ASTM B48-00

(Specification)Standard Specification for Soft Rectangular and Square Bare Copper Wire for Electrical Conductors

Standard Specification for Soft Rectangular and Square Bare Copper Wire for Electrical Conductors

SCOPE

1.1 This specification covers soft or annealed bare copper wire, rectangular or square in shape with rounded corners (Explanatory Note 1).

1.2 For the purpose of this specification, the wire is classified as follows:

1.2.1 Type A -For all applications except those involving edgewise bending.

1.2.2 Type B -For applications involving edgewise bending. Type B wire of thickness less than 0.020 in. (0.51 mm) or with a ratio of width to thickness greater than 30 to 1 is not contemplated in this specification.

1.3 Unless otherwise specified by the purchaser, Type A material shall be furnished.

1.4 For referee purposes, inch-pound units shall be used throughout this specification, except for Sections 12 and 13.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 48 – 00

Standard Specification for

Soft Rectangular and Square Bare Copper Wire for

Electrical Conductors

ThisstandardisissuedunderthefixeddesignationB48;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Ordering Information

1.1 This specification covers soft or annealed bare copper 3.1 Orders for material to this specification shall include the

wire, rectangular or square in shape with rounded corners following information:

(Explanatory Note 1). 3.1.1 Quantity of each size,

1.2 For the purpose of this specification, the wire is classi- 3.1.2 Type of wire (see 1.1, 1.2, and 1.3),

fied as follows: 3.1.3 Wire size: thickness and width, in inches or millime-

1.2.1 Type A—For all applications except those involving tres (see 6.1),

edgewise bending. 3.1.4 Type of copper, if special (see Section 4),

1.2.2 Type B—For applications involving edgewise bend- 3.1.5 Package size (see 16.1),

ing. Type B wire of thickness less than 0.020 in. (0.51 mm) or 3.1.6 Special package marking, if required, and

with a ratio of width to thickness greater than 30 to 1 is not 3.1.7 Place of inspection. (see Section 15).

contemplated in this specification.

4. Material

1.3 Unless otherwise specified by the purchaser, Type A

material shall be furnished. 4.1 The material shall be copper of such quality and purity

that the finished product shall have the properties and charac-

1.4 For referee purposes, inch-pound units shall be used

throughout this specification, except for Sections 12 and 13. teristics prescribed in this specification.

4.2 SpecificationB49 defines the materials suitable for use.

2. Referenced Documents

5. Manufacture

2.1 ASTM Standards:

B49 Specification for Copper Redraw Rod for Electrical 5.1 The wire shall be annealed after the last drawing or

rolling to size and shape, and shall be so processed as to

Purposes

B 193 Test Method for Resistivity of Electrical Conductor produce a uniformly soft product with a clean surface.

5.2 The finished wire shall not contain joints except such as

Materials

B 279 Test Method for Stiffness of Bare Soft Square and have passed through drawing dies. Necessary joints in the wire

and rods prior to final drawing shall be made in accordance

Rectangular Copper andAluminum Wire for Magnet Wire

Fabrication with good commercial practice.

E8 Test Methods forTensionTesting of Metallic Materials

6. Dimensions and Permissible Variations

E29 Practice for Using Significant Digits in Test Data to

6.1 The dimensions shall be expressed in decimal fractions

Determine Conformance with Specifications

of an inch or in millimetres. Unless otherwise specified, it will

2.2 Other Document:

be assumed that the dimensions are in inches. (Explanatory

NBS Handbook 100— Copper Wire Tables

Note 6, Explanatory Note 7, and Explanatory Note 8.)

6.2 The thickness shall not vary from that specified by more

This specification is under the jurisdiction of ASTM Committee B-1 on

than the amounts prescribed in Table 1.

Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on

6.3 The width shall not vary from that specified by more

Conductors of Copper and Copper Alloys.

than the amounts prescribed in Table 2.

Current edition approved April 10, 2000. Published June 2000. Originally

published as B 48 – 68. Last previous edition B 48 – 92.

