ASTM B862-01

(Specification)Standard Specification for Titanium and Titanium Alloy Welded Pipe

Standard Specification for Titanium and Titanium Alloy Welded Pipe

SCOPE

1.1 This specification covers the requirements for 26 grades of titanium and titanium alloy welded pipe intended for general corrosion resisting and elevated temperature service as follows:

1.1.1 Grade 1—Unalloyed titanium, low oxygen,

1.1.2 Grade 2—Unalloyed titanium, standard oxygen,

1.1.3 Grade 3—Unalloyed titanium, medium oxygen,

1.1.4 Grade 5—Titanium alloy (6 % aluminum, 4 % vanadium),

1.1.5 Grade 7—Unalloyed titanium plus 0.12 % to 0.25 % palladium, standard oxygen,

1.1.6 Grade 9—Titanium alloy (3 % aluminum, 2.5 % vanadium),

1.1.7 Grade 11—Unalloyed titanium plus 0.12 % to 0.25 % palladium, low oxygen,

1.1.8 Grade 12—Titanium alloy (0.3 % molybdenum, 0.8 % nickel),

1.1.9 Grade 13—Titanium alloy (0.5 % nickel, 0.05 % ruthenium), low oxygen,

1.1.10 Grade 14—Titanium alloy (0.5 % nickel, 0.05 % ruthenium), standard oxygen,

1.1.11Grade 15—Titanium alloy (0.5 % nickel, 0.05 % ruthenium), medium oxygen,

1.1.12 Grade 16—Unalloyed titanium plus 0.04 % to 0.08 % palladium, standard oxygen,

1.1.13 Grade 17—Unalloyed titanium plus 0.04 % to 0.08 % palladium, low oxygen,

1.1.14Grade 18—Titanium alloy (3 % aluminum, 2.5 % vanadium plus 0.04 % to 0.08 % palladium),

1.1.15 Grade 19—Titanium alloy (3 % aluminum, 8 % vanadium, 6 % chromium, 4 % zirconium, 4 % molybdenum),

1.1.16 Grade 20—Titanium alloy (3 % aluminum, 8 % vanadium, 6 % chromium, 4 % zirconium, 4 % molybdenum) plus 0.04 % to 0.08 % palladium,

1.1.17 Grade 21—Titanium alloy (15 % molybdenum, 3 % aluminum, 2.7 % niobium, 0.25 % silicon),

1.1.18 Grade 23—Titanium alloy (6 % aluminum, 4 % vanadium, extra low interstitial, ELI),

1.1.19 Grade 24—Titanium alloy (6 % aluminum, 4 % vanadium) plus 0.04 % to 0.08 % palladium,

1.1.20 Grade 25—Titanium alloy (6 % aluminum, 4 % vanadium) plus 0.3 % to 0.8 % nickel and 0.04 % to 0.08 % palladium,

1.1.21 Grade 26—Unalloyed titanium plus 0.08 % to 0.14 % ruthenium,

1.1.22 Grade 27—Unalloyed titanium plus 0.08 % to 0.14 % ruthenium,

1.1.23 Grade 28—Titanium alloy (3 % aluminum, 2.5 % vanadium) plus 0.08 % to 0.14 % ruthenium,

1.1.24 Grade 29—Titanium alloy (6 % aluminum, 4 % vanadium with extra low interstitial elements (ELI)) plus 0.08 % to 0.14 % ruthenium,

1.1.25 Grade 33—Titanium alloy (0.4% nickel, 0.015% palladium, 0.025% ruthenium, 0.15% chromium), and

1.1.26 Grade 34—Titanium alloy (0.4% nickel, 0.015% palladium, 0.025% ruthenium, 0.15% chromium).

1.2 Pipe 8 in. NPS (nominal pipe size) and larger is most frequently custom made for an order. In such cases, the purchaser carefully should consider the applicability of this specification. Since the pipe is custom made, the purchaser may choose a wall thickness other than those in to meet specific operating conditions. The purchaser may also be better served to specify only the portions of this specification that are required to meet the operating conditions (for example, annealing, flattening test, chemistry, properties, etc.)

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are for information only.

