ASTM D5311-92(2004)

(Test Method)Standard Test Method for Load Controlled Cyclic Triaxial Strength of Soil

Standard Test Method for Load Controlled Cyclic Triaxial Strength of Soil

SIGNIFICANCE AND USE

Cyclic triaxial strength test results are used for evaluating the ability of a soil to resist the shear stresses induced in a soil mass due to earthquake or other cyclic loading.

5.1.1 Cyclic triaxial strength tests may be performed at different values of effective confining pressure on isotropically consolidated specimens to provide data required for estimating the cyclic stability of a soil.

5.1.2 Cyclic triaxial strength tests may be performed at a single effective confining pressure, usually equal to 14.5 lb/in. 2(100 kN/m2), or alternate pressures as appropriate on isotropically consolidated specimens to compare cyclic strength results for a particular soil type with that of other soils, Ref (2).

The cyclic triaxial test is a commonly used technique for determining cyclic soil strength.

Cyclic strength depends upon many factors, including density, confining pressure, applied cyclic shear stress, stress history, grain structure, age of soil deposit, specimen preparation procedure, and the frequency, uniformity, and shape of the cyclic wave form. Thus, close attention must be given to testing details and equipment.

SCOPE

1.1 This test method covers the determination of the cyclic strength (sometimes called the liquefaction potential) of saturated soils in either undisturbed or reconstituted states by the load-controlled cyclic triaxial technique.

1.2 The cyclic strength of a soil is evaluated relative to a number of factors, including: the development of axial strain, magnitude of applied cyclic stress, number of cycles of stress application, development of excess pore-water pressure, and state of effective stress. A comprehensive review of factors affecting cyclic triaxial test results is contained in the literature ().

1.3 Cyclic triaxial strength tests are conducted under undrained conditions to simulate essentially undrained field conditions during earthquake or other cyclic loading.

1.4 Cyclic triaxial strength tests are destructive. Failure may be defined on the basis of the number of stress cycles required to reach a limiting strain or 100 % pore pressure ratio. See Section for Terminology.

1.5 This test method is generally applicable for testing cohesionless free draining soils of relatively high permeability. When testing well-graded materials, silts, or clays, it should be recognized that pore-water pressures monitored at the specimen ends to not in general represent pore-water pressure values throughout the specimen. However, this test method may be followed when testing most soil types if care is taken to ensure that problem soils receive special consideration when tested and when test results are evaluated.

1.6 There are certain limitations inherent in using cyclic triaxial tests to simulate the stress and strain conditions of a soil element in the field during an earthquake.

1.6.1 Nonuniform stress conditions within the test specimen are imposed by the specimen end platens. This can cause a redistribution of void ratio within the specimen during the test.

1.6.2 A 90 change in the direction of the major principal stress occurs during the two halves of the loading cycle on isotropically consolidated specimens.

1.6.3 The maximum cyclic shear stress that can be applied to the specimen is controlled by the stress conditions at the end of consolidation and the pore-water pressures generated during testing. For an isotropically consolidated contractive (volume decreasing) specimen tested in cyclic compression, the maximum cyclic shear stress that can be applied to the specimen is equal to one-half of the initial total axial pressure. Since cohesionless soils are not capable of taking tension, cyclic shear stresses greater than this value tend to lift the top platen from the soil specimen. Also, as the pore-water pressure increases during tests performed on isotropically consolidated specimens, the effective confining pressure is reduced, contributing to the tendency...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5311 – 92 (Reapproved 2004)

Standard Test Method for

Load Controlled Cyclic Triaxial Strength of Soil

This standard is issued under the fixed designation D5311; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6.2 A 90° change in the direction of the major principal

stress occurs during the two halves of the loading cycle on

1.1 This test method covers the determination of the cyclic

isotropically consolidated specimens.

strength (sometimes called the liquefaction potential) of satu-

1.6.3 The maximum cyclic shear stress that can be applied

rated soils in either undisturbed or reconstituted states by the

tothespecimeniscontrolledbythestressconditionsattheend

load-controlled cyclic triaxial technique.

ofconsolidationandthepore-waterpressuresgeneratedduring

1.2 The cyclic strength of a soil is evaluated relative to a

testing. For an isotropically consolidated contractive (volume

number of factors, including: the development of axial strain,

decreasing) specimen tested in cyclic compression, the maxi-

magnitude of applied cyclic stress, number of cycles of stress

mum cyclic shear stress that can be applied to the specimen is

application, development of excess pore-water pressure, and

equal to one-half of the initial total axial pressure. Since

state of effective stress. A comprehensive review of factors

cohesionless soils are not capable of taking tension, cyclic

affecting cyclic triaxial test results is contained in the literature

2 shear stresses greater than this value tend to lift the top platen

(1).

