ASTM D6666-04(2009)

(Guide)Standard Guide for Evaluation of Aqueous Polymer Quenchants

Standard Guide for Evaluation of Aqueous Polymer Quenchants

SIGNIFICANCE AND USE

The significance and use of each test method will depend on the system in use and the purpose of the test method listed under Section 7. Use the most recent editions of the test methods.

SCOPE

1.1 This guide provides information, without specific limits, for selecting standard test methods for testing aqueous polymer quenchants for initial qualification, determining quality, and the effect of aging.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6666 − 04(Reapproved 2009)

Standard Guide for

Evaluation of Aqueous Polymer Quenchants

This standard is issued under the fixed designation D6666; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3867 Test Methods for Nitrite-Nitrate in Water

D4327 Test Method for Anions in Water by Suppressed Ion

1.1 This guide provides information, without specific limits,

Chromatography

forselectingstandardtestmethodsfortestingaqueouspolymer

D5296 Test Method for Molecular Weight Averages and

quenchants for initial qualification, determining quality, and

Molecular Weight Distribution of Polystyrene by High

the effect of aging.

Performance Size-Exclusion Chromatography

1.2 This standard does not purport to address all of the

D6482 Test Method for Determination of Cooling Charac-

safety concerns, if any, associated with its use. It is the

teristics of Aqueous Polymer Quenchants by Cooling

responsibility of the user of this standard to establish appro-

Curve Analysis with Agitation (Tensi Method)

priate safety and health practices and determine the applica-

D6549 Test Method for Determination of Cooling Charac-

bility of regulatory requirements prior to use.

teristics of Quenchants by Cooling Curve Analysis with

Agitation (Drayton Unit)

2. Referenced Documents

E70 Test Method for pH of Aqueous Solutions With the

2.1 ASTM Standards:

Glass Electrode

D95 Test Method for Water in Petroleum Products and

E979 Practice for Evaluation of Antimicrobial Agents as

Bituminous Materials by Distillation

Preservatives for Invert Emulsion and Other Water Con-

D445 Test Method for Kinematic Viscosity of Transparent

taining Hydraulic Fluids

and Opaque Liquids (and Calculation of Dynamic Viscos-

E2275 Practice for Evaluating Water-Miscible Metalwork-

ity)

ing Fluid Bioresistance and Antimicrobial Pesticide Per-

D892 Test Method for Foaming Characteristics of Lubricat-

formance

ing Oils

D1744 Test Method for Determination of Water in Liquid

3. Terminology

Petroleum Products by Karl Fischer Reagent (Withdrawn

3.1 Definitions of Terms Specific to This Standard:

2000)

3.1.1 austenite, n—solidsolutionofoneormoreelementsin

D1747 Test Method for Refractive Index of Viscous Mate-

face-centered cubic iron (gamma iron) and unless otherwise

rials

designated, the solute is generally assumed to be carbon (1).

D1796 Test Method for Water and Sediment in Fuel Oils by

the Centrifuge Method (Laboratory Procedure)

3.1.2 austenitizing, n—forming austenite by heating a fer-

D2624 Test Methods for Electrical Conductivity ofAviation

rous alloy into the transformation range (partial austenitizing)

and Distillate Fuels

or above the transformation range (complete austenitizing).

D3519 Test Method for Foam in Aqueous Media (Blender

When used without qualification, the term implies complete

Test)

austenitizing (1).

D3601 Test Method for Foam In Aqueous Media (Bottle

3.1.3 aqueous polymer quenchant, n—a solution containing

Test)

water, and one or more water-soluble polymers including

poly(alkylene glycol), poly(vinyl pyrrolidone), poly(sodium

This guide is under the jurisdiction of ASTM Committee D02 on Petroleum

acrylate), and poly(ethyl oxazoline) (2, 3) and additives for

ProductsandLubricantsandisthedirectresponsibilityofSubcommitteeD02.L0.06

corrosion and foam control, if needed.

on Non-Lubricating Process Fluids.

