ASTM D1447-07(2012)e1

(Test Method)Standard Test Method for Length and Length Uniformity of Cotton Fibers by Photoelectric Measurement

Standard Test Method for Length and Length Uniformity of Cotton Fibers by Photoelectric Measurement

SIGNIFICANCE AND USE

This test method is considered satisfactory for acceptance testing when the levels of the laboratories are controlled by the use of the same reference standard cotton samples because the current estimates of between-laboratory precision are acceptable under these conditions. If there are differences of practical significance between reported test results for two laboratories (or more), comparative tests should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, ensure the test samples to be used are as homogeneous as possible, are drawn from the material from which the disparate test results were obtained, and are randomly assigned in equal numbers to each laboratory for testing. The test from the two laboratories should be compared using a statistical test for unpaired data, at a probability level chosen prior to the testing series. If a bias is found, either its cause must be found and corrected, or future test results for that material must be adjusted in consideration of the known bias.

Fibrograph measurements provide a relatively fast method for determining the length and length uniformity of the fibers in a sample of cotton in a reproducible manner.

Results of the Fibrograph length tests do not necessarily agree with those obtained by other methods for measuring lengths of cotton fibers because of the effect of fiber crimp and other factors.

Fibrograph tests are more objective than commercial staple length classifications and also provide additional information on fiber length uniformity of cotton fibers. The cotton quality information provided by these results is used in research studies and quality surveys, in checking commercial staple length classifications, in assembling bales of cotton into uniform lots, and for other purposes.

Fibrograph measurements are based on the assumptions that a fiber is caught randomly along its length.

SCOPE

1.1 This test method covers the measurement of the length and length uniformity of cotton fibers by use of photoelectric measurement. The test method is applicable to fibers taken from raw or partially processed cotton (up to card mat) or some types of cotton waste, but not to fibers from blends of cotton with other fibers or to fibers recovered from cotton yarns, fabrics or to 100 % synthetic fibers.

1.2 This test method is especially adapted for determining the length and length uniformity of cotton fibers by models of the Digital Fibrograph, hereafter referred to as Fibrograph.

Note 1—Instructions for the use of Manual and Servo Fibrograph Models were included in the text of Test Method D1447 in 1971 and previous editions.

Note 2—For other methods covering the measurement of the length of cotton fibers refer to Test Method D1440.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D1447 − 07 (Reapproved 2012)

Standard Test Method for

Length and Length Uniformity of Cotton Fibers by

Photoelectric Measurement

This standard is issued under the fixed designation D1447; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—The terminology section was updated in July 2012.

1. Scope D3025 Practice for Standardizing Cotton Fiber Test Results

by Use of Calibration Cotton Standards

1.1 This test method covers the measurement of the length

D7139 Terminology for Cotton Fibers

and length uniformity of cotton fibers by use of photoelectric

measurement. The test method is applicable to fibers taken

3. Terminology

fromraworpartiallyprocessedcotton(uptocardmat)orsome

types of cotton waste, but not to fibers from blends of cotton

3.1 For all terminology related to D13.11, refer to Termi-

with other fibers or to fibers recovered from cotton yarns,

nology D7139.

fabrics or to 100 % synthetic fibers.

3.1.1 The following terms are relevant to this standard:

fibrogram, mean length, uniformity index, upper-half-mean

1.2 This test method is especially adapted for determining

length.

the length and length uniformity of cotton fibers by models of

the Digital Fibrograph, hereafter referred to as Fibrograph.

3.2 For all other terminology related to textiles, refer to

NOTE 1—Instructions for the use of Manual and Servo Fibrograph

Terminology D123.

Models were included in the text of Test Method D1447 in 1971 and

previous editions.

4. Summary of Test Method

NOTE 2—For other methods covering the measurement of the length of

cotton fibers refer to Test Method D1440.

4.1 Fibers are placed on comb(s) in such a way that they are

1.3 The values stated in SI units are to be regarded as

caught at random points along their lengths to form a beard.

standard. No other units of measurement are included in this

The beard is scanned photoelectrically from base to tip, the

standard.

amount of light passing through the beard being used as a

measure of the number of fibers that extend various distances

1.4 This standard does not purport to address all of the

from the comb(s).

