ASTM B395/B395M-18

(Specification)Standard Specification for U-Bend Seamless Copper and Copper Alloy Heat Exchanger and Condenser Tubes

Standard Specification for U-Bend Seamless Copper and Copper Alloy Heat Exchanger and Condenser Tubes

ABSTRACT

This specification establishes the requirements for condenser, evaporator, and heat exchanger U-bends that are manufactured from seamless copper and copper alloy tube. The material of manufacture shall be of such quality and purity that the finished product shall have the properties and characteristics specified. The material shall conform to the chemical composition requirements specified. Tensile test, expansion test, flattening test, mercurous nitrate test or ammonia vapor test, nondestructive examination, hydrostatic test, and pneumatic test shall be made to conform to the requirements specified.

SIGNIFICANCE AND USE

18.1 For purpose of determining compliance with the specified limits for requirements of the properties listed in the following table, an observed value or a calculated value shall be rounded as indicated in accordance with the rounding method of Practice E29.

Property

Rounded Unit for Observed or

Calculated Value

Chemical composition

nearest unit in the last

right-hand significant

digit used in expressing

the limiting value

Tensile strength

nearest ksi [nearest 5 MPa]

Elongation

nearest 1 %

Expansion

nearest 1 %

Grain size

nearest multiple of 0.005 mm

SCOPE

1.1 This specification2 establishes the requirements for condenser, evaporator, and heat exchanger U-bend tubes that are manufactured from seamless copper and copper alloy tube.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This specification is applicable to product 2 in. [50 mm] or less, inclusive, in diameter.

