ASTM D5766/D5766M-02a(2007)

(Test Method)Standard Test Method for Open Hole Tensile Strength of Polymer Matrix Composite Laminates

Standard Test Method for Open Hole Tensile Strength of Polymer Matrix Composite Laminates

SIGNIFICANCE AND USE

This test method is designed to produce notched tensile strength data for structural design allowables, material specifications, research and development, and quality assurance. Factors that influence the notched tensile strength and should therefore be reported include the following: material, methods of material fabrication, accuracy of lay-up, laminate stacking sequence and overall thickness, specimen geometry (including hole diameter, diameter-to-thickness ratio, and width-to-diameter ratio), specimen preparation (especially of the hole), specimen conditioning, environment of testing, specimen alignment and gripping, speed of testing, time at temperature, void content, and volume percent reinforcement. Properties that may be derived from this test method include the following:

5.1.1 Open-hole (notched) tensile strength (OHT).

SCOPE

1.1 This test method determines the open hole tensile strength of multidirectional polymer matrix composite laminates reinforced by high-modulus fibers. The composite material forms are limited to continuous-fiber or discontinuous-fiber (tape or fabric, or both) reinforced composites in which the laminate is balanced and symmetric with respect to the test direction. The range of acceptable test laminates and thicknesses are described in 8.2.1.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text the inch-pound units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5766/D5766M–02a(Reapproved2007)

Standard Test Method for

Open Hole Tensile Strength of Polymer Matrix Composite

Laminates

This standard is issued under the fixed designation D5766/D5766M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D3039/D3039M Test Method for Tensile Properties of

Polymer Matrix Composite Materials

1.1 This test method determines the open hole tensile

D3171 TestMethodsforConstituentContentofComposite

strength of multidirectional polymer matrix composite lami-

Materials

nates reinforced by high-modulus fibers. The composite mate-

D3878 Terminology for Composite Materials

rialformsarelimitedtocontinuous-fiberordiscontinuous-fiber

E6 Terminology Relating to Methods of Mechanical Test-

(tape or fabric, or both) reinforced composites in which the

ing

laminate is balanced and symmetric with respect to the test

E177 Practice for Use of the Terms Precision and Bias in

direction. The range of acceptable test laminates and thick-

ASTM Test Methods

nesses are described in 8.2.1.

E456 Terminology Relating to Quality and Statistics

1.2 The values stated in either SI units or inch-pound units

E691 Practice for Conducting an Interlaboratory Study to

are to be regarded separately as standard. Within the text the

Determine the Precision of a Test Method

inch-pound units are shown in brackets. The values stated in

E 1309 Guide for Identification of Fiber-Reinforced

each system are not exact equivalents; therefore, each system

Polymer-Matrix Composite Materials in Databases

must be used independently of the other. Combining values

E1434 GuideforRecordingMechanicalTestDataofFiber-

from the two systems may result in nonconformance with the

Reinforced Composite Materials in Databases

standard.

E1471 Guide for Identification of Fibers, Fillers, and Core

1.3 This standard does not purport to address all of the

Materials in Computerized Material Property Databases

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety and health practices and determine the applica-

3.1 Definitions—TerminologyD3878definestermsrelating

bility of regulatory limitations prior to use.

to high-modulus fibers and their composites. Terminology

2. Referenced Documents D883 defines terms relating to plastics. Terminology E6

2 defines terms relating to mechanical testing. Terminology

2.1 ASTM Standards:

E456 and Practice E177 define terms relating to statistics. In

D792 TestMethodsforDensityandSpecificGravity(Rela-

the event of a conflict between terms, Terminology D3878

tive Density) of Plastics by Displacement

shall have precedence over the other standards.

D883 Terminology Relating to Plastics

3.2 Definitions of Terms Specific to This Standard::

D2584 Test Method for Ignition Loss of Cured Reinforced

Resins

NOTE 1—If the term represents a physical quantity, its analytical

D2734 Test Methods for Void Content of Reinforced Plas-

dimensionsarestatedimmediatelyfollowingtheterm(orlettersymbol)in

fundamental dimension form, using the following ASTM standard sym-

tics

bology for fundamental dimensions, shown within square brackets: [M]

for mass, [L] for length, [T] for time, [u] for thermodynamic temperature,

and[nd]fornon-dimensionalquantities.Useofthesesymbolsisrestricted

This test method is under the jurisdiction of ASTM Committee D30 on

to analytical dimensions when used with square brackets, as the symbols

Composite Materials and is the direct responsibility of Subcommittee D30.05 on

Structural Test Methods. may have other definitions when used without the brackets.

