ASTM E694-99

(Specification)Standard Specification for Laboratory Glass Volumetric Apparatus

Standard Specification for Laboratory Glass Volumetric Apparatus

SCOPE

1.1 This specification covers general requirements common to glass volumetric apparatus. Specific dimensions and tolerances for applicable instruments are given in other specifications as cited throughout this specification. Glass must conform to specifications E438 and be calibrated in accordance with Practice E542.

1.1.1 Class A -Each instrument shall be marked with the letter to signify compliance with applicable construction and accuracy requirements. Instruments may be marked with an identification marker (serial number) at the option of the manufacturer.

1.1.2 Class B -General purpose instruments are of the same basic design as Class A. However, volumetric tolerances for Class B instruments shall be within twice the specified range allowed for Class A unless otherwise specified.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 694 – 99

Standard Specification for

Laboratory Glass Volumetric Apparatus

This standard is issued under the fixed designation E 694; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 1272 Specification for Graduated Cylinders

E 1878 Specification for Laboratory Glass Volumetric

1.1 This specification covers general requirements common

Flasks, Special Use

to glass volumetric apparatus. Specific dimensions and toler-

ances for applicable instruments are given in other specifica-

3. General Requirements

tionsascitedthroughoutthisspecification.Glassmustconform

3.1 Units of Volume—The unit of volume shall be the cubic

to specifications E 438 and be calibrated in accordance with

3 3

centimetre(cm )or,inspecialcases,thecubicdecimetre(dm )

Practice E 542.

or cubic millimetre (mm ).

1.1.1 Class A—Each instrument shall be marked with the

letter A to signify compliance with applicable construction and

NOTE 1—The term millilitre (mL) is commonly used as a special name

accuracy requirements. Instruments may be marked with an for the cubic centimetre (cm ) and, similarly the litre for the cubic

3 3

decimetre (dm ) and the microlitre (µL) for the cubic millimetre (mm ),

identification marker (serial number) at the option of the

in accordance with the International System of Units (SI).

manufacturer.

1.1.2 Class B—Generalpurposeinstrumentsareofthesame

3.2 Standard Temperature—The standard reference tem-

basic design as Class A. However, volumetric tolerances for perature, that is, the temperature at which the article of

Class B instruments shall be within twice the specified range

volumetric glassware is intended to contain or deliver its

allowed for Class A unless otherwise specified. nominal volume (nominal capacity), shall be 20°C.

NOTE 2—When it is necessary in tropical countries to work at an

2. Referenced Documents

ambient temperature considerably above 20°C, and it is not desired to use

2.1 ASTM Standards:

the standard reference temperature of 20°C, it is recommended that a

C 188 Test Method for Density of Hydraulic Cement

temperature of 27°C be adopted.

E 237 Specification for Microvolumetric Vessels (Volumet-

3.3 Material and Annealing—Volumetric glassware shall be

ric Flasks and Centrifuge Tubes)

constructed of glass of suitable chemical and thermal proper-

E 287 Specification for Burets

ties. It shall be as free as possible from visible defects and shall

E 288 Specification for Volumetric Flasks

conform to Specification E 671.

E 438 Specifications for Glasses in Laboratory Apparatus

3.4 Limit of Error—On an article having multiple gradua-

E 542 Practice for Calibration of Volumetric Ware

tion lines, the limit of volumetric error may occur at any

E 671 Specification for Maximum Permissible Thermal Re-

graduation line unless otherwise specified. For example, on a

sidual Stress in Annealed Glass Laboratory Apparatus

100-mL graduated cylinder having a limit of error of 61.00

E 675 Specification for Interchangeable Taper-Ground

mL, the volume at 10 mL could range from 9.00 to 11.00 mL.

Stopcocks and Stoppers

3.5 Stability—Vessels provided with a flat base shall stand

E 676 Specification for Interchangeable Taper-Ground

firmly thereon without rocking when placed on a level surface

Joints

and, unless specified otherwise, the axis of the graduated

E 788 Specification for Pipet, Blood Diluting

portion of the vessel should be vertical. Except for special

E 911 Specification for Glass Stopcocks with Polytetrafluo-

cases, vessels shall not topple when placed empty and without

roethylene (PTFE) Plugs

a stopper on a surface inclined at an angle to the horizontal of

E 969 Specification for Volumetric (Transfer) Pipets

15° for sizes 25 cm or greater and 10° for vessels less than 25

E 1045 Specification for Pipet, Sahli Hemoglobin

cm .Vesselsprovidedwithabasethatisnotcircularshallmeet

this requirement in all directions.

