ASTM D197-87(2002)

(Test Method)Standard Test Method for Sampling and Fineness Test of Pulverized Coal

Standard Test Method for Sampling and Fineness Test of Pulverized Coal

SCOPE

1.1 This test method covers the determination of the fineness by sieve analysis of coal sampled from a dry pulverizing operation. It is not applicable to products of wet milling or to fines that have clustered into an agglomerated mass.

1.2 The values stated in inch-pound units shall be regarded as the standard. Sample weights of 1000 g or less shall be expressed in metric units.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D197–87(Reapproved 2002)

Standard Test Method for

Sampling and Fineness Test of Pulverized Coal

This standard is issued under the fixed designation D 197; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4.2 Drying Oven—A device for passing slightly heated air

over the sample. The oven should be capable of maintaining a

1.1 This test method covers the determination of the fine-

temperature of 18 to 27°F (10 to 15°C) above room tempera-

ness by sieve analysis of coal sampled from a dry pulverizing

ture with a maximum oven temperature of 104°F (40°C). Air

operation. It is not applicable to products of wet milling or to

changes should be at the rate of 1 to 4/min.

fines that have clustered into an agglomerated mass.

4.3 Sieves, square-hole, woven-wire cloth conforming to

1.2 The values stated in inch-pound units shall be regarded

SpecificationE11:

as the standard. Sample weights of 1000 g or less shall be

No. 8 USA Standard (2.36 mm)

expressed in metric units.

No. 16 USA Standard (1.18 mm)

1.3 This standard does not purport to address all of the

No. 30 USA Standard (600 µm)

safety concerns, if any, associated with its use. It is the

No. 50 USA Standard (300 µm)

No. 100 USA Standard (150 µm)

responsibility of the user of this standard to establish appro-

No. 200 USA Standard (75 µm)

priate safety and health practices and determine the applica-

No. 325 USA Standard (45 µm)

bility of regulatory limitations prior to use.

Thesieveframesshallbe8in.(203mm)indiameter,andthe

2. Referenced Documents height of the sieve from the top of the frame to the cloth shall

be either 2 in. (50.8 mm) or 1 in. (25.4 mm). Selection of

2.1 ASTM Standards:

specificsizesisoptional,dependingontheobjectiveofthetest.

E11 Specification for Wire-Cloth Sieves for Testing Pur-

2 4.3.1 Since the finer mesh sieves in particular are suscep-

poses

tible to damage by distortion resulting from undue pressure,

3. Significance and Use accidental scraping with hard brushes, etc., each sieve should

be closely inspected and discarded if it shows evidence of

3.1 This test method provides a means for assisting in the

damage.

evaluation of pulverizers and pulverizer systems in terms of

4.4 Mechanical Sieving Machine—The mechanical sieving

fineness specifications. It may also be used to confirm the

machine shall be designed to provide both a circular motion

influence of coal fineness on combustion performance and to

and a tapping action. It shall be designed to accept an assembly

evaluate carbon loss. By consent among interested parties, it

of vertically nested circular sieves as described in 4.3. The

may be used for evaluation of coal fineness in preparation,

machine action shall be such that results as described in

pneumatic transfer systems, etc.

Section 7 are obtained within the allotted time frame. Action

4. Apparatus

shall not be sufficiently severe to generate new fines by particle

degradation. To facilitate the sieving operation, a control

4.1 Sample Containers—Heavy vapor impervious bags,

switch device with timer is recommended. Other equipment

properly sealed, or noncorroding cans such as those with an

designs may be used provided the results are comparable.

airtight, friction top or screw top sealed with a rubber gasket

4.5 Balance, Laboratory—Approximately 1000-g capacity,

and pressure sensitive tape for use in storage and transport of

sensitivity 0.1 g.

the laboratory sample. Glass containers sealed with rubber

4.6 Sampling Device (Storage System)—An instrument

gaskets may be used, but care must be taken to avoid breakage

(scoop, dipper, or other suitable device) for collecting incre-

in transport.

ments that will constitute the total sample.

