ASTM D8065/D8065M-16(2023)

(Specification)Standard Classification System and Basis for Specification for Specifying Plastic Films

Standard Classification System and Basis for Specification for Specifying Plastic Films

SIGNIFICANCE AND USE

4.1 The purpose of this classification system is to provide a method of adequately identifying plastic films using a system that applies universally for plastic films. It further provides a means for specifying these films by the use of a simple line call-out designation.

4.2 This classification system was developed to permit the addition of additional film products and property values.

4.3 It is intended that the classification of plastic sheeting, >0.25 mm [0.010 in.] thickness, multi-layer structures, blends, and other variants will be addressed in related standards.

SCOPE

1.1 This standard provides a classification system for tabulating the properties of unfilled, single-layer plastic films.

Note 1: The classification system serves many of the needs of industries using plastic films. The standard is subject to revision as the need requires; therefore, the latest revision should always be used.

Note 2: Film is defined in Terminology D883 as an optional term for sheeting having a nominal thickness no greater than 0.25 mm [0.010 in.].

1.2 The classification system and subsequent line call-out (specification) is intended to be a means of identifying plastic films used for applications including industrial, packaging, construction, and agriculture. It is not intended for the selection of materials to be used in films. This selection should be made by those having expertise in the plastics field after careful consideration of the end-use requirements, the environment to which the films will be exposed, the fabrication process to be employed, the inherent properties of the material not covered in this document, and the economic factors.

1.3 This classification system is based on the premise that plastic films can be arranged into broad generic families based on materials with similar composition using basic film properties. A system is thus established which, together with values describing additional requirements, permits as complete a description as desired of the selected film.

1.4 In all cases where the provisions of this classification system would conflict with the referenced ASTM specification for a particular film product, the latter shall take precedence.

Note 3: It is strongly recommended that this classification system be used for all new applications and specifications and that the specification of films using existing standards be expeditiously withdrawn or converted to this classification system.

1.5 This classification system applies to commercial products and, as such, there is no control over the manufacturing parameters employed in producing the film. It shall be the responsibility of those developing the specification documents utilizing this classification system to identify the critical parameters and values to be used for the cell classifications and suffix requirements.

1.6 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 4: There is no known ISO equivalent to this standard.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8065/D8065M − 16 (Reapproved 2023)

Standard Classification System and Basis for Specification for

Specifying Plastic Films

This standard is issued under the fixed designation D8065/D8065M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope utilizing this classification system to identify the critical

parameters and values to be used for the cell classifications and

1.1 This standard provides a classification system for tabu-

suffix requirements.

lating the properties of unfilled, single-layer plastic films.

1.6 Units—The values stated in either SI units or inch-

NOTE 1—The classification system serves many of the needs of

pound units are to be regarded separately as standard. The

industries using plastic films. The standard is subject to revision as the

values stated in each system may not be exact equivalents;

need requires; therefore, the latest revision should always be used.

therefore, each system shall be used independently of the other.

NOTE 2—Film is defined in Terminology D883 as an optional term for

Combining values from the two systems may result in non-

sheeting having a nominal thickness no greater than 0.25 mm [0.010 in.].

conformance with the standard.

1.2 The classification system and subsequent line call-out

1.7 This standard does not purport to address all of the

(specification) is intended to be a means of identifying plastic

safety concerns, if any, associated with its use. It is the

films used for applications including industrial, packaging,

responsibility of the user of this standard to establish appro-

construction, and agriculture. It is not intended for the selection

priate safety, health, and environmental practices and deter-

of materials to be used in films. This selection should be made

mine the applicability of regulatory limitations prior to use.

by those having expertise in the plastics field after careful

consideration of the end-use requirements, the environment to

NOTE 4—There is no known ISO equivalent to this standard.

which the films will be exposed, the fabrication process to be

1.8 This international standard was developed in accor-

employed, the inherent properties of the material not covered

dance with internationally recognized principles on standard-

in this document, and the economic factors.

ization established in the Decision on Principles for the

1.3 This classification system is based on the premise that

Development of International Standards, Guides and Recom-

plastic films can be arranged into broad generic families based mendations issued by the World Trade Organization Technical

on materials with similar composition using basic film prop-

Barriers to Trade (TBT) Committee.

erties. A system is thus established which, together with values

describing additional requirements, permits as complete a 2. Referenced Documents

description as desired of the selected film.

