ASTM D197-87(2002)

(Test Method)Standard Test Method for Sampling and Fineness Test of Pulverized Coal

Standard Test Method for Sampling and Fineness Test of Pulverized Coal

SCOPE

1.1 This test method covers the determination of the fineness by sieve analysis of coal sampled from a dry pulverizing operation. It is not applicable to products of wet milling or to fines that have clustered into an agglomerated mass.

1.2 The values stated in inch-pound units shall be regarded as the standard. Sample weights of 1000 g or less shall be expressed in metric units.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D197–87(Reapproved 2002)

Standard Test Method for

1

Sampling and Fineness Test of Pulverized Coal

This standard is issued under the fixed designation D 197; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4.2 Drying Oven—A device for passing slightly heated air

over the sample. The oven should be capable of maintaining a

1.1 This test method covers the determination of the fine-

temperature of 18 to 27°F (10 to 15°C) above room tempera-

ness by sieve analysis of coal sampled from a dry pulverizing

ture with a maximum oven temperature of 104°F (40°C). Air

operation. It is not applicable to products of wet milling or to

changes should be at the rate of 1 to 4/min.

fines that have clustered into an agglomerated mass.

4.3 Sieves, square-hole, woven-wire cloth conforming to

1.2 The values stated in inch-pound units shall be regarded

SpecificationE11:

as the standard. Sample weights of 1000 g or less shall be

No. 8 USA Standard (2.36 mm)

expressed in metric units.

No. 16 USA Standard (1.18 mm)

1.3 This standard does not purport to address all of the

No. 30 USA Standard (600 µm)

safety concerns, if any, associated with its use. It is the

No. 50 USA Standard (300 µm)

No. 100 USA Standard (150 µm)

responsibility of the user of this standard to establish appro-

No. 200 USA Standard (75 µm)

priate safety and health practices and determine the applica-

No. 325 USA Standard (45 µm)

bility of regulatory limitations prior to use.

Thesieveframesshallbe8in.(203mm)indiameter,andthe

2. Referenced Documents height of the sieve from the top of the frame to the cloth shall

be either 2 in. (50.8 mm) or 1 in. (25.4 mm). Selection of

2.1 ASTM Standards:

specificsizesisoptional,dependingontheobjectiveofthetest.

E11 Specification for Wire-Cloth Sieves for Testing Pur-

2 4.3.1 Since the finer mesh sieves in particular are suscep-

poses

tible to damage by distortion resulting from undue pressure,

3. Significance and Use accidental scraping with hard brushes, etc., each sieve should

be closely inspected and discarded if it shows evidence of

3.1 This test method provides a means for assisting in the

damage.

evaluation of pulverizers and pulverizer systems in terms of

4.4 Mechanical Sieving Machine—The mechanical sieving

fineness specifications. It may also be used to confirm the

machine shall be designed to provide both a circular motion

influence of coal fineness on combustion performance and to

and a tapping action. It shall be designed to accept an assembly

evaluate carbon loss. By consent among interested parties, it

of vertically nested circular sieves as described in 4.3. The

may be used for evaluation of coal fineness in preparation,

machine action shall be such that results as described in

pneumatic transfer systems, etc.

Section 7 are obtained within the allotted time frame. Action

4. Apparatus

shall not be sufficiently severe to generate new fines by particle

degradation. To facilitate the sieving operation, a control

4.1 Sample Containers—Heavy vapor impervious bags,

switch device with timer is recommended. Other equipment

properly sealed, or noncorroding cans such as those with an

designs may be used provided the results are comparable.

airtight, friction top or screw top sealed with a rubber gasket

4.5 Balance, Laboratory—Approximately 1000-g capacity,

and pressure sensitive tape for use in storage and transport of

sensitivity 0.1 g.

the laboratory sample. Glass containers sealed with rubber

4.6 Sampling Device (Storage System)—An instrument

gaskets may be used, but care must be taken to avoid breakage

(scoop, dipper, or other suitable device) for collecting incre-

in transport.

ments that will constitute the total sample.