Current edition approved April 15, 2009. Published July 2009. Originally

3.1.4 biodegradation, n—theprocessbywhichasubstrateis

approved in 2001. Last previous edition approved in 2004 as D6666 – 04. DOI:

converted by biological, usually microbiological, agents into

10.1520/D6666-04R09.

simple, environmentally acceptable derivatives. (4)

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

The last approved version of this historical standard is referenced on The boldface numbers in parentheses refer to the list of references at the end of

www.astm.org. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6666 − 04 (2009)

FIG. 1 Cooling Mechanisms of the Quenching Process

3.1.5 biodeterioration, n—loss of product quality and per- 3.1.13 quenchant medium, n—any liquid or gas, or mixture,

formance and could be regarded as the initial stages of usedtocontrolthecoolingofametaltofacilitatetheformation

biodegradation(see3.1.4),butinthewrongplaceatthewrong of the desired microstructure and properties. (1)

time, that is when the product is stored or in use. (4)

3.1.14 quench severity, n—the ability of a quenchant me-

3.1.6 convective cooling, n—after continued cooling, and

dium to extract heat from hot metal. (6)

the interfacial temperature between the cooling metal and the

3.1.15 transformation temperatures, n—characteristic tem-

aqueous polymer quenchant is less than the boiling point of the

peratures that are important in the formation of martensitic

water in the quenchant solution at which point cooling occurs

microstructure of steel including: A —equilibrium austeniti-

e1

by a convective cooling process. For convective cooling, fluid

zation phase change temperature; M —temperature at which

S

motion is due to density differences and the action of gravity

transformation of austenite to martensite starts during cooling

and includes both natural motion and forced circulation (1, 5).

and M—temperature at which transformation of austenite to

f

This process is illustrated in Fig. 1.

martensite is completed during cooling. (1)

