ASTM D7542-21

(Test Method)Standard Test Method for Air Oxidation of Carbon and Graphite in the Kinetic Regime

Standard Test Method for Air Oxidation of Carbon and Graphite in the Kinetic Regime

SIGNIFICANCE AND USE

5.1 This test method can be used to measure the rate of oxidation for various grades of manufactured carbon and graphite in standard conditions, and can be used for quality control purposes.

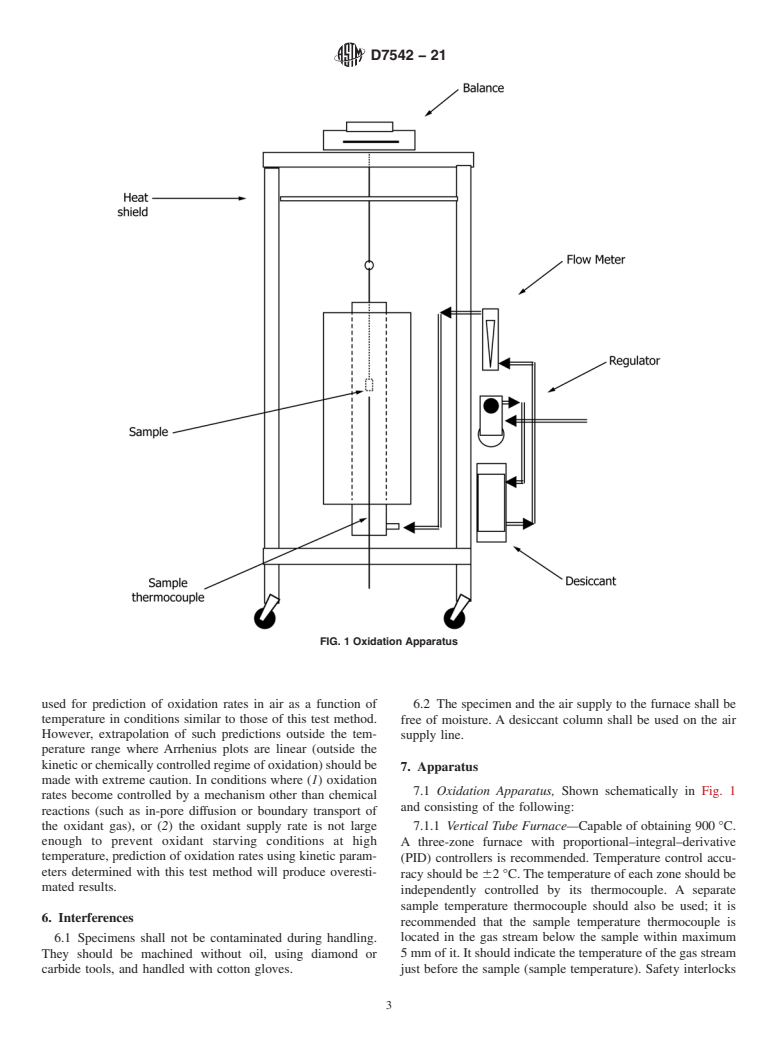

5.2 The following conditions are standardized in this test method: size and shape of the graphite specimens; their placement in the vertical furnace with upwards air flow; the method for continuous weight variation measurement using an analytical scale with under-the-scale port; the air flow rate, which must be high enough to ensure that oxidation is not oxygen-starved at the highest temperature used; the initial and final points on the weight loss curve used for calculation of oxidation rate.

5.3 This test method also provides kinetic parameters (apparent activation energy and logarithm of pre-exponential factor) for the oxidation reaction, and a standard oxidation temperature. The results characterize the effect of temperature on oxidation rates in air, and the oxidation resistance of machined carbon or graphite specimens with standard size and shape, in the kinetic, or chemically controlled, oxidation regime. This information is useful for discrimination between material grades with different impurity levels, grain size, pore structure, degree of graphitization, or antioxidation treatments, or a combination thereof.

