ASTM A424/A424M-09a(2016)

(Specification)Standard Specification for Steel, Sheet, for Porcelain Enameling

Standard Specification for Steel, Sheet, for Porcelain Enameling

ABSTRACT

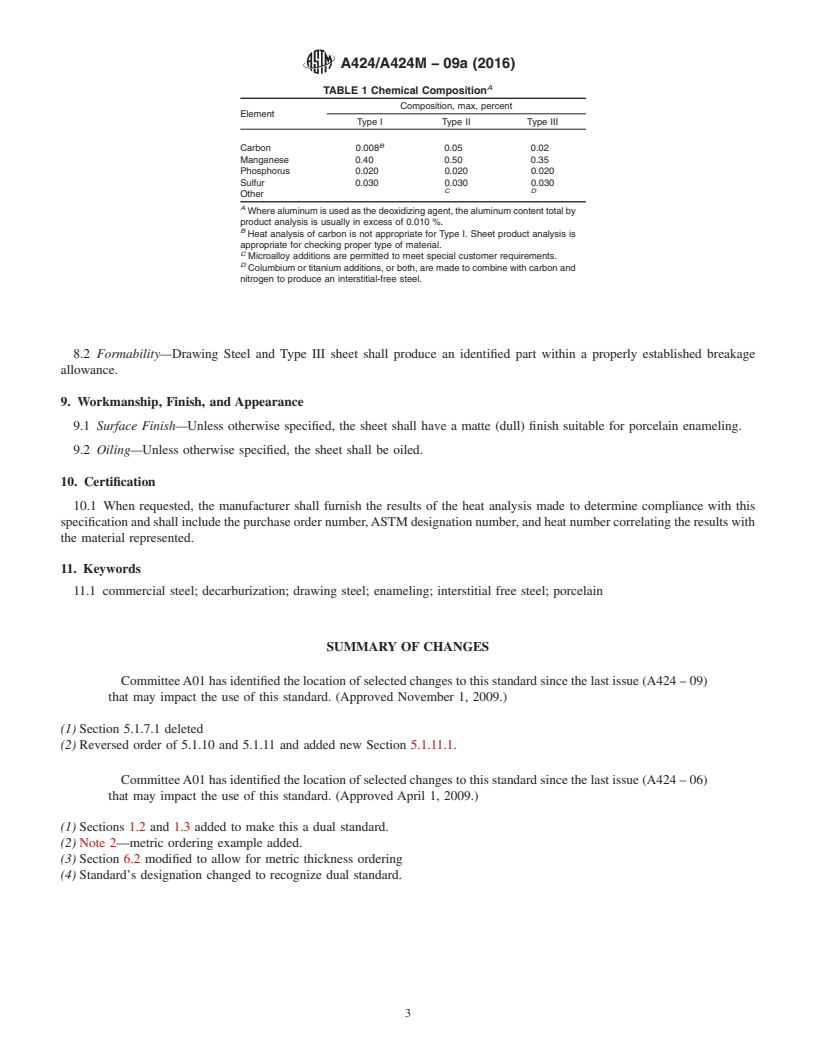

This specification covers standard requirements for sheet steel in coils and cut lengths for porcelain enameling. Heat analysis of Type I, Type II, and Type III steels shall conform to the prescribed chemical composition for carbon, manganese, phosphorus, sulfur, and others. However, an exception is made on carbon, since heat analysis of carbon is not appropriate for Type I. The material shall also conform to the required mechanical properties such as bending and formability.

SCOPE

1.1 This specification covers sheet steel in coils and cut lengths for porcelain enameling. The compositions and processing of these steels are such that articles for porcelain enameling may be fabricated from them and, under proper conditions, enameled. The steels are furnished as Type I, Type II, and Type III. Type I and Type II are supplied in two designations, Commercial Steel and Drawing Steel. Type III steel is interstitial-free and does not require a designation.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 Tolerances are found in General Requirements Specifications A568/A568M and A635/A635M. The appropriate General Requirements specification is applied based on the thickness and width of the product ordered.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A424/A424M −09a (Reapproved 2016)

Standard Specification for

Steel, Sheet, for Porcelain Enameling

This standard is issued under the fixed designationA424/A424M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 3. Terminology

1.1 This specification covers sheet steel in coils and cut

3.1 Definitions—For definitions of other terms used in this

lengths for porcelain enameling. The compositions and pro-

specification, refer to Terminology A941.