1.4 Optional supplementary requirements are provided for pipe where a greater degree of testing is desired. These supplementary requirements may be invoked by the purchaser, when desired, by specifying in the order.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 862 – 01

Standard Specification for

1

Titanium and Titanium Alloy Welded Pipe

This standard is issued under the fixed designation B 862; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope vanadium) plus 0.04 % to 0.08 % palladium,

1.1.20 Grade 25—Titanium alloy (6 % aluminum, 4 %

1.1 This specification covers the requirements for 26 grades

vanadium) plus 0.3 % to 0.8 % nickel and 0.04 % to 0.08 %

of titanium and titanium alloy welded pipe intended for general

palladium,

corrosion resisting and elevated temperature service as follows:

1.1.21 Grade 26—Unalloyed titanium plus 0.08 % to

1.1.1 Grade 1—Unalloyed titanium, low oxygen,

0.14 % ruthenium,

1.1.2 Grade 2—Unalloyed titanium, standard oxygen,

1.1.22 Grade 27—Unalloyed titanium plus 0.08 % to

1.1.3 Grade 3—Unalloyed titanium, medium oxygen,

0.14 % ruthenium,

1.1.4 Grade 5—Titanium alloy (6 % aluminum, 4 % vana-

1.1.23 Grade 28—Titanium alloy (3 % aluminum, 2.5 %

dium),

vanadium) plus 0.08 % to 0.14 % ruthenium,

1.1.5 Grade 7—Unalloyed titanium plus 0.12 % to 0.25 %

1.1.24 Grade 29—Titanium alloy (6 % aluminum, 4 %

palladium, standard oxygen,

vanadium with extra low interstitial elements (ELI)) plus

1.1.6 Grade 9—Titanium alloy (3 % aluminum, 2.5 % va-

0.08 % to 0.14 % ruthenium,

nadium),

1.1.25 Grade 33—Titanium alloy (0.4% nickel, 0.015%

1.1.7 Grade 11—Unalloyed titanium plus 0.12 % to 0.25 %

palladium, 0.025% ruthenium, 0.15% chromium), and

palladium, low oxygen,

1.1.26 Grade 34—Titanium alloy (0.4% nickel, 0.015%

1.1.8 Grade 12—Titanium alloy (0.3 % molybdenum,

palladium, 0.025% ruthenium, 0.15% chromium).

0.8 % nickel),

1.2 Pipe 8 in. NPS (nominal pipe size) and larger is most

1.1.9 Grade 13—Titanium alloy (0.5 % nickel, 0.05 % ru-

frequently custom made for an order. In such cases, the

thenium), low oxygen,

purchaser carefully should consider the applicability of this

1.1.10 Grade 14—Titanium alloy (0.5 % nickel, 0.05 %

specification. Since the pipe is custom made, the purchaser

ruthenium), standard oxygen,

may choose a wall thickness other than those in Table 1 to meet

1.1.11 Grade 15—Titanium alloy (0.5 % nickel, 0.05 %

specific operating conditions. The purchaser may also be better

ruthenium), medium oxygen,

served to specify only the portions of this specification that are

1.1.12 Grade 16—Unalloyed titanium plus 0.04 % to

required to meet the operating conditions (for example, anneal-

0.08 % palladium, standard oxygen,

ing, flattening test, chemistry, properties, etc.)

1.1.13 Grade 17—Unalloyed titanium plus 0.04 % to

1.3 The values stated in inch-pound units are to be regarded

0.08 % palladium, low oxygen,

as standard. The values given in parentheses are for informa-

1.1.14 Grade 18—Titanium alloy (3 % aluminum, 2.5 %

tion only.

vanadium plus 0.04 % to 0.08 % palladium),

1.4 Optional supplementary requirements are provided for

1.1.15 Grade 19—Titanium alloy (3 % aluminum, 8 %

pipe where a greater degree of testing is desired. These

vanadium, 6 % chromium, 4 % zirconium, 4 % molybdenum),

supplementary requirements may be invoked by the purchaser,

1.1.16 Grade 20—Titanium alloy (3 % aluminum, 8 %

when desired, by specifying in the order.