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4.2 The Fibrograph shows the amount and the length

priate safety and health practices and determine the applica-

readings from the Fibrogram being sensed on separate dials.

bility of regulatory limitations prior to use.

5. Significance and Use

2. Referenced Documents

5.1 This test method is considered satisfactory for accep-

2.1 ASTM Standards:

tance testing when the levels of the laboratories are controlled

D123 Terminology Relating to Textiles

by the use of the same reference standard cotton samples

D1440 Test Method for Length and Length Distribution of

because the current estimates of between-laboratory precision

Cotton Fibers (Array Method)

are acceptable under these conditions. If there are differences

D1441 Practice for Sampling Cotton Fibers for Testing

of practical significance between reported test results for two

D1776 Practice for Conditioning and Testing Textiles

laboratories (or more), comparative tests should be performed

to determine if there is a statistical bias between them, using

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

competent statistical assistance.As a minimum, ensure the test

and is the direct responsibility of Subcommittee D13.11 on Cotton Fibers.

samples to be used are as homogeneous as possible, are drawn

Current edition approved July 1, 2012. Published August 2012. Originally

ε1

from the material from which the disparate test results were

approved in 1955. Last previous edition approved in 2007 as D1447 – 07 . DOI:

10.1520/D1447-07R12E01.

obtained, and are randomly assigned in equal numbers to each

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

laboratoryfortesting.Thetestfromthetwolaboratoriesshould

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

be compared using a statistical test for unpaired data, at a

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. probability level chosen prior to the testing series. If a bias is

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D1447 − 07 (2012)

FIG. 1 Fibrosampler

found, either its cause must be found and corrected, or future 7. Sampling

test results for that material must be adjusted in consideration

7.1 Division into Lots—For acceptance testing purposes, the

of the known bias.

purchaser and the supplier shall agree on what material

5.2 Fibrograph measurements provide a relatively fast

constitutes a lot.

method for determining the length and length uniformity of the

7.2 LotSample—Asalotsampleforacceptancetesting,take

fibers in a sample of cotton in a reproducible manner.

at random the number of shipping containers directed in an

5.3 Results of the Fibrograph length tests do not necessarily

applicable material specification or other agreement between

agree with those obtained by other methods for measuring

the purchaser and the supplier, such as an agreement to use

lengths of cotton fibers because of the effect of fiber crimp and

Practice D1441.

other factors.

7.3 Laboratory Sample—As a laboratory sample for accep-

5.4 Fibrograph tests are more objective than commercial

tance testing, select and prepare a 30 to 50 g subsample from

staple length classifications and also provide additional infor-

eachoftheshippingcontainersinthelotsample,proceedingas

mation on fiber length uniformity of cotton fibers. The cotton

directed in Practice D1441 using either the blended sample

quality information provided by these results is used in

procedure or the subsample procedure as agreed between the

research studies and quality surveys, in checking commercial

purchaser and the supplier.

staple length classifications, in assembling bales of cotton into

7.4 Test Specimens—As directed in Section 10, prepare

uniform lots, and for other purposes.

either two or four specimens from each subsample in the

5.5 Fibrograph measurements are based on the assumptions

laboratory sample. For acceptance testing, test either two or

that a fiber is caught randomly along its length.

four specimens from each subsample in the laboratory sample

as agreed between the purchaser and the supplier.