cessing of these steels are such that articles for porcelain

3.2 Definitions of Terms Specific to This Standard:

enameling may be fabricated from them and, under proper

3.2.1 base coat—also known as ground coat. This coating

conditions, enameled. The steels are furnished as Type I, Type

layer is applied directly to the steel and promotes adhesion of

II, and Type III. Type I and Type II are supplied in two

the coating system to the steel.

designations, Commercial Steel and Drawing Steel. Type III

3.2.2 cover coat—This coating layer is usually applied over

steel is interstitial-free and does not require a designation.

the base or ground coat to improve the appearance and provide

1.2 The values stated in either SI units or inch-pound units

the proper color.

are to be regarded separately as standard. The values stated in

3.2.3 direct cover coat—This refers to a single coating

each system may not be exact equivalents; therefore, each

application that provides both adequate adhesion and appear-

system shall be used independently of the other. Combining

ance.

values from the two systems may result in non-conformance

with the standard.

4. Classification

1.3 Tolerances are found in General Requirements Specifi-

cationsA568/A568MandA635/A635M.TheappropriateGen- 4.1 Types:

eral Requirements specification is applied based on the thick-

4.1.1 Type I steel has an extremely low carbon level

ness and width of the product ordered.

achieved through sheet decarburization. This material is suit-

able for direct cover coat enameling practice, but this require-

2. Referenced Documents

ment must be indicated by the purchaser in accordance with

5.1.6. This material is also suitable for ground and cover coat

2.1 ASTM Standards:

A568/A568M Specification for Steel, Sheet, Carbon, enameling practice. It has good sag resistance and good

formability.

Structural,andHigh-Strength,Low-Alloy,Hot-Rolledand

Cold-Rolled, General Requirements for

4.1.2 Type II steel is suitable for applications where ground

A635/A635M Specification for Steel, Sheet and Strip, and cover coat enameling operations are employed. The

Heavy-Thickness Coils, Hot-Rolled, Alloy, Carbon,

composition of the Type II steel is obtained in melting

Structural, High-Strength Low-Alloy, and High-Strength operations.

Low-Alloy with Improved Formability, General Require-

4.1.3 Type III is an interstitial-free steel and is suitable for

ments for

applications where ground and cover coat enameling opera-

A941 TerminologyRelatingtoSteel,StainlessSteel,Related

tions are employed. The composition of the Type III steel is

Alloys, and Ferroalloys

obtained in melting operations. It has good sag resistance and

excellent formability.

1 4.2 Product Designations:

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloysand is the direct responsibility of Subcommittee

4.2.1 Commercial Steel is intended for parts where bending,

A01.19 on Steel Sheet and Strip.

moderate forming, or moderate drawing may be involved.

Current edition approved May 1, 2016. Published May 2016. Originally

4.2.2 Drawing Steel is intended for fabricating identified

approved in 1958. Last previous edition approved in 2009 as A424/A424M – 09a.

DOI: 10.1520/A0424_A0424M-09AR16.

parts where the draw is particularly severe or where the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

material shall be essentially free of changes in mechanical

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

properties over a period of time. Drawing Steel should be

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. specified where the formed material shall be essentially free of

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A424/A424M − 09a (2016)

cover coat, 0.048 in. by 35 in. by 96 in., Part 2587, Range Top, or, 50 000

such surface disturbances as stretcher strains or fluting without

kg, ASTM A424M – -NN Porcelain Enameling Sheet, Type I, Drawing

the need of prior roller leveling.

Steel, direct cover coat, 1.22 mm by 890 mm by 2440 mm, Part 2587,

4.2.3 Type III interstitial-free steel is intended for fabricat-

Range Top.”

ing identified parts where the most severe drawing or forming

is involved and where the material must be free of changes in

6. General Requirements for Delivery

mechanical properties over a period of time and free of such

6.1 Material furnished under this specification shall con-

surface disturbances as stretcher strains or fluting without the

form to the applicable requirements of the current edition of

need of prior roller leveling.

Specification A568/A568M.

