ASTM E633-00(2005)

(Guide)Standard Guide for Use of Thermocouples in Creep and Stress-Rupture Testing to 1800°F (1000°C) in Air

Standard Guide for Use of Thermocouples in Creep and Stress-Rupture Testing to 1800°F (1000°C) in Air

SIGNIFICANCE AND USE

This guide presents techniques on the use of thermocouples and associated equipment for measuring temperature in creep and stress-rupture testing in air at temperatures up to 1800°F (1000°C).

Since creep and stress-rupture properties are highly sensitive to temperature, users should make every effort practicable to make accurate temperature measurements and provide stable control of the test temperature. The goal of this guide is to provide users with good pyrometric practice and techniques for precise temperature control for creep and stress-rupture testing.

Techniques are given in this guide for maintaining a stable temperature throughout the period of test.

If the techniques of this guide are followed, the difference between “indicated”3 temperature and “true”4 temperature will be reduced to the lowest practical level.

SCOPE

1.1 This guide covers the use of ANSI thermocouple Types K, N, R, and S for creep and stress-rupture testing at temperatures up to 1800°F (1000°C) in air at one atmosphere of pressure. It does not cover the use of sheathed thermocouples.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E633 − 00(Reapproved 2005)

Standard Guide for

Use of Thermocouples in Creep and Stress-Rupture Testing

to 1800°F (1000°C) in Air

This standard is issued under the fixed designation E633; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This guide provides basic information, options, and guidelines to enable the user to apply

thermocouples, temperature measurement, and control equipment with sufficient accuracy to satisfy

the temperature requirements for creep and stress-rupture testing of materials.

1. Scope E344Terminology Relating to Thermometry and Hydrom-

etry

1.1 This guide covers the use ofANSI thermocouple Types

E574Specification for Duplex, Base Metal Thermocouple

K, N, R, and S for creep and stress-rupture testing at tempera-

Wire With Glass Fiber or Silica Fiber Insulation

tures up to 1800°F (1000°C) in air at one atmosphere of

E1129/E1129MSpecification for Thermocouple Connectors

pressure. It does not cover the use of sheathed thermocouples.

E1684Specification for Miniature Thermocouple Connec-

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

tors

as the standard. The values given in parentheses are for

information only. 3. Terminology

1.3 This standard does not purport to address all of the 3.1 Definitions—Unless otherwise indicated, the definitions

safety concerns, if any, associated with its use. It is the

given in Terminology E344 shall apply.

responsibility of the user of this standard to establish appro-

4. Classification

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 4.1 The following thermocouple types are identified in

Tables E230:

2. Referenced Documents

4.1.1 Type K—Nickel—10 % chromium ( + ) versus

nickel—5% (aluminum, silicon) (−),

2.1 ASTM Standards:

4.1.2 Type N—Nickel—14% chromium, 1.5% silicon (+)

E139Test Methods for Conducting Creep, Creep-Rupture,

versus nickel—4.5% silicon—0.1% magnesium (−),

and Stress-Rupture Tests of Metallic Materials

4.1.3 Type R—Platinum—13% rhodium (+) versus plati-

E207TestMethodforThermalEMFTestofSingleThermo-

num (−),

element Materials by Comparison with a Reference Ther-

4.1.4 Type S—Platinum—10% rhodium (+) versus plati-

moelement of Similar EMF-Temperature Properties

num (−).

E220Test Method for Calibration of Thermocouples By

Comparison Techniques

5. Summary of Guide

E230Specification and Temperature-Electromotive Force

5.1 This guide will help the user to conduct a creep or

(EMF) Tables for Standardized Thermocouples

stress-rupture test with the highest degree of temperature

E292Test Methods for ConductingTime-for-Rupture Notch

precision available. It provides information on the proper

Tension Tests of Materials

application of thermocouples that are used to measure and

control the temperature of the test specimen. It also points out

This guide is under the jurisdiction of ASTM Committee E28 on Mechanical

sources of error and suggests methods to eliminate them.

TestingandisthedirectresponsibilityofSubcommitteeE28.04onUniaxialTesting.

Current edition approved May 1, 2005. Published May 2005. Originally

6. Significance and Use

approved in 1987. Last previous edition approved in 2000 as E633–00. DOI:

10.1520/E0633-00R05.