1 3.6 Stoppers and Stopcocks:

This specification is under the jurisdiction of ASTM Committee E-41 on

Laboratory Apparatus and is the direct responsibility of Subcommittee E41.01 on 3.6.1 Stoppers—Glassstoppersshouldbegroundsoastobe

Apparatus.

interchangeable, in which case the ground portions shall be in

Current edition approved Dec. 10, 1999. Published March 2000. Originally

accordance with Specification E 675. Stoppers of a suitable

published as E694 – 79. Last previous edition E694 – 95.

inert plastics material may be permitted as an alternative to

Annual Book of ASTM Standards, Vol 04.01.

Annual Book of ASTM Standards, Vol 14.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 694

glass. In such cases, the glass socket into which the stopper fits ation lines shall be varied so as to be clearly distinguishable

shall be in accordance with Specification E 675. All stoppers and shall be in accordance with the following provisions:

shall bear a proper size identification.

3.9.1 Graduation Pattern I:

3.6.2 Stopcocks—Stopcocks and similar devices shall be

3.9.1.1 The length of the short lines should be approxi-

designed to permit smooth and precise control of outflow and

mately, but not less than, 50 % of the circumference of the

to prevent a rate of leakage greater than that allowed in the

article.

specification for the article and shall be in accordance with

3.9.1.2 The length of the medium lines should be approxi-

Specification E 675. Stopcocks shall be made from glass or

mately 65 % of the circumference of the article and should

from suitable inert plastics material.

extend symmetrically at each end beyond the end of the short

3.7 Graduation Lines:

lines.

3.7.1 Graduation lines shall be clean, permanent lines of

3.9.1.3 The long lines should extend completely around the

uniform vertical thickness. This thickness shall be 0.2–0.6 mm

circumference of the article, but a gap, not exceeding 10 % of

for articles not having a scale. On articles having a scale, the

the circumference, may be permitted (see 3.6).

specified thickness of the lines shall be 0.2–0.4 mm. All

3.9.2 Graduation Pattern II:

graduation lines shall lie in planes at right angles to the

3.9.2.1 The length of the short lines should be not less than

longitudinal axis of the graduated portion of the article. On

10 % and not more than 20 % of the circumference of the

articles provided with a flat base, the graduation lines shall

article.

therefore lie in planes parallel to the base.

3.9.2.2 The length of the medium lines should be approxi-

3.7.2 In general, graduation lines should be confined to

mately 1.5 times the length of the short lines and should extend

cylindrical portions of an article’s cross section and should

symmetrically at each end beyond the end of the short lines.

preferably be situated not less than 10 mm from any change in

3.9.2.3 The long lines should extend completely around the

diameter. In special circumstances, preferably for Class B

circumference of the article, but a gap, not exceeding 10 % of

articles only, graduation lines may be provided on a parallel

the circumference, may be permitted (see 3.6).

side portion of noncircular cross section or on a conical or

3.9.3 Graduation Pattern III:

tapered portion of the article.

3.9.3.1 The length of the short lines should not be less than

3.7.3 On articles not having a scale, all graduation lines

10 % and not more than 20 % of the circumference of the

should extend completely around the circumference of the

article.

article, except that a gap, not exceeding 10 % of the circum-

3.9.3.2 The length of the medium lines should be approxi-

ference, may be permitted. In the case of an article that is

mately 1.5 times the length of the short lines and should extend

restricted as to the normal direction of viewing in use, the gap

symmetrically at each end beyond the ends of the short lines.

should be at the right or left of the normal direction of view.

3.9.3.3 The length of the long lines should be not less than

3.8 Spacing of Graduation Lines—There should be no

twice the length of the short lines and should extend symmetri-

evident irregularity spacing of graduation lines (except in

cally at each end beyond the ends of the short and medium

special cases where the scale is on a conical or tapered portion

lines.

of the article and a change of subdivision takes place). The

3.9.4 In special cases where scales are required on noncir-

minimum distance, L, between the centers of adjacent gradu-

cular cross section or conical or tapered portions of an article,

ation lines shall be not less, in relation to diameter, than that

the requirements of 3.8.1, 3.8.2, or 3.8.3 should be modified

calculated as follows:

appropriately.

