ASTM D2782-94(1996)

(Test Method)Standard Test Method for Measurement of Extreme-Pressure Properties of Lubricating Fluids (Timken Method)

Standard Test Method for Measurement of Extreme-Pressure Properties of Lubricating Fluids (Timken Method)

SCOPE

1.1 This test method covers the determination of the load-carrying capacity of lubricating fluids by means of the Timken Extreme Pressure Tester.

Note 1—This test method is suitable for testing fluids having a viscosity of less than about 5000 cSt (5000 mm2/s) at 40°C. For testing fluids having a higher viscosity, refer to Note 4 in .

1.2 The values stated in SI units are to be regarded as standard. Because the equipment used in this test method is available only in inch-pound units, SI units are omitted when referring to the equipment and the test specimens.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 7.1, 7.2, 8.1, 8.2, 9.4, and 10.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2782 – 94 (Reapproved 1996) An American National Standard

Standard Test Method for

Measurement of Extreme-Pressure Properties of Lubricating

Fluids (Timken Method)

This standard is issued under the fixed designation D 2782; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This test method was adopted as a joint ASTM-IP Standard.

This test method has been approved by the sponsoring committees and accepted by the cooperating societies in accordance with

established procedures.

1. Scope 2.2 ASTM Adjuncts: ASTM

Three Glossy Prints of Test Blocks Showing Scars (D 2782)

1.1 This test method covers the determination of the load-

carrying capacity of lubricating fluids by means of the Timken

3. Terminology

Extreme Pressure Tester.

3.1 Definitions:

NOTE 1—This test method is suitable for testing fluids having a

3.1.1 extreme pressure (EP) additive, n, in a lubricant—a

viscosity of less than about 5000 cSt (5000 mm /s) at 40°C. For testing

substance that minimizes damage to metal surfaces in contact

fluids having a higher viscosity, refer to Note 7 in 9.1.

under high-stress rubbing conditions. D 4175

1.2 The values stated in SI units are to be regarded as

3.1.2 lubricant, n—any substance interposed between two

standard. Because the equipment used in this test method is

surfaces for the purpose of reducing friction or wear between

available only in inch-pound units, SI units are omitted when

them. G40

referring to the equipment and the test specimens.

3.1.3 scoring, n, in tribology—a severe form of wear

1.3 This standard does not purport to address all of the

characterized by the formation of extensive grooves and

safety concerns, if any, associated with its use. It is the

scratches in the direction of sliding. G40

responsibility of the user of this standard to establish appro-

3.1.4 wear, n—damage to a solid surface generally involv-

priate safety and health practices and determine the applica-

ing progressive loss of material, due to relative motion between

bility of regulatory limitations prior to use. Specific precau-

that surface and a contacting substance or substances. G40

tionary statements are given in Note 2, Note 3, Note 4, and

3.2 Definitions of Terms Specific to This Standard:

Note 8.

3.2.1 load-carrying capacity of a lubricant— as determined

by this test method, the maximum load or pressure that can be

2. Referenced Documents

sustained by the lubricant (when used in the given system

2.1 ASTM Standards:

under specific conditions) without failure of the sliding contact

D 235 Specification for Mineral Spirits (Petroleum Spirits)

surfaces as evidenced by scoring or seizure or asperity weld-

(Hydrocarbon Drycleaning Solvents)

ing.

D 329 Specification for Acetone

3.2.2 OK value, n—as determined by this test method, the

D 2509 Test Method for Measurement of Extreme Pressure

maximum mass (weight) added to the load lever weight pan, at

Properties of Lubricating Grease (Timken Method)

which no scoring or seizure occurs.

D 4175 Terminology Relating to Petroleum, Petroleum

3.2.3 score value, n—as determined by this test method, the

Products, and Lubricants

minimum mass (weight) added to the load lever weight pan, at

G 40 Terminology Relating to Wear and Erosion

which scoring or seizure occurs.