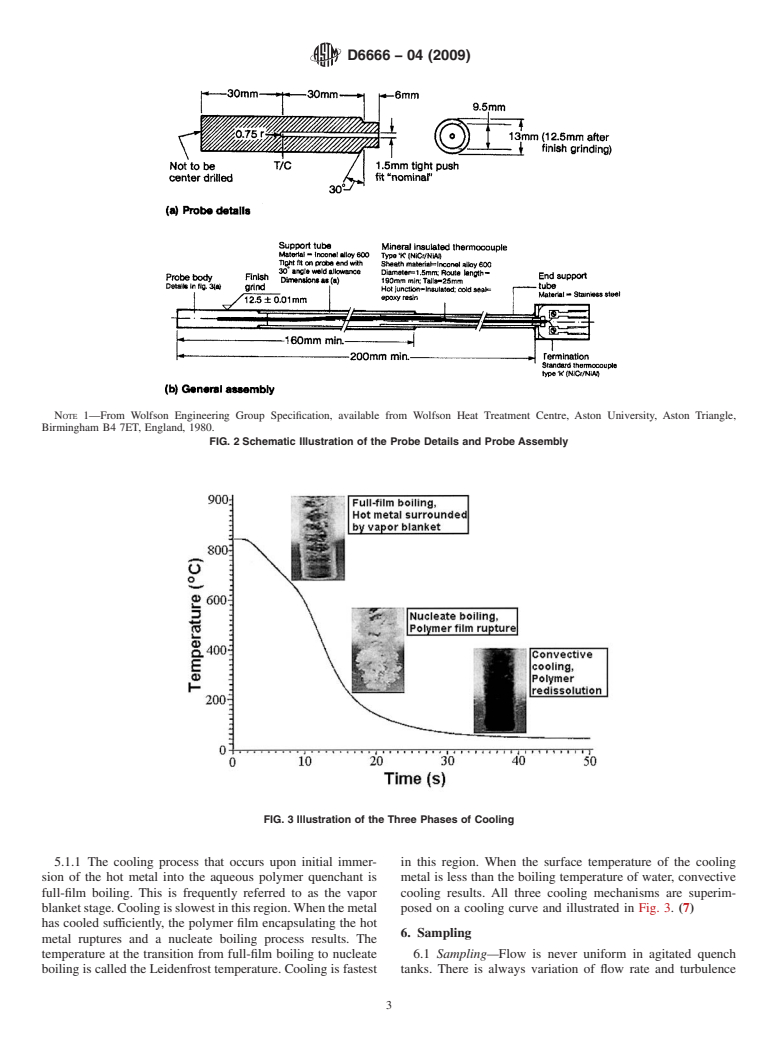

3.1.7 cooling curve, n—a graphical representation of the

coolingtime(t)—temperature(T)responseoftheprobesuchas

4. Significance and Use

that shown in Fig. 1. (5)

4.1 The significance and use of each test method will

3.1.8 cooling curve analysis, n—the process of quantifying

depend on the system in use and the purpose of the test method

thecoolingcharacteristicsofaquenchantmediumbasedonthe

listed under Section 7. Use the most recent editions of the test

temperature versus time profile obtained by cooling a pre-

methods.

heated metal probe assembly (see Fig. 2) under specified

conditions which include: probe alloy and dimensions, probe

5. Quenching Process

and bath temperature, agitation rate, and aqueous polymer

quenchant concentration.

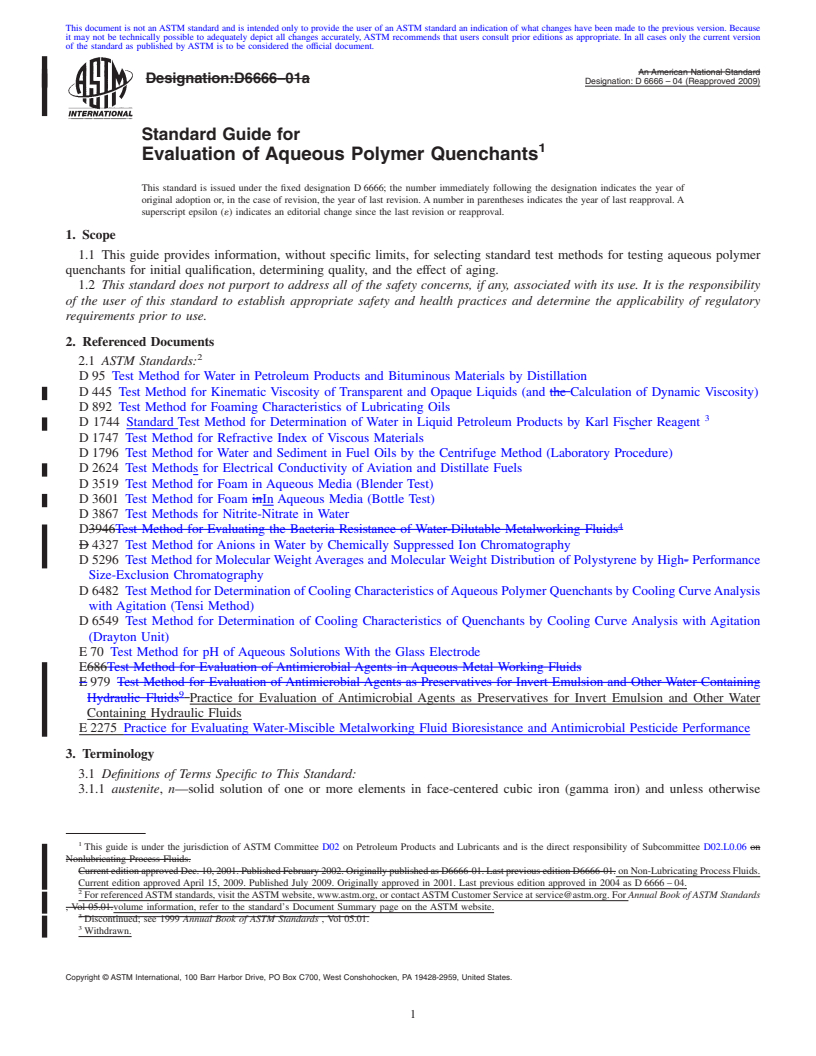

5.1 Aqueous Polymer Quenchant Cooling Mechanisms

—Upon initial immersion of a heated metal into a solution of

3.1.9 cooling rate curve, n—obtained by calculating the first

an aqueous polymer quenchant, an insulating polymer film,

derivative (dT/dt) of the cooling time-temperature curve as

which controls the heat transfer rate from the hot metal into the

illustrated in Fig. 1. (5)

