ASTM G55-07(2013)

(Test Method)Standard Test Method for Evaluating Pipeline Coating Patch Materials

Standard Test Method for Evaluating Pipeline Coating Patch Materials

SIGNIFICANCE AND USE

3.1 Holidays in pipeline coatings may be repaired by circumferential wrapping with a suitable pipe wrap tape. However, this technique is not always practicable and patching may be required. The effectiveness of a patch material depends upon its adhesion to the original pipeline coating to effect sealing.

3.2 The results of this accelerated test have been found to yield comparative data useful for the selection of patching materials. The user is cautioned against the use of this method for absolute material properties characterization.

3.3 This procedure provides an accelerated method by exposing the patch to a severe radius of curvature on small-diameter pipe. The specimen is also exposed to a stress voltage in the presence of a highly conductive electrolyte.

SCOPE

1.1 This test method provides an accelerated means of determining the relative sealing abilities of pipeline patching materials that are used to seal holidays in pipeline coatings on steel pipe. This test method is intended for utilization of specimens of pipeline coatings on small-diameter pipe, for representing coatings used for buried or submerged service, and where the purpose of the coating is to provide an electrical barrier between the steel pipe and its environment.

1.2 This test method is not intended for evaluating patch materials that are overlapped upon themselves.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G55 − 07 (Reapproved 2013)

Standard Test Method for

Evaluating Pipeline Coating Patch Materials

ThisstandardisissuedunderthefixeddesignationG55;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mayberequired.Theeffectivenessofapatchmaterialdepends

upon its adhesion to the original pipeline coating to effect

1.1 This test method provides an accelerated means of

sealing.

determining the relative sealing abilities of pipeline patching

materials that are used to seal holidays in pipeline coatings on 3.2 The results of this accelerated test have been found to

steel pipe. This test method is intended for utilization of yield comparative data useful for the selection of patching

specimens of pipeline coatings on small-diameter pipe, for materials. The user is cautioned against the use of this method

representing coatings used for buried or submerged service, for absolute material properties characterization.

and where the purpose of the coating is to provide an electrical

3.3 This procedure provides an accelerated method by

barrier between the steel pipe and its environment.

exposing the patch to a severe radius of curvature on small-

1.2 This test method is not intended for evaluating patch diameterpipe.Thespecimenisalsoexposedtoastressvoltage

materials that are overlapped upon themselves. in the presence of a highly conductive electrolyte.

1.3 The values stated in SI units are to be regarded as the

4. Apparatus

standard. The values given in parentheses are for information

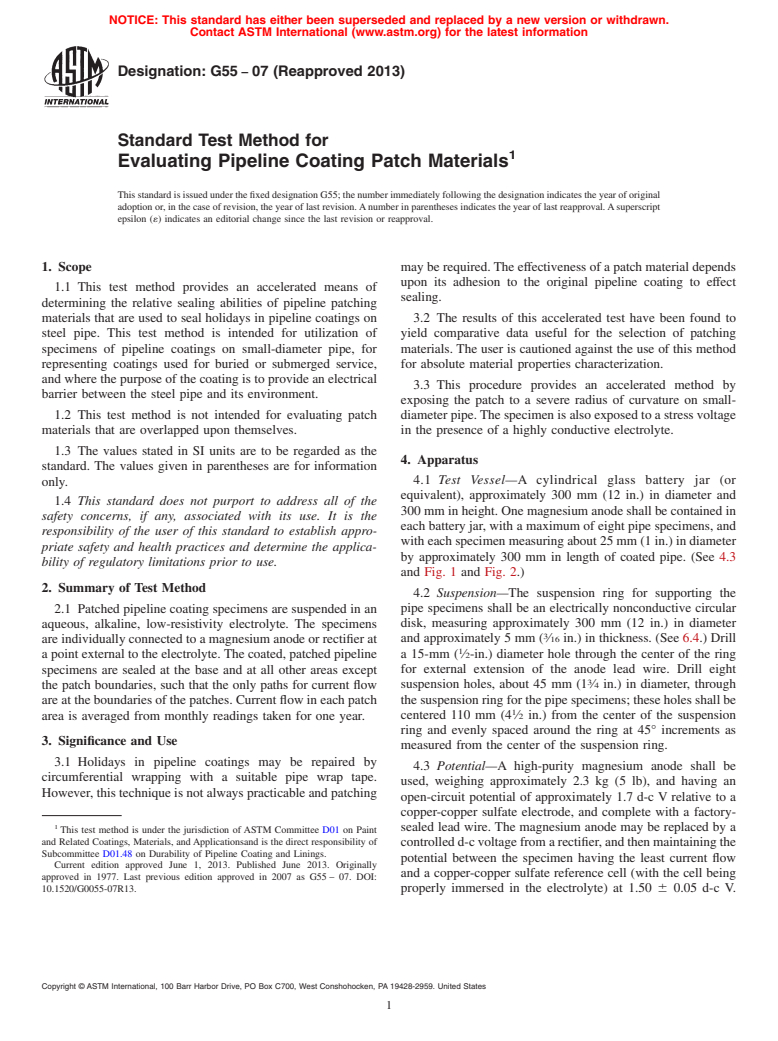

4.1 Test Vessel—A cylindrical glass battery jar (or

only.

