ASTM D1512-15a

(Test Method)Standard Test Methods for Carbon Black—pH Value

Standard Test Methods for Carbon Black—pH Value

SIGNIFICANCE AND USE

3.1 The pH level of a carbon black is known to affect the vulcanization of some rubber compounds.

SCOPE

1.1 These test methods, Test Method A—Boiling Slurry and Test Method B—Sonic Slurry, are used to indicate the pH of the carbon black surface by measuring the pH of water in contact with the carbon black.

Note 1: The pH of the carbon black is often used in this industry to indicate the relative acidity or alkalinity of carbon black and will be used in the remainder of these test methods to describe this property.

Note 2: Test Method A and Test Method B do not always give the same results.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1512 − 15a

StandardTest Methods for

1

Carbon Black—pH Value

This standard is issued under the fixed designation D1512; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope TEST METHOD A—BOILING SLURRY

1.1 These test methods,Test MethodA—Boiling Slurry and

4. Apparatus

Test Method B—Sonic Slurry, are used to indicate the pH of

4.1 pH Meter, (digital is recommended) having an accuracy

the carbon black surface by measuring the pH of water in

contact with the carbon black. of 60.05 pH and equipped with a combination electrode and

RNC connector.

NOTE 1—The pH of the carbon black is often used in this industry to

3

indicate the relative acidity or alkalinity of carbon black and will be used

4.2 Container, stainless steel or copper, 125 cm or larger.

in the remainder of these test methods to describe this property.

4.3 Hot Plate.

NOTE 2—Test Method A and Test Method B do not always give the

same results.

4.4 High Speed Mill, Mixer or Mortar and Pestle.

1.2 The values stated in SI units are to be regarded as the

3

4.5 Beakers, glass, 100 cm graduated with watch glasses.

standard. The values in parentheses are for information only.

4.6 Magnetic Stir Plate.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 4.7 Magnetic Stir Bars.

responsibility of the user of this standard to establish appro-

5. Reagents

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5.1 Purity of Reagents—Reagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that

2. Referenced Documents

all reagents shall conform to the specifications of the Commit-

2

2.1 ASTM Standards:

tee onAnalytical Reagents of theAmerican Chemical Society,

D1193 Specification for Reagent Water 3

where such specifications are available. Other grades may be

D1799 Practice for Carbon Black—Sampling Packaged

used, provided it is first ascertained that the reagent is of

Shipments

sufficiently high purity to permit its use without lessening the

D1900 Practice for Carbon Black—Sampling Bulk Ship-

accuracy of the determination.

ments

5.2 Purity of Water—Unless otherwise indicated, references

D4483 Practice for Evaluating Precision for Test Method

to water shall be understood to mean reagent water as defined

Standards in the Rubber and Carbon Black Manufacturing

by Type 1 in Specification D1193.

Industries

E70 Test Method for pH of Aqueous Solutions With the

5.3 Distilled Water, high purity.

Glass Electrode

5.4 Buffer Solutions, pH of 4.00, 7.00, and 10.00.

3. Significance and Use

5.5 Acetone, reagent grade.

3.1 The pH level of a carbon black is known to affect the

6. Sampling

vulcanization of some rubber compounds.

6.1 Samples shall be taken in accordance with Practices

1

These test methods are under the jurisdiction of ASTM Committee D24 on

D1799 or D1900.

Carbon Black and are the direct responsibility of Subcommittee D24.31 on

Non-Carbon Black Components of Carbon Black.

Current edition approved Sept. 1, 2015. Published December 2015. Originally

3

approved in 1975. Last previous edition approved in 2015 as D1512 – 15. DOI: Reagent Chemicals, American Chemical Society Specifications, American

10.1520/D1512-15A. Chemical Society, Washington, DC. For suggestions on the testing of reagents not

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or listed by the American Chemical Society, see Analar Standards for Laboratory