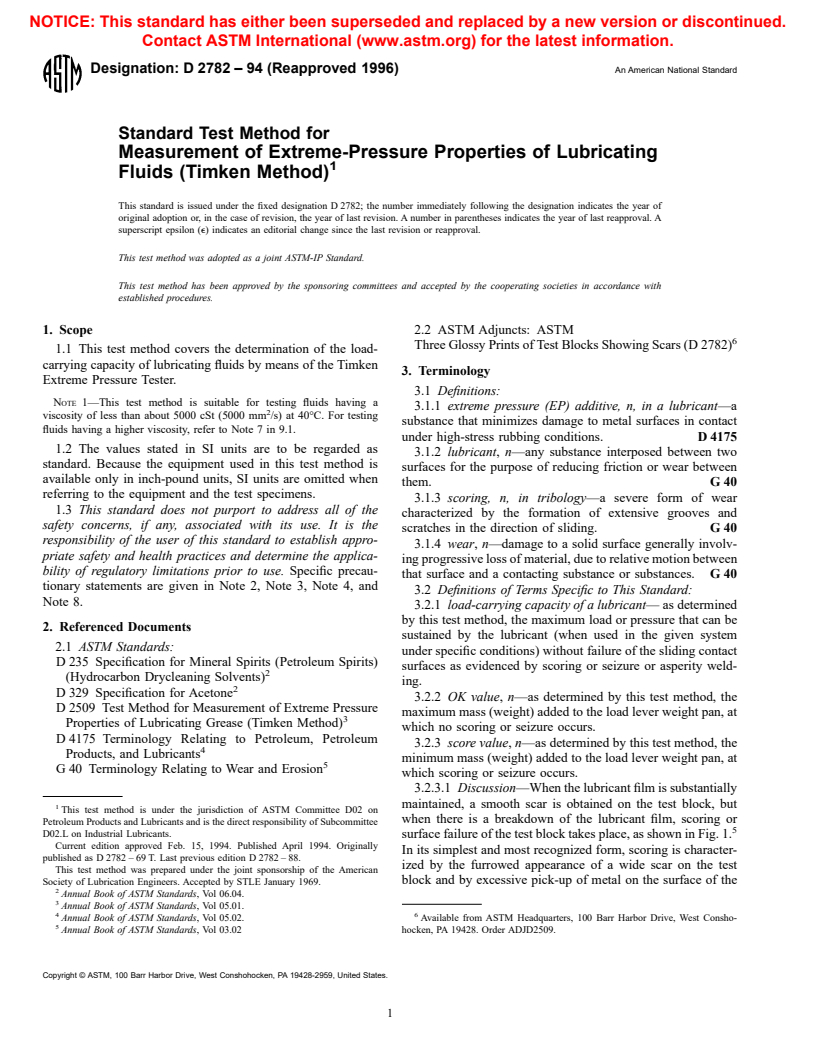

3.2.3.1 Discussion—When the lubricant film is substantially

maintained, a smooth scar is obtained on the test block, but

This test method is under the jurisdiction of ASTM Committee D02 on

when there is a breakdown of the lubricant film, scoring or

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.L on Industrial Lubricants. surface failure of the test block takes place, as shown in Fig. 1.

Current edition approved Feb. 15, 1994. Published April 1994. Originally

In its simplest and most recognized form, scoring is character-

published as D 2782 – 69 T. Last previous edition D 2782 – 88.

ized by the furrowed appearance of a wide scar on the test

This test method was prepared under the joint sponsorship of the American

Society of Lubrication Engineers. Accepted by STLE January 1969. block and by excessive pick-up of metal on the surface of the

Annual Book of ASTM Standards, Vol 06.04.

Annual Book of ASTM Standards, Vol 05.01.