2.1 ASTM Standards:

D149 Test Method for Dielectric Breakdown Voltage and

1.4 In all cases where the provisions of this classification

Dielectric Strength of Solid Electrical Insulating Materials

system would conflict with the referenced ASTM specification

at Commercial Power Frequencies

for a particular film product, the latter shall take precedence.

D150 Test Methods for AC Loss Characteristics and Permit-

NOTE 3—It is strongly recommended that this classification system be

tivity (Dielectric Constant) of Solid Electrical Insulation

used for all new applications and specifications and that the specification

D257 Test Methods for DC Resistance or Conductance of

of films using existing standards be expeditiously withdrawn or converted

Insulating Materials

to this classification system.

D774/D774M Test Method for Bursting Strength of Paper

1.5 This classification system applies to commercial prod-

(Withdrawn 2010)

ucts and, as such, there is no control over the manufacturing

D882 Test Method for Tensile Properties of Thin Plastic

parameters employed in producing the film. It shall be the

Sheeting

responsibility of those developing the specification documents

D883 Terminology Relating to Plastics

D1003 Test Method for Haze and Luminous Transmittance

of Transparent Plastics

This standard is under the jurisdiction of ASTM Committee D20 on Plastics

D1004 Test Method for Tear Resistance (Graves Tear) of

and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and

Molded Products.

Current edition approved Nov. 1, 2023. Published November 2023. Originally

approved in 2016. Last previous edition approved in 2016 as D8065/D8065M – 16. The last approved version of this historical standard is referenced on

DOI: 10.1520/D8065_D8065M-16R23. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D8065/D8065M − 16 (2023)

Plastic Film and Sheeting D6988 Guide for Determination of Thickness of Plastic Film

D1203 Test Methods for Volatile Loss from Plastics Using Test Specimens

D7192 Test Method for High Speed Puncture Properties of

Activated Carbon Methods

D1204 Test Method for Linear Dimensional Changes of Plastic Films Using Load and Displacement Sensors

D7209 Guide for Waste Reduction, Resource Recovery, and

Nonrigid Thermoplastic Sheeting or Film at Elevated

Use of Recycled Polymeric Materials and Products (With-

Temperature

drawn 2015)

D1239 Test Method for Resistance of Plastic Films to

E29 Practice for Using Significant Digits in Test Data to

Extraction by Chemicals

Determine Conformance with Specifications

D1434 Test Method for Determining Gas Permeability Char-

E96/E96M Test Methods for Gravimetric Determination of

acteristics of Plastic Film and Sheeting

Water Vapor Transmission Rate of Materials

D1709 Test Methods for Impact Resistance of Plastic Film

F88/F88M Test Method for Seal Strength of Flexible Barrier

by the Free-Falling Dart Method

Materials

D1746 Test Method for Transparency of Plastic Sheeting

D1790 Test Method for Brittleness Temperature of Plastic

3. Terminology

Sheeting by Impact

3.1 Definitions—The definitions used in this classification

D1894 Test Method for Static and Kinetic Coefficients of

system are in accordance with Terminology D883.

Friction of Plastic Film and Sheeting (Withdrawn 2023)

D1922 Test Method for Propagation Tear Resistance of

4. Significance and Use

Plastic Film and Thin Sheeting by Pendulum Method

4.1 The purpose of this classification system is to provide a

D1938 Test Method for Tear-Propagation Resistance (Trou-

method of adequately identifying plastic films using a system

ser Tear) of Plastic Film and Thin Sheeting by a Single-

that applies universally for plastic films. It further provides a

Tear Method

means for specifying these films by the use of a simple line

D2176 Test Method for Folding Endurance of Paper and

call-out designation.

Plastics Film by the M.I.T. Tester

D2275 Test Method for Voltage Endurance of Solid Electri-

4.2 This classification system was developed to permit the

cal Insulating Materials Subjected to Partial Discharges

addition of additional film products and property values.

(Corona) on the Surface

4.3 It is intended that the classification of plastic sheeting,

D2305 Test Methods for Polymeric Films Used for Electri-

>0.25 mm [0.010 in.] thickness, multi-layer structures, blends,

cal Insulation

and other variants will be addressed in related standards.

D2457 Test Method for Specular Gloss of Plastic Films and

Solid Plastics 5. Classification

D2578 Test Method for Wetting Tension of Polyethylene and

5.1 Films shall be classified by their generic polymer

Polypropylene Films

composition, specific sub-group, type, and other defining

D2582 Test Method for Puncture-Propagation Tear Resis-

characteristics as shown in the following examples.

tance of Plastic Film and Thin Sheeting

NOTE 5—It should be emphasized that the scope of the following

D2732 Test Method for Unrestrained Linear Thermal

examples and tables are not limited to the information shown and can be

Shrinkage of Plastic Film and Sheeting

supplemented to include additional materials, descriptors, properties, etc.