from the soil specimen. Also, as the pore-water pressure

1.3 Cyclic triaxial strength tests are conducted under und-

increases during tests performed on isotropically consolidated

rained conditions to simulate essentially undrained field con-

specimens,theeffectiveconfiningpressureisreduced,contrib-

ditions during earthquake or other cyclic loading.

uting to the tendency of the specimen to neck during the

1.4 Cyclictriaxialstrengthtestsaredestructive.Failuremay

extension portion of the load cycle, invalidating test results

be defined on the basis of the number of stress cycles required

beyond that point.

to reach a limiting strain or 100% pore pressure ratio. See

1.6.4 While it is advised that the best possible undisturbed

Section 3 for Terminology.

specimens be obtained for cyclic strength testing, it is some-

1.5 This test method is generally applicable for testing

times necessary to reconstitute soil specimens. It has been

cohesionless free draining soils of relatively high permeability.

shownthatdifferentmethodsofreconstitutingspecimenstothe

Whentestingwell-gradedmaterials,silts,orclays,itshouldbe

same density may result in significantly different cyclic

recognized that pore-water pressures monitored at the speci-

strengths. Also, undisturbed specimens will almost always be

menendstonotingeneralrepresentpore-waterpressurevalues

stronger than reconstituted specimens.

throughout the specimen. However, this test method may be

1.6.5 Theinteractionbetweenthespecimen,membrane,and

followedwhentestingmostsoiltypesifcareistakentoensure

confining fluid has an influence on cyclic behavior. Membrane

that problem soils receive special consideration when tested

compliance effects cannot be readily accounted for in the test

and when test results are evaluated.

procedure or in interpretation of test results. Changes in

1.6 There are certain limitations inherent in using cyclic

pore-water pressure can cause changes in membrane penetra-

triaxialteststosimulatethestressandstrainconditionsofasoil

tion in specimens of cohesionless soils. These changes can

element in the field during an earthquake.

significantly influence the test results.

1.6.1 Nonuniformstressconditionswithinthetestspecimen

1.6.6 The mean total confining pressure is asymmetric

are imposed by the specimen end platens. This can cause a

during the compression and extension stress application when

redistribution of void ratio within the specimen during the test.

the chamber pressure is constant. This is totally different from

the symmetric stress in the simple shear case of the level

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland

ground liquefaction.

Rock and is the direct responsibility of Subcommittee D18.09 on Dynamic

Properties of Soils. 1.7 The values stated in both inch-pound and SI units are to

Current edition approved Oct. 15, 1992. Published January 1993.

be regarded separately as the standard. The values given in

The boldface numbers in parentheses refer to a list of references at the end of

parentheses are for information only.

the text.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5311 – 92 (2004)

1.8 This standard does not purport to address all of the 3.2.1 full or 100 % pore pressure ratio— a condition in

safety concerns, if any, associated with its use. It is the which Du equals s8 .

3c

responsibility of the user of this standard to establish appro- 3.2.2 peak pore pressure ratio—themaximumporepressure

priate safety and health practices and determine the applica- ratio measured during a particular loading sequence.

bility of regulatory limitations prior to use. 3.2.3 peak (single amplitude) strain—the maximum axial

strain (from the origin or initial step) in either compression or

2. Referenced Documents

extension produced during a particular loading sequence.

3.2.4 peak to peak (double amplitude) strain— the differ-

2.1 ASTM Standards:

ence between the maximum axial strain in compression and

D422 Test Method for Particle-Size Analysis of Soils

extensionduringagivencycleundercyclicloadingconditions.

D653 Terminology Relating to Soil, Rock, and Contained

3.2.5 pore pressure ratio—the ratio, expressed as a percent-

Fluids

age, of the change of excess pore-water pressure, D u,tothe

D854 Test Method for Specific Gravity of Soils

effective minor principal stress, s8 , at the end of primary

D1587 Practice for Thin-Walled Tube Sampling of Soils

3c

D2216 TestMethodforLaboratoryDeterminationofWater consolidation.