5.4 Accurately determined kinetic parameters, like activation energy and logarithm of pre-exponential factor, can be used for prediction of oxidation rates in air as a function of temperature in conditions similar to those of this test method. However, extrapolation of such predictions outside the temperature range where Arrhenius plots are linear (outside the kinetic or chemically controlled regime of oxidation) should be made with extreme caution. In conditions where (1) oxidation rates become controlled by a mechanism other than chemical reactions (such as in-pore diffusion or boundary transport of the oxidant gas), or (2) the oxidant supply rate is no...

SCOPE

1.1 This test method recommends a standard procedure for measuring oxidation rates in air of various grades of nuclear graphite and/or manufactured carbon. Following the standard procedure recommended here, one can obtain kinetic parameters that characterize the oxidation resistance in standard conditions of tested materials and that can be used to for materials selection and qualification, and for quality control purposes in the fabrication process.

1.2 This test method covers the rate of oxidative weight loss per exposed nominal geometric surface area, or per initial weight of machined test specimens of standard size and shape, or both. The test is valid in the temperature range where the rate of air oxidation of graphite and manufactured carbon is limited by reaction kinetics.

1.3 This test method also provides a standard oxidation temperature (as defined in 3.1.7), and the kinetic parameters of the oxidation reaction, namely the apparent activation energy and the logarithm of pre-exponential factor in Arrhenius equation. The kinetic parameters of Arrhenius equation are calculated from the temperature dependence of oxidation rates measured over the temperature range where Arrhenius plots (as defined in 3.1.8) are linear, which is defined as the “kinetic” or “chemical control” oxidation regime. For typical nuclear grade graphite materials it was found that the practical range of testing temperatures is from about 500 °C to 550 °C up to about 700 °C to 750 °C.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international s...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7542 − 21

Standard Test Method for

1

Air Oxidation of Carbon and Graphite in the Kinetic Regime

This standard is issued under the fixed designation D7542; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.6 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This test method recommends a standard procedure for

ization established in the Decision on Principles for the

measuring oxidation rates in air of various grades of nuclear

Development of International Standards, Guides and Recom-

graphite and/or manufactured carbon. Following the standard

mendations issued by the World Trade Organization Technical

procedure recommended here, one can obtain kinetic param-

Barriers to Trade (TBT) Committee.

eters that characterize the oxidation resistance in standard

conditions of tested materials and that can be used to for

2. Referenced Documents

materials selection and qualification, and for quality control

2

2.1 ASTM Standards:

purposes in the fabrication process.

C559Test Method for Bulk Density by Physical Measure-

1.2 Thistestmethodcoverstherateofoxidativeweightloss

ments of Manufactured Carbon and Graphite Articles

per exposed nominal geometric surface area, or per initial

E691Practice for Conducting an Interlaboratory Study to

weight of machined test specimens of standard size and shape,

Determine the Precision of a Test Method

or both. The test is valid in the temperature range where the

E898Practice for Calibration of Non-Automatic Weighing

rate of air oxidation of graphite and manufactured carbon is

Instruments

limited by reaction kinetics.

E1582Test Method forTemperature Calibration ofThermo-

gravimetric Analyzers

1.3 This test method also provides a standard oxidation

E1970PracticeforStatisticalTreatmentofThermoanalytical

temperature (as defined in 3.1.7), and the kinetic parameters of

Data

the oxidation reaction, namely the apparent activation energy

and the logarithm of pre-exponential factor in Arrhenius

3. Terminology

equation. The kinetic parameters of Arrhenius equation are

3.1 Definitions:

calculated from the temperature dependence of oxidation rates

measuredoverthetemperaturerangewhereArrheniusplots(as 3.1.1 Definitions are ordered by oxidation rates first, fol-

lowed by activation energy as calculated from oxidation rates.

defined in 3.1.8) are linear, which is defined as the “kinetic” or

“chemical control” oxidation regime. For typical nuclear grade 3.1.2 area-normalized oxidation rate (OR ), n—rate of

a

weight loss due to oxidation of a machined test specimen at a

graphite materials it was found that the practical range of

testing temperatures is from about 500°C to 550°C up to given temperature, divided by the nominal geometric surface

area of the specimen.

about 700°C to 750°C.