equivalent), approximately 300 mm (12 in.) in diameter and

1.4 This standard does not purport to address all of the

300mminheight.Onemagnesiumanodeshallbecontainedin

safety concerns, if any, associated with its use. It is the

each battery jar, with a maximum of eight pipe specimens, and

responsibility of the user of this standard to establish appro-

witheachspecimenmeasuringabout25mm(1in.)indiameter

priate safety and health practices and determine the applica-

by approximately 300 mm in length of coated pipe. (See 4.3

bility of regulatory limitations prior to use.

and Fig. 1 and Fig. 2.)

2. Summary of Test Method

4.2 Suspension—The suspension ring for supporting the

2.1 Patched pipeline coating specimens are suspended in an pipe specimens shall be an electrically nonconductive circular

disk, measuring approximately 300 mm (12 in.) in diameter

aqueous, alkaline, low-resistivity electrolyte. The specimens

areindividuallyconnectedtoamagnesiumanodeorrectifierat and approximately 5 mm ( ⁄16 in.) in thickness. (See 6.4.) Drill

a 15-mm ( ⁄2-in.) diameter hole through the center of the ring

apointexternaltotheelectrolyte.Thecoated,patchedpipeline

specimens are sealed at the base and at all other areas except for external extension of the anode lead wire. Drill eight

suspension holes, about 45 mm (1 ⁄4 in.) in diameter, through

the patch boundaries, such that the only paths for current flow

areattheboundariesofthepatches.Currentflowineachpatch thesuspensionringforthepipespecimens;theseholesshallbe

centered 110 mm (4 ⁄2 in.) from the center of the suspension

area is averaged from monthly readings taken for one year.

ring and evenly spaced around the ring at 45° increments as

3. Significance and Use

measured from the center of the suspension ring.

3.1 Holidays in pipeline coatings may be repaired by

4.3 Potential—A high-purity magnesium anode shall be

circumferential wrapping with a suitable pipe wrap tape.

used, weighing approximately 2.3 kg (5 lb), and having an

However,thistechniqueisnotalwayspracticableandpatching

open-circuit potential of approximately 1.7 d-c V relative to a

copper-copper sulfate electrode, and complete with a factory-

sealed lead wire. The magnesium anode may be replaced by a

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplicationsand is the direct responsibility of

controlledd-cvoltagefromarectifier,andthenmaintainingthe

Subcommittee D01.48 on Durability of Pipeline Coating and Linings.

potential between the specimen having the least current flow

Current edition approved June 1, 2013. Published June 2013. Originally

and a copper-copper sulfate reference cell (with the cell being

approved in 1977. Last previous edition approved in 2007 as G55– 07. DOI:

10.1520/G0055-07R13. properly immersed in the electrolyte) at 1.50 6 0.05 d-c V.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