Current edition approved May 1, 2007. Published June 2007. Originally

3.2.1 nominal value, n—a value, existing in name only,

approved in 1995. Last previous edition approved in 2002 as D 5766/

assigned to a measurable property for the purpose of conve-

D5766M–02a.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

nient designation. Tolerances may be applied to a nominal

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

value to define an acceptable range for the property.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5766/D5766M–02a (2007)

3.2.2 principal material coordinate system, n—a coordinate common aerospace practice to develop notched design allow-

system with axes that are normal to the planes of symmetry able strengths based on gross section stress to account for

inherent to a material. various stress concentrations (fastener holes, free edges, flaws,

3.2.2.1 Discussion—Common usage, at least for Cartesian damage, and so forth) not explicitly modeled in the stress

axes (123, xyz, and so forth), generally assigns the coordinate analysis.

system axes to the normal directions of planes of symmetry in

4.2 Theonlyacceptablefailuremodeforultimateopen-hole

order that the highest property value in a normal direction (for

tensilestrengthisonewhichpassesthroughtheholeinthetest

elastic properties, the axis of greatest stiffness) would be 1 or

specimen.

x, and the lowest (if applicable) would be 3 or z. Anisotropic

materials do not have a principal material coordinate system

5. Significance and Use

duetothetotallackofsymmetry,while,forisotropicmaterials,

5.1 This test method is designed to produce notched tensile

any coordinate system is a principal material coordinate

strength data for structural design allowables, material speci-

system. In laminated composites the principal material coordi-

fications, research and development, and quality assurance.

nate system has meaning only with respect to an individual

Factors that influence the notched tensile strength and should

orthotropic lamina. The related term for laminated composites

therefore be reported include the following: material, methods

is “reference coordinate system.”

of material fabrication, accuracy of lay-up, laminate stacking

3.2.3 reference coordinate system, n—a coordinate system

sequence and overall thickness, specimen geometry, specimen

for laminated composites used to define ply orientations. One

preparation (especially of the hole), specimen conditioning,

of the reference coordinate system axes (normally the Carte-

environment of testing, specimen alignment and gripping,

sian x-axis) is designated the reference axis, assigned a

speed of testing, void content, and volume percent reinforce-

position, and the ply principal axis of each ply in the laminate

ment. Properties that may be derived from this test method

is referenced relative to the reference axis to define the ply

include the following:

orientation for that ply.

5.1.1 Open hole (notched) tensile strength (OHT).

3.2.4 specially orthotropic, adj—a description of an ortho-

tropic material as viewed in its principal material coordinate

6. Interferences

system. In laminated composites, a specially orthotropic lami-

nate is a balanced and symmetric laminate of the [0/90]

i j ns 6.1 Hole Preparation—Due to the dominating presence of

family as viewed from the reference coordinate system, such

the notch, and the lack of need to measure the material

that the membrane-bending coupling terms of the laminate

response,resultsfromthistestmethodarerelativelyinsensitive

constitutive relation are zero.

to parameters that would be of concern in an unnotched tensile

3.3 Symbols:

propertytest.However,sincethenotchdominatesthestrength,

3.3.1 A—cross-sectional area of a specimen.

consistent preparation of the hole, without damage to the

3.3.2 CV—coefficient of variation statistic of a sample

laminate, is important to meaningful results. Damage caused

population for a given property (in percent).

by hole preparation will affect strength results. Some types of

3.3.3 D—hole diameter.

damage, such as delaminations, can blunt the stress concentra-

3.3.4 h—specimen thickness.

tion because of the hole, increasing the load-carrying capacity

3.3.5 n—number of specimens per sample population.

of the specimen and the calculated strength.

3.3.6 N—number of plies in laminate under test.

6.2 Geometry—Resultsareaffectedbytheratioofspecimen

OHTu

3.3.7 F —ultimateopenhole(notched)tensilestrength

x

width to hole diameter; this ratio should be maintained at 6,

in the test direction.

unless the experiment is investigating the influence of this

max

3.3.8 P —maximum load carried by test specimen prior

ratio.Resultsmayalsobeaffectedbytheratioofholediameter

to failure.

to thickness; the preferred ratio is the range from 1.5 to 3.0

3.3.9 s —standard deviation statistic of a sample popula-

n−1

unless the experiment is investigating the influence of this

tion for a given property.

ratio.