6.1 This guide presents techniques on the use of thermo-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

couples and associated equipment for measuring temperature

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in creep and stress-rupture testing in air at temperatures up to

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 1800°F (1000°C).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E633 − 00 (2005)

6.2 Since creep and stress-rupture properties are highly knownprimaryteststandard,traceabletotheNationalInstitute

sensitive to temperature, users should make every effort of Standards and Technology.

practicable to make accurate temperature measurements and

7.3 Temperature Control Equipment Requirements—Atem-

provide stable control of the test temperature. The goal of this

perature controller or temperature control system should be

guide is to provide users with good pyrometric practice and

selectedonthebasisofstability(variationsof 61°F(0.5°C)or

techniques for precise temperature control for creep and

less), and accuracy (uncertainty of 61.5°F (0.7°C) or less).

stress-rupture testing.

Generally, a control system with proportional band, automatic

6.3 Techniques are given in this guide for maintaining a

reset, and slow approach to final set point features should be

stable temperature throughout the period of test.

used. When employing an automatic feedback control system,

the tuning constants or control algorithm shall be optimized,

6.4 If the techniques of this guide are followed, the differ-

3 4

not only to maintain the test specimen at the set point without

ence between “indicated” temperature and “true” tempera-

excessive deviations, but to eliminate or limit the amount of

ture will be reduced to the lowest practical level.

overshoot upon initial heating.

7. Apparatus

NOTE 1—The same precautions regarding reference junction compen-

7.1 Instrumentation may be individual instruments, a data sation in the control device apply as in 7.2.1.

acquisition system (multipoint recorders or digital type), a

7.3.1 Configuration—The control configuration may take

computer-based control system, or a combination of these

one of several forms:

devices. (Warning—Since each thermocouple is “grounded”

7.3.1.1 The center thermocouple is connected to a control

by contacting the specimen, it is necessary that the instrumen-

loopthatstrivestomaintainthetemperatureofthecenterofthe

tationtreateachthermocoupleasisolatedor“floating”fromall

reduced section at set point. The upper and lower thermo-

other thermocouples. Neither leg should be connected to a

couplesareusedtomeasurethetemperaturesattheendsofthe

commongroundattheinstrumentationendofthesystem.Also,

reduced section. Means shall be provided to adjust the heating

equipment having a high common mode rejection ratio is

poweraboveandbelowthecentertoequalizethetemperatures.

necessary because of the proximity of strong electromagnetic

7.3.1.2 The bottom and top thermocouples may be con-

fields from the heating elements of the furnace.)

nectedtocontrolloopsthatregulatethepowertotheupperand

7.2 Temperature Measurement Instrumentation—The mea-

lower heaters independently. Thus, the end temperatures are

surement system should be able to resolve the thermocouple

maintained automatically. The center thermocouple is used

signal to 60.1°F (0.05°C). The temperature indication should

only as a monitor.

havenomorethan 61.0°F(0.5°C)uncertaintyforthepurposes

7.3.2 Control System Recalibration and Reliability—The

of this test. In addition, where specific corrections for the

control system should be subjected to routine recalibration, as

calibration of individual thermocouples or a thermocouple lot

circumstances and type of equipment dictate. The checking

is required, the capability of the instrumentation system to

procedure should include calibration of the controller and a

accommodate these data shall be considered.

sensitivity check. A calibration circuit, as shown in Appendix

7.2.1 Reference Junction Compensation:

X1, should be employed.

7.2.1.1 Thermocouples are usually calibrated to a 32°F

7.4 Heating Equipment—Furnaces should be appropriately

(0°C) reference temperature. Unless an ice point reference is

sized or adjusted relative to the workload and heat losses to

used, some means must be provided to compensate for the

provide a zone of uniform temperature across the specimen.

temperature where the thermoelectric circuit connects to the

Because creep and stress-rupture testing is usually done at

instrument (refer to MNL-12 on Reference Junctions ).

constanttemperatureandwithanunchangingfurnaceload,the

7.2.1.2 Reference junction compensation is usually per-

main requirement is a well-insulated furnace, capable of

formed within the instrumentation itself. Most devices or

achieving the desired temperatures. The top and bottom open-

electronic data acquisition systems measure the temperature

ings should be closed to limit convection losses, but the

where the thermoelements connect to the input terminals and

furnace should not be sealed airtight.

introduce a compensating emf to simulate the ice point.