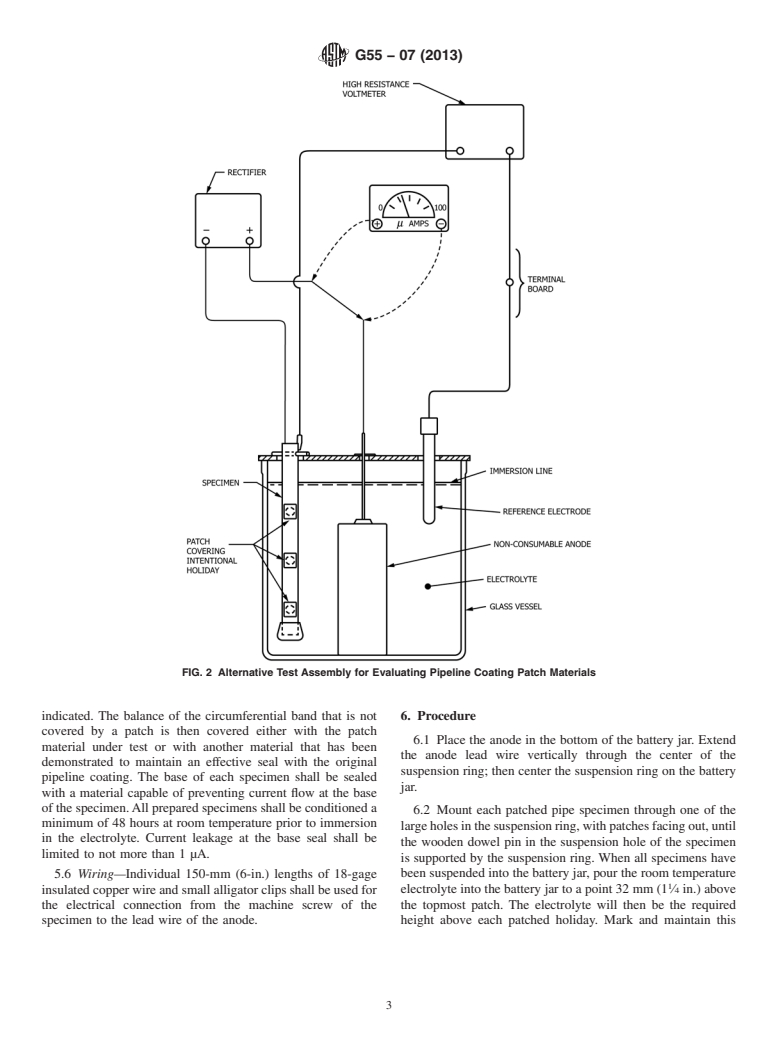

G55 − 07 (2013)

4.5.5 Voltmeter, for direct current, having an internal resis-

tance of not less than 10 MΩ and having a range from 0.01 to

5.0 V.

4.5.6 Full-Wave Rectifier, optional, 0 to 0.05% ripple,

capable of maintaining 1.50 6 0.05 d-c V relative to a

copper-coppersulfatecell,andhavingacapacityforatleast10

A of direct current.

5. Test Specimens

5.1 Dimensions—The specimen shall be steel pipe approxi-

mately 25 mm (1 in.) in diameter, approximately 300 mm (12

in.) in length, and previously coated with the desired original

pipeline coating.

5.2 Circuit Tap—A 5-mm ( ⁄16-in.) diameter hole shall be

drilled or tapped (or a self-tapping screw may be used) at a

point 13 mm ( ⁄2 in.) below the top of each specimen. This tap

is for a machine screw anode lead wire connection.

5.3 Pipe Suspension Support Holes—A6-mm( ⁄4-in.)diam-

eter hole shall be drilled completely through both walls of the

coatedpipespecimenatapoint20mm( ⁄4in.)fromthetopend

of the specimen and located vertically beneath the circuit tap

hole.Ashort length of wooden dowel pin about 5 mm ( ⁄16 in.)

indiametershallbeusedasaninsertionthroughthesuspension

holes to support and level the pipe specimen on the circular

suspension ring when the suspension ring is mounted on the

battery jar.

5.4 Intentional Holidays—A 4-fluted 13-mm ( ⁄2-in.) diam-

eterfacingbitshallbeusedtodrillintentionalholidaysthrough

FIG. 1 Test Assembly for Evaluating Pipeline Coating Patch Ma-

terials the original pipeline coating to the metal. Drilling such

holidays shall be practiced on scrap pieces of small-diameter

coatedpipe,priortodrillingtheholidaysinthetestspecimens.

(See Note 1.) The anode should be composed of a suitable Drilling shall not be any deeper than necessary into the metal

ofthepipe.Threeholidaysshallbepreparedoneachspecimen

nonconsumable material. This option will avoid the precipi-

tation of magnesium salts on the specimens. in a vertical line directly underneath the circuit tap to corre-

spond to electrolyte immersions of 38 mm (1 ⁄2 in.), 114 mm

NOTE 1—The potential of the magnesium anode will approximate this

1 1

(4 ⁄2in.),and190mm(7 ⁄2in.),asmeasuredfromthetopofthe

range over the life of the test. If a calomel electrode is used for the

holiday to the surface of the electrolyte. The thickness of the

reference cell, the potential should be−1.43 6 0.05 d-c V.

suspension ring shall be considered for its effect in elevating

4.4 Electrolyte—Use 1% each by weight of anhydrous pure

the pipe specimens in the electrolyte.

grades of sodium chloride, sodium sulfate, and sodium

carbonate, dissolved in either distilled water or demineralized 5.5 Patches—Asquare patch configuration of 25 by 25 mm

water. This electrolyte shall never be less alkaline than (1 by 1 in.), evenly centered about the holiday, shall be lightly

pH=10.0 and should be within a resistivity range from 20 to marked. This will provide a minimum patch overlap of 6 mm

35Ω · cm. ( ⁄4 in.) as measured perpendicular to the center of each patch

edge to the circumference of the holiday. The top and bottom

4.5 Instruments:

edges of each patch shall be in the horizontal plane. Each

4.5.1 Resistivity Meter, capable of measuring 20 to 40Ω·cm

marked patch area shall be lightly buffed with 120-grit sand-

in an aqueous solution.

paper. A primer shall be applied using clean cotton on a stick

4.5.2 pH meter, capable of measuring 0 to 14 pH.

to extend the primer to the edges of the marked patch area

4.5.3 Thermometer, ASTM Type 17C or equivalent, 19 to

when specified by the manufacturer of the patch. The manu-

27°C.

facturers’specifieddryingtimeshallbeusedforprimersbefor

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.