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Standards volume information, refer to the standard’s Document Summary page on and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

the ASTM website. MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

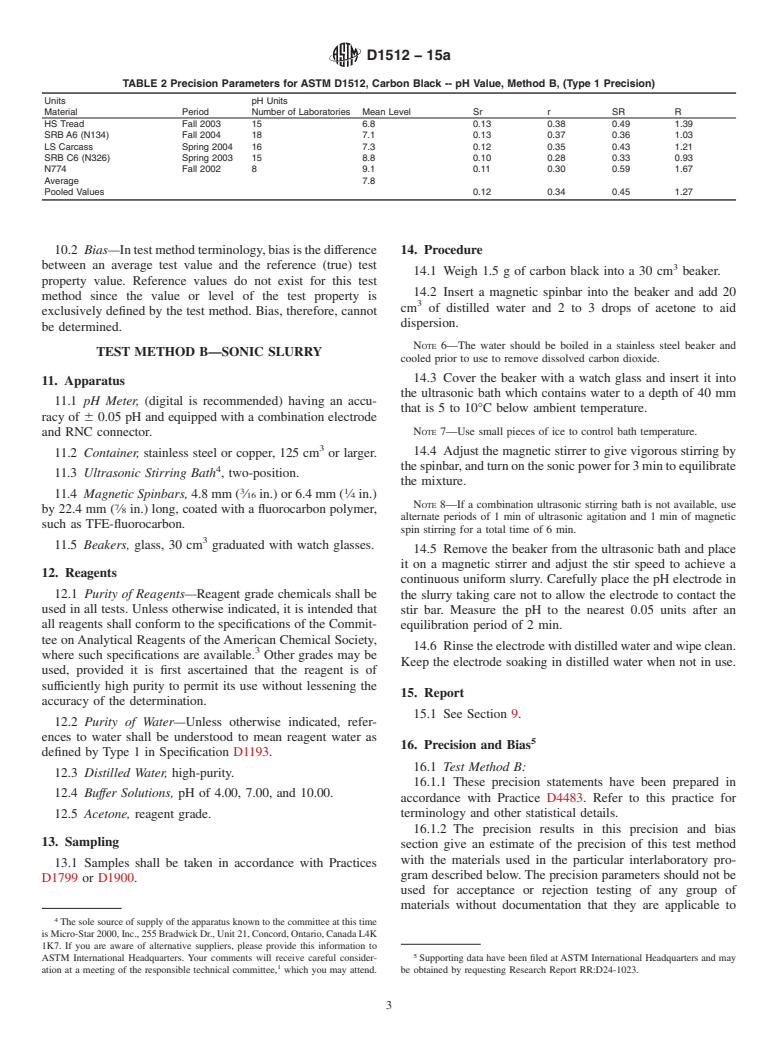

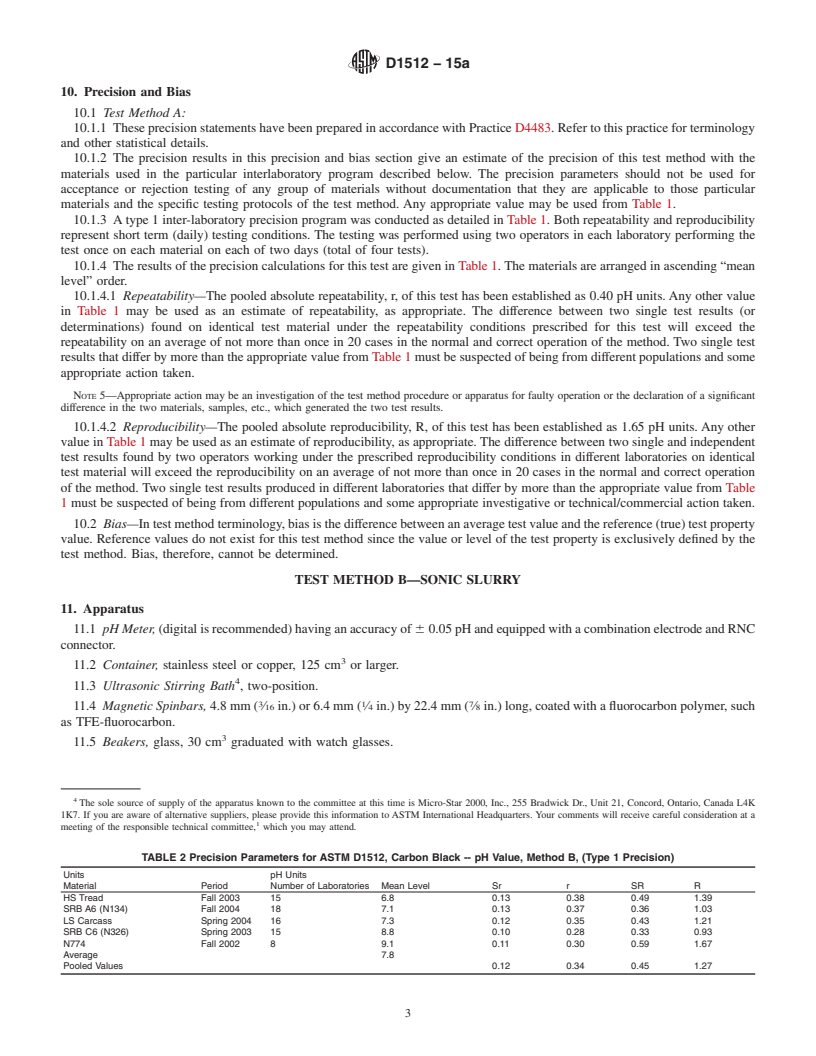

D1512 − 15a

7. Calibration 10.1.2 The precision results in this precision and bias

section give an estimate of the precision of this test method

7.1 Calibrate the pH meter using buffer solutions according

with the materials used in the particular interlaboratory pro-

to manufacturer’s instructions.

gram described below. The precision parameters should not be

used for acceptance or rejection testing of any group of

8. Procedure

materials without documentation that they are applicab

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1512 − 15 D1512 − 15a

Standard Test Methods for

1

Carbon Black—pH Value

This standard is issued under the fixed designation D1512; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 These test methods, Test Method A—Boiling Slurry and Test Method B—Sonic Slurry, are used to indicate the pH of the

carbon black surface by measuring the pH of water in contact with the carbon black.

NOTE 1—The pH of the carbon black is often used in this industry to indicate the relative acidity or alkalinity of carbon black and will be used in the

remainder of these test methods to describe this property.

NOTE 2—Test Method A and Test Method B do not always give the same results.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D1799 Practice for Carbon Black—Sampling Packaged Shipments

D1900 Practice for Carbon Black—Sampling Bulk Shipments

D4483 Practice for Evaluating Precision for Test Method Standards in the Rubber and Carbon Black Manufacturing Industries

E70 Test Method for pH of Aqueous Solutions With the Glass Electrode

3. Significance and Use

3.1 The pH level of a carbon black is known to affect the vulcanization of some rubber compounds.