6. Apparatus

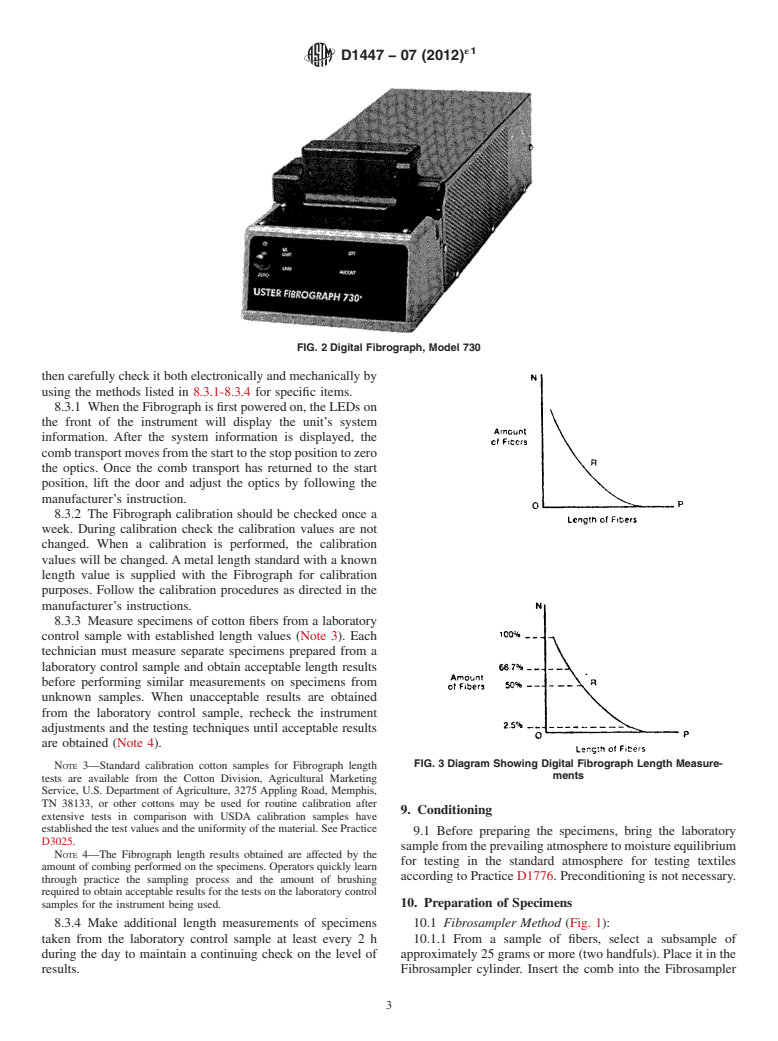

6.1 Fibrograph, digital model, with accessory equipment as

8. Preparation and Adjustment of Apparatus

shown in Fig. 2.

8.1 Set up the Fibrograph and adjust it as directed in the

6.2 Fibrosampler, for the preparation of test specimens

manufacturer’s instructions for the model being used.

(required) as shown in Fig. 1.

8.2 Set up and adjust the Fibrosampler as directed in the

manufacturer’s instructions.

Instruments and accessories meeting these requirements may be obtained from

8.3 Before making Fibrograph length tests, allow the instru-

Uster Technologies, Inc., 456 Troy Circle, P. O. Box 51270, Knoxville, TN

37919-1270. ment to warm up until it is electronically stable (5 minutes),

´1

D1447 − 07 (2012)

FIG. 2 Digital Fibrograph, Model 730

then carefully check it both electronically and mechanically by

using the methods listed in 8.3.1-8.3.4 for specific items.

8.3.1 When the Fibrograph is first powered on, the LEDs on

the front of the instrument will display the unit’s system

information. After the system information is displayed, the

combtransportmovesfromthestarttothestoppositiontozero

the optics. Once the comb transport has returned to the start

position, lift the door and adjust the optics by following the

manufacturer’s instruction.

8.3.2 The Fibrograph calibration should be checked once a

week. During calibration check the calibration values are not

changed. When a calibration is performed, the calibration

values will be changed.Ametal length standard with a known

length value is supplied with the Fibrograph for calibration

purposes. Follow the calibration procedures as directed in the

manufacturer’s instructions.

8.3.3 Measure specimens of cotton fibers from a laboratory

control sample with established length values (Note 3). Each

technician must measure separate specimens prepared from a

laboratory control sample and obtain acceptable length results

before performing similar measurements on specimens from

unknown samples. When unacceptable results are obtained

from the laboratory control sample, recheck the instrument

adjustments and the testing techniques until acceptable results

are obtained (Note 4).

FIG. 3 Diagram Showing Digital Fibrograph Length Measure-

NOTE 3—Standard calibration cotton samples for Fibrograph length

ments

tests are avai

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.