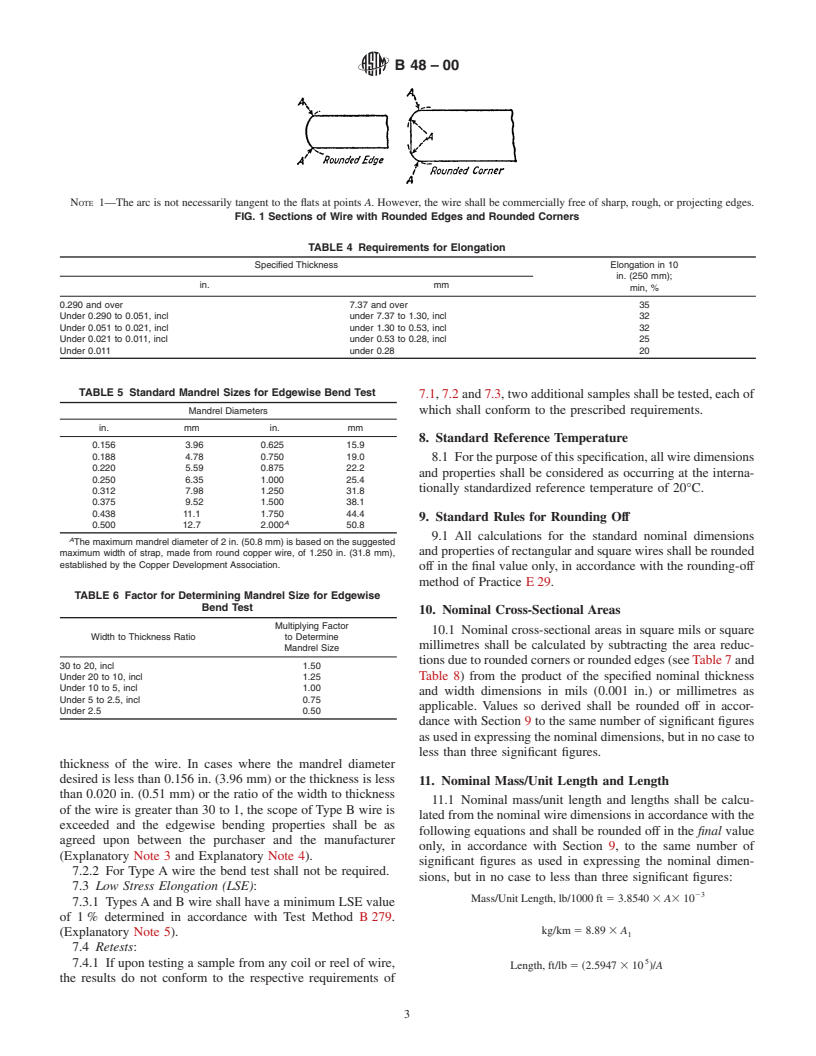

6.4 The wire shall have rounded corners or rounded edges

Annual Book of ASTM Standards, Vol 02.01.

as specified in Table 3 and as shown in Fig. 1. Where rounded

Annual Book of ASTM Standards, Vol 02.03.

4 corners are required, the corners of the wire shall be rounded

Annual Book of ASTM Standards, Vol 03.01.

Annual Book of ASTM Standards, Vol 14.02.

Available from National Institute of Standards and Technology, (NIST),

Gaithersburg, MD 20899.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 48–00

TABLE 1 Variation in Thickness

Width

Specified Thickness

Over 1,000 1.000 in. (25.4 mm) Under

in. (25.4 mm) to 0.492 in. (12.5 mm) 0.492 in. (12.5 mm)

Permissible Variation in Thickness, max, plus and minus

in. mm

in % mm in. % mm in. % mm

0.501 and over 12.73 and over . 1 . . 1 . . . .

under to, incl under to, incl

0.501 0.280 12.73 7.11 . 1 . . 1 . 0.003 . 0.076

0.280 0.201 7.11 5.11 0.003 . 0.08 . 1 . . 1 .

0.201 0.098 5.11 2.49 0.0025 . 0.064 . 1 . . 1 .

