ASTM G116-99

(Practice)Standard Practice for Conducting Wire-on-Bolt Test for Atmospheric Galvanic Corrosion

Standard Practice for Conducting Wire-on-Bolt Test for Atmospheric Galvanic Corrosion

SCOPE

1.1 This practice covers the evaluation of atmospheric galvanic corrosion of any anodic material that can be made into a wire when in contact with a cathodic material that can be made into a threaded rod.

1.2 When certain materials are used for the anode and cathode, this practice has been used to rate the corrosivity of atmospheres.

1.3 The wire-on-bolt test was first described in 1955 (1), and has since been used extensively under the name CLIMAT Test (CLassify Industrial and Marine ATmospheres) to determine corrosivity of atmospheres (2-4).

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G 116 – 99

Standard Practice for

Conducting Wire-on-Bolt Test for Atmospheric Galvanic

Corrosion

This standard is issued under the fixed designation G 116; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Surfaces Exposed to Wetting Conditions as in Atmospheric

Corrosion Testing

1.1 This practice covers the evaluation of atmospheric

G 91 Practice for Monitoring Atmospheric SO Using the

galvanic corrosion of any anodic material that can be made into

Sulfation Plate Technique

a wire when in contact with a cathodic material that can be

G 92 Practice for Characterization of Atmospheric Test

made into a threaded rod.

Sites

1.2 When certain materials are used for the anode and

G 104 Test Method for Assessing Galvanic Corrosion

cathode, this practice has been used to rate the corrosivity of

Caused by the Atmosphere

atmospheres.

1.3 The wire-on-bolt test was first described in 1955 (1),

3. Terminology

and has since been used extensively with standard materials to

3.1 For definitions of terms used in this practice, refer to

determine corrosivity of atmospheres under the names CLI-

Terminology G 15. For conventions related to this method,

MAT Test (CLassify Industrial and Marine ATmospheres) (2-5)

refer to Practice G 3.

and ATCORR (ATmospheric CORRosivity) (6-9).

1.4 This standard does not purport to address all of the

4. Summary of Practice

safety concerns, if any, associated with its use. It is the

4.1 The practice consists of wrapping a wire of the anode

responsibility of the user of this standard to establish appro-

material around the threads of a bolt or threaded rod of the

priate safety and health practices and determine the applica-

cathode material, exposing the assembly to atmosphere, and

bility of regulatory limitations prior to use.

determining mass loss of the anode wire after exposure.

Reference specimens of the anode wire on a threaded, non-

2. Referenced Documents

conductive, non-porous rod are used to separate general and

2.1 ASTM Standards:

crevice corrosion effects from galvanic corrosion effects.

G 1 Practice for Preparing, Cleaning, and Evaluating Cor-

rosion Test Specimens

5. Significance and Use

G 3 Practice for Conventions Applicable to Electrochemical

3 5.1 The small size of the wire compared to the short

Measurements in Corrosion Testing

galvanic interaction distance in atmospheric exposures gives a

G 15 Terminology Relating to Corrosion and Corrosion

3 large cathode-to-anode area ratio which accelerates the gal-

Testing

vanic attack. The area between the wire and the threads creates

G 16 Guide for Applying Statistics to Analysis of Corrosion

3 a long, tight crevice, also accelerating the corrosion. For these

Data

reasons, this practice, with a typical exposure period of 90

G 50 Practice for Conducting Atmospheric Corrosion Tests

3 days, is the most rapid atmospheric galvanic corrosion test,

on Metals

particularly compared to Test Method G 104. The short dura-

G 82 Guide for Development and Use of a Galvanic Series

3 tion of this test means that seasonal atmospheric variability can

for Predicting Galvanic Corrosion Performance

be evaluated. (If average performance over a 1-year period is

G 84 Practice for Measurement of Time-of-Wetness on

desired, several staggered exposures are required with this

technique.) Reproducibility of this practice is somewhat better

than other atmospheric galvanic corrosion tests.

This practice is under the jurisdiction of ASTM Committee G-1 on Corrosion

of Metals and is the direct responsibility of Subcommittee G01.04 on Atmospheric 5.2 The major disadvantage of this test is that the anode

Corrosion.

material must be available in wire form and the cathodic

Current edition approved April 10, 1999. Published June 1999. Originally

published as G 116 – 93. Last previous edition G 116 – 93.

The boldface numbers in parentheses refer to the list of references at the end of

this standard.

3 4

Annual Book of ASTM Standards, Vol 03.02. Nylon 66 has been found suitable for this purpose.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G116

material must be available in the form of a threaded rod. This

should be compared to Test Method G 104 where plate or sheet

material is used exclusively.

