ASTM D4014-03

(Specification)Standard Specification for Plain and Steel-Laminated Elastomeric Bearings for Bridges

Standard Specification for Plain and Steel-Laminated Elastomeric Bearings for Bridges

SCOPE

1.1 This specification covers bearings, which consist of all elastomer or of alternate laminates of elastomer and steel, when the function of the bearings is to transfer loads or accommodate relative movement between a bridge superstructure and its supporting structure, or both.

1.2 The values stated in SI units are to be regarded as the standard.

Note 1—The words "elastomer" or "elastomeric" will be used interchangeably with the word "rubber" in this specification.

1.3 The following safety hazards caveat pertains only to the test methods portion, Section B, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4014 – 03

Standard Specification for

Plain and Steel-Laminated Elastomeric Bearings for

1

Bridges

This standard is issued under the fixed designation D4014; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 1418 Practice for Rubber and Rubber Latices—

3

Nomenclature

1.1 This specification covers bearings, which consist of all

D2000 Classification System for Rubber Products inAuto-

elastomer or of alternate laminates of elastomer and steel,

4

motive Applications

when the function of the bearings is to transfer loads or

D2137 Test Methods for Rubber Property—Brittleness

accommodate relative movement between a bridge superstruc-

3

Point of Flexible Polymers and Coated Fabrics

ture and its supporting structure, or both.

D 2240 Test Method for Rubber Property—Durometer

1.2 The values stated in SI units are to be regarded as the

3

Hardness

standard.

D3183 Practice for Rubber—Preparation of Pieces forTest

NOTE 1—The words “elastomer” or “elastomeric” will be used inter- 3

Purposes from Products

changeably with the word “rubber” in this specification.

5

E4 Practices for Force Verification of Testing Machines

1.3 The following safety hazards caveat pertains only to the

3. Terminology

test methods portion, Section B, of this specification: This

standarddoesnotpurporttoaddressallofthesafetyconcerns,

3.1 Definitions:

ifany,associatedwithitsuse.Itistheresponsibilityoftheuser

3.1.1 design load—the mean compressive stress applied to

of this standard to establish appropriate safety and health

the area of the steel laminate.

practices and determine the applicability of regulatory limita-

3.1.2 external load plate—a steel plate bonded to the top or

tions prior to use.

bottom elastomeric surface of a bearing, or both.

3.1.3 lot—unless otherwise specified in the contract or

2. Referenced Documents

purchaseorder,alotshallconsistofasingletypeofbearing,of

2.1 ASTM Standards:

the same design and material, submitted for inspection at the

2

A36/A36M Specification for Carbon Structural Steel

same time.

D395 Test Methods for Rubber Property—Compression

3.1.4 plain elastomeric bearing pad—a bearing that con-

3

Set

sists only of elastomeric material.

D412 Test Methods for Vulcanized Rubber and Thermo-

3.1.5 plain elastomeric sandwich bearing—a bearing that

3

plastic Elastomers—Tension

consistsofasinglelayerofelastomericmaterialbondedtoone

D518 Test Method for Rubber Deterioration—Surface

or two external load plates (3.1.2).

3

Cracking

3.1.6 steel-laminated elastomeric bearing—a bearing

D573 Test Method for Rubber—Deterioration in an Air

molded of elastomeric material with one or more steel lami-

3

Oven

nates embedded in and bonded to it, and to which one or two

D 832 Practice for Rubber Conditioning for Low-

external load plates (3.1.2) may be bonded.

3

Temperature Testing

4. Classification

D1149 Test Method for Rubber Deterioration Surface

3

Ozone Cracking in a Chamber

4.1 The bearings are furnished in four types as follows:

D1415 Test Method for Rubber Property—International

4.1.1 Plain Elastomeric Bearing Pad.

3

Hardness

4.1.2 Plain Elastomeric Sandwich Bearing.

4.1.3 Steel-Laminated Elastomeric Bearing.

4.1.4 Steel-Laminated Elastomeric Bearing with External

1

This specification is under the jurisdiction ofASTM Committee D04 on Road

Load Plate(s).

and Paving Materials and is the direct responsibility of Subcommittee D04.32 on

Bridges and Structures.