0.098 0.051 2.49 1.30 0.002 . 0.051 0.001 . 0.03 0.001 . 0.03

0.051 . 1.30 . 0.0015 . 0.038 0.001 . 0.03 0.001 . 0.03

TABLE 2 Variation in Width

Specified Width

Permissible Variation in Width,

max, plus and minus

In. mm

0.492 and over 12.5 and over 1 % but not to exceed 0.016 in. (0.406 mm)

Under 0.492 to 0.315, incl under 12.5 to 8.00, incl 0.003 in. (0.076 mm)

Under 0.315 to 0.098, incl under 8.00 to 2.49, incl 1 %

Under 0.098 under 2.49 0.001 in. (0.025 mm)

TABLE 3 Requirements for Rounded Corners and Rounded Edges

Specified Thickness Corner Radius for Specified Width

in. mm in. mm in. mm

under under

0.748 19.0

in. mm

0.748 to 19.0 to under under

and and

0.187, 4.75, 0.187 4.75

over over

incl incl

0.689 and over 17.50 and over 0.188 4.78 0.188 4.78 . .

under to, incl under to, incl

0.689 0.439 17.50 11.15 0.125 3.18 0.094 2.39 . .

0.439 0.280 11.15 7.10 0.094 2.39 0.039 1.00 . .

0.280 0.177 7.10 4.50 0.063 1.60 0.039 1.00 0.039 1.00

0.177 0.124 4.50 3.15 0.063 1.60 0.03 0.80 0.03 0.80

A B B

0.124 0.098 3.15 2.15 rounded edge 0.03 0.80 0.026 0.67

C C A B B

0.098 0.063 2.15 1.60 rounded edge 0.03 0.80 0.020 0.50

D D A E E

0.063 . 1.60 . rounded edge full rounded edge full rounded edge

A

A rounded edge is an edge produced by (1) rolling wire to the size specified either with or without edging rolls or (2) drawing through a die (see Fig. 1).

B

Rectangularwirewithathicknessunder0.124in.(3.15mm)to0.063in.(1.60mm)andawidthunder0.751in.(19.08mm)to0.189in.(4.80mm)maybemanufactured

with the corner radius specified for the same thickness and a width under 0.189 in. (4.80 mm).

C

Square wire 0.072 in. (1.83 mm) and under shall have a corner radius of 0.016 in. (0.41 mm) 6 25 %.

D

Rectangular wire with a thickness under 0.063 in. (1.60 mm) to 0.03 in. (0.80 mm) may be manufactured with a corner radius of 0.016 in. (0.41 mm) 6 25 %.

E

Except as permitted by Footnote B, rectangular wire less than 0.751 in. (19.08 mm) wide with full rounded edge shall have a radius half the thickness of the wire, 6

25 %.

within the limits of radii, 25 % under and 25 % over (as 7.1.3 Elongation tests shall be made in accordance withTest

determined by a radius gage) those radii values specified in Methods E8 on representative samples. The elongation shall

Table 3. be determined as the permanent increase in length, due to the

6.5 From each shipping unit, approximately 12 ft (3.66 m) breaking of the wire in tension, measured between gage marks

shall be unwound and the wire gaged at six places between placed originally 10 in. (250 mm) apart upon the test specimen

points 12 in. (30.5 cm) and 12 ft (3.66 m) from the end. The (Explanatory Note 2). The fracture shall be in between gage

shipping unit shall be rejected if the average of the measure- marks and not closer than 1 in. (25 mm) to either gage mark.

ments obtained is not within the limits specified in 6.2 and 6.3.

7.2 Bending:

7.2.1 Both edges of Type B wire shall withstand bending

7. Physical Requirements

edgewise through 180° around the mandrel indicated without

7.1 Elongation: cracking. The mandrel shall be one of the sizes shown in Table

7.1.1 Type A wire shall conform to the requirements for 5 and shall be the size that is equal to or next larger than the

elongation given in Table 4. figure obtained by multiplying the width of the wire by the

7.1.2 ForType B wire elongation tests shall not be required. factor in Table 6, corresponding to the ratio of the width to the

B 48–00

NOTE 1—The arc is not necessarily tangent to the flats at points A. However, the wire shall be commercially free of sharp, rough, or projecting edges.