cooler quenchant solution, forms around the hot metal which is

3.1.10 dragout, n—solution carried out of a bath on the

separatedbyavaporfilm(Fig.3) (7)forthequenchingprocess

metal being quenched and associated handling equipment. (1)

in a poly(alkylene glycol) quenchant. The overall heat transfer

3.1.11 full-film boiling, n—upon initial immersion of hot

mediating properties of the film are dependent on both the film

steel into a quenchant solution, a vapor blanket surrounds the

thickness (a function of polymer concentration) and interfacial

metal surface resulting in full-film boiling as shown in Fig. 1.

film viscosity (a function of polymer type and bath tempera-

(5)

ture).Thetimingoffilmformationandsubsequentfilmrupture

3.1.12 nucleate boiling, n—when the vapor blanket sur- and removal is dependent on the film strength of the polymer,

rounding the hot metal collapses and a nucleate boiling process agitation (both direction and mass flow), and turbulence of the

occurs as illustrated in Fig. 1. (5) polymer solution surrounding the cooling metal.

D6666 − 04 (2009)

NOTE 1—From Wolfson Engineering Group Specification, available from Wolfson Heat Treatment Centre, Aston University, Aston Triangle,

Birmingham B4 7ET, England, 1980.

FIG. 2 Schematic Illustration of the Probe Details and Probe Assembly

FIG. 3 Illustration of the Three Phases of Cooling

5.1.1 The cooling process that occurs upon initial immer- in this region. When the surface temperature of the cooling

sion of the hot metal into the aqueous polymer quenchant is metal is less than the boiling temperature of water, convective

full-film boiling. This is frequently referred to as the vapor cooling results. All three cooling mechanisms are superim-

blanketstage.Coolingisslowestinthisregion.Whenthemetal posed on a cooling curve and illustrated in Fig. 3. (7)

has cooled sufficiently, the polymer film encapsulating the hot

6. Sampling

metal ruptures and a nucleate boiling process results. The

temperature at the transition from full-film boiling to nucleate 6.1 Sampling—Flow is never uniform in agitated quench

boiling is called the Leidenfrost temperature. Cooling is fastest tanks. There is always variation of flow rate and turbulence

D6666 − 04 (2009)

(A) New aqueous polymer quenchant solution.

(B) Used quenchant solution with oil contamination (see separated upper layer).

FIG. 4 Sample of Oil Contaminated Aqueous Polymer Quenchant

from top to bottom and across the tank. This means there may polymer quenchant in a clear glass container, such as a bottle.

be significant variations of particulate contamination including A sample of an oil-contaminated fluid is illustrated in Fig. 4.

carbon from the heat treating process and metal scale. For (7) However, if the oil readily separates from the aqueous

uniform sampling, a number of sampling recommendations polymer quenchant solution (Fig. 4), it may be removed by

have been developed. skimming. On the other hand, oil may form a milky-white

6.1.1 Sampling Recommendations: emulsion which is not readily reclaimed by heat treaters.

6.1.1.1 Minimum Sampling Time—The circulation pumps

7.1.1.1 Other problems that are easy to identify visually

shall be in operation for at least 1 h prior to taking a sample includecarbonandsludgecontaminationwhichoftenresultsin

from the quench system.

cracking problems. Metal scale contamination is often identi-

6.1.1.2 Sampling Position—For each system, the well- fiable by its magnetic properties by placing a magnet on the

mixed sample shall be taken from the same position each time

outside of the bottle next to the scale and determining if the

that system is sampled. The position in the tank where the scale exhibits any attraction for the magnet. Carbon, sludge,

sample is taken shall be recorded.