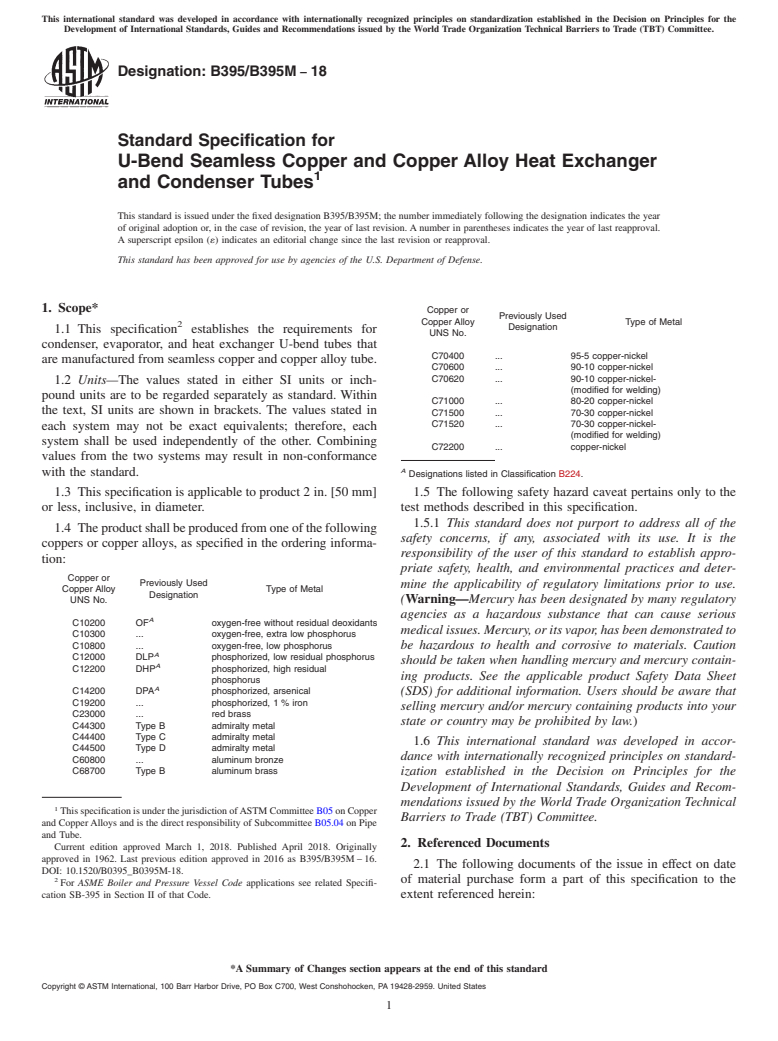

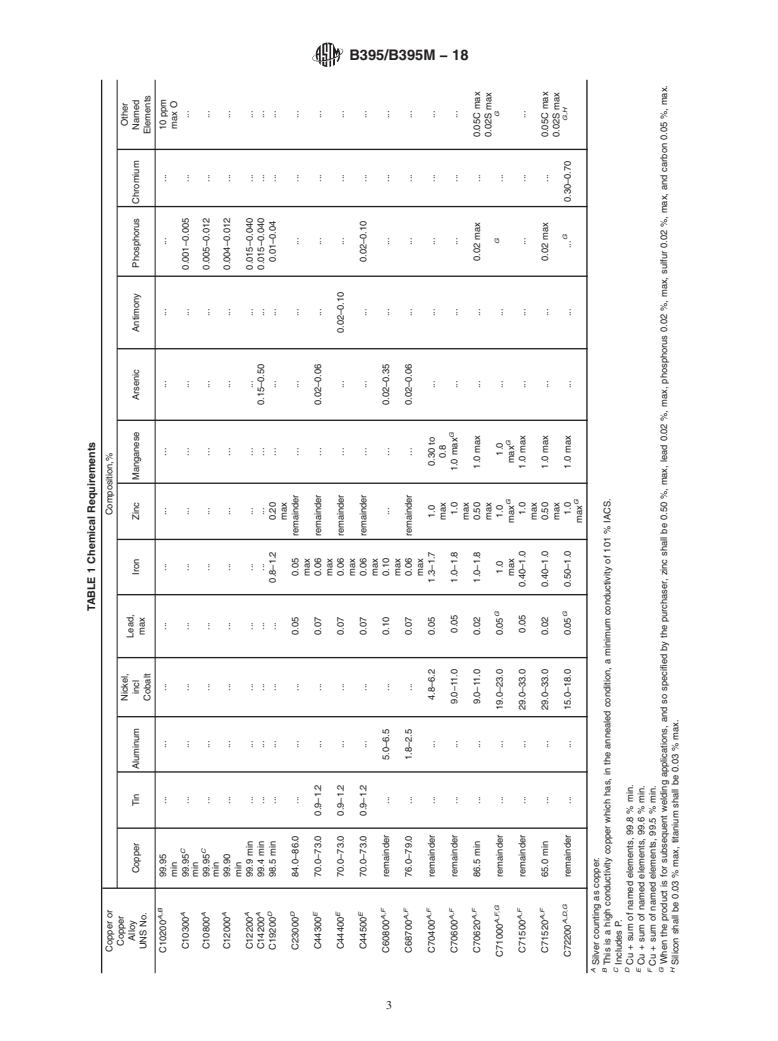

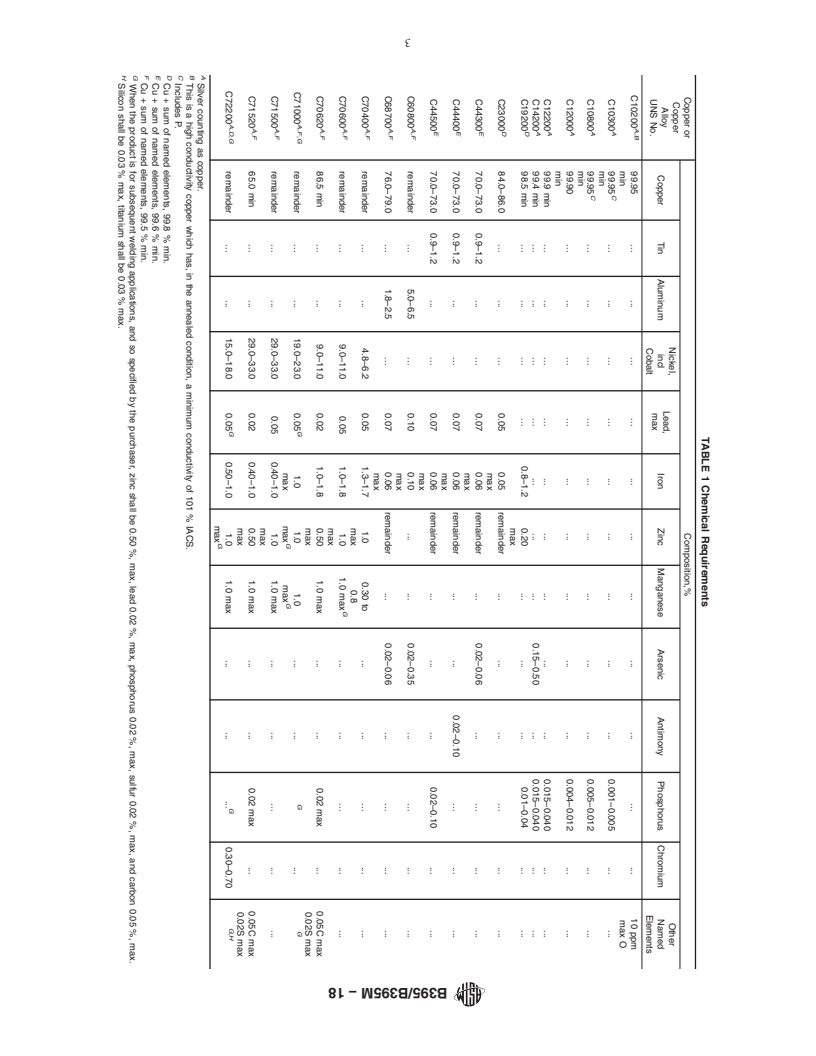

1.4 The product shall be produced from one of the following coppers or copper alloys, as specified in the ordering information:

Copper or

Copper Alloy

UNS No.

Previously Used

Designation

Type of Metal

C10200

OFA

oxygen-free without residual deoxidants

C10300

...

oxygen-free, extra low phosphorus

C10800

...

oxygen-free, low phosphorus

C12000

DLPA

phosphorized, low residual phosphorus

C12200

DHPA

phosphorized, high residual phosphorus

C14200

DPAA

phosphorized, arsenical

C19200

...

phosphorized, 1 % iron

C23000

...

red brass

C44300

Type B

admiralty metal

C44400

Type C

admiralty metal

C44500

Type D

admiralty metal

C60800

...

aluminum bronze

C68700

Type B

aluminum brass

C70400

...

95-5 copper-nickel

C70600

...

90-10 copper-nickel

C70620

...

90-10 copper-nickel-

(modified for welding)

C71000

...

80-20 copper-nickel

C71500

...

70-30 copper-nickel

C71520

...

70-30 copper-nickel-

(modified for welding)

C72200

...

copper-nickel(A) Designations listed in Classification B224.

1.5 The following safety hazard caveat pertains only to the test methods described in this specification.

