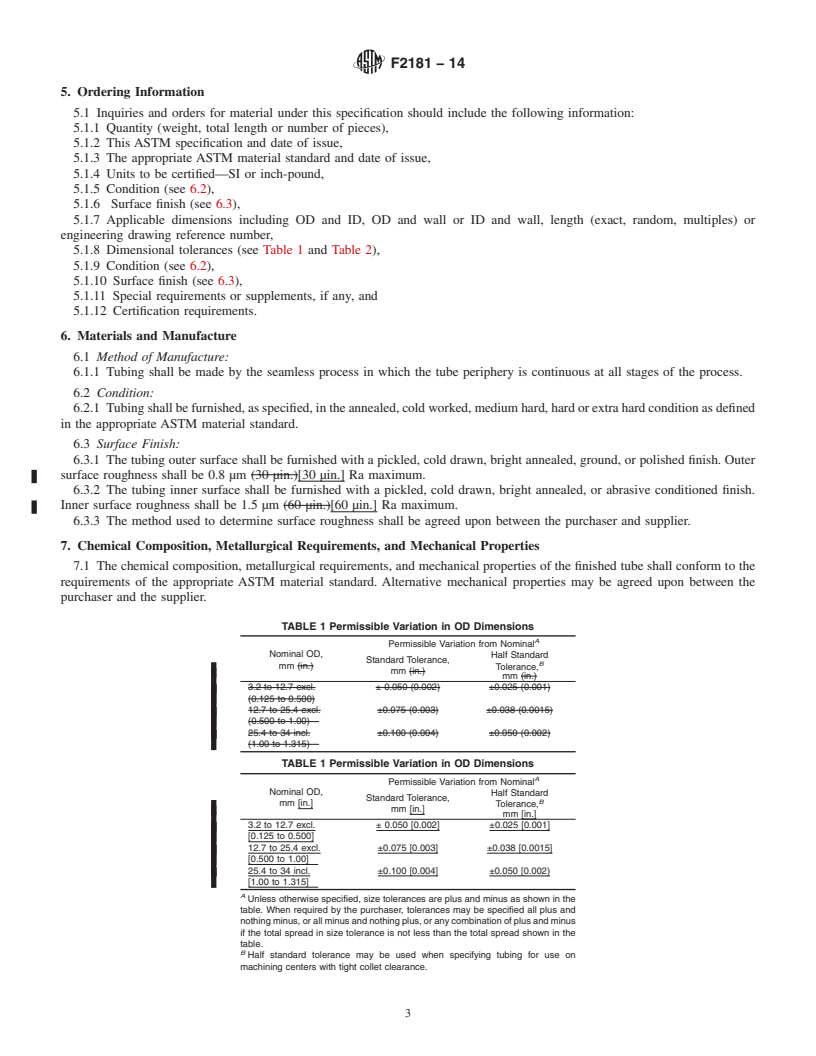

1.2 This specification applies to cold finished, straight length tubing from 3 to 34 mm (0.125[0.125 to 1.315 in.)in.] nominal

outside diameter (OD) and 0.5 mm (0.020 in.)[0.020 in.] and greater nominal wall thickness.

1.3 The specifications in 2.1 are referred to as the ASTM material standard(s) in this specification.

1.4 The values stated in either inch-pound or SI units or inch-pound units are to be regarded separately as standard. Inch-pound

units are shown in parentheses. The values stated in each system may not be exact equivalents; therefore, each system shall be used

independently of the other. Combining values from the two systems may result in non-conformancenonconformance with the

standard.

2. Referenced Documents

2

2.1 ASTM Material Standards:

F138 Specification for Wrought 18Chromium-14Nickel-2.5Molybdenum Stainless Steel Bar and Wire for Surgical Implants

(UNS S31673)

F1314 Specification for Wrought Nitrogen Strengthened 22 Chromium–13 Nickel–5 Manganese–2.5 Molybdenum Stainless

Steel Alloy Bar and Wire for Surgical Implants (UNS S20910)

F1586 Specification for Wrought Nitrogen Strengthened 21Chromium—10Nickel—3Manganese—2.5Molybdenum Stainless

Steel Alloy Bar for Surgical Implants (UNS S31675)

F2229 Specification for Wrought, Nitrogen Strengthened 23Manganese-21Chromium-1Molybdenum Low-Nickel Stainless

Steel Alloy Bar and Wire for Surgical Implants (UNS S29108)

F2581 Specification for Wrought Nitrogen Strengthened 11Manganese-17Chromium-3Molybdenum Low-Nickel Stainless Steel

Alloy Bar and Wire for Surgical Implants (UNS S29225)

2.2 ASTM Tubing Standards:

A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

A269 Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service

A632 Specification for Seamless and Welded Austenitic Stainless Steel Tubing (Small-Diameter) for General Service

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

F2257 Specification for Wrought Seamless or Welded and Drawn 18 Chromium-14Nickel-2.5Molybdenum Stainless Steel Small

Diameter Tubing for Surgical Implants (UNS S31673)

IEEE/ASTM SI 10 American National Standard for Use of the International System of Units (SI): The Modern Metric System

3

2.3 ISO Standards:

ISO 5832-1 Implants for Surgery—Metallic Materials—Part 1: Wrought Stainless Steel

ISO 5832-9 Implants for Surgery—Metallic Materials—Part 9: Wrought High Nitrogen Stainless Steel

1

This specification is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.12 on Metallurgical Materials.

Current edition approved Feb. 1, 2009Oct. 1, 2014. Published July 2009January 2015. Originally approved in 2002. Last previous edition approved 20082009 as

F2181 – 08.F2181 – 09. DOI: 10.1520/F2181-09.10.1520/F2181-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2181 − 14

ISO 9001 Quality Management System—Requirements

ISO 13485 Medical devices - Quality management systems - Requir

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.