D2838 Test Method for Shrink Tension and Orientation

as needed.

Release Stress of Plastic Film and Thin Sheeting

5.2 Generic classification shall follow the examples shown

D2923 Test Method for Rigidity of Polyolefin Film and

in Table 1 or, in accordance with D883, followed by the letter

Sheeting (Withdrawn 2015)

“F” for film.

D3354 Test Method for Blocking Load of Plastic Film by the

5.3 If applicable, the film is further classified by sub-groups

Parallel Plate Method

and types identified by a single-digit numerical codes as shown

D3417 Test Method for Enthalpies of Fusion and Crystalli-

by the examples described in Tables 2-4.

zation of Polymers by Differential Scanning Calorimetry

(DSC) (Withdrawn 2004) 5.4 The film shall be further classified with two single digits

D3420 Test Method for Pendulum Impact Resistance of to describe the process used to manufacture the film and the

Plastic Film film gauge as shown by the examples shown in Table 5.

D3801 Test Method for Measuring the Comparative Burning

NOTE 6—Example (1), a Low density Polyethylene blown film, nominal

Characteristics of Solid Plastics in a Vertical Position

gauge of 15 μ –PEF3011.

D3892 Practice for Packaging/Packing of Plastics

D3985 Test Method for Oxygen Gas Transmission Rate

TABLE 1 Examples of Generic Classifications (Based on Existing

Through Plastic Film and Sheeting Using a Coulometric

Standards)

Sensor

Generic Classifications

D4272/D4272M Test Method for Total Energy Impact of

PE Polythylene

PP Polypropylene

Plastic Films by Dart Drop

PET Poly(ethylene terephthalate)

D5946 Test Method for Corona-Treated Polymer Films Us-

PVC Poly(vinyl chloride)

ing Water Contact Angle Measurements

D8065/D8065M − 16 (2023)

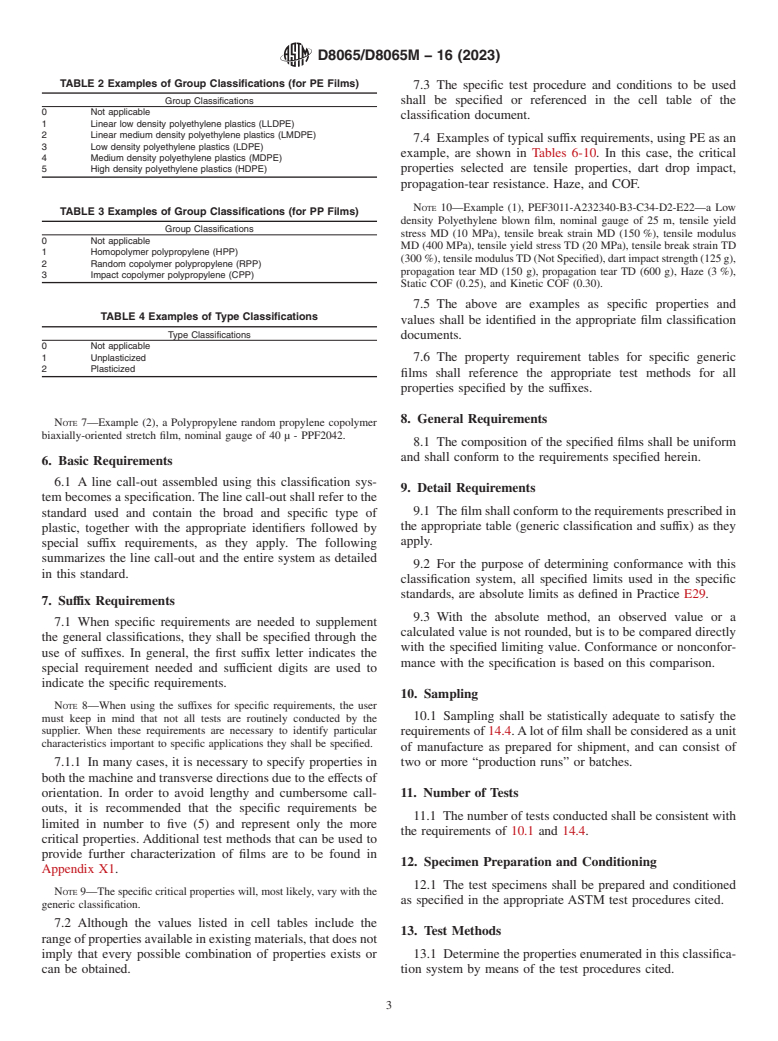

TABLE 2 Examples of Group Classifications (for PE Films)

7.3 The specific test procedure and conditions to be used

Group Classifications shall be specified or referenced in the cell table of the

0 Not applicable

classification document.