1.5.1 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. (Warning—Mercury has been designated by many regulatory agencies as a hazardous substance that can cause serious medical issues. Mercury, or its vapor, has been demonstrated to be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Safety Data Sheet (SDS) for additional information. Users should be awar...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B395/B395M −18

Standard Specification for

U-Bend Seamless Copper and Copper Alloy Heat Exchanger

1

and Condenser Tubes

This standard is issued under the fixed designation B395/B395M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

Copper or

Previously Used

Copper Alloy Type of Metal

2

Designation

1.1 This specification establishes the requirements for

UNS No.

condenser, evaporator, and heat exchanger U-bend tubes that

C70400 . 95-5 copper-nickel

are manufactured from seamless copper and copper alloy tube.

C70600 . 90-10 copper-nickel

C70620 . 90-10 copper-nickel-

1.2 Units—The values stated in either SI units or inch-

(modified for welding)

pound units are to be regarded separately as standard. Within

C71000 . 80-20 copper-nickel

the text, SI units are shown in brackets. The values stated in

C71500 . 70-30 copper-nickel

C71520 . 70-30 copper-nickel-

each system may not be exact equivalents; therefore, each

(modified for welding)

system shall be used independently of the other. Combining

C72200 . copper-nickel

values from the two systems may result in non-conformance

A

with the standard.

Designations listed in Classification B224.

