ASTM B827-05

(Practice)Standard Practice for Conducting Mixed Flowing Gas (MFG) Environmental Tests

Standard Practice for Conducting Mixed Flowing Gas (MFG) Environmental Tests

SCOPE

1.1 This practice provides procedures for conducting environmental tests involving exposures to controlled quantities of corrosive gas mixtures.

1.2 This practice provides for the required equipment and methods for gas, temperature, and humidity control which enable tests to be conducted in a reproducible manner. Reproducibility is measured through the use of control coupons whose corrosion films are evaluated by mass gain, coulometry, or by various electron and X-ray beam analysis techniques. Reproducibility can also be measured by in situ corrosion rate monitors using electrical resistance or mass/frequency change methods.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use. See 5.1.2.4.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B827–05

Standard Practice for

1

Conducting Mixed Flowing Gas (MFG) Environmental Tests

This standard is issued under the fixed designation B 827; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Tests for Electrodeposits and Related Metallic Coatings

B 808 Test Method for Monitoring of Atmospheric Corro-

1.1 This practice provides procedures for conducting envi-

sion Chambers by Quartz Crystal Microbalances

ronmental tests involving exposures to controlled quantities of

B 810 Test Method for Calibration of Atmospheric Corro-

corrosive gas mixtures.

sion Test Chambers by Change in Mass of Copper Cou-

1.2 This practice provides for the required equipment and

pons

methods for gas, temperature, and humidity control which

B 825 Test Method for Coulometric Reduction of Surface

enable tests to be conducted in a reproducible manner. Repro-

Films on Metallic Test Samples

ducibility is measured through the use of control coupons

B 826 Test Method for Monitoring Atmospheric Corrosion

whose corrosion films are evaluated by mass gain, coulometry,

Tests by Electrical Resistance Probes

or by various electron and X-ray beam analysis techniques.

B 845 Guide for Mixed Flowing Gas (MFG) Tests for

Reproducibility can also be measured by in situ corrosion rate

Electrical Contacts

monitors using electrical resistance or mass/frequency change

D 1193 Specification for Reagent Water

methods.

D 2912 Test Method for Oxidant Content of the Atmo-

1.3 The values stated in SI units are to be regarded as the

3

sphere (Neutral KI)

standard.

D 2914 Test Methods for Sulfur Dioxide Content of the

1.4 This standard does not purport to address all of the

Atmosphere (West-Gaeke Method)

safety concerns, if any, associated with its use. It is the

D 3449 Test Method for Sulfur Dioxide in Workplace At-

responsibility of the user of this standard to become familiar

3

mospheres (Barium Perchlorate Method)

with all hazards including those identified in the appropriate

D 3464 Test Method forAverageVelocity in a Duct Using a

Material Safety Data Sheet for this product/material as pro-

Thermal Anemometer

vided by the manufacturer, to establish appropriate safety and

D 3609 Practice for Calibration Techniques Using Perme-

health practices, and determine the applicability of regulatory

ation Tubes

limitations prior to use. See 5.1.2.4.

D 3824 Test Methods for Continuous Measurement of Ox-

2. Referenced Documents ides of Nitrogen in theAmbient orWorkplaceAtmosphere

2

by the Chemiluminescent Method

2.1 ASTM Standards:

D 4230 Test Method of Measuring Humidity With Cooled-

B 542 Terminology Relating to Electrical Contacts and

Surface Condensation (Dew-Point) Hygrometer

Their Use

E 902 Practice for Checking the Operating Characteristics

B 765 Guide for Selection of Porosity and Gross Defects

of X-Ray Photoelectron Spectrometers

G91 Practice for Monitoring Atmospheric SO Using Sul-

2

1

This practice is under the jurisdiction ofASTM Committee B02 on Nonferrous

fation Plate Technique

Metals and Alloys and is the direct responsibility of Subcommittee B02.11 on

Electrical Contact Test Methods.

3. Terminology

Current edition approved May 1, 2005. Published June 2005. Originally

3.1 Definitions relating to electrical contacts are in accor-

approved in 1992. Last previous edition approved in 2003 as B 827 - 97 (2003).

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

dance with Terminology B 542.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

3

the ASTM website. Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B827–05

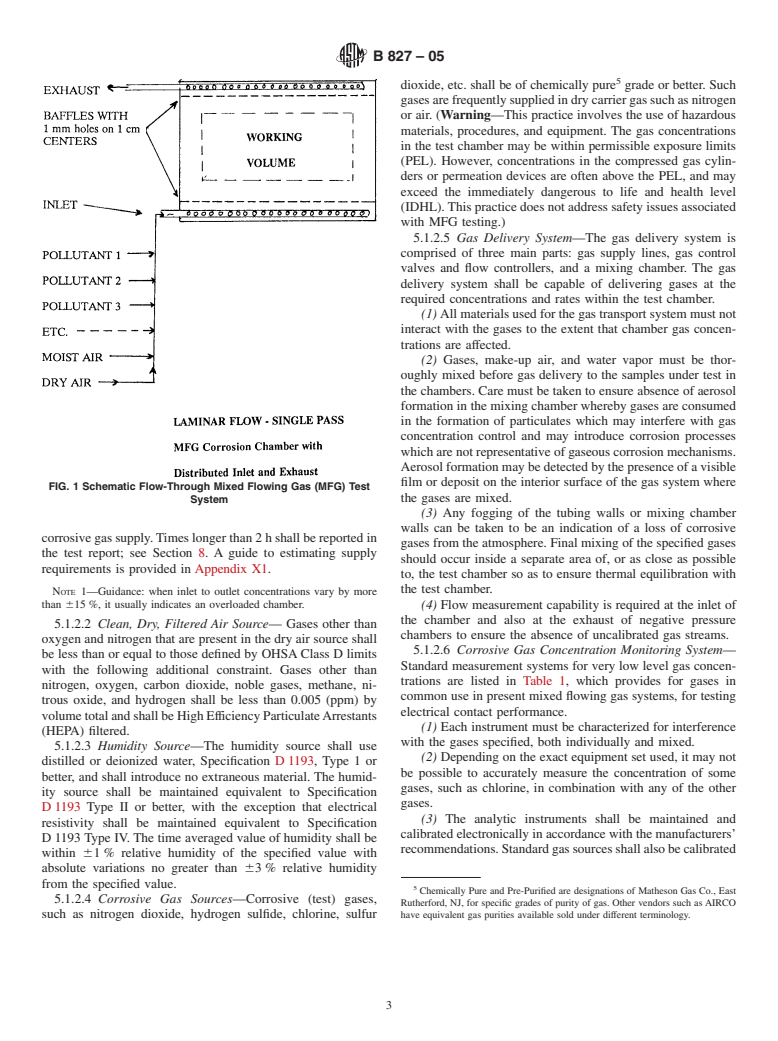

4. Significance and Use 5.1.1.1 The chamber shall consist of an enclosure made of

nonreactive, low-absorbing, nonmetallic materials contained

4.1 Mixed flowing gas (MFG) tests are used to simulate or

within a cabinet or oven capable of maintaining the tempera-

amplify exposure to environmental conditions which electrical

ture to a maximum tolerance of 61°C with a preferred

contactsorconnectorscanbeexpectedtoexperienceinvarious

4 tolerance held to 60.5°C within the usable chamber working

application environments (1, 2).

space accordance with 7.3, with a means to introduce and

4.2 Test samples which have been exposed to MFG tests

exhaust gases from the chamber.

have ranged from bare metal surfaces, to electrical connectors,

5.1.1.2 The chamber isolates the reactive gases

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.