ASTM F992-17

(Specification)Standard Specification for Valve Label Plates

Standard Specification for Valve Label Plates

ABSTRACT

This specification covers the materials, dimensions, inscription, and methods of inscribing for shipboard valve label plates. Label plates shall be classified by type, grade, class, size, and letter size in accordance with material and method of inscribing, method of attachment, thickness of sheet, strip, or plate, dimensions, and letter size to be used. Types and materials: type I - anodized aluminium, engraved; type II - anodized aluminium, metal photo; type III - stainless steel, engraved; type IV - brass, engraved; and type V - plastic, engraved. Grades and methods of attachment: grade A - adhesive on metal bracket (backling plate); grade B - metal strapping or screw; grade C - welding; grade D - secured by handwheel nut; and grade E - connection to valve stem, bonnet, or flange. Inscription on label plates shall include the system identification number, valve identification number, and the function of the valve. The pressure in line, where the line is coming from or going to, or both, may be included along with any other pertinent information.

SCOPE

1.1 This specification covers the materials, dimensions, inscription, and methods of inscribing for shipboard valve label plates.

1.2 Fasteners shall be ordered separately and are not included in this specification.

1.3 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F992 −17 An American National Standard

Standard Specification for

1

Valve Label Plates

ThisstandardisissuedunderthefixeddesignationF992;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ANSI Y14.38Abbreviations and Acronyms for Use on

4

Drawings and Related Documents

1.1 This specification covers the materials, dimensions,

inscription,andmethodsofinscribingforshipboardvalvelabel

3. Classification

plates.

3.1 Label plates shall be classified by type, grade, class,

1.2 Fasteners shall be ordered separately and are not in-

size, and letter size in accordance with material and method of

cluded in this specification.

inscribing, method of attachment, thickness of sheet, strip, or

1.3 The values stated in inch-pound units are to be regarded

plate, dimensions, and letter size to be used.

asstandard.Nootherunitsofmeasurementareincludedinthis

3.2 Types and Materials:

standard.

3.2.1 Type I—Anodized aluminum, engraved.

1.4 This international standard was developed in accor-

3.2.2 Type II—Anodized aluminum, metal photo.

dance with internationally recognized principles on standard-

3.2.3 Type III—Stainless steel, engraved.

ization established in the Decision on Principles for the

3.2.4 Type IV—Brass, engraved.

Development of International Standards, Guides and Recom-

3.2.5 Type V—Plastic, engraved.

mendations issued by the World Trade Organization Technical

3.3 Grades and Methods of Attachment:

Barriers to Trade (TBT) Committee.

3.3.1 Grade A—Adhesive on metal bracket (backing plate)

(Sizes A through J).

2. Referenced Documents

3.3.2 Grade B—Metal strapping or screw (Sizes A through

2

2.1 ASTM Standards:

J).

A240Specification for Chromium and Chromium-Nickel

3.3.3 Grade C—Welding (Sizes A through J) See also the

Stainless Steel Plate, Sheet, and Strip for PressureVessels

American Bureau of Shipping Standards.

and for General Applications

3.3.4 Grade D—Secured by handwheel nut (Sizes K

B36/B36MSpecification for Brass Plate, Sheet, Strip, And

through R).