L 5 ~0.8 1 0.02D! (1)

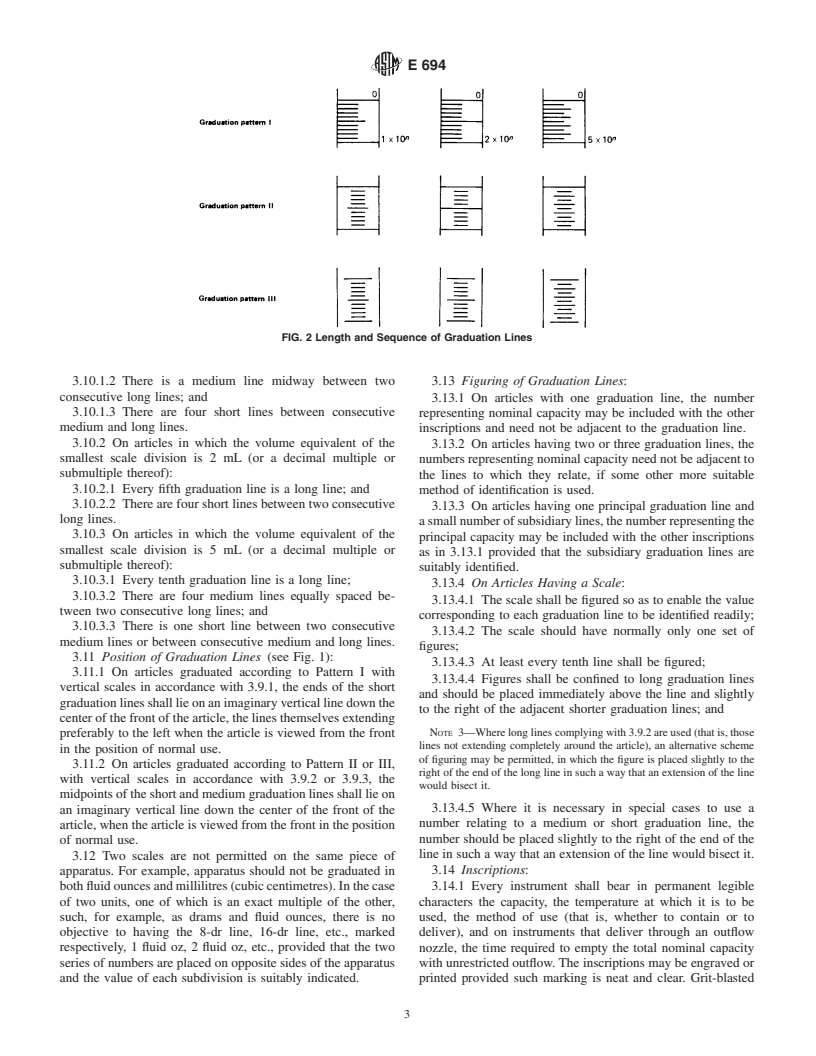

3.10 Sequence of Graduation Lines (see Fig. 2):

3.10.1 On articles in which the volume equivalent of the

where D is the maximum permitted internal diameter of the

tube in millimetres (see also Annex A1). smallest scale division is millilitre (or a decimal multiple or

submultiple thereof):

3.9 Length of Graduation Lines (see Fig. 1)—On articles of

circular cross section having a scale, the length of the gradu- 3.10.1.1 Every tenth graduation line is a long line;

FIG. 1 Position of Graduation Lines

E 694

FIG. 2 Length and Sequence of Graduation Lines

3.10.1.2 There is a medium line midway between two 3.13 Figuring of Graduation Lines:

consecutive long lines; and

3.13.1 On articles with one graduation line, the number

3.10.1.3 There are four short lines between consecutive representing nominal capacity may be included with the other

medium and long lines.

inscriptions and need not be adjacent to the graduation line.