4 6

Annual Book of ASTM Standards, Vol 05.02. Available from ASTM Headquarters, 100 Barr Harbor Drive, West Consho-

Annual Book of ASTM Standards, Vol 03.02 hocken, PA 19428. Order ADJD2509.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 2782

FIG. 1 Test Blocks Showing Various Types of Scar

FIG. 1 Continued Scoring

test cup. The form of surface failure more usually encountered, 6. Apparatus

however, consists of a comparatively smooth scar, which 7

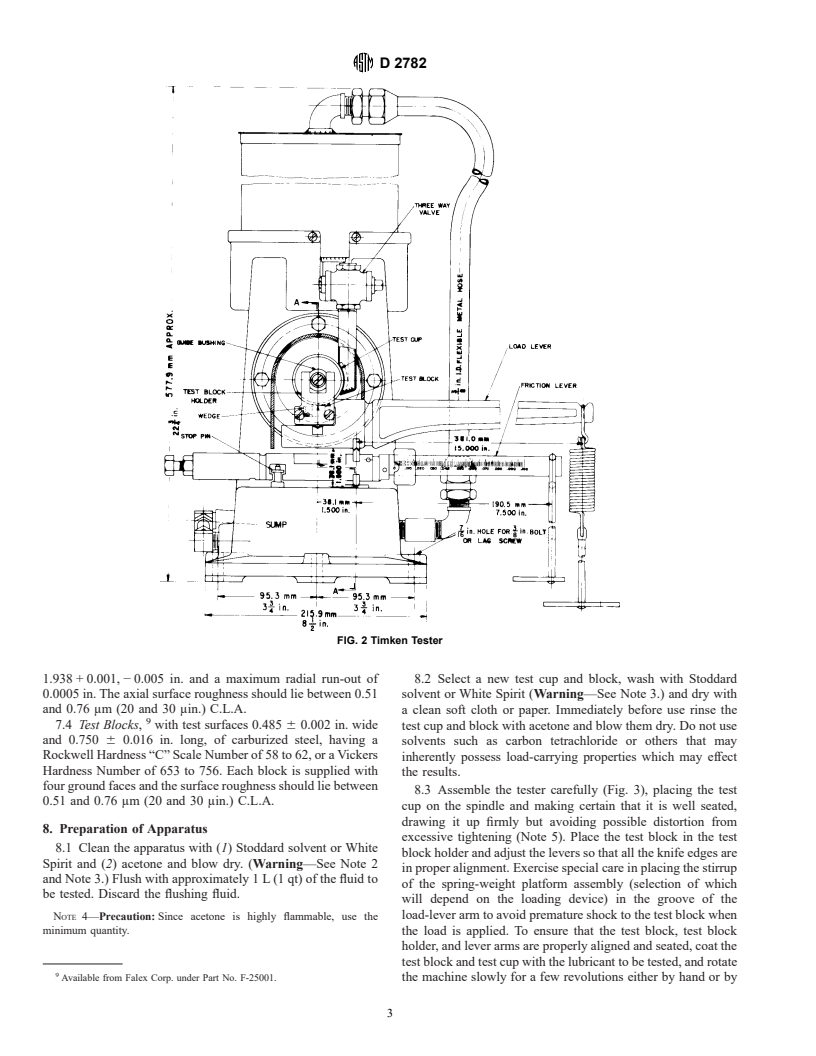

6.1 Timken Extreme Pressure Tester, described in detail in

shows local damage that usually extends beyond the width of

Annex A1 and illustrated in Fig. 2.

the scar. Scratches or striations that occur in an otherwise 6

6.2 Sample Feed Device, for supplying the test specimens

smooth scar and that do not extend beyond the width of the scar

with fluid is described in Annex A1.

are not considered as evidence of scoring. 6

6.3 Loading Mechanism, for applying and removing the

3.2.4 seizure or asperity welding—localized fusion of metal

load weights without shock at the uniform rate of 0.91 to 1.36

between the rubbing surfaces of the test pieces. Seizure is

kg/s (2 to 3 lb/s). A detailed description is given in Annex A1.

usually indicated by streaks appearing on the surface of the test

6.4 Microscope, low-power (503 to 603) having suffi-

cup, an increase in friction and wear, or unusual noise and

cient clearance under objective to accommodate the test block.

vibration. Throughout this test method the term seizure is

It should be fitted with a filar micrometer so that the scar width

understood to mean seizure or asperity welding.

may be measured with an accuracy of6 0.05 mm (60.002 in.).