(Moisture) Content of Soil and Rock

4. Summary of Test Method

D2850 Test Method for Unconsolidated, Undrained Com-

4.1 A cylindrical soil specimen is sealed in a watertight

pressive Strength of Cohesive Soils in Triaxial Compres-

rubber membrane and confined in a triaxial chamber where it

sion

is subjected to a confining pressure.An axial load is applied to

D 4220 Practice for Preserving and Transporting Soil

the top of the specimen by a load rod.

Samples

4.2 Specimens are consolidated isotropically (equal axial

D4253 TestMethodsforMaximumIndexDensityandUnit

and radial stress). Tubing connections to the top and bottom

Weight of Soils Using a Vibratory Table

specimen platens permit flow of water during saturation,

D4254 Test Method for Minimum Index Density and Unit

consolidation and measurement of pore-water pressure during

Weight of Soils and Calculation of Relative Density

cyclic loading.

D4318 Test Method for Liquid Limit, Plastic Limit, and

4.3 Following saturation and consolidation, the specimen is

Plasticity Index of Soils

subjected to a sinusoidally varying axial load by means of the

D4767 Test Method for Consolidated-Undrained Triaxial

loadrodconnectedtothespecimentopplaten.Thecyclicload,

Compression Test on Cohesive Soils

specimen axial deformation, and porewater pressure develop-

3. Terminology ment with time are monitored.

4.4 The test is conducted under undrained conditions to

3.1 Definitions:

approximate essentially undrained field conditions during

3.1.1 Definitions for terms used in this test method (includ-

earthquake or other dynamic loading. The cyclic loading

ing liquefaction) are in accordance with Terminology D653.

generally causes an increase in the pore-water pressure in the

Additional descriptions of terms are defined in 3.2 and in 10.2

specimen, resulting in a decrease in the effective stress and an

and Fig. 1.

increase in the cyclic axial deformation of the specimen.

3.2 Definitions of Terms Specific to This Standard:

4.5 Failure may be defined as when the peak excess pore-

water pressure equals the initial effective confining pressure,

full or 100% pore pressure ratio (sometimes called initial

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

liquefaction), or in terms of a limiting cyclic strain or perma-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

nent strain.

Standardsvolume information, refer to the standard’s Document Summary page on

the ASTM website.

5. Significance and Use

5.1 Cyclic triaxial strength test results are used for evaluat-

ing the ability of a soil to resist the shear stresses induced in a

soil mass due to earthquake or other cyclic loading.

5.1.1 Cyclic triaxial strength tests may be performed at

different values of effective confining pressure on isotropically

consolidated specimens to provide data required for estimating

the cyclic stability of a soil.

5.1.2 Cyclic triaxial strength tests may be performed at a

single effective confining pressure, usually equal to 14.5 lb/in.

2(100 kN/m ), or alternate pressures as appropriate on isotro-

pically consolidated specimens to compare cyclic strength

resultsforaparticularsoiltypewiththatofothersoils,Ref (2).

5.2 Thecyclictriaxialtestisacommonlyusedtechniquefor

determining cyclic soil strength.