Current edition approved Feb. 10, 2003. Published May 2003. Orginally

approved in 1981. Last previous edition approved in 1995 as D4014-89 (1995).

2 4

Annual Book of ASTM Standards, Vol 01.04. Annual Book of ASTM Standards, Vol 09.02.

3 5

Annual Book of ASTM Standards, Vol 09.01. Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4014–03

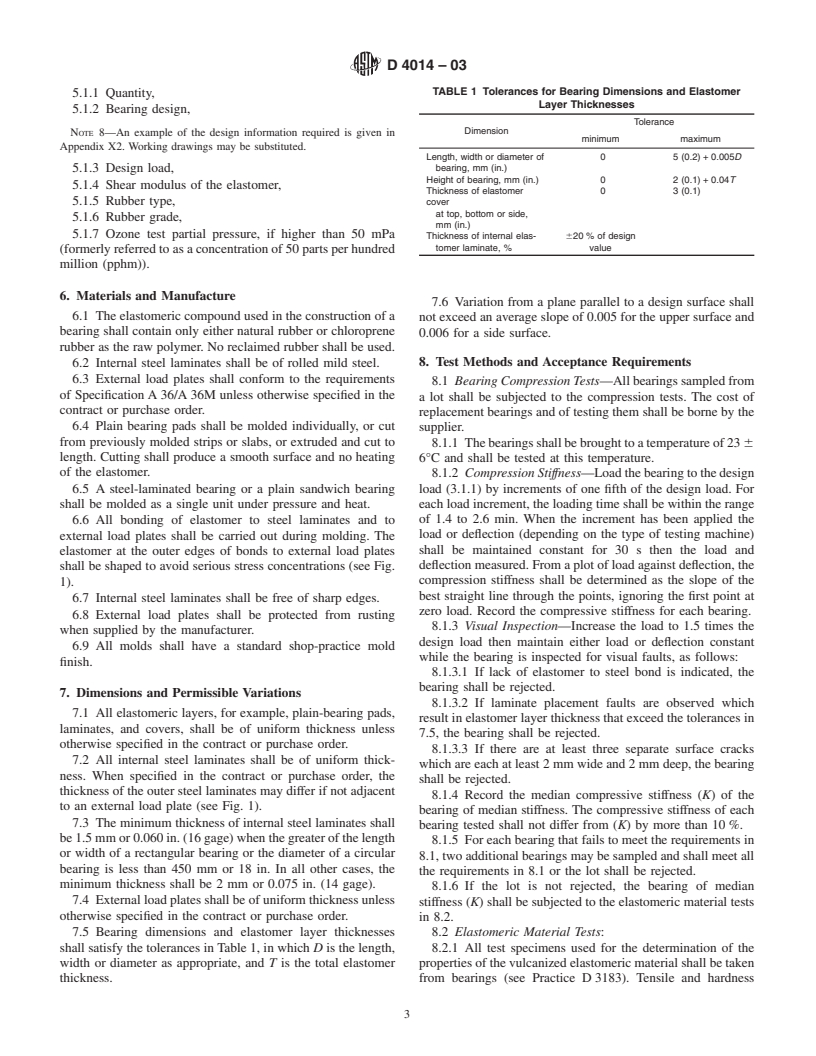

NOTE 2—Examplesofthetypesofelastomericbearingconstructionare

4.3.1 Grade 0—Suitable for continuous use down to+5°C.

given in Fig. 1.

4.3.2 Grade 2—Sub-zero temperatures occur at night and

NOTE 3—The adjective elastomeric is omitted in this specification

occasionally persist for no more than 1 or 2 days.

when referring to bearing types.

4.3.3 Grade 3—Sameas2butoccasionalperiodsofupto2

4.2 The elastomer for the manufacture of the bearing is

weeks continuously below zero.

furnished in two types as follows:

4.3.4 Grade5—Sub-zerotemperaturesdownto−40°Cper-

4.2.1 Type CR—Chloroprene rubber.

sisting for several months each year with up to 2 months

4.2.2 Type NR—Natural rubber.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.