ASTM D4603-03(2011)e1

(Test Method)Standard Test Method for Determining Inherent Viscosity of Poly(Ethylene Terephthalate) (PET) by Glass Capillary Viscometer

Standard Test Method for Determining Inherent Viscosity of Poly(Ethylene Terephthalate) (PET) by Glass Capillary Viscometer

SIGNIFICANCE AND USE

The inherent viscosity is relatable to the composition and molecular weight of a polyester resin. It must be controlled so that the processability and end properties of the resin remain in a desired range.

SCOPE

1.1 This test method is for the determination of the inherent viscosity of poly(ethylene terephthalate) (PET) soluble at 0.50 % concentration in a 60/40 phenol/1,1,2,2-tetrachloroethane solution by means of a glass capillary viscometer. Highly crystalline forms of PET that are not soluble in this solvent mixture will require a different procedure.

1.2 The inherent viscosity values obtained by this test method are comparable with those obtained using differential viscometry described in Test Method D5225.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazards statements are given in Section 8.

Note 1—This test method and ISO 1628-5 are similar but not technically equivalent. This ISO standard gives an option of solvents for PET. Solvent specified in this ASTM test method is one of the options in the ISO method. ISO also uses Type 1C Ubbelohde viscometer, rather than the 1B, and reports viscosity number, rather than inherent viscosity.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D4603 − 03 (Reapproved 2011)

Standard Test Method for

Determining Inherent Viscosity of Poly(Ethylene

Terephthalate) (PET) by Glass Capillary Viscometer

This standard is issued under the fixed designation D4603; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Reapproved with editorial change to 6.5 in November 2011.

1. Scope D446 Specifications and Operating Instructions for Glass

Capillary Kinematic Viscometers

1.1 This test method is for the determination of the inherent

D1972 Practice for Generic Marking of Plastic Products

viscosity of poly(ethylene terephthalate) (PET) soluble at

D5225 Test Method for Measuring Solution Viscosity of

0.50 % concentration in a 60/40 phenol/1,1,2,2-

Polymers with a Differential Viscometer

tetrachloroethane solution by means of a glass capillary vis-

E1 Specification for ASTM Liquid-in-Glass Thermometers

cometer.HighlycrystallineformsofPETthatarenotsolublein

IEEE/ASTM SI-10 Practice for Use of the International

this solvent mixture will require a different procedure.

System of Units (SI)

1.2 The inherent viscosity values obtained by this test

E691 Practice for Conducting an Interlaboratory Study to

method are comparable with those obtained using differential

Determine the Precision of a Test Method

viscometry described in Test Method D5225.

2.2 ISO Standard:

1.3 The values stated in SI units are to be regarded as the ISO 1628-5 Determination of the Viscosity of Polymers in

standard. The values given in parentheses are for information

Dilute Solution Using Capillary Viscometers—Part 5:

only. Thermoplastic Polyester (TP) homopolymers and Copo-

lymers.

1.4 This standard does not purport to address all of the

2.3 NIST Standard:

safety concerns, if any, associated with its use. It is the

C 602 Testing of Glass Volumetric Apparatus

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3. Terminology

bility of regulatory limitations prior to use. Specific hazards

statements are given in Section 8.

3.1 Units, symbols, and abbreviations used in this test

method are those recommended in Practice IEEE/ASTM

NOTE 1—This test method and ISO 1628-5 are similar but not techni-

SI-10.

cally equivalent. This ISO standard gives an option of solvents for PET.

Solvent specified in this ASTM test method is one of the options in the

3.2 Definitions of Terms Specific to This Standard:

ISOmethod.ISOalsousesType1CUbbelohdeviscometer,ratherthanthe

3.2.1 inherent viscosity (also known as the logarithmic

1B, and reports viscosity number, rather than inherent viscosity.

viscosity number)—defined by the equation given in 11.1.

2. Referenced Documents

3.2.2 PET—as outlined in Practice D1972. The PET acro-

nym may be used to avoid trademark infringement and to

2.1 ASTM Standards:

comply with various state or federal laws.