Rolled Bar

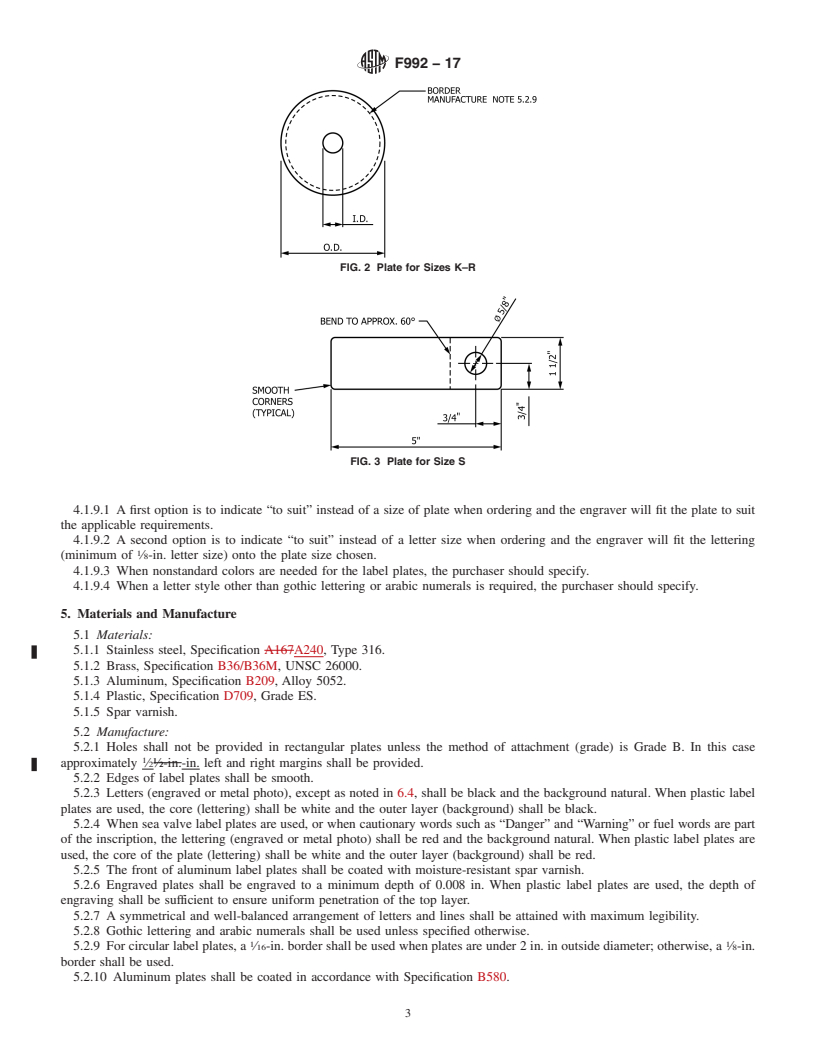

3.3.5 GradeE—Connectiontovalvestem,bonnet,orflange

B209Specification for Aluminum and Aluminum-Alloy

(Size S).

Sheet and Plate

3.4 Class and Thickness:

B580Specification for Anodic Oxide Coatings on Alumi-

1

3.4.1 Class 1— ⁄8 in.

num

3.4.2 Class 2—16 gage.

D709Specification for Laminated Thermosetting Materials

3.4.3 Class 3—20 gage.

2.2 Other Documents:

3.4.4 Class 4—24 gage.

American Bureau of Shipping Rules for Building and

3

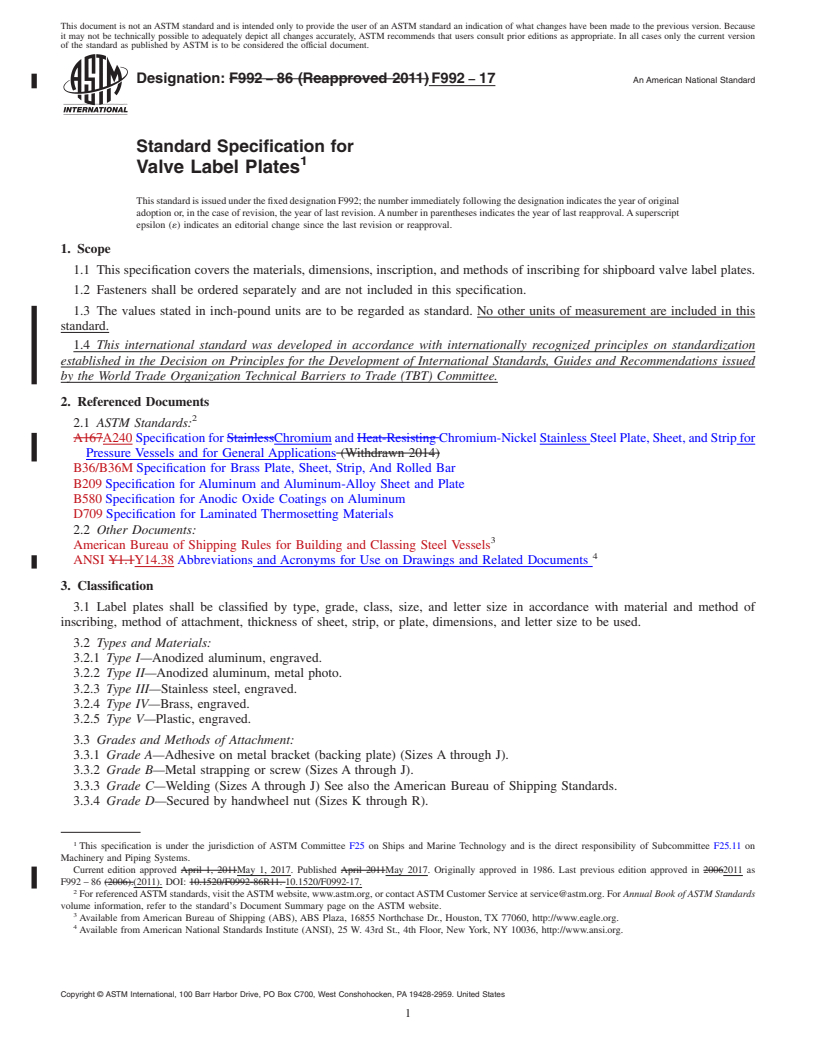

3.5 Size and Dimensions: (length by width) or (outside

Classing Steel Vessels

diameter (OD) by inside diameter (ID).)