and scale may be removed from the quenchant by filtration or

6.1.1.3 Sampling Values—If a sample is taken from a centrifugation. Alternatively, the quenchant mixture may be

sampling valve, then sufficient quenchant should be taken and

allowed to settle, the quenchant solution pumped off, and the

discarded to ensure that the sampling valve and associated separated solids then removed by shoveling. The amount of

piping has been flushed before the sample is taken.

insoluble suspended solids or tramp oils may be quantified by

6.1.1.4 Effect of Quenchant Addition as Make-Up due to

a modification of Test Method D1796 where the aqueous

Dragout—It is important to determine the quantity and fre- quenchant is centrifuged without further dilution as described

quency of new quenchant additions, as large additions of new

in the method. The amount of tramp oil in the quenchant is

quenchant solution will have an effect on the test results, in determined from the insoluble liquid layer at the top of the

particular, the cooling curve. If a sample was taken just after a

centrifuge tube and the volume of the insoluble sediment is

large addition of new quenchant, this shall be taken into taken from the bottom of the centrifuge tube.

consideration when interpreting the cooling curve for this

7.1.2 Refractive Index, (Test Method D1747)—One of the

sample.

most common methods of monitoring the concentration of

6.1.1.5 Sampling Containers—Samples shall be collected in

aqueous polymer quenchants formulated using poly(alkylene

newcontainers.Undernocircumstancesshallusedbeverageor

glycol) coploymers is refractive index. As Fig. 5 (7) shows,

food containers be used because of the potential for fluid

there is a linear relationship between quenchant concentration

contamination and leakage.

and refractive index. The refractive index of the quenchant

solution is determined using an Abbé refractometer (Test

7. Recommended Test Procedures

Method D1747) equipped with a constant temperature bath.

Although the refractive index could potentially be used at any

7.1 Performance-Related Physical and Chemical Proper-

ties: temperature within the control limits of the constant tempera-

ture bath, typically either 40ºC or 100ºF is selected.

7.1.1 Appearance—Contamination of aqueous polymer

quenchants by such fluids as hydraulic or quench oils may 7.1.2.1 Although refractive index is a relatively simple and

result in a non-uniform quench with thermal gradients suffi- a rapid method for determination of polymer quenchant con-

cient to cause cracking or increased distortion, or possible centration, it is not sensitive to low levels of polymer degra-

staining,ofthemetalbeingquenched.Thesimplesttest(andan dation and it is often significantly affected by solution con-

excellent test) is to examine the appearance of an aqueous tamination.

D6666 − 04 (2009)

FIG. 5 Illustration of the Linear Relationship Between Refractive Index and Concentration

NOTE 1—Refractive index is typically unsuitable for aqueous polymer

If the absolute value of the difference in delta is greater than

quenchantsformulatedwithpolymerswithmolecularweightsgreaterthan

6-8, the source of this difference, contamination or degrada-

50 000 to 60 000 because the total concentration is relatively low. Small

tion, should be determined.

changes in polymer concentration may result even from normal use which

impart significant process effects but the corresponding variation in 7.1.5 Water Content (Test Methods D95 and D1744)—

refractive index may not be detectable.

Aqueous polymer quenchants are composed of water, a water

NOTE 2—Although it is most desirable to use an Abbé refractometer

soluble polymer and an additive package to provide corrosion

becauseofitssensitivity,thisisonlypracticalinalaboratoryenvironment

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D6666–01a Designation: D 6666 – 04 (Reapproved 2009)

Standard Guide for

Evaluation of Aqueous Polymer Quenchants

This standard is issued under the fixed designation D 6666; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide provides information, without specific limits, for selecting standard test methods for testing aqueous polymer

quenchants for initial qualification, determining quality, and the effect of aging.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

requirements prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D95 Test Method for Water in Petroleum Products and Bituminous Materials by Distillation

D 445 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and the Calculation of Dynamic Viscosity)

