ASTM D1294-05

(Test Method)Standard Test Method for Tensile Strength and Breaking Tenacity of Wool Fiber Bundles 1-in. (25.4-mm) Gage Length

Standard Test Method for Tensile Strength and Breaking Tenacity of Wool Fiber Bundles 1-in. (25.4-mm) Gage Length

SIGNIFICANCE AND USE

Test Method D 1294 for the determination of tensile strength may be used for the acceptance testing of commercial shipments of wool, but caution is advised since technicians may fail to get good agreement between results. Comparative tests as directed in 5.1.1 may be advisable.

5.1.1 If there are differences of practical significance between reported test results for two laboratories (or more), comparative test should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, use the samples for such a comparative test that are as homogenous as possible, drawn from the same lot of material as the samples that resulted in disparate results during initial testing and randomly assigned in equal numbers to each laboratory. The test results from the laboratories involved should be compared using a statistical test for unpaired data, a probability level chosen prior to the testing series. If bias is found, either its cause must be found and corrected, or future test results for that material must be adjusted in consideration of the known bias.

This test method is useful in studying the relationship between fiber strength and product quality; results should be considered comparative rather than fundamental since the strength found will be lower than the sum of the strengths of the individual fibers present due to slight differences in tensioning.

Elongation may be obtained also but the accuracy of elongation measurements is limited and their determination is, therefore, not included as a formal part of this test method.

The basic differences between the procedures employed in this test method and those of Test Method D 2524 are in the gage lengths employed and the methods of clamping. In Test Method D 2524, specific clamps are required whereas in Test Method D 1294, any conventional clamps may be used. Results for breaking load determined by Test Method D 2524 average 30 % higher than those obtained ...

SCOPE

1.1 This test method covers the determination of the breaking force (or load) and estimation of the tensile strength and tenacity of wool fiber bundles with a 1-in. (25.4-mm) gage length. A procedure for preparation of the fiber bundle is included.

1.2 The values stated in inch-pound units are to be regarded as standard; the values in SI units are provided for information only. Because the instrument is calibrated in inch-pound units, inch-pound units are shown first, contrary to Committee D13 policy.

Note 1--For other methods of measuring breaking tenacity of fiber bundles, refer to Test Methods D1445 and D2524.

Note 2--This test method can be used for other fibers that lend themselves to the same kind of preparation but the difference in density must be taken into account when calculating the tensile strength. It is not necessary to know or correct for the density of a fiber when calculating breaking tenacity.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibiltiy of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1294 − 05

StandardTest Method for

Tensile Strength and Breaking Tenacity of Wool Fiber

1

Bundles 1-in. (25.4-mm) Gage Length

This standard is issued under the fixed designation D1294; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4845Terminology Relating to Wool

1.1 This test method covers the determination of the break-

3. Terminology

ing force (or load) and estimation of the tensile strength and

tenacity of wool fiber bundles with a 1-in. (25.4-mm) gage

3.1 For all terminology related to Wool and Wool Felt,

length. A procedure for preparation of the fiber bundle is

D13.13, refer to Terminology D4845.

included.

3.1.1 Thefollowingtermsarerelevanttothisstandard:gage

length, recycled wool, tenacity, tensile strength, wool (as

1.2 The values stated in inch-pound units are to be regarded

defined in the Wool Products Labeling Act of 1939).

as standard; the values in SI units are provided for information

only. Because the instrument is calibrated in inch-pound units,

3.2 For all other terminology related to textiles see Termi-

inch-pound units are shown first, contrary to Committee D13

nology D123.

policy.

4. Summary of Test Method

NOTE 1—For other methods of measuring breaking tenacity of fiber

bundles, refer to Test Methods D1445 and D2524.