7

3.5.1 Size A—Rectangular 2 by ⁄8 in.

1

1

3.5.2 Size B—Rectangular 2 by 1 ⁄2 in.

This specification is under the jurisdiction ofASTM Committee F25 on Ships

7

and Marine Technology and is the direct responsibility of Subcommittee F25.11 on

3.5.3 Size C—Rectangular 3 by ⁄8 in.

Machinery and Piping Systems.

1

3.5.4 Size D—Rectangular 3 by 1 ⁄2 in.

Current edition approved May 1, 2017. Published May 2017. Originally

1

3.5.5 Size E—Rectangular 3 by 2 ⁄4 in.

approved in 1986. Last previous edition approved in 2011 as F992–86 (2011).

7

3.5.6 Size F—Rectangular 4 by ⁄8 in.

DOI: 10.1520/F0992-17.

2

1

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.5.7 Size G—Rectangular 4 by 1 ⁄2 in.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Available from American Bureau of Shipping (ABS), ABS Plaza, 16855 Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Northchase Dr., Houston, TX 77060, http://www.eagle.org. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F992−17

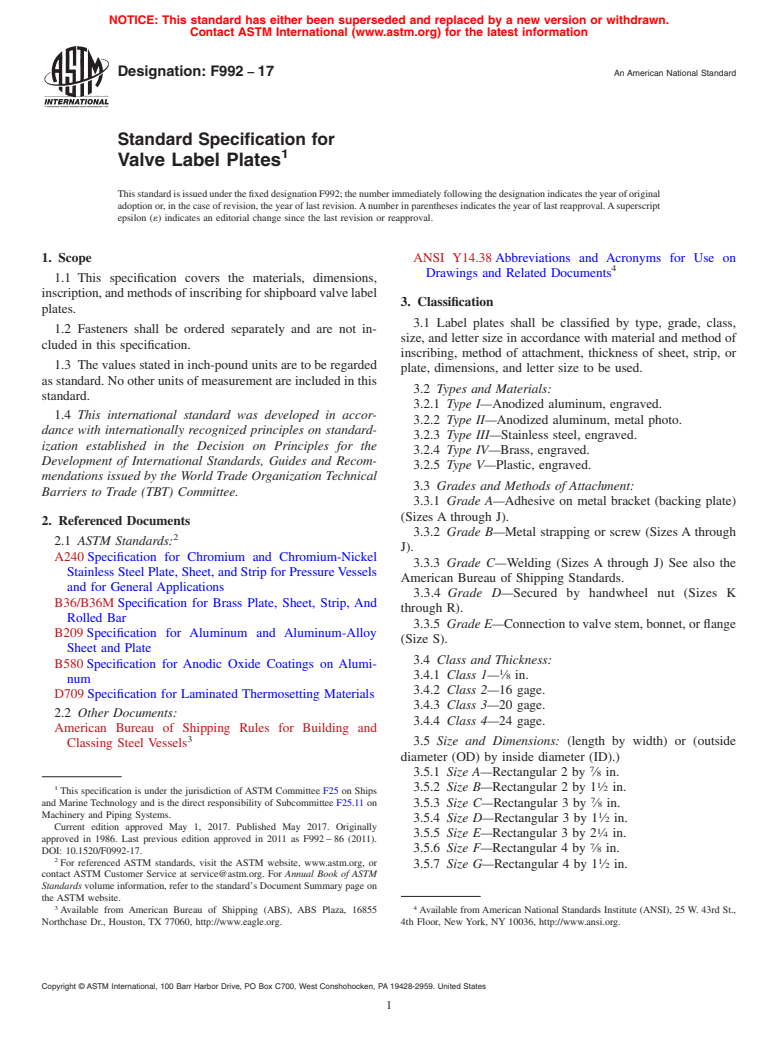

FIG. 1 Plate for Sizes A–J

3

3.6.3 Letter Size 3— ⁄16-in. letter, approximately five letters

per inch.

1

3.6.4 Letter Size 4— ⁄8-in. letter, approximately eight letters

per inch.