4.7 Sampling Device (Direct-Fired System)—Apparatus as

described in 6.2.1 and 6.2.2.

This test method is under the jurisdiction of ASTM Committee D05 on Coal

and Coke, and is the direct responsibility of Subcommittee D05.07 on Physical

4.8 Sample Riffle with Pans—Amanual sample divider that

Characteristics of Coal.

splits the coal stream into a number of alternate elements.

Current edition approved Sept. 25, 1987. Published November 1987. Originally

1 1

e1

Riffledivisionsshouldbeinthesizerangefrom ⁄4to ⁄2in.(6.4

published as D 197 – 24 T. Last previous edition D 197 – 87 (1994) .

Annual Book of ASTM Standards, Vol 14.02. to 12.7 mm).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D197–87 (2002)

5. Sampling, Storage System collect such samples from vertical pipes, as in horizontal pipes

a greater amount of segregation may take place.

5.1 In the pulverized coal storage system, the coal after

pulverization is conveyed into bins. 6.2 ApparatusforSampleCollection—Because it is difficult

to collect a representative sample of solids from a moving

5.1.1 Collection of Gross Sample—Collect not less than ten

increments of representative pulverized coal preferably as it is coal-air stream, it is essential that the equipment and sampling

being discharged from the collector. This is best accomplished procedures are uniformly consistent to assure valid and repro-

by collecting increments of not less than 50 g at regular ducible results. Recommended equipment and sampling ar-

intervals by means of a scoop, dipper, or a device capable of rangements are shown in Fig. 2 and Fig. 3. Except in

removing an increment from a specific location within the

circumstanceswherestationaryinterferencesintheareaaround

stream of pulverized coal. Place the increments in the sample the sampling location prohibits the use of the sampling

container and seal.

equipmentasshowninFig.3,changestotheequipmentshould

5.1.2 Preparation of the Laboratory Sample—Asmall riffle

not be allowed. Changes may produce inconsistent results.