5.3 An additional limitation is that the more anodic material

of the pair must be known beforehand (from information such

as in Guide G 82) or assemblies must be made with the

material combinations reversed.

5.4 The morphology of the corrosion attack or its effect on

mechanical properties of the base materials cannot be assessed

by this practice. Test Method G 104 is preferable for this

purpose.

5.5 This test has been used under the names CLIMAT and

ATCORR to determine atmospheric corrosivity by exposing

identical specimens made from 1100 aluminum (UNS A91100)

wire wrapped around threaded rods of nylon, 1010 mild steel

(UNS G10100 or G10080), and CA110 copper (UNS C11000).

Atmospheric corrosivity is a function of the material that is

corroding, however. The relative corrosivity of atmospheres

could be quite different if a different combination of materials

is chosen.

6. Interferences

6.1 The manufacturing process used to make the wire and

rod may affect their corrosion potentials and polarization

behavior. Material in these forms may not behave galvanically

the same as material in the form of interest, such as fasteners

in sheet roofing for example. Although unlikely, this may even

FIG. 1 Components for Making Wire-on-Bolt Exposure

lead to a situation where reversing the materials may also Assemblies

reverse their anode-cathode relationship, resulting in attack

during service of a material which was resistant during testing

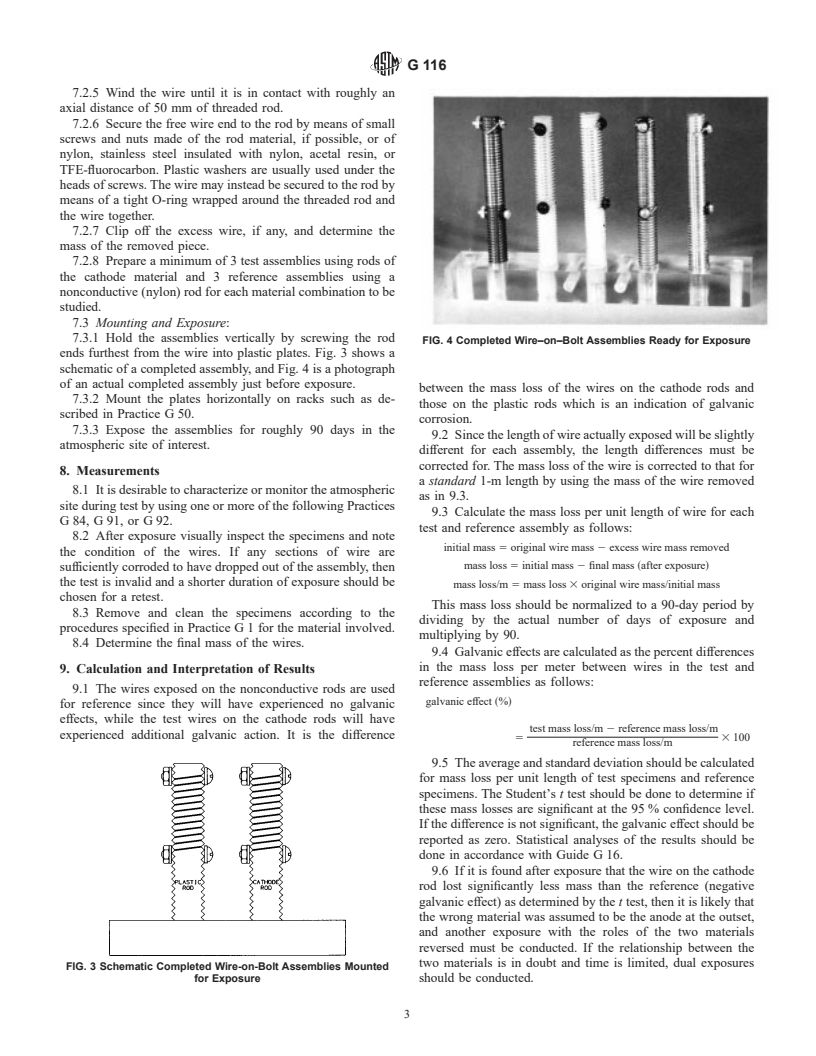

7.2.4 Wrap the wire tightly around the rod so that it lies

as a wire.