D445 Test Method for Kinematic Viscosity of Transparent

and Opaque Liquids (and Calculation of Dynamic Viscos-

4. Summary of Test Method

ity)

4.1 The inherent viscosity is determined by measuring the

flow time of a solution of known polymer concentration and

This test method is under the jurisdiction ofASTM Committee D20 on Plastics the flow time of the pure solvent in a capillary viscometer at a

and is the direct responsibility of Subcommittee D20.70 on Analytical Methods

fixed temperature. The inherent viscosity value is calculated

(D20.70.05).

from the flow time values.

Current edition approved Nov. 15, 2011. Published April 2012. Originally

approved in 1986. Last previous edition approved in 2003 as D4603 – 03. DOI:

10.1520/D4603-03R11E01.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

Standards volume information, refer to the standard’s Document Summary page on Available from National Institute of Standards and Technology (NIST), 100

the ASTM website. Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

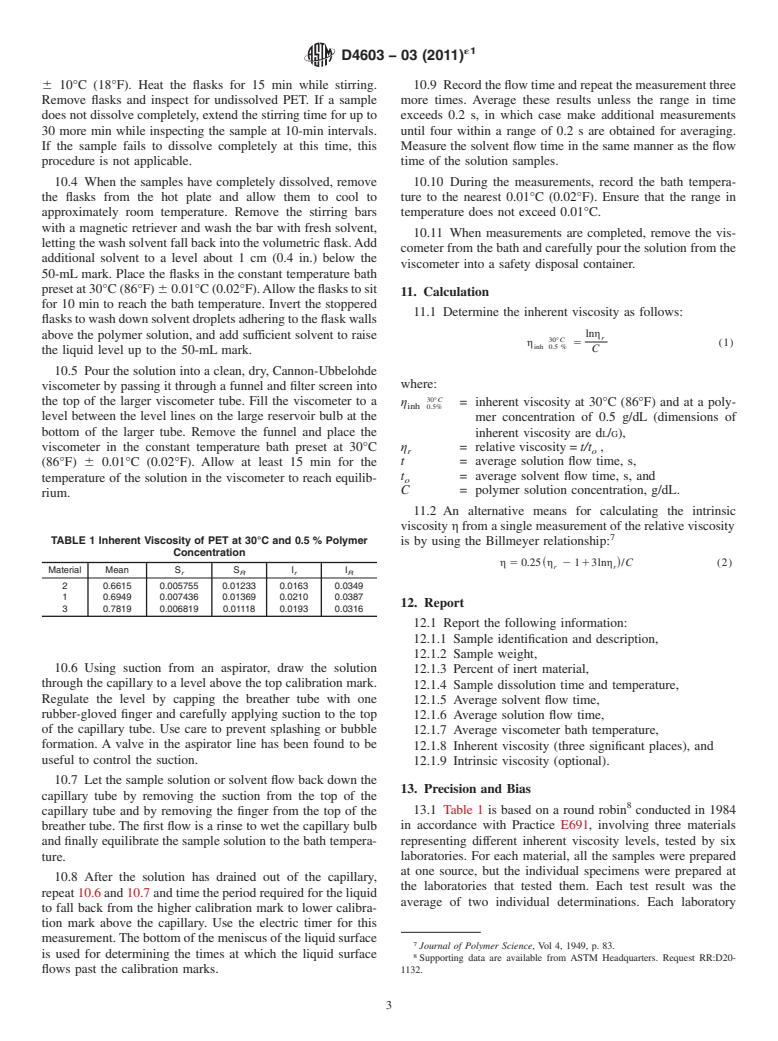

D4603 − 03 (2011)

5. Significance and Use a hydrogen chloride scavenger to the solvent, such as 0.2

weight % n-octyl-bis-(isoethyl mercaptoacetate).

5.1 The inherent viscosity is relatable to the composition

andmolecularweightofapolyesterresin.Itmustbecontrolled 7.3 Reagent Grade Methylene Chloride and Acetone, rins-

sothattheprocessabilityandendpropertiesoftheresinremain ing solvents.

in a desired range.