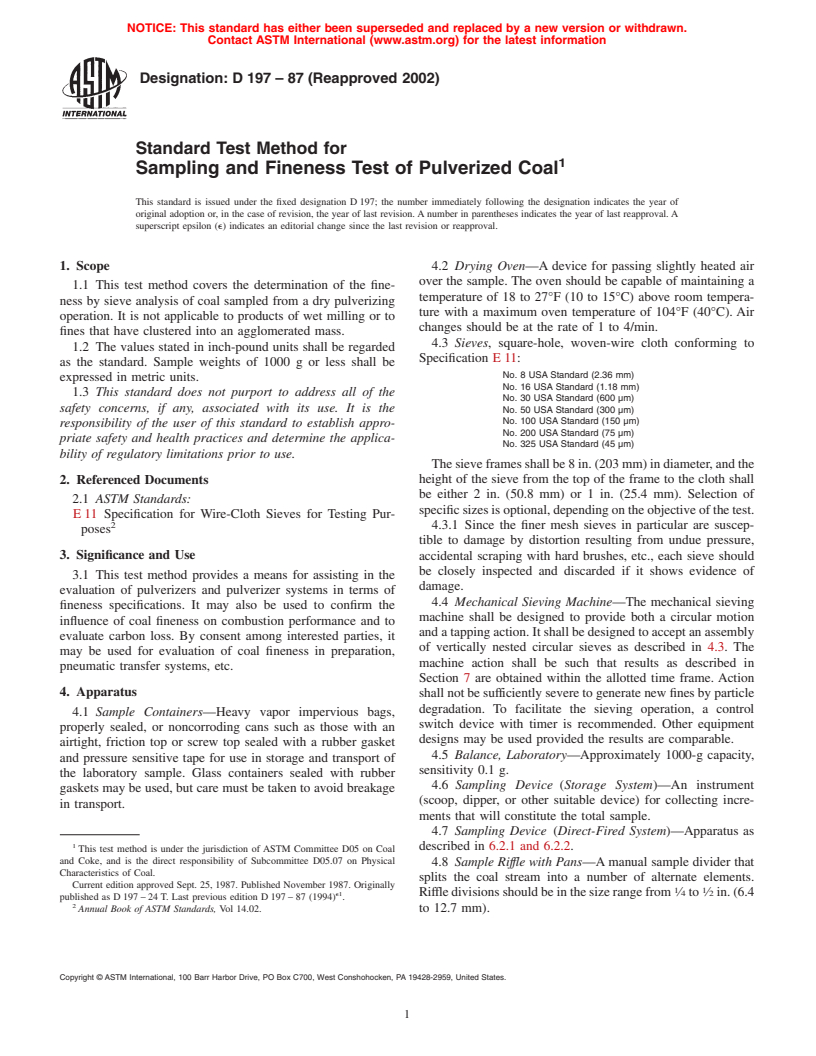

(Fig. 1) can be used for mixing and dividing the sample by

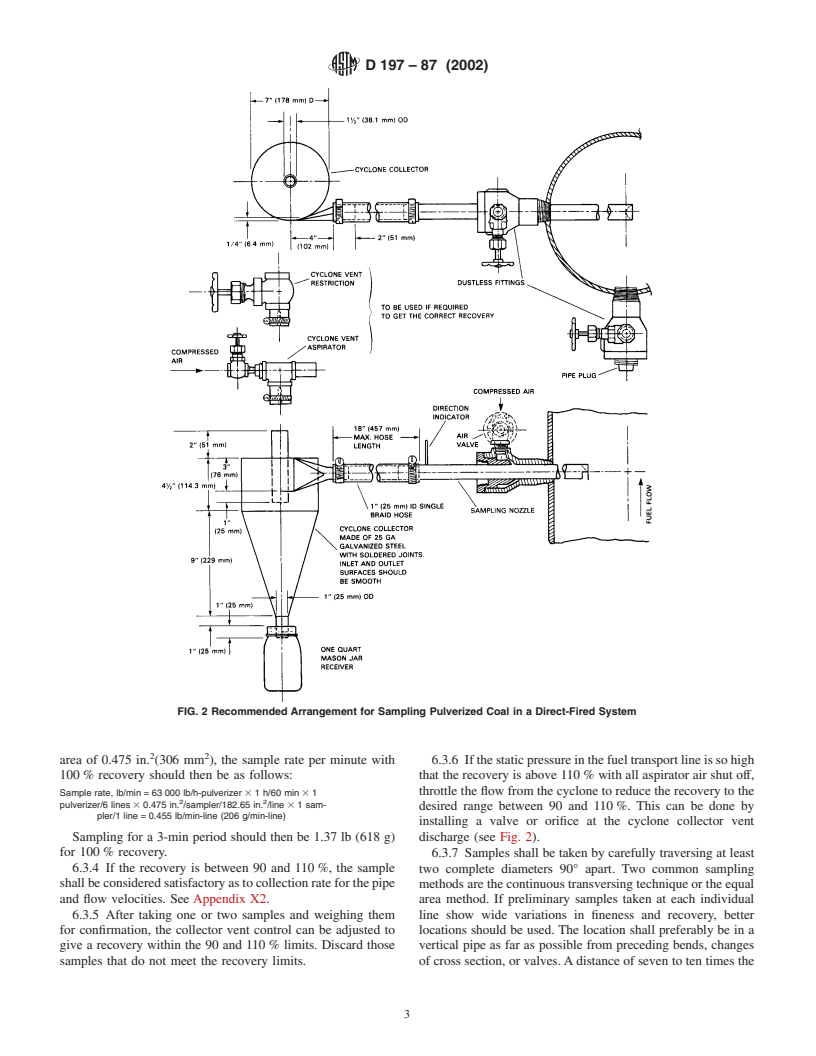

6.2.1 Fig. 2 shows the recommended arrangement for sam-

splitting. An enclosed riffle is preferred. Mix the gross sample

pling pulverized coal in a direct-fired system using a dustless

by splitting and recombining the halves a minimum of two

sampling connection with an aspirator and a cyclone collector.

times. Divide the sample amount by successive riffle splitting

In collecting the sample, turn on the compressed air to the

operations on one half of the sample until the sample is divided

dustless connection and adjust to give a balanced pressure at

to approximately 500 g for the laboratory sample. To correctly

the connection. Insert the sampling tip into the dustless

use the riffle, the sample must be poured over the side of a pan

connection with the tip facing directly into the coal-air stream.

