ASTM D6114-97(2002)

(Specification)Standard Specification for Asphalt-Rubber Binder

Standard Specification for Asphalt-Rubber Binder

ABSTRACT

This specification covers asphalt-rubber binder, consisting of a blend of paving grade asphalt cements, ground recycled tire (that is, vulcanized) rubber and other additives, as needed, for use as binder in pavement construction. The rubber shall be blended and interacted in the hot asphalt cement sufficiently to cause swelling of the rubber particles prior to use. Tests shall be performed to conform with the physical requirements of the asphalt-rubber binder, in accordance with the following test methods: apparent viscosity; modified test method; penetration; softening point; resilience; flash point; thin-film oven test residue; and penetration retention.

SCOPE

1.1 This specification covers asphalt-rubber binder, consisting of a blend of paving grade asphalt cements, ground recycled tire (that is, vulcanized) rubber and other additives, as needed, for use as binder in pavement construction. The rubber shall be blended and interacted in the hot asphalt cement sufficiently to cause swelling of the rubber particles prior to use.

Note 1—It has been found that at least 15 % rubber by weight of the total blend is usually necessary to provide acceptable properties of asphalt-rubber.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.3 The following precautionary caveat pertains to the test method portions only, Sections 4 and 5 of this Specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 4.3.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6114 – 97 (Reapproved 2002)

Standard Specification for

Asphalt-Rubber Binder

This standard is issued under the fixed designation D 6114; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 946 Specification for Penetration-Graded Asphalt Ce-

ment for Use in Pavement Construction

1.1 This specification covers asphalt-rubber binder, consist-

D 1754 Test Method for Effects of Heat andAir onAsphal-

ing of a blend of paving grade asphalt cements, ground

tic Materials (Thin-Film Oven Test)

recycled tire (that is, vulcanized) rubber and other additives, as

D 1864 Test Method for Moisture in Mineral Aggregate

needed, for use as binder in pavement construction.The rubber

Used on Built-Up Roofs

shall be blended and interacted in the hot asphalt cement

D 2196 Test Methods for Rheological Properties of Non-

sufficiently to cause swelling of the rubber particles prior to

Newtonian Materials by Rotational (Brookfield type) Vis-

use.

cometer

NOTE 1—It has been found that at least 15 % rubber by weight of the

D 2872 TestMethodforEffectofHeatandAironaMoving

total blend is usually necessary to provide acceptable properties of

Film of Asphalt (Rolling Thin-Film Oven Test)

asphalt-rubber.

D 3381 Specification for Viscosity-Graded Asphalt Cement

1.2 The values stated in SI units are to be regarded as the

for Use in Pavement Construction

standard. The inch-pound units given in parentheses are for

D 5329 Test Methods for Sealants and Fillers, Hot-Applied,

information only.

for Joints and Cracks in Asphaltic and Portland Cement

1.3 The following precautionary caveat pertains to the test

Concrete Pavements

method portions only, Sections 4 and 5 of this Specification:

D 5644 Test Methods for Rubber Compounding

This standard does not purport to address all of the safety

Materials—Determination of Particle Size Distribution of

concerns, if any, associated with its use. It is the responsibility

Recycled Vulcanizate Particulate Rubber

of the user of this standard to establish appropriate safety and

3. Materials

health practices and determine the applicability of regulatory

limitations prior to use. Specific precautionary statements are

3.1 Asphalt Cement—The asphalt cement shall meet the

given in 4.3.2.

requirements of Specification D 946 or Table1or3of

Specification D 3381. Acceptable grades shall be able to

2. Referenced Documents

produce the properties of Table 1 of this specification when

2.1 ASTM Standards:

interacted with ground recycled tire rubber.

D5 Test Method for Penetration of Bituminous Materials

3.2 Ground Recycled Tire Rubber:

D36 Test Method for Softening Point of Bitumen (Ring-

3.2.1 The ground recycled tire rubber shall contain less than

and-Ball Apparatus)

0.75 % moisture by weight and shall be free flowing. The

D93 Test Methods for Flash Point by Pensky-Martens

specific gravity of the rubber shall be 1.15 6 0.05. The ground

Closed Cup Tester

recycled tire rubber shall contain no visible nonferrous metal

D 140 Practice for Sampling Bituminous Materials

particles and no more than 0.01 % ferrous metal particles by

weight.

1 3.2.2 For use in hot mix binders, the fiber content shall not

This specification is under the jurisdiction of ASTM Committee D04 on Road

and Paving Materials and is the direct responsibility of Subcommittee D04.40 on exceed 0.5 % by weight of ground recycled tire rubber.

Asphalt Specifications.

Howeverforuseinbindersforsprayapplications,fibercontent

Current edition approved May 10, 1997. Published October 1998. Originally

shall not exceed 0.1 % by weight. Up to 4 % by weight of

published as D 6114 – 97. Last previous edition D 6114 – 97.

mineral powder (such as talc) is permitted to prevent sticking

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

andcakingoftherubberparticles.Otherforeigncontaminating

Standards volume information, refer to the standard’s Document Summary page on

materials (see Note 2) shall be less than 0.25 % by weight.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 6114 – 97 (2002)