7.4 Chromic Acid, cleaning solution.

6. Apparatus

8. Hazards

6.1 Cannon Ubbelohde Type 1B Viscometer, as described in

8.1 The solvent used in this procedure is a mixture of 60

Specifications and Operating Instructions D446.

weight % phenol and 40 weight % 1,1,2,2-tetrachloroethane.

Both compounds and the mixture are toxic and require care in

6.2 Viscometer Holder.

handling. Make reference to the material safety data sheets

6.3 Electric Timer, readable to 0.1 s, as described in Test

available from the suppliers of these compounds for dealing

Method D445.

with the hazards they present. In addition to using a hood for

6.4 Constant Temperature Bath, control label at 30°C

adequate ventilation in handling these materials, protection

(86°F) 6 0.01°C (0.02°F).

against skin contact is essential.

6.5 Kinematic Viscosity Thermometer ASTM 118 (for use at

8.2 Obtain the material safety data sheets for methylene

30°C), conforming to Specification E1. Thermometric devices

chloride, acetone, and the chromic acid solution used for

such as liquid-in-glass thermometers, resistance temperature

cleaning the testing equipment from their suppliers. Consult

detectors, thermistors and thermocouples with equal or better

the material safety data sheets before using the materials.

accuracieswithinthetemperaturerangeinvolved,maybeused.

9. Conditioning

6.6 Temperature Controllable Magnetic Stirring Hot Plate.

9.1 If the sample of PET contains 0.5 % or more of inert

6.7 TFE-Fluorocarbon Plastic-Coated Stirring Bars and a

material such as titanium dioxide or glass fiber, determine the

Magnetic Bar Retriever.

amount of inert material accurately by a procedure suitable for

6.8 Volumetric Flasks and Stoppers, 50-mL capacity, con-

the type of inert material present.

forming to the standards of accuracy in NIST Circular No.

9.2 If the sample is suspected of being wet (in excess of the

C 602.

moisture level derived from exposure to ambient humidity

6.9 Analytical Balance, with readout to 0.0001 g.

conditions), dry the sample in an oven for a suggested

minimum of2hat 65°C (149°F) 6 5°C (9°F) or until a

6.10 Borosilicate Funnels.

constant weight of 6 0.1 % is reached. Moisture picked up

6.11 Stainless Steel Filter Screening, 325-mesh or finer.

from ambient humidity will weigh 0.30 % and is negligible in

6.12 Aspirator.

this procedure. (See Note 2.)

6.13 Wiley Mill Grinder, with 20-mesh stainless steel

NOTE 2—Use a suitable technical method to determine moisture

screen. content.

9.3 If the sample is difficult to dissolve, reduce the sample

6.14 Drying Oven, for equipment.

size by grinding it to a 20-mesh screen size in a Wiley Mill or

7. Reagents and Materials

other size reduction technique. Avoid overheating the sample

during the grinding operation. It is possible to maintain a low

7.1 Purity of Reagents—Reagent grade chemicals shall be

temperature by grinding in the presence of dry ice or liquid

used in all tests. Unless otherwise indicated, it is intended that

nitrogen. Grind a 15 to 20- g sample, representative of the

all reagents shall conform to the specifications of the Commit-

entire lot being tested. It is likely that drying is necessary after

tee on Analytical Reagents of the American Chemical Society

the dry ice grinding step.

where such specifications are available. Other grades are

permitted to be used, providing it is first ascertained that the

10. Procedure

reagent is of sufficiently high purity to permit its use without

10.1 Accurately weigh between 0.2475 and 0.2525 g (accu-

lessening the accuracy of the determination.

rate to 60.0002 g) of sample into a clean, dry 50-mL

7.2 Phenol/1,1,2,2-tetrachloroethane Solution, 60/40

volumetric flask. If the sample contains more than 0.5 % inert

weight%mixture(0.5%moisturemaximum,protectedinsuch

material, weigh the amount of sample necessary to give the

a manner as to maintain this maximum level). Protect PET

specified amount of PET.

against the degradation which has been found to occasionally

10.2 Place a TFE-fluorocarbon plastic-coated stirring bar

occur during the heating stage in 10.3 through the addition of

into the flask and add approximat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.