(a third pan is necessary) and not from an end or corner, nor

Readjust the compressed air to give a balanced pressure with

from a container such as, a pail or jar. Transfer the sample to

the nozzle inserted. Traverse the fuel transport line across the

a sample container and seal.

entirediameterofthepipebymovingatauniformratewiththe

5.1.3 As an alternative to riffle mixing and splitting, the

tipfacingdirectlyintothecoal-airstream.Theaspiratingairon

sample can be prepared as follows: Place the gross sample on

the cyclone collector may or may not be used, depending on

asheetofrubber,plastic,orpaperandmixitbyraisingfirstone

the static pressure in the fuel transport line, as discussed in

corner of the cloth and then the other so as to roll the coal over

6.3.7.

and over at least 20 times. After mixing, divide the sample.

6.2.2 Fig. 3 shows detailed dimensions of a recommended

Continue the operations of mixing and dividing until the

sampling tip. The area of the tip shown is 0.5 by 0.95 in. or

sample is divided sufficiently so that all of one of the divisions

2 2

0.475 in. (12.7 by 24.1 mm or 306 mm ), which is the

weighs approximately 500 g. This shall constitute the labora-

projected area of the tip facing the coal-air stream. Other tip

tory sample.

configurations and dimensions can be employed provided they

permit the collection of an unbiased sample from the coal

6. Sampling, Direct-Fired System

stream. See Appendix X1.

6.1 In the direct-fired system, the coal is pulverized and

6.3 Collection of Gross Sample:

delivered directly to the furnace in an air stream. It is difficult

6.3.1 In sampling, it is essential that the velocity into the

to obtain representative samples, as it is necessary to sample

sampling tip be nearly the same as the velocity in the pipe. If

the coal from a moving stream of coal-air mixture inside the

the velocity in the sampling tube is insufficient, the full quota

pipe between the pulverizer and furnace. It is preferable to

of the coarse particles will be entrained, but some of the fine

particles that should be caught will follow the air in passing

around the tip. If the velocity in the sampling tube is greater,

more than the proper number of fine particles will be drawn

into the sampling tip.

6.3.2 A procedure for confirming sample validity is in-

cluded in Appendix X4.

6.3.3 Asample obtained in a given time should be weighed

and compared with the weight of coal passing through the fuel

transport line. The weight of the coal passing through the pipe

may be determined from the total coal to the pulverizer divided

by number of pipes. The weight of coal passing through the

fuel transport line, multiplied by the ratio of the cross-sectional

area of the sampling tip to that of the pipe, should be

approximately equal to the sample weight (see 6.3.9). For

example, if a pulverizer has an output of 63 000 lb of coal per

hourpassingthroughsixlines,andifeachlineis15.25in.(387

mm) in inside diameter, with a cross-sectional area of 182.65

2 2

in. (1170 cm ) and if the standard sampler has a tip opening of

FIG. 1 Sample Divider (Riffle) 0.5 by 0.95 in. (12.7 mm by 24.1 mm) and a cross-sectional

D197–87 (2002)

FIG. 2 Recommended Arrangement for Sampling Pulverized Coal in a Direct-Fired System

2 2

area of 0.475 in. (306 mm ), the sample rate per minute with 6.3.6 Ifthestaticpressureinthefueltransportlineissohigh

100 % recovery should then be as follows: that the recovery is above 110 % with all aspirator air shut off,

throttle the flow from the cyclone to reduce the recovery to the

Sample rate, lb/min = 63 000 lb/h-pulverizer 31h/60min 3 1

2 2

pulverizer/6 lines 3 0.475 in. /sampler/182.65 in. /line 3 1 sam-

desired range between 90 and 110 %. This can be done by

pler/1 line = 0.455 lb/min-line (206 g/min-line)

installing a valve or orifice at the cyclone collector vent

Sampling for a 3-min period should then be 1.37 lb (618 g) discharge (see Fig. 2).

for 100 % recovery.