3.10.2 On articles in which the volume equivalent of the

3.13.2 On articles having two or three graduation lines, the

smallest scale division is 2 mL (or a decimal multiple or

numbers representing nominal capacity need not be adjacent to

submultiple thereof):

the lines to which they relate, if some other more suitable

3.10.2.1 Every fifth graduation line is a long line; and

method of identification is used.

3.10.2.2 There are four short lines between two consecutive

3.13.3 On articles having one principal graduation line and

long lines.

asmallnumberofsubsidiarylines,thenumberrepresentingthe

3.10.3 On articles in which the volume equivalent of the

principal capacity may be included with the other inscriptions

smallest scale division is 5 mL (or a decimal multiple or

as in 3.13.1 provided that the subsidiary graduation lines are

submultiple thereof):

suitably identified.

3.10.3.1 Every tenth graduation line is a long line;

3.13.4 On Articles Having a Scale:

3.10.3.2 There are four medium lines equally spaced be-

3.13.4.1 The scale shall be figured so as to enable the value

tween two consecutive long lines; and

corresponding to each graduation line to be identified readily;

3.10.3.3 There is one short line between two consecutive

3.13.4.2 The scale should have normally only one set of

medium lines or between consecutive medium and long lines.

figures;

3.11 Position of Graduation Lines (see Fig. 1):

3.13.4.3 At least every tenth line shall be figured;

3.11.1 On articles graduated according to Pattern I with

3.13.4.4 Figures shall be confined to long graduation lines

vertical scales in accordance with 3.9.1, the ends of the short

and should be placed immediately above the line and slightly

graduationlinesshalllieonanimaginaryverticallinedownthe

to the right of the adjacent shorter graduation lines; and

center of the front of the article, the lines themselves extending

preferably to the left when the article is viewed from the front NOTE 3—Where long lines complying with 3.9.2 are used (that is, those

lines not extending completely around the article), an alternative scheme

in the position of normal use.

of figuring may be permitted, in which the figure is placed slightly to the

3.11.2 On articles graduated according to Pattern II or III,

right of the end of the long line in such a way that an extension of the line

with vertical scales in accordance with 3.9.2 or 3.9.3, the

would bisect it.

midpoints of the short and medium graduation lines shall lie on

3.13.4.5 Where it is necessary in special cases to use a

an imaginary vertical line down the center of the front of the

number relating to a medium or short graduation line, the

article, when the article is viewed from the front in the position

number should be placed slightly to the right of the end of the

of normal use.

line in such a way that an extension of the line would bisect it.

3.12 Two scales are not permitted on the same piece of

3.14 Inscriptions:

apparatus. For example, apparatus should not be graduated in

bothfluidouncesandmillilitres(cubiccentimetres).Inthecase 3.14.1 Every instrument shall bear in permanent legible

of two units, one of which is an exact multiple of the other, characters the capacity, the temperature at which it is to be

such, for example, as drams and fluid ounces, there is no used, the method of use (that is, whether to contain or to

objective to having the 8-dr line, 16-dr line, etc., marked deliver), and on instruments that deliver through an outflow

respectively, 1 fluid oz, 2 fluid oz, etc., provided that the two nozzle, the time required to empty the total nominal capacity

series of numbers are placed on opposite sides of the apparatus with unrestricted outflow. The inscriptions may be engraved or

and the value of each subdivision is suitably indicated. printed provided such marking is neat and clear. Grit-blasted

E 694

serial numbers will be permitted with the same provision. 4.1.3 Dual-Purpose Flask—A flask may be graduated both

Every instrument shall bear the name or trademark of the to contain and to deliver, provided the intention of the different

maker.EveryClassAinstrumentmaybearthesymbol A.Serial marks is clearly indicated and provided the distance between

numbersmaybemarkedoneachinstrumentattheoptionofthe the two marks is not less than 1 mm.

manufacturer and detachable parts, such as stoppers, stop-

4.1.4 Special-Purpose Volumetric Flasks— Certain types of

cocks, etc., belonging thereto, if not interchangeably ground,

special-purpose volumetric flasks, such as the Engler or Say-

shallbearthesamenumber.Interchangeableground-glassparts

bolt viscosity flasks and the Kohlrausch and Stift sugar flasks,

shall be marked on both members with the proper standard

while not in conformity with all the special requir

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.