6.5 Timer, graduated in minutes and seconds.

4. Summary of Test Method

4.1 The tester is operated with a steel test cup rotating

7. Reagents and Materials

against a steel test block. The rotating speed is 123.71 6 0.77

7.1 Acetone, conforming to Specification D 329.

m/min (405.88 6 2.54 ft/min) which is equivalent to a spindle

NOTE 2—Warning: Extremely flammable. Harmful when inhaled. See

speed of 800 6 5 rpm. Fluid samples are preheated to 37.8 6

A3.1.

2.8°C (100 6 5°F) before starting the test.

4.2 Two determinations are made: the minimum load (score 7.2 Stoddard Solvent or White Spirit, conforming to Speci-

fication D 235.

value) that will rupture the lubricant film being tested between

the rotating cup and the stationary block and cause scoring or

NOTE 3—Warning: Flammable. See A3.2.

seizure; and the maximum load (OK value) at which the

7.3 Test Cups, of carburized steel, having a Rockwell

rotating cup will not rupture the lubricant film and cause

Hardness “C” Scale Number of 58 to 62, or a Vickers Hardness

scoring or seizure between the rotating cup and the stationary

Number of 653 to 756. The cups have a width of 0.514 6 0.002

block.

in., a perimeter of 6.083 6 0.009 in., a diameter of

5. Significance and Use

5.1 This test method is used widely for the determination of

Falex Corp., 1020 Airpark Dr., Sugar Grove, IL 60554 is a satisfactory source

extreme pressure properties for specification purposes. Users

of supply.

are cautioned to carefully consider the precision and bias

Available from Falex Corp., 1020 Airpark Dr., Sugar Grove, IL 60554, under

statements herein when establishing specification limits. Part No. F-25061.

D 2782

FIG. 2 Timken Tester

1.938 + 0.001, − 0.005 in. and a maximum radial run-out of 8.2 Select a new test cup and block, wash with Stoddard

0.0005 in. The axial surface roughness should lie between 0.51 solvent or White Spirit (Warning—See Note 3.) and dry with

and 0.76 μm (20 and 30 μin.) C.L.A. a clean soft cloth or paper. Immediately before use rinse the

7.4 Test Blocks, with test surfaces 0.485 6 0.002 in. wide

test cup and block with acetone and blow them dry. Do not use

and 0.750 6 0.016 in. long, of carburized steel, having a solvents such as carbon tetrachloride or others that may

Rockwell Hardness “C” Scale Number of 58 to 62, or a Vickers

inherently possess load-carrying properties which may effect

Hardness Number of 653 to 756. Each block is supplied with

the results.

four ground faces and the surface roughness should lie between

8.3 Assemble the tester carefully (Fig. 3), placing the test

0.51 and 0.76 μm (20 and 30 μin.) C.L.A.

cup on the spindle and making certain that it is well seated,

drawing it up firmly but avoiding possible distortion from

8. Preparation of Apparatus

excessive tightening (Note 5). Place the test block in the test

8.1 Clean the apparatus with (1) Stoddard solvent or White

block holder and adjust the levers so that all the knife edges are

Spirit and (2) acetone and blow dry. (Warning—See Note 2

in proper alignment. Exercise special care in placing the stirrup

and Note 3.) Flush with approximately 1 L (1 qt) of the fluid to

of the spring-weight platform assembly (selection of which

be tested. Discard the flushing fluid.

will depend on the loading device) in the groove of the

load-lever arm to avoid premature shock to the test block when

NOTE 4—Precaution: Since acetone is highly flammable, use the

minimum quantity. the load is applied. To ensure that the test block, test block

holder, and lever arms are properly aligned and seated, coat the

test block and test cup with the lubricant to be tested, and rotate

Available from Falex Corp. under Part No. F-25001. the machine slowly for a few revolutions either by hand or by

D 2782

FIG. 2 (continued)

located in the tester reservoir or by heating the fluid prior to filling the

reservoir. If an immersion heater is used, localized overheating must be

avoided. This may be done by stirring or by circulating prior to the

assembly of the lever arm.