5.3 Cyclic strength depends upon many factors, including

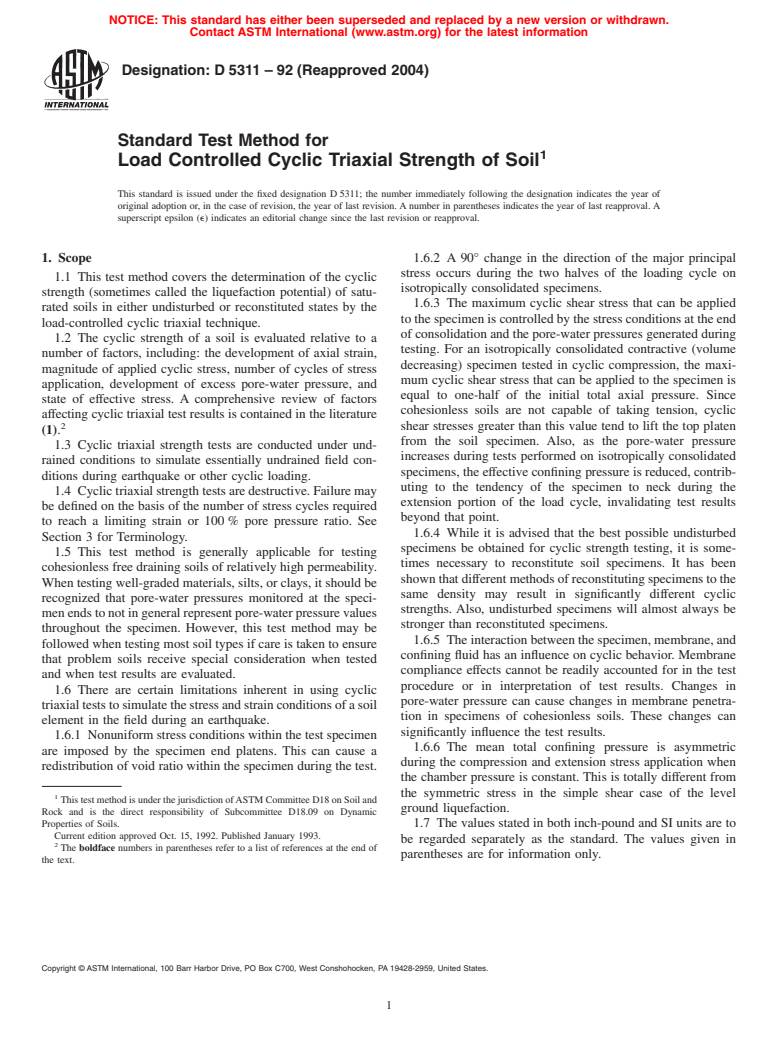

FIG. 1 Schematic Representation of Load-Controlled Cyclic

Triaxial Strength Test Equipment density, confining pressure, applied cyclic shear stress, stress

D 5311 – 92 (2004)

history, grain structure, age of soil deposit, specimen prepara-

tionprocedure,andthefrequency,uniformity,andshapeofthe

cyclic wave form. Thus, close attention must be given to

testing details and equipment.

6. Apparatus

6.1 In many ways, triaxial equipment suitable for cyclic

triaxial strength tests is similar to equipment used for the

unconsolidated-undrained triaxial compression test (see Test

Method D2850) and the consolidated-undrained triaxial com-

pression test (see Test Method D4767). However, there are

special features described in the following subsections that are

requiredtoperformacceptablecyclictriaxialtests.Aschematic

representation of a typical load-controlled cyclic triaxial

strength test set-up is shown in Fig. 1.

6.2 Triaxial Compression Cell—Theprimaryconsiderations

in selecting the cell are tolerances for the piston, top cap, and

low friction piston seal.

6.2.1 Twolinearballbushingsorsimilarbearingsshouldbe

used to guide the load rod to minimize friction and to maintain

alignment.

6.2.2 The load rod diameter should be large enough to

minimize lateral bending.Aminimum load rod diameter of ⁄6

the specimen diameter has been used successfully in many

laboratories.

6.2.3 The load rod seal is a critical element in triaxial cell

design for cyclic soils testing. The seal must exert negligible

friction on the load rod. The maximum acceptable piston

friction tolerable without applying load corrections is com-

monly considered to be 6 2% of the maximum single

amplitude cyclic load applied in the test. The use of an air

bushing as proposed in Ref (3) will meet or exceed these

requirements.