D 892 Test Method for Foaming Characteristics of Lubricating Oils

D 1744 Standard Test Method for Determination of Water in Liquid Petroleum Products by Karl Fischer Reagent

D 1747 Test Method for Refractive Index of Viscous Materials

D 1796 Test Method for Water and Sediment in Fuel Oils by the Centrifuge Method (Laboratory Procedure)

D 2624 Test Methods for Electrical Conductivity of Aviation and Distillate Fuels

D 3519 Test Method for Foam in Aqueous Media (Blender Test)

D 3601 Test Method for Foam inIn Aqueous Media (Bottle Test)

D 3867 Test Methods for Nitrite-Nitrate in Water

D3946Test Method for Evaluating the Bacteria Resistance of Water-Dilutable Metalworking Fluids

D 4327 Test Method for Anions in Water by Chemically Suppressed Ion Chromatography

D 5296 Test Method for Molecular WeightAverages and Molecular Weight Distribution of Polystyrene by High- Performance

Size-Exclusion Chromatography

D 6482 Test Method for Determination of Cooling Characteristics ofAqueous Polymer Quenchants by Cooling CurveAnalysis

with Agitation (Tensi Method)

D 6549 Test Method for Determination of Cooling Characteristics of Quenchants by Cooling Curve Analysis with Agitation

(Drayton Unit)

E70 Test Method for pH of Aqueous Solutions With the Glass Electrode

E686Test Method for Evaluation of Antimicrobial Agents in Aqueous Metal Working Fluids

E 979 Test Method for Evaluation of Antimicrobial Agents as Preservatives for Invert Emulsion and Other Water Containing

Hydraulic Fluids Practice for Evaluation of Antimicrobial Agents as Preservatives for Invert Emulsion and Other Water

Containing Hydraulic Fluids

E 2275 Practice for Evaluating Water-Miscible Metalworking Fluid Bioresistance and Antimicrobial Pesticide Performance

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 austenite, n—solid solution of one or more elements in face-centered cubic iron (gamma iron) and unless otherwise

This guide is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.L0.06 on

Nonlubricating Process Fluids.

CurrenteditionapprovedDec.10,2001.PublishedFebruary2002.OriginallypublishedasD6666-01.LastpreviouseditionD6666-01. onNon-LubricatingProcessFluids.

Current edition approved April 15, 2009. Published July 2009. Originally approved in 2001. Last previous edition approved in 2004 as D 6666 – 04.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 05.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Discontinued; see 1999 Annual Book of ASTM Standards , Vol 05.01.

Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6666–04 (2009)

designated, the solute is generally assumed to be carbon (1).

3.1.2 austenitizing, n—formingaustenitebyheatingaferrousalloyintothetransformationrange(partialaustenitizing)orabove

the transformation range (complete austenitizing). When used without qualification, the term implies complete austenitizing (1).

3.1.3 aqueous polymer quenchant, n—a solution containing water, and one or more water-soluble polymers including

poly(alkylene glycol), poly(vinyl pyrrolidone), poly(sodium acrylate), and poly(ethyl oxazoline) (2, 3) and additives for corrosion

and foam control, if needed.

3.1.4 biodegradation, n—the process by which a substrate is converted by biological, usually microbiological, agents into

simple, environmentally acceptable derivatives. (4)

3.1.5 biodeterioration, n—loss of product quality and performance and could be regarded as the initial stages of biodegradation

(see 3.1.4) , but in the wrong place at the wrong time, that is when the product is stored or in use. (4)

3.1.6 convective cooling, n—aftercontinuedcooling,andtheinterfacialtemperaturebetweenthecoolingmetalandtheaqueous

polymer quenchant is less than the boiling point of the water in the quenchant solution at which point cooling occurs by a

convectivecoolingprocess.Forconvectivecooling,fluidmotionisduetodensitydifferencesandtheactionofgravityandincludes

both natural motion and forced circulation (1, 5). This process is illustrated in Fig. 1.

