ASTM F3033-16

(Practice)Standard Practice for Installation of a Single-Sized, Cured-In-Place Liner Utilizing an Inflatable Bladder for Resurfacing Manhole Walls of Various Shapes and Sizes

Standard Practice for Installation of a Single-Sized, Cured-In-Place Liner Utilizing an Inflatable Bladder for Resurfacing Manhole Walls of Various Shapes and Sizes<rangeref></rangeref >

SIGNIFICANCE AND USE

5.1 This practice is for use by designers and specifiers, regulatory agencies, owners, and inspection organizations who are involved in the rehabilitation of manholes ranging from 24 in. (0.61 m) and larger in diameter without excavation through the use of a resin-impregnated tube installed within an existing manhole. As for any practice, modifications may be required for specific job conditions.

5.1.1 The CIPMH liner is suitable for circular and non-circular manholes with varying diameters along the depth of the manhole.

5.2 The design engineer shall determine the CIPMH liner requirement to withstand external loads.

SCOPE

1.1 This practice covers requirements for the cured-in-place rehabilitation of manholes without excavation, utilizing an inflatable bladder, and not limited to sanitary sewer manholes.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 There is no similar or equivalent ISO standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Particular attention is drawn to those safety regulations and requirements involving entering into and working in confined spaces.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F3033 −16

Standard Practice for

Installation of a Single-Sized, Cured-In-Place Liner Utilizing

an Inflatable Bladder for Resurfacing Manhole Walls of

1,2

Various Shapes and Sizes

This standard is issued under the fixed designation F3033; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This practice covers requirements for the cured-in-place

3.1 Definitions—unless otherwise indicated, definitions are

rehabilitation of manholes without excavation, utilizing an inaccordancewithTerminologyF412,andabbreviationsarein

inflatable bladder, and not limited to sanitary sewer manholes.

accordance with Terminology D1600.

1.2 The values stated in inch-pound units are to be regarded 3.2 Definitions of Terms Specific to This Standard:

as standard. The values given in parentheses are mathematical

3.2.1 bonded—adhered to the manhole walls.

conversions to SI units that are provided for information only

3.2.2 chimney—the upper portion of a manhole - including

and are not considered standard.

the corbel section, adjusting rings, and the frame/lid.

1.3 There is no similar or equivalent ISO standard.

3.2.3 CIPMH—Cured-In-Place Manhole.

1.4 This standard does not purport to address all of the

3.2.4 close-fitting—fitting tightly to the manhole walls.

safety concerns, if any, associated with its use. It is the

3.2.5 compression seal—a gasket that forms a seal between

responsibility of the user of this standard to establish appro-

the original manhole and the cured-in-place liner.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Particular attention 3.2.6 design engineer—a licensed professional engineer in

isdrawntothosesafetyregulationsandrequirementsinvolving the state where the installation is to take place.

entering into and working in confined spaces.

3.2.7 freeze/thaw cycle—occurs when an area experiences

fluctuations in a temperature range from 28°F (-2.2°C) to 50°F

2. Referenced Documents

(10°C).

3

2.1 ASTM Standards:

3.2.8 impermeable barrier—an air-tight corrosion resistant

D543 Practices for Evaluating the Resistance of Plastics to

film formed when the inflation bladder is left behind perma-

Chemical Reagents

nently bonded to the interior of the cured-in-place manhole,

D1600 Terminology forAbbreviatedTerms Relating to Plas-

when a compatible epoxy resin system is used.

tics

3.2.9 inflation bladder—is a single sized polymer based

F412 Terminology Relating to Plastic Piping Systems

air-tight tube that is sized equal to or less than the smallest

cross section of a manhole corbel area.

3.2.9.1 Discussion—The bladder is subjected to a pressur-

1

This practice is under the jurisdiction of ASTM Committee F17 on Plastic

ized fluid. It expands and presses the liner against the walls of

Piping Systems and is the direct responsibility of Subcommittee F17.67 on

the manhole.

