ASTM D153-84(2003)

(Test Method)Standard Test Methods for Specific Gravity of Pigments

Standard Test Methods for Specific Gravity of Pigments

SCOPE

1.1 These test methods cover three procedures for determining the specific gravity of pigments, as follows:

Test Method A—For Routine Testing of Several Samples Simultaneously.

Test Method B—For Tests Requiring Greater Accuracy than Test Method A.

Test Method C—For Rapid and Accurate Testing of Single Samples.

1.2 The specific gravity value obtained by these procedures may be used with the weight of a dry pigment to determine the volume occupied by the pigment in a coating formulation.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Sections 5, 11, and 15.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 153 – 84 (Reapproved 2003)

Standard Test Methods for

1

Specific Gravity of Pigments

This standard is issued under the fixed designation D 153; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

NOTE 1—The Weld type with the cap seal on the outside of the neck of

1. Scope

the bottle is preferred because there is less danger of trapping air just

1.1 These test methods cover three procedures for determin-

under the capillary tube than with types having the ground glass seal on

ing the specific gravity of pigments, as follows:

the inside of the neck.

Test Method A—For Routine Testing of Several Samples

4.2 Water Bath, maintained at 25 6 0.5°C and equipped

Simultaneously.

with a stirring device.

Test Method B—For Tests Requiring Greater Accuracy than

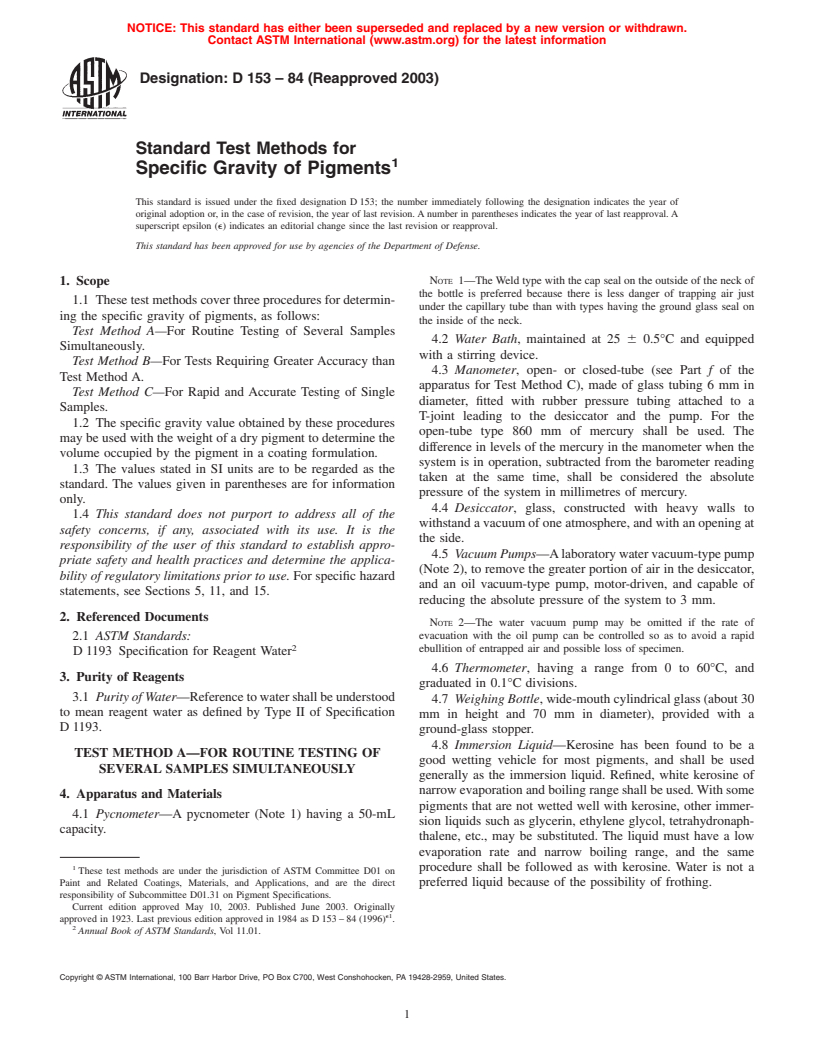

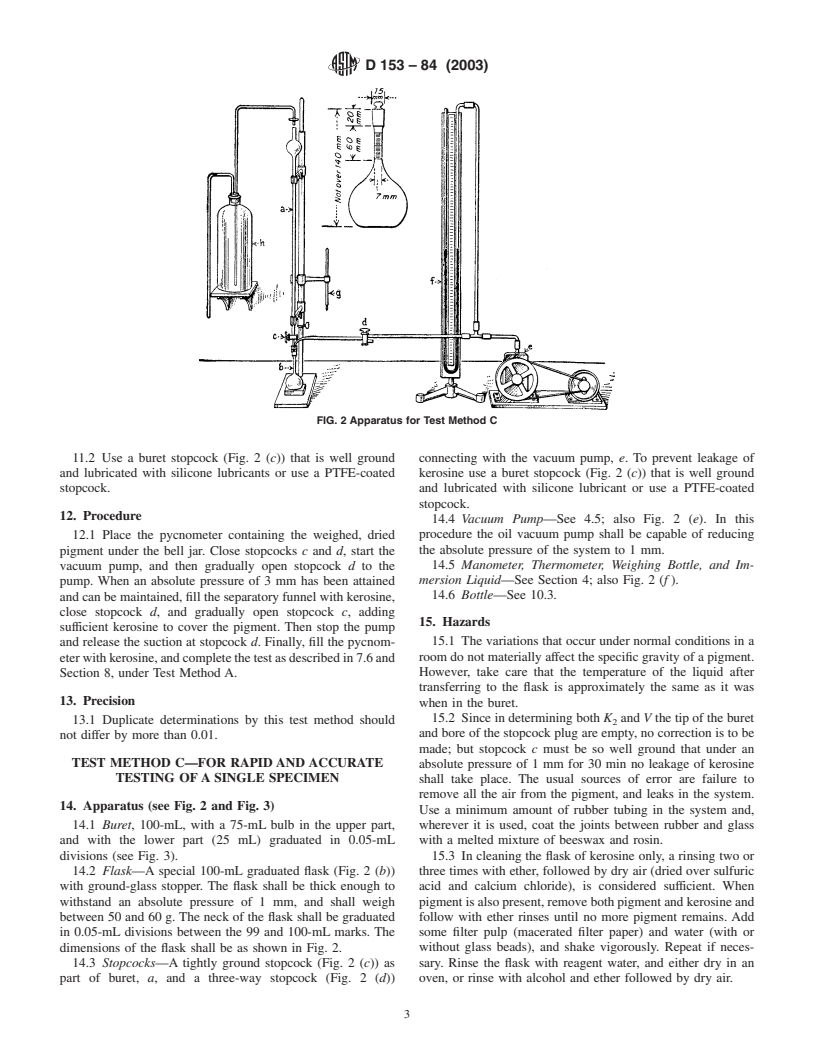

4.3 Manometer, open- or closed-tube (see Part f of the

Test Method A.

apparatus for Test Method C), made of glass tubing 6 mm in

Test Method C—For Rapid and Accurate Testing of Single

diameter, fitted with rubber pressure tubing attached to a

Samples.

T-joint leading to the desiccator and the pump. For the

1.2 The specific gravity value obtained by these procedures

open-tube type 860 mm of mercury shall be used. The

may be used with the weight of a dry pigment to determine the

difference in levels of the mercury in the manometer when the

volume occupied by the pigment in a coating formulation.

system is in operation, subtracted from the barometer reading

1.3 The values stated in SI units are to be regarded as the

taken at the same time, shall be considered the absolute

standard. The values given in parentheses are for information

pressure of the system in millimetres of mercury.

only.

4.4 Desiccator, glass, constructed with heavy walls to

1.4 This standard does not purport to address all of the