vanadium, 6 % chromium, 4 % zirconium, 4 % molybdenum)

plus 0.04 % to 0.08 % palladium,

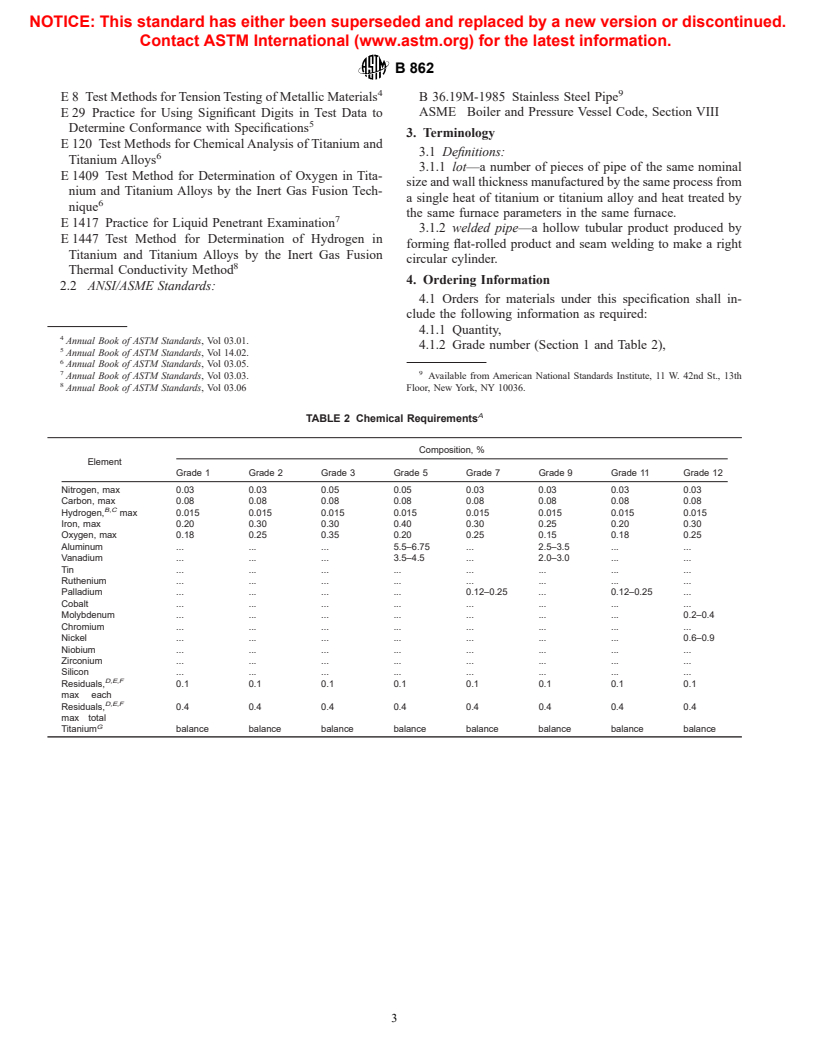

2. Referenced Documents

1.1.17 Grade 21—Titanium alloy (15 % molybdenum, 3 %

2.1 ASTM Standards:

aluminum, 2.7 % niobium, 0.25 % silicon),

A 370 Test Methods and Definitions for Mechanical Testing

1.1.18 Grade 23—Titanium alloy (6 % aluminum, 4 %

2

of Steel Products

vanadium, extra low interstitial, ELI),

B 600 Guide for Descaling and Cleaning Titanium and

1.1.19 Grade 24—Titanium alloy (6 % aluminum, 4 %

3

Titanium Alloy Surfaces

1

This specification is under the jurisdiction of ASTM Committee B10 on

Reactive and Refractory Metals and Alloys and is the direct responsibility of

2

Subcommittee B10.01 on Titanium. Annual Book of ASTM Standards, Vol 01.03.

3

Current edition approved Nov. 10, 2001. Published January 2002. Originally Annual Book of ASTM Standards, Vol 02.04.

published as B 862 – 95. Last previous edition B 862 – 99.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 862

2

NOTICE: This standard has either been superseded and replaced by a new version or discontinued. Contact ASTM International

TABLE 1 Dimensions of Pipe

(www.astm.org) for the latest information.

NOTE 1—Schedule sizes conform to ANSI/ASME B36.19 (for “S” sizes) or B36.10 (for non-S sizes).

NOTE 2—T

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.