1.3 Thisspecificationisapplicabletoproduct2in.[50mm] 1.5 The following safety hazard caveat pertains only to the

test methods described in this specification.

or less, inclusive, in diameter.

1.5.1 This standard does not purport to address all of the

1.4 Theproductshallbeproducedfromoneofthefollowing

safety concerns, if any, associated with its use. It is the

coppers or copper alloys, as specified in the ordering informa-

responsibility of the user of this standard to establish appro-

tion:

priate safety, health, and environmental practices and deter-

Copper or

Previously Used

mine the applicability of regulatory limitations prior to use.

Copper Alloy Type of Metal

Designation

UNS No. (Warning—Mercury has been designated by many regulatory

agencies as a hazardous substance that can cause serious

A

C10200 OF oxygen-free without residual deoxidants

medical issues. Mercury, or its vapor, has been demonstrated to

C10300 . oxygen-free, extra low phosphorus

C10800 . oxygen-free, low phosphorus be hazardous to health and corrosive to materials. Caution

A

C12000 DLP phosphorized, low residual phosphorus

should be taken when handling mercury and mercury contain-

A

C12200 DHP phosphorized, high residual

ing products. See the applicable product Safety Data Sheet

phosphorus

A

C14200 DPA phosphorized, arsenical (SDS) for additional information. Users should be aware that

C19200 . phosphorized, 1 % iron

selling mercury and/or mercury containing products into your

C23000 . red brass

state or country may be prohibited by law.)

C44300 Type B admiralty metal

C44400 Type C admiralty metal

1.6 This international standard was developed in accor-

C44500 Type D admiralty metal

dance with internationally recognized principles on standard-

C60800 . aluminum bronze

C68700 Type B aluminum brass

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

Barriers to Trade (TBT) Committee.

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

and Tube.

2. Referenced Documents

Current edition approved March 1, 2018. Published April 2018. Originally

approved in 1962. Last previous edition approved in 2016 as B395/B395M–16.

2.1 The following documents of the issue in effect on date

DOI: 10.1520/B0395_B0395M-18.

2 of material purchase form a part of this specification to the

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

cation SB-395 in Section II of that Code. extent referenced herein:

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B395/B395M−18

3

2.2 ASTM Standards: 3.2.3 u-bend tube, n—atubebent180°inasingleplaneinto

B153Test Method for Expansion (Pin Test) of Copper and a U-shape.