4. Ordering Information

4.1 Ordersformaterialunderthisspecificationshallinclude

the following:

4.1.1 ASTM Designation and year of issue.

4.1.2 Type.

4.1.3 Grade.

4.1.4 Class.

FIG. 2 Plate for Sizes K–R

4.1.5 Size.

4.1.6 Letter size.

4.1.7 Color of lettering (if other than default color black,

standard red words, or white when plastic is used).

4.1.8 Inscription (as to be put on label).

4.1.9 Optional characteristics:

4.1.9.1 Afirst option is to indicate “to suit” instead of a size

ofplatewhenorderingandtheengraverwillfittheplatetosuit

the applicable requirements.

4.1.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F992 − 86 (Reapproved 2011) F992 − 17 An American National Standard

Standard Specification for

1

Valve Label Plates

This standard is issued under the fixed designation F992; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the materials, dimensions, inscription, and methods of inscribing for shipboard valve label plates.

1.2 Fasteners shall be ordered separately and are not included in this specification.

1.3 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this

standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A167A240 Specification for StainlessChromium and Heat-Resisting Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for

Pressure Vessels and for General Applications (Withdrawn 2014)

B36/B36M Specification for Brass Plate, Sheet, Strip, And Rolled Bar

B209 Specification for Aluminum and Aluminum-Alloy Sheet and Plate

B580 Specification for Anodic Oxide Coatings on Aluminum

D709 Specification for Laminated Thermosetting Materials

2.2 Other Documents:

3

American Bureau of Shipping Rules for Building and Classing Steel Vessels

4

ANSI Y1.1Y14.38 Abbreviations and Acronyms for Use on Drawings and Related Documents

3. Classification

3.1 Label plates shall be classified by type, grade, class, size, and letter size in accordance with material and method of

inscribing, method of attachment, thickness of sheet, strip, or plate, dimensions, and letter size to be used.

3.2 Types and Materials:

3.2.1 Type I—Anodized aluminum, engraved.

3.2.2 Type II—Anodized aluminum, metal photo.

3.2.3 Type III—Stainless steel, engraved.

3.2.4 Type IV—Brass, engraved.

3.2.5 Type V—Plastic, engraved.

3.3 Grades and Methods of Attachment:

3.3.1 Grade A—Adhesive on metal bracket (backing plate) (Sizes A through J).

3.3.2 Grade B—Metal strapping or screw (Sizes A through J).

3.3.3 Grade C—Welding (Sizes A through J) See also the American Bureau of Shipping Standards.

3.3.4 Grade D—Secured by handwheel nut (Sizes K through R).

1

This specification is under the jurisdiction of ASTM Committee F25 on Ships and Marine Technology and is the direct responsibility of Subcommittee F25.11 on

Machinery and Piping Systems.

Current edition approved April 1, 2011May 1, 2017. Published April 2011May 2017. Originally approved in 1986. Last previous edition approved in 20062011 as

F992 – 86 (2006).(2011). DOI: 10.1520/F0992-86R11. 10.1520/F0992-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Bureau of Shipping (ABS), ABS Plaza, 16855 Northchase Dr., Houston, TX 77060, http://www.eagle.org.

4

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F992 − 17

3.3.5 Grade E—Connection to valve stem, bonnet, or flange (Size S).

3.4 Class and Thickness:

1

3.4.1 Class 1— ⁄8 in.

3.4.2 Class 2—16 gage.

3.4.3 Class 3—20 gage.

3.4.4 Class 4—24 gage.

3.5 Size and Dimensions: (length by width) or (outside diameter (OD) by inside diameter (ID).)

7

3.5.1 Size A—Rectangular 2 by ⁄8 in.

1

3.5.2 Size B—Rectangular 2 by 1 ⁄2 in.

7

3.5.3 Size C—Rectangular 3 by ⁄8 in.

1

3.5.4 Size D—Rectangular 3 by 1 ⁄2 in.

1

3.5.5 Size E—Rectangular 3 by 2 ⁄4 in.

7

3.5.6 Size F—Rectangular 4 by ⁄8 in.

1

3.5.7 Size G—Rectangular 4 by 1 ⁄2 in.

1

3.5.8 Size H—Rectangular 4 by 2 ⁄4 in.

1

3.5.9 Size J—Rectangular 4 by 3 ⁄4 in.

3 5

3.5.10 Size K—Circular 1 ⁄16 by ⁄16 in.

1 5

3.5.11 Size L—Circular 1 ⁄2 by ⁄16 in.

3 3

3.5.12 Size M—Circular 1 ⁄4 by ⁄8 in.

3

3.5.13 Size N—Circular 2 by ⁄8 in.

3 7

3.5.14 Size P—

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.