1 Linear low density polyethylene plastics (LLDPE)

2 Linear medium density polyethylene plastics (LMDPE)

7.4 Examples of typical suffix requirements, using PE as an

3 Low density polyethylene plastics (LDPE)

example, are shown in Tables 6-10. In this case, the critical

4 Medium density polyethylene plastics (MDPE)

5 High density polyethylene plastics (HDPE) properties selected are tensile properties, dart drop impact,

propagation-tear resistance. Haze, and COF.

NOTE 10—Example (1), PEF3011-A232340-B3-C34-D2-E22—a Low

TABLE 3 Examples of Group Classifications (for PP Films)

density Polyethylene blown film, nominal gauge of 25 m, tensile yield

Group Classifications

stress MD (10 MPa), tensile break strain MD (150 %), tensile modulus

0 Not applicable

MD (400 MPa), tensile yield stress TD (20 MPa), tensile break strain TD

1 Homopolymer polypropylene (HPP)

(300 %), tensile modulus TD (Not Specified), dart impact strength (125 g),

2 Random copolymer polypropylene (RPP)

propagation tear MD (150 g), propagation tear TD (600 g), Haze (3 %),

3 Impact copolymer polypropylene (CPP)

Static COF (0.25), and Kinetic COF (0.30).

7.5 The above are examples as specific properties and

TABLE 4 Examples of Type Classifications

values shall be identified in the appropriate film classification

Type Classifications

documents.

0 Not applicable

1 Unplasticized

7.6 The property requirement tables for specific generic

2 Plasticized

films shall reference the appropriate test methods for all

properties specified by the suffixes.

8. General Requirements

NOTE 7—Example (2), a Polypropylene random propylene copolymer

biaxially-oriented stretch film, nominal gauge of 40 μ - PPF2042.

8.1 The composition of the specified films shall be uniform

and shall conform to the requirements specified herein.

6. Basic Requirements

6.1 A line call-out assembled using this classification sys-

9. Detail Requirements

tem becomes a specification. The line call-out shall refer to the

9.1 The film shall conform to the requirements prescribed in

standard used and contain the broad and specific type of

the appropriate table (generic classification and suffix) as they

plastic, together with the appropriate identifiers followed by

apply.

special suffix requirements, as they apply. The following

summarizes the line call-out and the entire system as detailed

9.2 For the purpose of determining conformance with this

in this standard.

classification system, all specified limits used in the specific

standards, are absolute limits as defined in Practice E29.

7. Suffix Requirements

9.3 With the absolute method, an observed value or a

7.1 When specific requirements are needed to supplement

calculated value is not rounded, but is to be compared directly

the general classifications, they shall be specified through the

with the specified limiting value. Conformance or nonconfor-

use of suffixes. In general, the first suffix letter indicates the

mance with the specification is based on this comparison.

special requirement needed and sufficient digits are used to

indicate the specific requirements.

10. Sampling

NOTE 8—When using the suffixes for specific requirements, the user

10.1 Sampling shall be statistically adequate to satisfy the

must keep in mind that not all tests are routinely conducted by the

supplier. When these requirements are necessary to identify particular

requirements of 14.4. A lot of film shall be considered as a unit

characteristics important to specific applications they shall be specified.

of manufacture as prepared for shipment, and can consist of

7.1.1 In many cases, it is necessary to specify properties in two or more “production runs” or batches.

both the machine and transverse directions due to the effects of

orientation. In order to avoid lengthy and cumbersome call- 11. Number of Tests

outs, it is recommended that the specific requirements be

11.1 The number of tests conducted shall be consistent with

limited in number to five (5) and represent only the more

the requirements of 10.1 and 14.4.

critical properties. Additional test methods that can be used to

provide further characterization of films are to be found in

12. Specimen Preparation and Conditioning

Appendix X1.

12.1 The test specimens shall be prepared and conditioned

NOTE 9—The specific critical properties will, most likely, vary with the

as specified in the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.