Trenchless Plastic Pipeline Technology.

Current edition approved Feb. 1, 2016. Published March 2016. DOI: 10.1520/

3.2.10 inflation device—a device that is outfitted with an

F3033–16

inflation bladder that when inflated presses the liner tube

2

The Standard Practice For The Installation Of A Single-Sized Cured-In-Place

against the manhole walls.

Liner For Manholes Having Various Sizes is covered by patents (LMK

Technologies, Inc. 1779 Chessie Lane, Ottawa, IL 61350). Interested parties are

3.2.11 inflow and infiltration—the intrusion of extraneous

invited to submit information regarding the identification of acceptable alternatives

water through a manhole.

to this patented item to the Committee on Standards,ASTM Headquarters, 100 Barr

Harbor Drive, West Conshohocken, PA 19428-2959. Your comments will receive

3.2.12 glass reinforcing mat—a woven roving glass mat

carefulconsiderationatameetingoftheresponsibletechnicalcommitteewhichmay

used to increase tensile strength in the upper corbel section for

attend

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

increased freeze/thaw resistance.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.2.13 single sized liner—a textile liner tube that is con-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. structed having expansive properties, sufficient to stretch

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

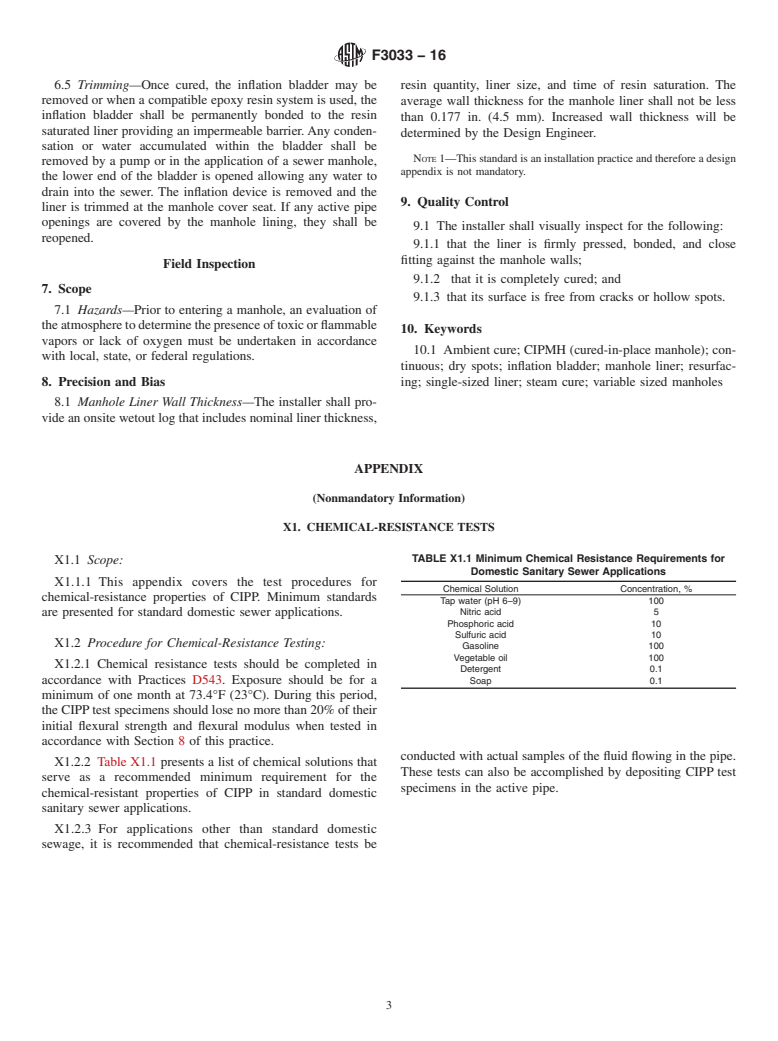

F3033−16

conforming to both the barrel and the corbel sections by the pressure washing such as abrasive blastin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.