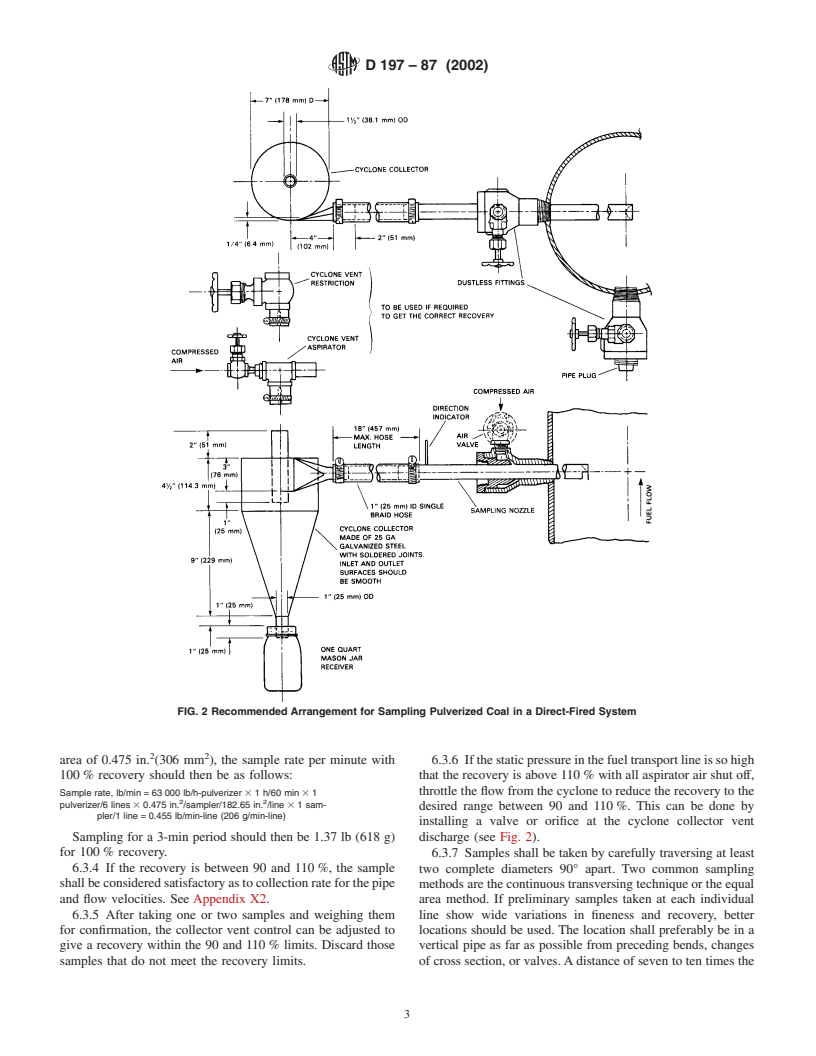

4.7 Sampling Device (Direct-Fired System)—Apparatus as

1

described in 6.2.1 and 6.2.2.

This test method is under the jurisdiction of ASTM Committee D05 on Coal

and Coke, and is the direct responsibility of Subcommittee D05.07 on Physical

4.8 Sample Riffle with Pans—Amanual sample divider that

Characteristics of Coal.

splits the coal stream into a number of alternate elements.

Current edition approved Sept. 25, 1987. Published November 1987. Originally

1 1

e1

Riffledivisionsshouldbeinthesizerangefrom ⁄4to ⁄2in.(6.4

published as D 197 – 24 T. Last previous edition D 197 – 87 (1994) .

2

Annual Book of ASTM Standards, Vol 14.02. to 12.7 mm).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D197–87 (2002)

5. Sampling, Storage System collect such samples from vertical pi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.