7.2.1.3 The input connections shall be isothermal and

8. Hazards

shielded from sudden changes of temperature.

7.2.2 Recalibration—The accuracy of the temperature mea-

8.1 The duration of a creep test ranges from a few hours to

surement equipment may be affected by component aging,

several hundred hours at elevated temperatures, at least par-

environment, handling, or wear. Therefore, a periodic recali-

tially unattended by operators. Such tests are normally ended

bration of the measuring instrumentation with a checking

beforetestspecimenfailure.Stress-rupturetestsmayoperateat

instrument is necessary. The checking instrument should be of

higher stresses, higher temperatures, and for shorter times than

higher accuracy than the measurement system, and to ensure

creep tests, but they normally continue until the specimen has

conformity to national standards, it should be calibrated with a

achieved its required life or has failed.

8.2 The stability of the emf of the thermocouples and the

As defined in Practice E139 and Test Methods E292.

rapid response of the control system to any changes of

As defined in Practice E139.

temperature over the period of the test are crucial to maintain

Manual on the Use of Thermocouples in Temperature Measurement, ASTM

MNL-12. the specimen within the allowable temperature band.

E633 − 00 (2005)

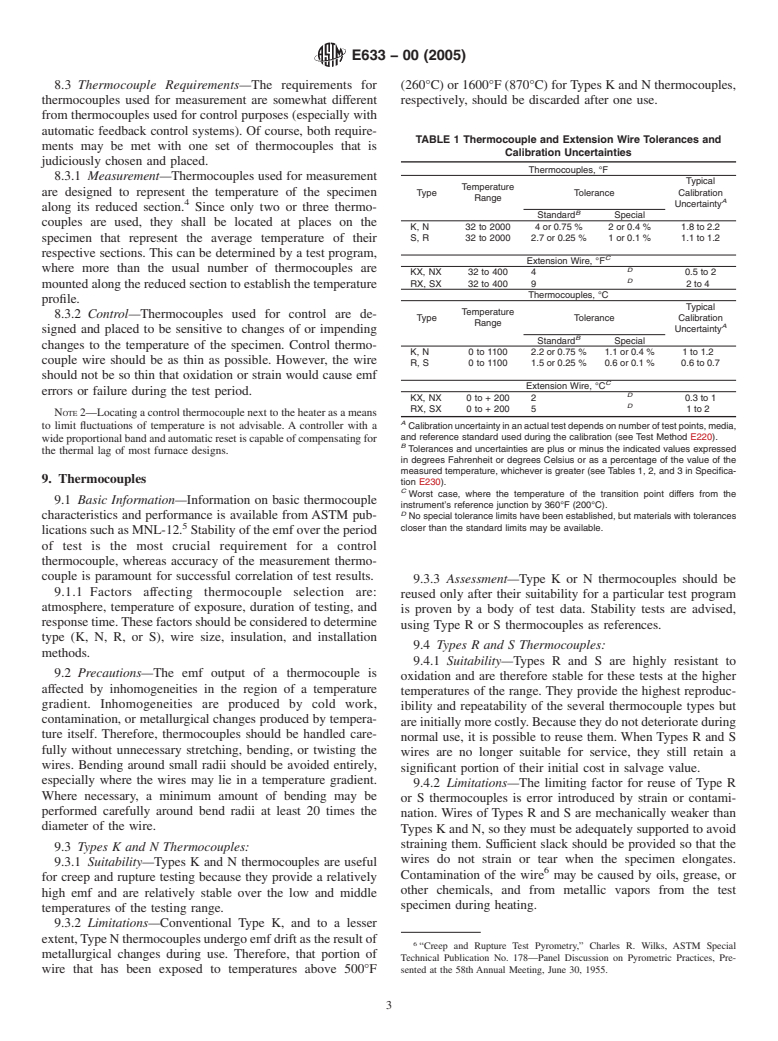

8.3 Thermocouple Requirements—The requirements for (260°C) or 1600°F (870°C) forTypes K and N thermocouples,

thermocouples used for measurement are somewhat different respectively, should be discarded after one use.

from thermocouples used for control purposes (especially with

automatic feedback control systems). Of course, both require-

TABLE 1 Thermocouple and Extension Wire Tolerances and

ments may be met with one set of thermocouples that is

Calibration Uncertainties

judiciously chosen and placed.