3.3.10 w—specimen width.

6.3 Material Orthotropy—The degree of laminate orthot-

3.3.11 x—test result for an individual specimen from the

i

ropy strongly affects the failure mode and measured OHT

sample population for a given property.

strength. Valid OHT strength results should only be reported

3.3.12 x¯—mean or average (estimate of mean) of a sample

when appropriate failure modes are observed, in accordance

population for a given property.

with 11.4.

3.3.13 s—normal stress.

6.4 Thickness Scaling—Thick composite structures do not

4. Summary of Test Method

necessarilyfailatthesamestrengthsasthinstructureswiththe

same laminate orientation (that is, strength does not always

4.1 A uniaxial tension test of a balanced, symmetric lami-

scale linearly with thickness). Thus, data gathered using this

nate is performed in accordance with Test Method D3039/

test method may not translate directly into equivalent thick-

D3039M, although with a centrally located hole. Edge-

structure properties.

mounted extensometer displacement transducers are optional.

Ultimate strength is calculated based on the gross cross- 6.5 Other—Additional sources of potential data scatter in

sectional area, disregarding the presence of the hole.While the testing of composite materials are described in Test Method

hole causes a stress concentration and reduced net section, it is D3039/D3039M.

D5766/D5766M–02a (2007)

7. Apparatus 8.2.2 Dimensions—The width of the specimen is 36 6 1

mm [1.50 6 0.05 in.] and the length range is 200 to 300 mm

7.1 Apparatus shall be in accordance with Test Method

[8.0 to 12.0 in.].The notch consists of a centrally located hole,

D3039/D3039M.Additionally, a micrometer or gage capable

6 6 0.06 mm [0.250 6 0.003 in.] in diameter, centered by

of determining the hole diameter to 60.025 mm [60.001 in.]

length to within 0.12 mm [0.005 in.] and by width to within

is required.

0.05 mm [0.002 in.]. While tabs may be used, they are not

required and generally not needed, since the open hole acts as

8. Sampling and Test Specimens

sufficient stress riser to force failure in the notched region.

8.1 Sampling—Sampling shall be in accordance with Test

8.3 Specimen Preparation—Special care shall be taken to

Method D3039/D3039M.