OTE 7—Fluids having a viscosity above about 5000 cSt (5000 mm /s)

N

at 40°C often cannot be tested at the prescribed fluid temperature of 37.8

6 2.8°C (100 6 5°F) because of inability of the pump to recirculate the

fluid at this temperature. However, results from limited cooperative tests,

covered in Tables A1.1 and A1.2, indicate that the starting fluid tempera-

ture could be increased to 65.6°C (150°F) to obtain adequate flow without

affecting OK or score values. Testing of such high-viscosity fluids at room

temperature in the Test Method D 2509 grease feeder also appears valid

but may be difficult because of fluid leakage.

FIG. 3 Assembly of Tester Showing Test Pieces

9.2 Set the discharge valve at full open. Allow the lubricant

to flood the test cup and block. When the sump is about half

suitable control mechanism. When the parts are in alignment,

filled with the fluid, start the motor and run for 30 s to break-in.

the fluid will be wiped off the cup over its entire width.

If the equipment used is equipped with acceleration control,

NOTE 5—At this point it is recommended that a dial indicator used to start the motor and increase the spindle speed gradually to

check the radial run-out of the cup in situ not exceed 0.025 mm (0.001 in.)

achieve 800 6 5 rpm after 15 s. Run for a further 15 s to

total indicator movement.

complete the break-in.

9.3 After a break-in period of 30 s, start the timer and apply

9. Procedure

at 8.9 to 13.3 N/s (2 to 3 lbf/s), a load that is less than the

9.1 Fill the reservoir of the tester to within 76 mm (3 in.) of

expected score load. In the absence of a better estimate, a

the top (approximately 3 L or 3 qt) with the fluid to be tested.

starting load of 30 lbf is recommended. The load-lever arm,

Preheat the fluid to 37.8 6 2.8°C (100 6 5°F).

spring-weight platform assembly is not considered a part of the

NOTE 6—The fluid may be heated by the use of an immersion heater applied load. In the event a lower starting load is used, it must

D 2782

be a multiple of 6. Then allow the machine to run at 800 6 5 the width of the scars on those blocks which successfully

rpm for 10 min 6 15 s after load application is initiated, unless carried this load. Make all measurements to 0.05 mm (0.002

a score is detected before that period. in.). Calculate the contact pressure, C, as follows:

9.4 If, after the load has been applied, scoring is evident by

C, psi 5 @L~X 1 G!#/YZ or @20~X 1 G!#/Z (1)

vibration or noise, stop the tester at once, turn off the flow of

C, MPa 5 9.81@L~X8 1 0.454G!#/Y8Z8 (2)

lubricant, and remove the load. Since the excessive heat

developed with deep scoring may alter the surface character-

where:

istics of the entire block, discard the test block.

L 5 mechanical advantage of load-lever arm, 10,

G 5 load-lever constant (value is stamped on lever arm of

NOTE 8—Precaution: The machine and test pieces may be hot at this

each tester),

point and care should be exercised in their handling.

X 5 mass (weight) placed on the weight pan, lb,

9.5 If no scoring is detected, allow the tester to run for 10

X8 5 mass (weight) placed on the weight pan, kg,

min 6 15 s from the start of the application of the load. At the

Y 5 length of test scar ( 1 2 in.),

/

end of the 10-min 6 15-s period, reverse the loading device

Y8 5 length of test scar (12.7 mm),

and remove the load from the lever arm. Turn off the motor,

Z 5 average width of test scar, in., and

allow the spindle to come to rest, then turn off the flow of fluid.

Z8 5 average width of test scar, mm.

Remove the load lever and inspect the condition of the test

10.2 For convenience, contact (unit) pressures in pounds per

block surface at 13 magnification. Microscopical observations

square inch are listed in Table X3.1.

shall not be used to define when scoring has occurred. The

11. Report

lubricant has failed at the imposed load if the wear scar

indicates any scoring or welding. 11.1 Report the OK and score values in terms of the mass

(weights) placed on the weight pan hanging from the end of the

NOTE 9—A microscope may be used to examine the wear scar for

load-lever arm; do not include the mass (weight) of the pan

further information as required in 10.2

assembly. Report the values in multiples of 5 lb above 30 lb

9.6 If no score is observed, turn the test block to expose a

and in multiples of 3 lb below 30 lb.

new surface of contact and, with a new test

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.