Thermocouples, °F

8.3.1 Measurement—Thermocouples used for measurement

Typical

Temperature

are designed to represent the temperature of the specimen Type Tolerance Calibration

Range

A

Uncertainty

along its reduced section. Since only two or three thermo-

B

Standard Special

couples are used, they shall be located at places on the

K, N 32 to 2000 4 or 0.75 % 2 or 0.4 % 1.8 to 2.2

specimen that represent the average temperature of their S, R 32 to 2000 2.7 or 0.25 % 1 or 0.1 % 1.1 to 1.2

respective sections. This can be determined by a test program,

C

Extension Wire, °F

where more than the usual number of thermocouples are D

KX, NX 32 to 400 4 0.5to2

D

RX, SX 32 to 400 9 2to4

mountedalongthereducedsectiontoestablishthetemperature

Thermocouples, °C

profile.

Typical

Temperature

8.3.2 Control—Thermocouples used for control are de-

Type Tolerance Calibration

Range

A

Uncertainty

signed and placed to be sensitive to changes of or impending

B

Standard Special

changes to the temperature of the specimen. Control thermo-

K, N 0 to 1100 2.2 or 0.75 % 1.1 or 0.4 % 1 to 1.2

couple wire should be as thin as possible. However, the wire

R, S 0 to 1100 1.5 or 0.25 % 0.6 or 0.1 % 0.6 to 0.7

should not be so thin that oxidation or strain would cause emf

C

Extension Wire, °C

errors or failure during the test period.

D

KX, NX 0 to + 200 2 0.3to1

D

RX, SX 0 to + 200 5 1to2

NOTE2—Locatingacontrolthermocouplenexttotheheaterasameans

A

to limit fluctuations of temperature is not advisable. A controller with a Calibration uncertainty in an actual test depends on number of test points, media,

and reference standard used during the calibration (see Test Method E220).

wideproportionalbandandautomaticresetiscapableofcompensatingfor

B

Tolerances and uncertainties are plus or minus the indicated values expressed

the thermal lag of most furnace designs.

in degrees Fahrenheit or degrees Celsius or as a percentage of the value of the

measured temperature, whichever is greater (see Tables 1, 2, and 3 in Specifica-

9. Thermocouples

tion E230).

C

Worst case, where the temperature of the transition point differs from the

9.1 Basic Information—Information on basic thermocouple

instrument’s reference junction by 360°F (200°C).

D

characteristics and performance is available from ASTM pub- No special tolerance limits have been established, but materials with tolerances

closer than the standard limits may be available.

licationssuchasMNL-12. Stabilityoftheemfovertheperiod

of test is the most crucial requirement for a control

thermocouple, whereas accuracy of the measurement thermo-

couple is paramount for successful correlation of test results.

9.3.3 Assessment—Type K or N thermocouples should be

9.1.1 Factors affecting thermocouple selection are:

reused only after their suitability for a particular test program

atmosphere, temperature of exposure, duration of testing, and

is proven by a body of test data. Stability tests are advised,

responsetime.Thesefactorsshouldbeconsideredtodetermine

using Type R or S thermocouples as references.

type (K, N, R, or S), wire size, insulation, and installation

9.4 Types R and S Thermocouples:

methods.

9.4.1 Suitability—Types R and S are highly resistant to

9.2 Precautions—The emf output of a thermocouple is

oxidation and are therefore stable for these tests at the higher

affected by inhomogeneities in the region of a temperature

temperatures of the range. They provide the highest reproduc-

gradient. Inhomogeneities are produced by cold work,

ibility and repeatability of the several thermocouple types but

contamination, or metallurgical changes produced by tempera-

areinitiallymorecostly.Becausetheydonotdeteriorateduring

ture itself. Therefore, thermocouples should be handled care-

normal use, it is possible to reuse them. When Types R and S

fully without unnecessary stretching, bending, or twisting the

wires are no longer suitable for service, they still retain a

wires. Bending around small radii should be avoided entirely,

significant portion of their initial cost in salvage value.

especially where the wires may lie in a temperature gradient.

9.4.2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.