4.3 Porcelain Enamels:

6.2 Productscoveredbythisspecificationareproducedonly

4.3.1 Ground coat enamels are glasses used primarily for

to either decimal thickness where decimal thickness tolerances

their bonding characteristics. They may be applied after proper

apply or to metric thickness where metric thickness tolerances

metal preparation (either pickle or pickle-free depending on

apply.

enamel system). These glasses may be applied as either dry

powders or wet slips. This type enamel is suitable for all three

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A424/A424M − 09a A424/A424M − 09a (Reapproved 2016)

Standard Specification for

Steel, Sheet, for Porcelain Enameling

This standard is issued under the fixed designation A424/A424M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers sheet steel in coils and cut lengths for porcelain enameling. The compositions and processing of

these steels are such that articles for porcelain enameling may be fabricated from them and, under proper conditions, enameled.

The steels are furnished as Type I, Type II, and Type III. Type I and Type II are supplied in two designations, Commercial Steel

and Drawing Steel. Type III steel is interstitial-free and does not require a designation.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 Tolerances are found in General Requirements Specifications A568/A568M and A635/A635M. The appropriate General

Requirements specification is applied based on the thickness and width of the product ordered.

2. Referenced Documents

2.1 ASTM Standards:

A568/A568M Specification for Steel, Sheet, Carbon, Structural, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled,

General Requirements for

A635/A635M Specification for Steel, Sheet and Strip, Heavy-Thickness Coils, Hot-Rolled, Alloy, Carbon, Structural,

High-Strength Low-Alloy, and High-Strength Low-Alloy with Improved Formability, General Requirements for

A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys

3. Terminology

3.1 Definitions—For definitions of other terms used in this specification, refer to Terminology A941.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 base coat—also known as ground coat. This coating layer is applied directly to the steel and promotes adhesion of the

coating system to the steel.

3.2.2 cover coat—This coating layer is usually applied over the base or ground coat to improve the appearance and provide the

proper color.

3.2.3 direct cover coat—This refers to a single coating application that provides both adequate adhesion and appearance.

4. Classification

4.1 Types:

4.1.1 Type I steel has an extremely low carbon level achieved through sheet decarburization. This material is suitable for direct

cover coat enameling practice, but this requirement must be indicated by the purchaser in accordance with 5.1.6. This material is

also suitable for ground and cover coat enameling practice. It has good sag resistance and good formability.

4.1.2 Type II steel is suitable for applications where ground and cover coat enameling operations are employed. The composition

of the Type II steel is obtained in melting operations.

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloysand is the direct responsibility of Subcommittee A01.19

on Steel Sheet and Strip.

Current edition approved Nov. 1, 2009May 1, 2016. Published December 2009May 2016. Originally approved in 1958. Last previous edition approved in 2009 as

A424 – 09.A424/A424M – 09a. DOI: 10.1520/A0424_A0424M-09a.10.1520/A0424_A0424M-09AR16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A424/A424M − 09a (2016)

4.1.3 Type III is an interstitial-free steel and is suitable for applications where ground and cover coat enameling operations are

employed. The composition of the Type III steel is obtained in melting operations. It has good sag resistance and excellent

formability.

4.2 Product Designations:

4.2.1 Commercial Steel is intended for parts where bending, moderate forming, or moderate drawing may be involved.

4.2.2 Drawing Steel is intended for fabricating identified parts where the draw is particularly severe or where the material shall

be essentially free of changes in mechanical properties over a period of time. Drawing Steel should be specified where the formed

material shall be essentially free of such surface disturbances as stretcher strains or fluting without the need of prior roller leveling.

4.2.3 Type III interstitial-free steel is intended for fabricating identified parts where the most severe drawing or forming is

involved and where the material must be free of changes in mechanical properties over a period of time and free of such surface

disturbances as stretcher strains or fluting without the need of prior roller leveling.

4.3 Porcelain Enamels:

4.3.1 Ground coat enamels are glasses used primarily for their bonding characteristics. They may be applied after proper metal

preparation (either pickle or pickle-free depending on enamel system). These glasses may be applied as either dry powders or wet

slips. This type enamel is suitable for all three types of steel (Type I, II, or III).

4.3.2 Cover coat enamels are appearance glasses applied for specific color, corrosion, alkali resistance, and so forth. These

enamels may be applied directly to Type I steels after suitable metal preparation. They may also be applied over fired ground coat

enamels. They may be applied as either dry powder or wet slip.

4.3.3 Two coat-one fire enamels are special glass systems applied as dry powders. They usually are applied as pick

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.