3.1.7 cooling curve, n—a graphical representation of the cooling time (t)—temperature (T) response of the probe such as that

shown in Fig. 1. (5)

3.1.8 cooling curve analysis, n—the process of quantifying the cooling characteristics of a quenchant medium based on the

temperatureversustimeprofileobtainedbycoolingapreheatedmetalprobeassembly(seeFig.2)underspecifiedconditionswhich

include: probe alloy and dimensions, probe and bath temperature, agitation rate, and aqueous polymer quenchant concentration.

3.1.9 cooling rate curve, n—obtained by calculating the first derivative (dT/ dt) of the cooling time-temperature curve as

illustrated in Fig. 1. (5)

3.1.10 dragout, n—solution carried out of a bath on the metal being quenched and associated handling equipment. (1)

3.1.11 full-film boiling, n—upon initial immersion of hot steel into a quenchant solution, a vapor blanket surrounds the metal

surface resulting in full-film boiling as shown in Fig. 1. (5)

3.1.12 nucleate boiling, n—when the vapor blanket surrounding the hot metal collapses and a nucleate boiling process occurs

as illustrated in Fig. 1. (5)

3.1.13 quenchant medium, n—any liquid or gas, or mixture, used to control the cooling of a metal to facilitate the formation

of the desired microstructure and properties. (1)

3.1.14 quench severity, n—the ability of a quenchant medium to extract heat from hot metal. (6)

3.1.15 transformation temperatures, n—characteristic temperatures that are important in the formation of martensitic

microstructure of steel including: A —equilibrium austenitization phase change temperature; M —temperature at which

e1 S

transformation of austenite to martensite starts during cooling and M—temperature at which transformation of austenite to

f

martensite is completed during cooling. (1)

Annual Book of ASTM Standards, Vol 05.02.

The boldface numbers in parentheses refer to the list of references at the end of this standard.

FIG. 1 Cooling Mechanisms of the Quenching Process

D6666–04 (2009)

NOTE 1—From Wolfson Engineering Group Specification, available from Wolfson Heat Treatment Centre, Aston University, Aston Triangle,

Birmingham B4 7ET, England, 1980.

FIG. 2 Schematic Illustration of the Probe Details and Probe Assembly

4. Significance and Use

4.1 Thesignificanceanduseofeachtestmethodwilldependonthesysteminuseandthepurposeofthetestmethodlistedunder

Section 7. Use the most recent editions of the test methods.

5. Quenching Process

5.1 Aqueous Polymer Quenchant Cooling Mechanisms—Uponinitialimmersionofaheatedmetalintoasolutionofanaqueous

polymer quenchant, an insulating polymer film, which controls the heat transfer rate from the hot metal into the cooler quenchant

solution, forms around the hot metal which is separated by a vapor film (Fig. 3) (7) for the quenching process in a poly(alkylene

glycol) quenchant. The overall heat transfer mediating properties of the film are dependent on both the film thickness (a function

of polymer concentration) and interfacial film viscosity (a function of polymer type and bath temperature). The timing of film

formation and subsequent film rupture and removal is dependent on the film strength of the polymer, agitation (both direction and

mass flow), and turbulence of the polymer solution surrounding the cooling metal.

5.1.1 The cooling process that occurs upon initial immersion of the hot metal into the aqueous polymer quenchant is full-film

boiling. This is frequently referred to as the vapor blanket stage. Cooling is slowest in this region. When the metal has cooled

sufficiently, the polymer film encapsulating the hot metal ruptures and a nucleate boiling process results. The temperature at the

transition from full-film boiling to nucleate boiling is called the Leidenfrost temperature. Cooling is fastest in this region. When

the surface temperature of the cooling metal is less than the boiling temperature of water, convective cooling results. All three

cooling mechanisms are superimposed on a cooling curve and illustrated in Fig. 3. (7)

6. Sampling

6.1 Sampling—Flow is never uniform in agitated quench tanks. There is always variation of flow rate and turbulence from top

to bottom and across the tank. This means there may be significant variations of particulate contamination including carbon from

the heat treating process and metal scale. For uniform sampling, a number of sampling recommendations have been developed.