TEST METHOD A—BOILING SLURRY

4. Apparatus

4.1 pH Meter, (digital is recommended) having an accuracy of 60.05 pH and equipped with a combination electrode and RNC

connector.

3

4.2 Container, stainless steel or copper, 125 cm or larger.

4.3 Hot Plate.

4.4 High Speed Mill, Mixer or Mortar and Pestle.

3

4.5 Beakers, glass, 100 cm graduated with watch glasses.

4.6 Magnetic Stir Plate.

4.7 Magnetic Stir Bars.

1

These test methods are under the jurisdiction of ASTM Committee D24 on Carbon Black and are the direct responsibility of Subcommittee D24.31 on Non-Carbon Black

Components of Carbon Black.

Current edition approved Jan. 1, 2015Sept. 1, 2015. Published February 2015December 2015. Originally approved in 1975. Last previous edition approved in 20122015

as D1512 – 05 (2012).D1512 – 15. DOI: 10.1520/D1512-15.10.1520/D1512-15A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1512 − 15a

5. Reagents

5.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where

3

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high

purity to permit its use without lessening the accuracy of the determination.

5.2 Purity of Water—Unless otherwise indicated, references to water shall be understood to mean reagent water as defined by

Type 1 in Specification D1193.

5.3 Distilled Water, high purity.

5.4 Buffer Solutions, pH of 4.00, 7.00, and 10.00.

5.5 Acetone, reagent grade.

6. Sampling

6.1 Samples shall be taken in accordance with Practices D1799 or D1900.

7. Calibration

7.1 Calibrate the pH meter using buffer solutions according to manufacturer’s instructions.

8. Procedure

8.1 Pulverize pelleted or lumpy carbon black to a fine powder, using either the high speed mixer or mortar and pestle.

3

8.2 Weigh 5 g of carbon black into a 100 cm glass beaker.

3

8.3 Add 50 cm of boiling, distilled water prepared in a stainless steel beaker and 2 to 3 drops of acetone to facilitate wetting

of the sample.

NOTE 3—A stainless steel beaker is used to eliminate contamination

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.