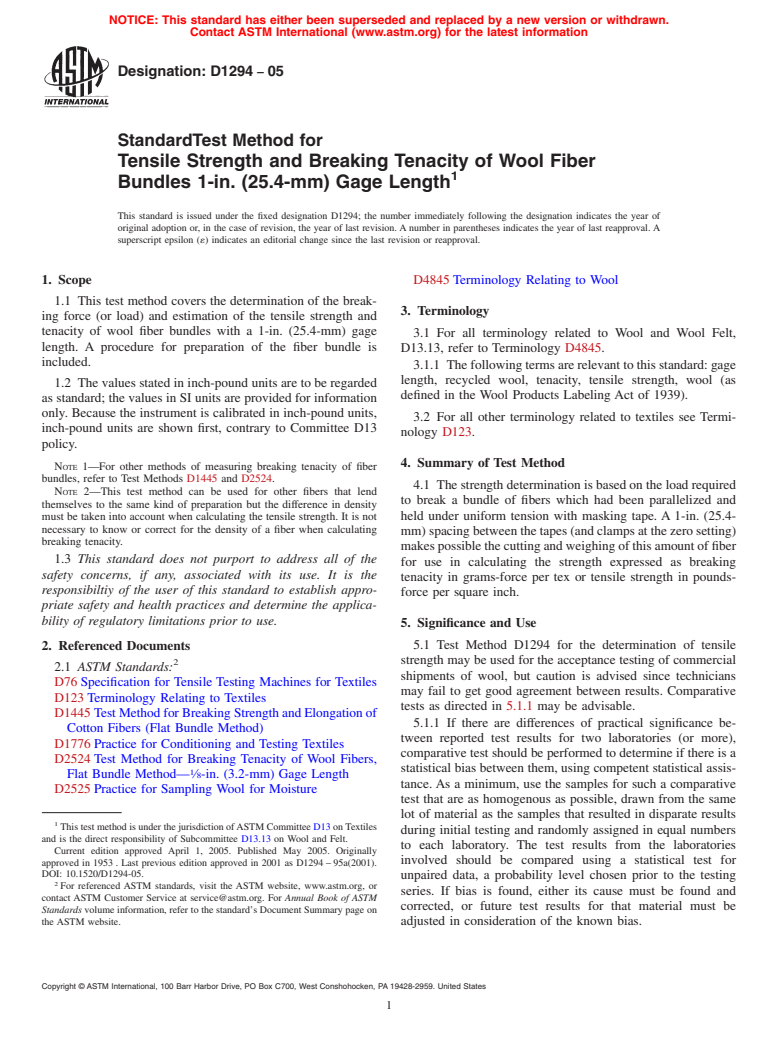

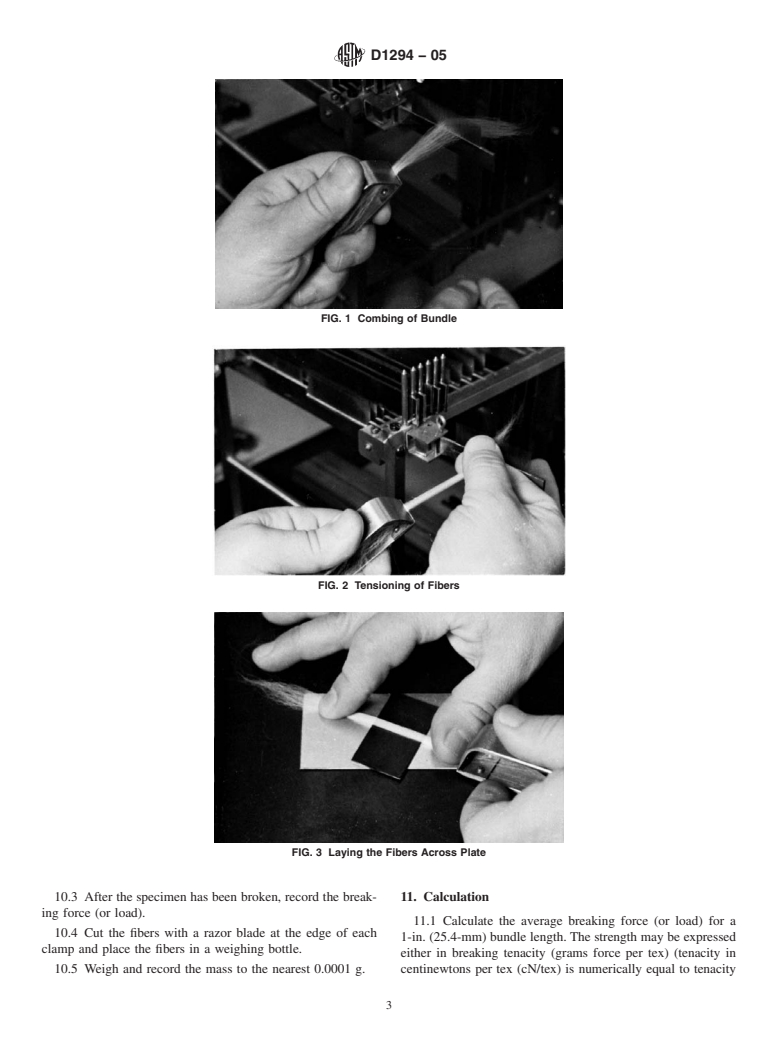

4.1 Thestrengthdeterminationisbasedontheloadrequired

NOTE 2—This test method can be used for other fibers that lend

to break a bundle of fibers which had been parallelized and

themselves to the same kind of preparation but the difference in density

must be taken into account when calculating the tensile strength. It is not held under uniform tension with masking tape. A 1-in. (25.4-

necessary to know or correct for the density of a fiber when calculating

mm)spacingbetweenthetapes(andclampsatthezerosetting)

breaking tenacity.

makespossiblethecuttingandweighingofthisamountoffiber

1.3 This standard does not purport to address all of the

for use in calculating the strength expressed as breaking

safety concerns, if any, associated with its use. It is the

tenacity in grams-force per tex or tensile strength in pounds-

responsibiltiy of the user of this standard to establish appro-

force per square inch.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5. Significance and Use

5.1 Test Method D1294 for the determination of tensile

2. Referenced Documents

strength may be used for the acceptance testing of commercial

2

2.1 ASTM Standards:

shipments of wool, but caution is advised since technicians

D76Specification for Tensile Testing Machines for Textiles

may fail to get good agreement between results. Comparative

D123Terminology Relating to Textiles

tests as directed in 5.1.1 may be advisable.

D1445TestMethodforBreakingStrengthandElongationof

5.1.1 If there are differences of practical significance be-

Cotton Fibers (Flat Bundle Method)

tween reported test results for two laboratories (or more),

D1776Practice for Conditioning and Testing Textiles

comparative test should be performed to determine if there is a

D2524Test Method for Breaking Tenacity of Wool Fibers,

statistical bias between them, using competent statistical assis-

1

Flat Bundle Method— ⁄8-in. (3.2-mm) Gage Length

tance.As a minimum, use the samples for such a comparative

D2525Practice for Sampling Wool for Moisture

test that are as homogenous as possible, drawn from the same

lot of material as the samples that resulted in disparate results

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD13onTextiles

during initial testing and randomly assigned in equal numbers

and is the direct responsibility of Subcommittee D13.13 on Wool and Felt.

to each laboratory. The test results from the laboratories

Current edition approved April 1, 2005. Published May 2005. Originally

involved should be compared using a statistical test for

approved in 1953. Last previous edition approved in 2001 as D1294–95a(2001).

DOI: 10.1520/D1294-05.

unpaired data, a probability level chosen prior to the testing

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

series. If bias is found, either its cause must be found and

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

corrected, or future test results for that material must be

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. adjusted in consideration of the known bias.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 -------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.