ensure that creation of the specimen hole does not delaminate

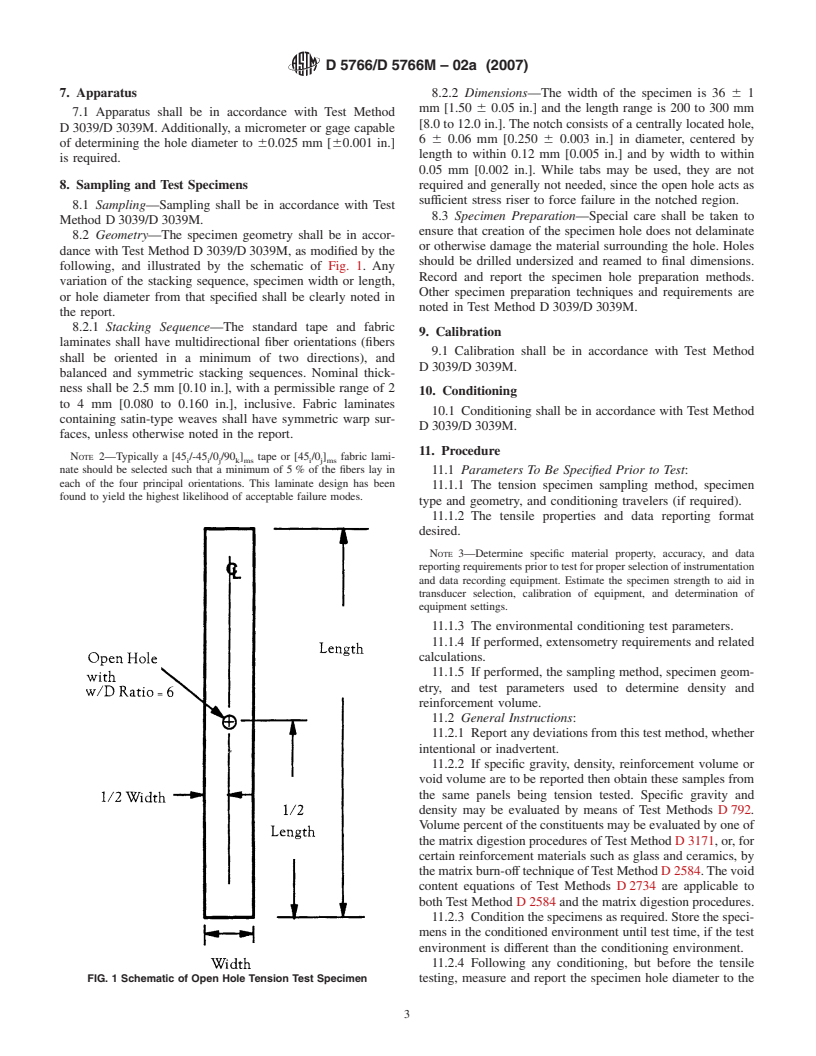

8.2 Geometry—The specimen geometry shall be in accor-

or otherwise damage the material surrounding the hole. Holes

dance with Test Method D3039/D3039M, as modified by the

should be drilled undersized and reamed to final dimensions.

following, and illustrated by the schematic of Fig. 1. Any

Record and report the specimen hole preparation methods.

variation of the stacking sequence, specimen width or length,

Other specimen preparation techniques and requirements are

or hole diameter from that specified shall be clearly noted in

noted in Test Method D3039/D3039M.

the report.

8.2.1 Stacking Sequence—The standard tape and fabric

9. Calibration

laminates shall have multidirectional fiber orientations (fibers

9.1 Calibration shall be in accordance with Test Method

shall be oriented in a minimum of two directions), and

D3039/D3039M.

balanced and symmetric stacking sequences. Nominal thick-

ness shall be 2.5 mm [0.10 in.], with a permissible range of 2

10. Conditioning

to 4 mm [0.080 to 0.160 in.], inclusive. Fabric laminates

10.1 Conditioning shall be in accordance with Test Method

containing satin-type weaves shall have symmetric warp sur-

D3039/D3039M.

faces, unless otherwise noted in the report.

11. Procedure

NOTE 2—Typically a [45/-45/0/90 ] tape or [45/0] fabric lami-

i i j k ms i j ms

nate should be selected such that a minimum of 5% of the fibers lay in 11.1 Parameters To Be Specified Prior to Test:

each of the four principal orientations. This laminate design has been

11.1.1 The tension specimen sampling method, specimen

found to yield the highest likelihood of acceptable failure modes.

type and geometry, and conditioning travelers (if required).

11.1.2 The tensile properties and data reporting format

desired.

NOTE 3—Determine specific material property, accuracy, and data

reportingrequirementspriortotestforproperselectionofinstrumentation

and data recording equipment. Estimate the specimen strength to aid in

transducer selection, calibration of equipment, and determination of

equipment settings.

11.1.3 The environmental conditioning test parameters.

11.1.4 If performed, extensometry requirements and related

calculations.

11.1.5 If performed, the sampling method, specimen geom-

etry, and test parameters used to determine density and

reinforcement volume.

11.2 General Instructions:

11.2.1 Reportanydeviationsfromthistestmethod,whether

intentional or inadvertent.

11.2.2 If specific gravity, density, reinforcement volume or

void volume are to be reported then obtain these samples from

the same panels being tension tested. Specific gravity and

density may be evaluated by means of Test Methods D792.

Volumepercentoftheconstituentsmaybeevaluatedbyoneof

thematrixdigestionproceduresofTestMethodD3171,or,for

certain reinforcement materials such as glass and ceramics, by

thematrixburn-offtechniqueofTestMethodD2584.Thevoid

content equations of Test Methods D2734 are applicable to

bothTest Method D2584 and the matrix digestion procedures.

11.2.3 Conditionthespecimensasrequired.Storethespeci-

mens in the conditioned environment until test time, if the test

environment is different than the conditioning environment.

11.2.4 Following any conditioning, but before the tensile

FIG. 1 Schematic of Open Hole Tension Test Specimen testing, measure and report the specimen hole diameter to the

D5766/D576

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.