6.3.7 Samples shall be taken by carefully traversing at least

6.3.4 If the recovery is between 90 and 110 %, the sample

two complete diameters 90° apart. Two common sampling

shallbeconsideredsatisfactoryastocollectionrateforthepipe

methods are the continuous transversing technique or the equal

and flow velocities. See Appendix X2.

area method. If preliminary samples taken at each individual

6.3.5 After taking one or two samples and weighing them line show wide variations in fineness and recovery, better

for confirmation, the collector vent control can be adjusted to locations should be used. The location shall preferably be in a

give a recovery within the 90 and 110 % limits. Discard those vertical pipe as far as possible from preceding bends, changes

samples that do not meet the recovery limits. of cross section, or valves.Adistance of seven to ten times the

D197–87 (2002)

FIG. 3 Detail of Sampling Nozzle

samplers. The collection is best accomplished by one person actually

pipe diameter is desirable. Sampling connections shall be

sampling, assisted by a person to facilitate equipment and sample

cleared of accumulated coal before taking samples.

handling.

6.3.8 Precautionsshouldbetakentokeepthesamplesabove

the water dew point during collection.

7. Fineness Test

6.3.9 When the sampling points are in the pipes and a

7.1 Drying Sample—Air-dry the entire laboratory sample in

pulverizer has two or more pipes, the total weight of the

a drying oven at 18 to 27°F (10 to 15°C) above room

samples from all the pipes should be compared with total coal

temperature. Continue the drying until the loss in weight is not

weight to check the recovery, as explained in 6.3.2-6.3.4.

more than 0.1 %/h.

6.3.10 When the air velocity and static pressure in each fuel

7.2 Dividing the Sample—After air-drying, divide the

transportlinearenearlyequal,thesamecyclonethrottlesetting

sample amount to 50 to 100 g as described in 5.1.2 and 5.1.3.

and the same air pressure at the aspirator should give about the

7.3 Sieve Test:

same sample tip velocity. Then, even if the coal is not equally

distributed in the several pipes, duplicate cyclone throttle

7.3.1 Select the proper sieve sizes for the test and thor-

settings should result in samples from each pipe that will be oughly clean each by carefully brushing and tapping to assure

approximately proportional in weight to the coal distribution,

that no solid particles from previous tests are trapped in the

but the total should be between 90 and 110 % of the propor- meshes. Nest the sieves together with the coarsest mesh at the

tional total coal flow. Samples at each point should be taken for

top and in descending order with the finest mesh at the bottom.

equal time periods and not by equal amounts collected. Each

Set a pan receiver at the bottom of the nest to receive the

sample may be sieved separately and the weighted average

undersize. Place 45 to 55 g of coal weighed to 60.05 g on the

used to obtain the average fineness of the pulverizer output or

top sieve and cover with a fitted cover to prevent loss.

the samples may be thoroughly mixed and one sieve determi-

7.3.2 Place the assembled set into the sieving machine and

nation made of the mixture, since the sample from each line

make the necessary adjustments for the sieving operation.

represents the proper proportion of the pulverizer output.

Adjust the timer for a 10-min period and start the machine. For

6.3.11 In storage systems, take samples at the outlet of the

hand sieving alternative, see Appendix X3.

cyclone collector. If the sampling location is under suction,

7.3.3 At the end of the sieving period, remove the stack, slip

provide the container with a cover that can be closed before it

off the receiver pan, and carefully brush into the pan receiver

is withdrawn from the sampling connection.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.