FIG. 1 Sections of Wire with Rounded Edges and Rounded Corners

TABLE 4 Requirements for Elongation

Specified Thickness Elongation in 10

in. (250 mm);

in. mm

min, %

0.290 and over 7.37 and over 35

Under 0.290 to 0.051, incl under 7.37 to 1.30, incl 32

Under 0.051 to 0.021, incl under 1.30 to 0.53, incl 32

Under 0.021 to 0.011, incl under 0.53 to 0.28, incl 25

Under 0.011 under 0.28 20

TABLE 5 Standard Mandrel Sizes for Edgewise Bend Test

7.1, 7.2 and 7.3, two additional samples shall be tested, each of

Mandrel Diameters which shall conform to the prescribed requirements.

in. mm in. mm

8. Standard Reference Temperature

0.156 3.96 0.625 15.9

0.188 4.78 0.750 19.0

8.1 Forthepurposeofthisspecification,allwiredimensions

0.220 5.59 0.875 22.2

and properties shall be considered as occurring at the interna-

0.250 6.35 1.000 25.4

tionally standardized reference temperature of 20°C.

0.312 7.98 1.250 31.8

0.375 9.52 1.500 38.1

0.438 11.1 1.750 44.4

9. Standard Rules for Rounding Off

A

0.500 12.7 2.000 50.8

9.1 All calculations for the standard nominal dimensions

A

The maximum mandrel diameter of 2 in. (50.8 mm) is based on the suggested

andpropertiesofrectangularandsquarewiresshallberounded

maximum width of strap, made from round copper wire, of 1.250 in. (31.8 mm),

established by the Copper Development Association.

off in the final value only, in accordance with the rounding-off

method of PracticeE29.

TABLE 6 Factor for Determining Mandrel Size for Edgewise

Bend Test

10. Nominal Cross-Sectional Areas

Multiplying Factor

10.1 Nominal cross-sectional areas in square mils or square

Width to Thickness Ratio to Determine

millimetres shall be calculated by subtracting the area reduc-

Mandrel Size

tions due to rounded corners or rounded edges (seeTable 7 and

30 to 20, incl 1.50

Table 8) from the product of the specified nominal thickness

Under 20 to 10, incl 1.25

Under 10 to 5, incl 1.00

and width dimensions in mils (0.001 in.) or millimetres as

Under 5 to 2.5, incl 0.75

applicable. Values so derived shall be rounded off in accor-

Under 2.5 0.50

dance with Section 9 to the same number of significant figures

as used in expressing the nominal dimensions, but in no case to

less than three significant figures.

thickness of the wire. In cases where the mandrel diameter

desired is less than 0.156 in. (3.96 mm) or the thickness is less

11. Nominal Mass/Unit Length and Length

than 0.020 in. (0.51 mm) or the ratio of the width to thickness

11.1 Nominal mass/unit length and lengths shall be calcu-

of the wire is greater than 30 to 1, the scope of Type B wire is

lated from the nominal wire dimensions in accordance with the

exceeded and the edgewise bending properties shall be as

following equations and shall be rounded off in the final value

agreed upon between the purchaser and the manufacturer

only, in accordance with Section 9, to the same number of

(Explanatory Note 3 and Explanatory Note 4).

significant figures as used in expressing the nominal dimen-

7.2.2 For Type A wire the bend test shall not be required.

sions, but in no case to less than three significant figures:

7.3 Low Stress Elongation (LSE):

Mass/Unit Length, lb/1000 ft 5 3.8540 3 A3 10

7.3.1 TypesAand B wire shall have a minimum LSE value

of 1 % determined in accordance with Test Method B 279.

kg/km 5 8.89 3 A

(Explanatory Note 5). 1

7.4 Retests:

7.4.1 If upon testing a sample from any coil or reel of wire,

Length, ft/lb 5 ~2.5947 3 10 !/A

the results do not conform to the respective requirements of

B 48–00

TABLE 7 Areas of Square Copper Wire

Calculated Area of

Nominal Corner

A

Nominal Size Perfect Calculated Departure Nominal Area Nominal Area Working Value