Copper-Alloy Pipe and Tubing

4. Ordering Information

B154Test Method for Mercurous Nitrate Test for Copper

Alloys

4.1 Includ

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

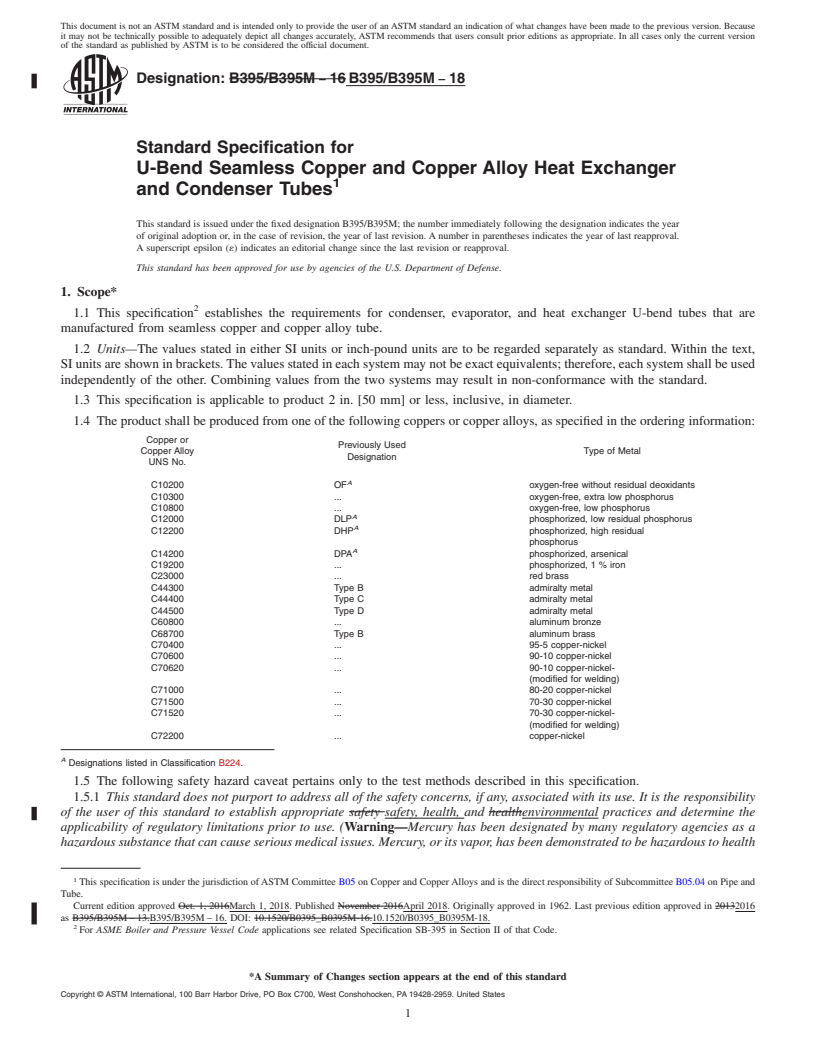

Designation: B395/B395M − 16 B395/B395M − 18

Standard Specification for

U-Bend Seamless Copper and Copper Alloy Heat Exchanger

1

and Condenser Tubes

This standard is issued under the fixed designation B395/B395M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

2

1.1 This specification establishes the requirements for condenser, evaporator, and heat exchanger U-bend tubes that are

manufactured from seamless copper and copper alloy tube.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text,

SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used

independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This specification is applicable to product 2 in. [50 mm] or less, inclusive, in diameter.

1.4 The product shall be produced from one of the following coppers or copper alloys, as specified in the ordering information:

Copper or

Previously Used

Copper Alloy Type of Metal

Designation

UNS No.

A

C10200 OF oxygen-free without residual deoxidants

C10300 . oxygen-free, extra low phosphorus

C10800 . oxygen-free, low phosphorus

A

C12000 DLP phosphorized, low residual phosphorus

A

C12200 DHP phosphorized, high residual

phosphorus

A

C14200 DPA phosphorized, arsenical

C19200 . phosphorized, 1 % iron

C23000 . red brass

C44300 Type B admiralty metal

C44400 Type C admiralty metal

C44500 Type D admiralty metal

C60800 . aluminum bronze

C68700 Type B aluminum brass

C70400 . 95-5 copper-nickel

C70600 . 90-10 copper-nickel

C70620 . 90-10 copper-nickel-

(modified for welding)

C71000 . 80-20 copper-nickel

C71500 . 70-30 copper-nickel

C71520 . 70-30 copper-nickel-

(modified for welding)

C72200 . copper-nickel

A

Designations listed in Classification B224.

1.5 The following safety hazard caveat pertains only to the test methods described in this specification.

1.5.1 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. (Warning—Mercury has been designated by many regulatory agencies as a

hazardous substance that can cause serious medical issues. Mercury, or its vapor, has been demonstrated to be hazardous to health

1

This specification is under the jurisdiction of ASTM Committee B05 on Copper and Copper Alloys and is the direct responsibility of Subcommittee B05.04 on Pipe and

Tube.

Current edition approved Oct. 1, 2016March 1, 2018. Published November 2016April 2018. Originally approved in 1962. Last previous edition approved in 20132016

as B395/B395M – 13.B395/B395M – 16. DOI: 10.1520/B0395_B0395M-16.10.1520/B0395_B0395M-18.

2

For ASME Boiler and Pressure Vessel Code applications see related Specification SB-395 in Section II of that Code.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B395/B395M − 18

and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable

product Safety Data Sheet (SDS) for additional information. Users should be aware that selling mercury and/or mercury

containing products into your state or country may be prohibited by law.)

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein:

3

2.2 ASTM Standards:

B153 Test Method for Expansion (Pin Test) of Copper and Copper-Alloy Pipe a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.