inside the threads using a jig such as that shown in Fig. 2. This

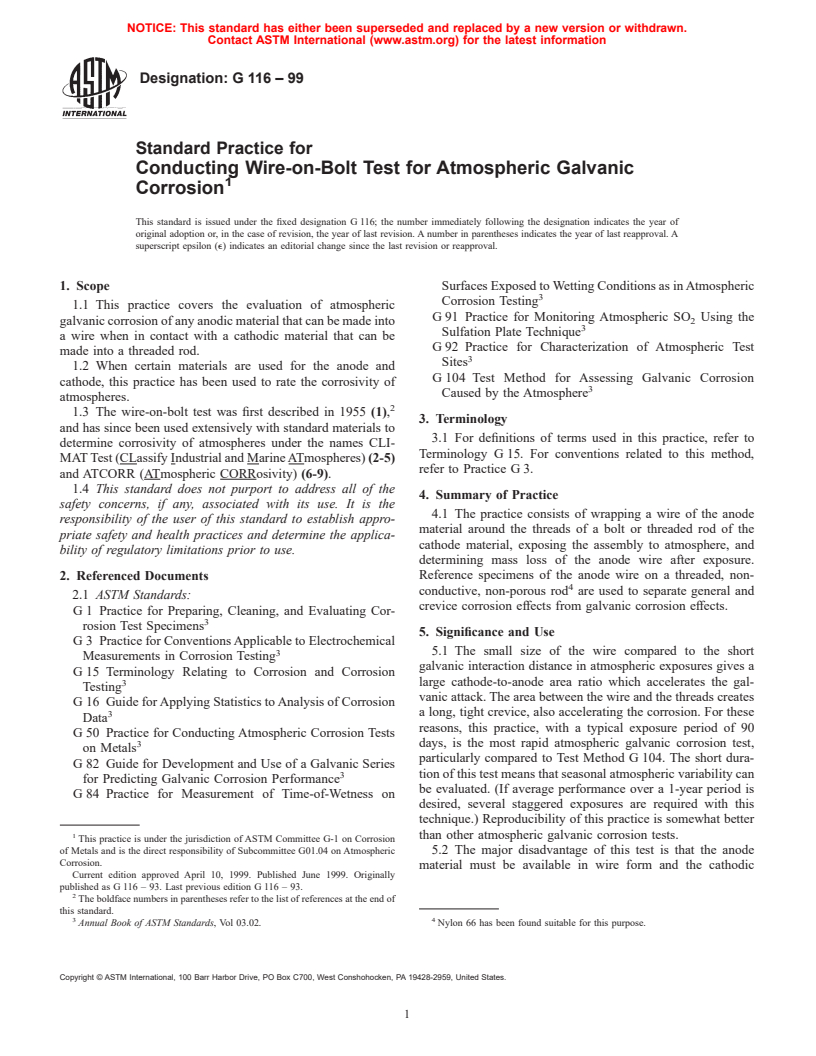

7. Procedure jig is used to keep constant tension on the wire while it is being

wound. While using this jig, wear clean cotton gloves to

7.1 Components:

prevent contamination of the surfaces of the wire or rod. If it is

7.1.1 The components used to construct the specimen as-

felt that the wire tension is not critical for the particular

semblies for this test are shown in Fig. 1.

application being tested, replace the use of the jig with

7.1.2 Prepare a 1-m length of 0.875 + 0.002-mm diameter

hand-winding.

wire of the anode material for each assembly. Other diameters

may be used, however, the diameter of the wire may affect the

test results, so that tests may only be compared if they use wire

of similar diameters. In selecting material for the wire, consider

the cold work and heat treatment of a wire may be significantly

different than for the component that the exposure is modeling.

7.1.3 Make the cathode material into M12 3 1.75 ( ⁄2 -13

-UNC threaded rods or bolts, 100-mm long. Either metric or

English threads may be used, but results may only be compared

between assemblies with similar thread types.

7.2 Making the Assemblies:

7.2.1 Thoroughly clean and degrease all parts before assem-

bly in accordance with Practice G 1.

7.2.2 Determine the mass of the wire to the nearest 0.0001

g.

7.2.3 Secure one end of the wire to a threaded rod using

small screws and nuts of the rod material, if possible, or of

nylon, stainless steel insulated with nylon, acetal resin, or

TFE-fluorocarbon. Plastic washers are usually used under the

heads of the screws. The wire may instead be secured to the rod

by means of a tight O-ring wrapped around the threaded rod

FIG. 2 Constant Tension Coil Winder for Wrapping Wire or

and the wire together. Threaded Rods

G116

7.2.5 Wind the wire until it is in contact with roughly an

axial distance of 50 mm of threaded rod.

7.2.6 Secure the free wire end to the rod by means of small

screws and nuts made of the rod material, if possible, or of

nylon, stainless steel insulated with nylon, acetal res

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.