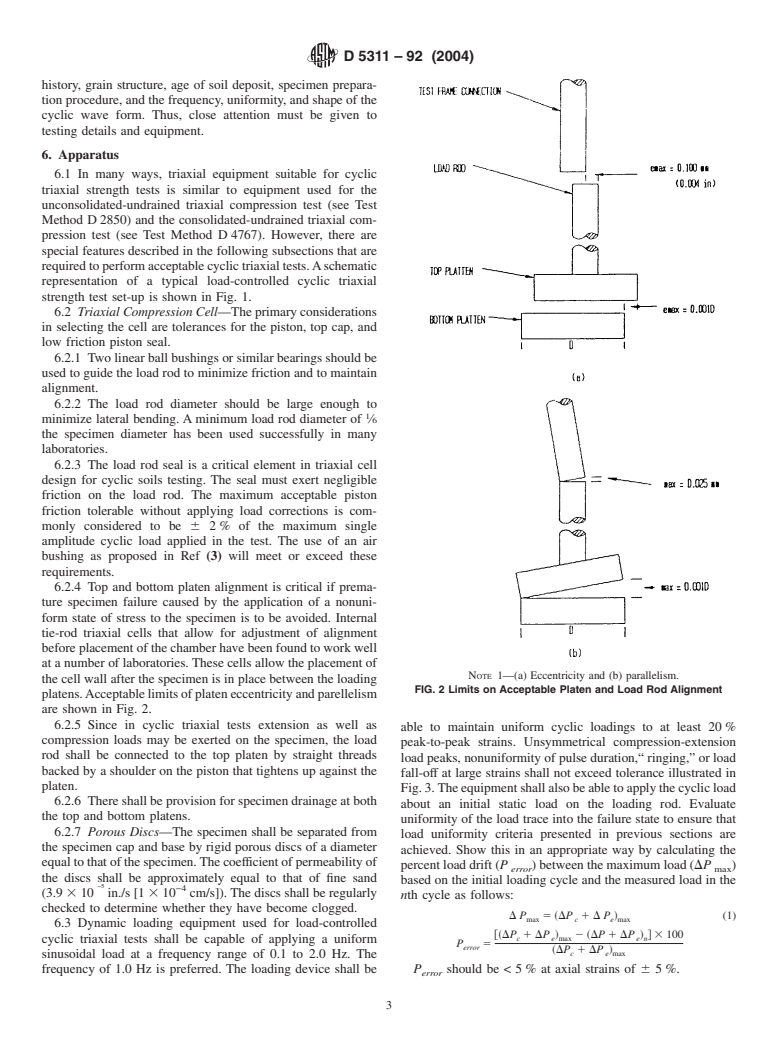

6.2.4 Top and bottom platen alignment is critical if prema-

ture specimen failure caused by the application of a nonuni-

form state of stress to the specimen is to be avoided. Internal

tie-rod triaxial cells that allow for adjustment of alignment

beforeplacementofthechamberhavebeenfoundtoworkwell

at a number of laboratories.These cells allow the placement of

NOTE 1—(a) Eccentricity and (b) parallelism.

the cell wall after the specimen is in place between the loading

FIG. 2 Limits on Acceptable Platen and Load Rod Alignment

platens.Acceptablelimitsofplateneccentricityandparellelism

are shown in Fig. 2.

6.2.5 Since in cyclic triaxial tests extension as well as

able to maintain uniform cyclic loadings to at least 20%

compression loads may be exerted on the specimen, the load

peak-to-peak strains. Unsymmetrical compression-extension

rod shall be connected to the top platen by straight threads

load peaks, nonuniformity of pulse duration,“ ringing,” or load

backed by a shoulder on the piston that tightens up against the

fall-off at large strains shall not exceed tolerance illustrated in

platen.

Fig.3.Theequipmentshallalsobeabletoapplythecyclicload

6.2.6 Thereshallbeprovisionforspecimendrainageatboth

about an initial static load on the loading rod. Evaluate

the top and bottom platens.

uniformity of the load trace into the failure state to ensure that

6.2.7 Porous Discs—The specimen shall be separated from

load uniformity criteria presented in previous sections are

the specimen cap and base by rigid porous discs of a diameter

achieved. Show this in an appropriate way by calculating the

equaltothatofthespecimen.Thecoefficientofpermeabilityof

percentloaddrift(P )betweenthemaximumload(DP )

error max

the discs shall be approximately equal to that of fine sand

based on the initial loading cycle and the measured load in the

−5

−4

(3.9 310 in./s [1 310 cm/s]).The discs shall be regularly

nth cycle as follows:

checked to determine whether they have become clogged.

D P 5 DP 1D P (1)

~ !

max c e max

6.3 Dynamic loading equipment used for load-controlled

@~DP 1DP ! 2 ~DP1DP ! # 3100

c e max e n

cyclic triaxial tests shall be capable of applying a uniform

P 5

error

~DP 1DP !

c e max

sinusoidal load at a frequency range of 0.1 to 2.0 Hz. The

frequency of 1.0 Hz is preferred. The loading device shall be P should be < 5% at axial strains of 65%.

error

D 5311 – 92 (2004)

the test specimen to ensure that the necessary measurement

accuracy is achieved. The minimum performance characteris-

tics of the load cell are presented in Table 1.

6.4.2 Axial Deformation Measurement— Displacement

measuring devices such as linear variable differential trans-

former (LVDT), potentiometer-type deformation transducers,

andeddycurrentsensorsmaybeusediftheyhaveanaccuracy

of 6 0.02% of the initial specimen height (see Table 1).

Accurate deformation measurements require that the trans-

ducer be properly mounted to avoid excessive mechanical

system compression between the load frame, the triaxial cell,

the load cell, and the loading piston.

6.4.3 Pore-Water Pressure Transducer— The specimen

pore-water pressure shall be measured to within 6 0.25 psi (2

kPa). Duri

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.