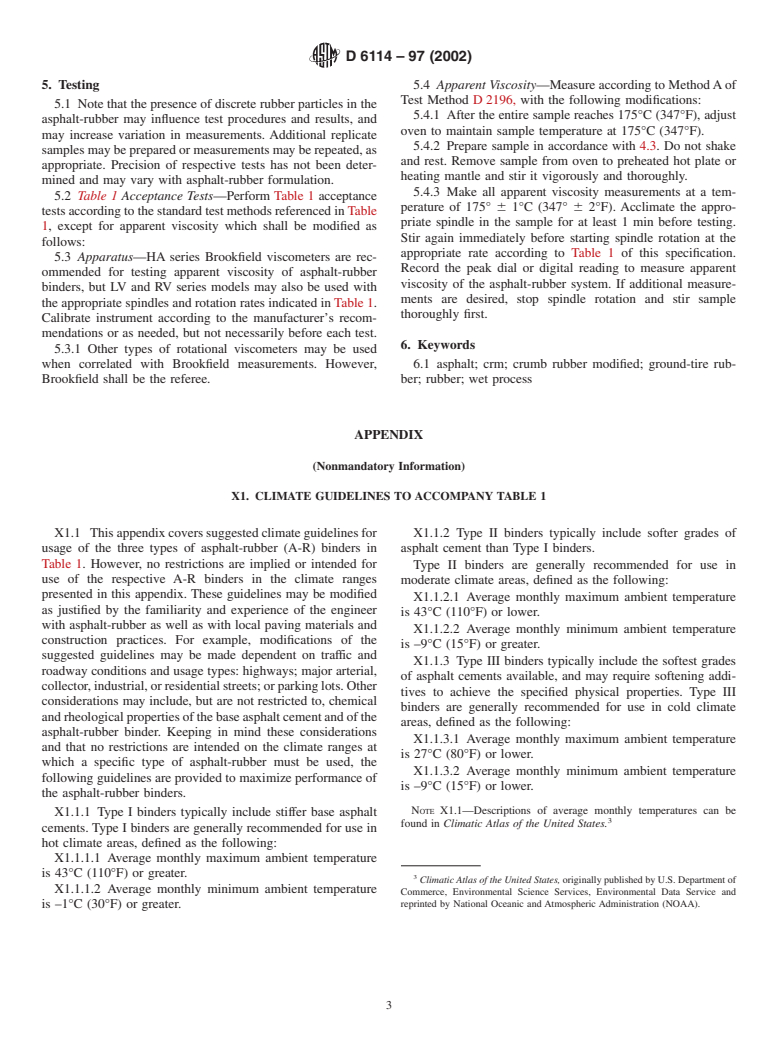

TABLE 1 Physical Requirements for Asphalt-Rubber Binder

A

Binder Designation Type I Type II Type III

Apparent Viscosity, 175°C (347°F):cP min 1500 1500 1500

Modified Test Method D 2196, Method

B,C

A, (see 5.4) max 5000 5000 5000

Penetration, 25°C (77°F) 100g, 5 s: min 25 25 50

⁄10 mm (Test Method D5) max 75 75 100

Penetration, 4°C (39.2°F), 200g , 60 s:

min 10 15 25

⁄10 mm (Test Method D5)

Softening Point: °C (°F) min 57.2 54.4 51.7

(Test Method D36) (135) (130) (125)

Resilience, 25°C (77°F): %

min 25 20 10

(Test Method D 5329)

Flash Point: °C (°F) min 232.2 232.2 232.2

(Test Method D93) (450) (450) (450)

Thin-Film Oven Test Residue (Test Method

.... .... .... ....

D

D 1754)

Penetration Retention, 4°C (39.2°F):

min 75 75 75

% of original (Test Method D5)

A

See Appendix for recommended climate guidelines for usage.

B

Either digital or dial reading Brookfield viscometers may be used - record peak measurement.

For LV series models, use spindle 3 at 12 rpm.

For RV and HA series models, use spindle 3 at 20 rpm.

C

Rion or Haake-type high range rotational viscometers may also be used (with Rotor No. 1) when correlated with Brookfield measurements, as may other rotational

viscometers. However Brookfield shall be the referee method.

D

RTFO Residue (See Test Method D 2872) may be substituted for TFOT Residue, except TFOT shall be the referee method in cases of dispute.

NOTE 2—Other foreign contaminants include, but are not limited to,

4.2 Asphalt-Rubber Sampling:

materials such as glass, sand, wood, etc.

4.2.1 Samplecontainersandhandlingshallbeinaccordance

3.2.3 It is recommended that no rubber particles should be

with Practice D 140.

retained on the 2.36 mm (No. 8) sieve. Rubber gradation

4.2.2 Representative samples shall be taken from a sample

should be agreed upon between purchaser and asphalt-rubber

valve or tap on the agitated tank in accordance with Practice

supplier for the specific mixture applications (see Note 3).

D 140, unless otherwise directed.

NOTE 3—It has been found that rubber gradiation may affect the

4.3 Preparation of Pre-Blended Asphalt-Rubber Samples

physical properties and performance of hot paving mixtures using

for Acceptance Testing:

asphalt-rubber binder.

4.3.1 Sample Melting and Heating—Loosen the cover of

3.3 Asphalt-Rubber:

the original sample container to relieve pressure, then place the

3.3.1 The asphalt-rubber shall be an interacted blend of

container in a preheated forced-draft oven and maintain oven

paving grade asphalt cement and ground recycled tire rubber.

temperature as required to heat sample to test temperature (see

Other additives not cited herein including other types of scrap

Note 4). After1hor when the asphalt-rubber material begins

rubber are permitted.

toliquify,removecover.Stirwithaspatulaasrequiredtoavoid

3.3.2 The asphalt-rubber shall not foam when heated to

localizedoverheatingofsampleandtoachieveuniformsample

175°C (347°F).

temperature. Replace cover and repeat these steps as needed.

3.3.3 Theasphalt-rubberblendshallconformtothephysical

requirements ofTable 1.This table was developed to provide a

NOTE 4—Only those samples which will be tested for viscosity at

reference for specifying asphalt-rubb

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.