withstand a vacuum of one atmosphere, and with an opening at

safety concerns, if any, associated with its use. It is the

the side.

responsibility of the user of this standard to establish appro-

4.5 VacuumPumps—Alaboratorywatervacuum-typepump

priate safety and health practices and determine the applica-

(Note 2), to remove the greater portion of air in the desiccator,

bility of regulatory limitations prior to use. For specific hazard

and an oil vacuum-type pump, motor-driven, and capable of

statements, see Sections 5, 11, and 15.

reducing the absolute pressure of the system to 3 mm.

2. Referenced Documents

NOTE 2—The water vacuum pump may be omitted if the rate of

evacuation with the oil pump can be controlled so as to avoid a rapid

2.1 ASTM Standards:

2

ebullition of entrapped air and possible loss of specimen.

D 1193 Specification for Reagent Water

4.6 Thermometer, having a range from 0 to 60°C, and

3. Purity of Reagents

graduated in 0.1°C divisions.

3.1 PurityofWater—Referencetowatershallbeunderstood

4.7 WeighingBottle, wide-mouth cylindrical glass (about 30

to mean reagent water as defined by Type II of Specification

mm in height and 70 mm in diameter), provided with a

D 1193.

ground-glass stopper.

4.8 Immersion Liquid—Kerosine has been found to be a

TEST METHODA—FOR ROUTINE TESTING OF

good wetting vehicle for most pigments, and shall be used

SEVERALSAMPLES SIMULTANEOUSLY

generally as the immersion liquid. Refined, white kerosine of

narrow evaporation and boiling range shall be used.With some

4. Apparatus and Materials

pigments that are not wetted well with kerosine, other immer-

4.1 Pycnometer—A pycnometer (Note 1) having a 50-mL

sion liquids such as glycerin, ethylene glycol, tetrahydronaph-

capacity.

thalene, etc., may be substituted. The liquid must have a low

evaporation rate and narrow boiling range, and the same

1

procedure shall be followed as with kerosine. Water is not a

These test methods are under the jurisdiction of ASTM Committee D01 on

Paint and Related Coatings, Materials, and Applications, and are the direct preferred liquid because of the possibility of frothing.

responsibility of Subcommittee D01.31 on Pigment Specifications.

Current edition approved May 10, 2003. Published June 2003. Originally

e1

approved in 1923. Last previous edition approved in 1984 as D 153 – 84 (1996) .

2

Annual Book of ASTM Standards, Vol 11.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 153 – 84 (2003)

5. Hazards taking care to add a sufficient quantity to prevent air bubbles

wherethepycnometerisclosed,andpermittocometoconstant

5.1 Before a desiccator i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.