6.1.1 Sampling Recommendations:

6.1.1.1 Minimum Sampling Time—The circulation pumps shall be in operation for at least 1 h prior to taking a sample from the

quench system.

6.1.1.2 Sampling Position—For each system, the well-mixed sample shall be taken from the same position each time that

system is sampled. The position in the tank where the sample is taken shall be recorded.

6.1.1.3 Sampling Values—If a sample is taken from a sampling valve, then sufficient quenchant should be taken and discarded

to ensure that the sampling valve and associated piping has been flushed before the sample is taken.

6.1.1.4 Effect of Quenchant Addition as Make-Up due to Dragout—It is important to determine the quantity and frequency of

new quenchant additions, as large additions of new quenchant solution will have an effect on the test results, in particular, the

D6666–04 (2009)

FIG. 3 Illustration of the Three Phases of Cooling

cooling curve. If a sample was taken just after a large addition of new quenchant, this shall be taken into consideration when

interpreting the cooling curve for this sample.

6.1.1.5 Sampling Containers—Samples shall be collected in new containers. Under no circumstances shall used beverage or

food containers be used because of the potential for fluid contamination and leakage.

7. Recommended Test Procedures

7.1 Performance-Related Physical and Chemical Properties:

7.1.1 Appearance—Contamination of aqueous polymer quenchants by such fluids as hydraulic or quench oils may result in a

non-uniform quench with thermal gradients sufficient to cause cracking or increased distortion, or possible staining, of the metal

being quenched.The simplest test (and an excellent test) is to examine the appearance of an aqueous polymer quenchant in a clear

glass container, such as a bottle. A sample of an oil-contaminated fluid is illustrated in Fig. 4. (7) However, if the oil readily

separates from the aqueous polymer quenchant solution (Fig. 4), it may be removed by skimming. On the other hand, oil may form

a milky-white emulsion which is not readily reclaimed by heat treaters.

7.1.1.1 Other problems that are easy to identify visually include carbon and sludge contamination which often results in

cracking problems. Metal scale contamination is often identifiable by its magnetic properties by placing a magnet on the outside

(A) New aqueous polymer quenchant solution.

(B) Usedquenchantsolutionwithoilcontamination(seeseparatedupperlayer).

FIG. 4 Sample of Oil Contaminated Aqueous Polymer Quenchant

D6666–04 (2009)

of the bottle next to the scale and determining if the scale exhibits any attraction for the magnet. Carbon, sludge, and scale may

be removed from the quenchant by filtration or centrifugation. Alternatively, the quenchant mixture may be allowed to settle, the

quenchant solution pumped off, and the separated solids then removed by shoveling. The amount of insoluble suspended solids

or tramp oils may be quantified by a modification of Test Method D 1796 where the aqueous quenchant is centrifuged without

further dilution as described in the method.The amount of tramp oil in the quenchant is determined from the insoluble liquid layer

at the top of the centrifuge tube and the volume of the insoluble sediment is taken from the bottom of the centrifuge tube.

7.1.2 Refractive Index, (Test Method D 1747)—One of the most common methods of monitoring the concentration of aqueous

polymer quenchants formulated using poly(alkylene glycol) coploymers is refractive index. As Fig. 5 (7) shows, there is a linear

relationship between quenchant concentration and refractive index. The refractive index of the quenchant solution is determined

usinganAbbérefractometer(TestMethodD 1747)equippedwithaconstanttemperaturebath.Althoughtherefractiveindexcould

potentially be used at any temperature within the control limits of the constant temperature bath, typically either 40ºC or 100ºF

is selected.

7.1.2.1 Although refractive index is a relatively simple and a rapid method for determination of polymer quenchant

concentration, it is not sensitive to low levels of polymer degradation and it is often significantly affected by solution

contamination.

NOTE 1—Refractive index is typically unsuitable for aqueous polymer quenchants formulated with polymers with molecular weights greater than 50

000 to 60 0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.