Radius

Square

2 2 2 2 2 2 2 2

in. mm mil mm in. mm mils mm mils mm mils mm

1 2 3 456 7 8 9 10 11 12

0.0508 1.290 2580.64 1.66493 0.016 0.41 219.75 0.14177 2360.89 1.52315 2.36 3 10 1.52

0.0571 1.450 3260.41 2.10349 0.016 0.41 219.75 0.14177 3040.66 1.96171 3.04 1.96

0.0641 1.628 4108.81 2.65038 0.016 0.41 219.75 0.14177 3889.06 2.50907 3.89 2.51

0.0720 1.829 5184.00 3.34451 0.016 0.41 219.75 0.14177 4964.25 3.20274 4.96 3.20

0.0808 2.052 6528.64 4.21202 0.020 0.51 343.36 0.22151 6185.28 3.99050 6.19 3.99

0.0907 2.304 8226.49 5.30740 0.020 0.51 343.36 0.22151 7883.13 5.08588 7.88 5.09

0.1019 2.588 10383.61 6.69909 0.026 0.66 580.28 0.37437 9803.33 6.32472 9.80 6.32

0.1144 2.906 13087.36 8.44344 0.026 0.66 580.28 0.37437 12507.08 8.06907 12.51 8.07

0.1285 3.264 16512.25 10.65304 0.032 0.81 879.00 0.56710 15633.25 10.08595 15.63 10.09

0.1443 3.665 20822.49 13.43384 0.032 0.81 879.00 0.56710 19943.49 12.86674 19.94 12.87

0.1620 4.115 26244.00 16.93158 0.032 0.81 879.00 0.56710 25365.00 16.36448 25.36† 16.36

0.1819 4.620 33087.61 21.34680 0.040 1.02 1373.44 0.88609 31714.17 20.46071 31.71 20.46

0.2043 5.189 41738.49 26.92800 0.040 1.02 1373.44 0.88609 40365.05 26.04192 40.37 26.04

0.2294 5.827 52624.36 33.95113 0.040 1.02 1373.44 0.88609 51250.92 33.06504 51.25 33.07

0.2576 6.543 66357.76 42.81137 0.040 1.02 1373.44 0.88609 64984.32 41.92528 64.98 41.93

0.2893 7.348 83694.49 53.99634 0.040 1.02 1373.44 0.88609 82321.05 53.11025 82.32 53.11

0.3249 8.252 105560.01 68.10310 0.040 1.02 1373.44 0.88609 104186.57 67.21701 104.2 67.22

0.3648 9.266 133097.04 85.86889 0.040 1.02 1373.44 0.88609 131723.60 84.98280 131.7 84.98

0.4096 10.404 167772.16 108.23989 0.040 1.02 1373.44 0.88609 166398.72 107.35380 166.4 107.4

0.4600 11.684 211600.00 136.51586 0.094 2.39 7584.82 4.89342 204015.18 131.62243 204.0 131.6

A

The reduction in area due to rounding the corners.

TABLE 8 Calculated Reduction in Area Due to Rounding of Corners of Rectangular Wire

Specified Width

in. mm in. mm in. mm

Specified Thickness under under

0.751 19.08 under under

0.751 to 19.08 to

and over and over 0.189 4.80

0.189, incl 4.80, incl

Calculated Reduction

in. mm

2 2 2 2 2 2

mils mm mils mm mils mm

0.689 and over 17.50 and over

30339.29 19.5732 30339.29 19.5737 . .

under to, incl under to, incl

0.689 0.439 17.50 11.15 13412.50 8.65321 7584.82 4.89342 . .

0.439 0.226 11.15 5.74 7584.82 4.89342 1373.44 0.88609 . .

0.226 0.166 5.24 4.22 3406.90 2.19805 1373.44 0.88609 1373.44 0.88609

0.166 0.126 4.22 3.20 3406.00 2.19805 879.00 0.56710 879.00 0.56710

AA

0.126 0.096 3.20 2.44 879.00 0.56710 580.28 0.37437

AA

0.096 0.061 2.44 1.55 879.00 0.56710 343.36 0.22152

A A A AAA

0.061 . 1.55 .

A 2

Forwirewithroundededge

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.