3.1.2.1 Discussion—The rate of weight loss is determined

1.4 The values stated in SI units are to be regarded as

by a linear fit of the weight loss plotted against time in the

standard. No other units of measurement are included in this

range from 5% to 10% loss of original specimen weight. The

standard.

-1 -2

units of area-normalized oxidation rate, OR,aregh m .

a

1.5 This standard does not purport to address all of the

3.1.3 weight-normalized oxidation rate (OR ), n—rate of

w

safety concerns, if any, associated with its use. It is the

weightlossduetooxidationofamachinedspecimenatagiven

responsibility of the user of this standard to establish appro-

temperature, divided by the initial weight of the specimen.

priate safety, health, and environmental practices and deter-

3.1.3.1 Discussion—The rate of weight loss is determined

mine the applicability of regulatory limitations prior to use.

by a linear fit of the weight loss plotted against time in the

range from 5% to 10% loss of original specimen weight. The

units of weight-normalized oxidation rate, OR are:

w

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

2

Subcommittee D02.F0 on Manufactured Carbon and Graphite Products. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2021. Published November 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2009. Last previous edition approved in 2015 as D7542–15. DOI: Standards vo

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7542 − 15 D7542 − 21

Standard Test Method for

1

Air Oxidation of Carbon and Graphite in the Kinetic Regime

This standard is issued under the fixed designation D7542; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method recommends a standard procedure for measuring oxidation rates in air of various grades of nuclear graphite

and/or manufactured carbon. Following the standard procedure recommended here, one can obtain kinetic parameters that

characterize the oxidation resistance in standard conditions of tested materials and that can be used to for materials selection and

qualification, and for quality control purposes in the fabrication process.

1.2 This test method covers the rate of oxidative weight loss per exposed nominal geometric surface area, or per initial weight of

machined test specimens of standard size and shape, or both. The test is valid in the temperature range where the rate of air

oxidation of graphite and manufactured carbon is limited by reaction kinetics.

1.3 This test method also provides a standard oxidation temperature (as defined in 3.1.7), and the kinetic parameters of the

oxidation reaction, namely the apparent activation energy and the logarithm of pre-exponential factor in Arrhenius equation. The

kinetic parameters of Arrhenius equation are calculated from the temperature dependence of oxidation rates measured over the

temperature range where Arrhenius plots (as defined in 3.1.8) are linear, which is defined as the “kinetic” or “chemical control”

oxidation regime. For typical nuclear grade graphite materials it was found that the practical range of testing temperatures is from

about 500 °C to 550 °C up to about 700 °C to 750 °C.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C559 Test Method for Bulk Density by Physical Measurements of Manufactured Carbon and Graphite Articles

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E898 Practice for Calibration of Non-Automatic Weighing Instruments

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.F0 on Manufactured Carbon and Graphite Products.

Current edition approved Oct. 1, 2015Nov. 1, 2021. Published November 2015November 2021. Originally approved in 2009. Last previous edition approved in 20092015

as D7542 – 09.D7542 – 15. DOI: 10.1520/D7542-15.10.1520/D7542-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7542 − 21

E1582 Test Method for Temperature Calibration of Thermogravimetric Analyzers

E1970 Practice for Statistical Treatment of Thermoanalytical Data

3. Terminology

3.1 Definitions:

3.1.1 Definitions are ordered by oxidation rates first, followed by activation energy as calculated from oxidation rates.

3.1.2 area-normalized oxidation rate (OR )—), n—rate of weight loss due to oxidation of a machined test specimen at a given

a

temperature, divided by the nominal geometric surface area of the specimen.

3.1.2.1 Discussion—

The rate of weight loss is determined by

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.