ASTM C1703-08(2013)

(Practice)Standard Practice for Sampling of Gaseous Uranium Hexafluoride

Standard Practice for Sampling of Gaseous Uranium Hexafluoride

SIGNIFICANCE AND USE

5.1 Uranium hexafluoride is normally produced and handled in large (typically 1 to 14-ton) quantities and must, therefore, be characterized by reference to representative samples (see ISO/DIS 7195). The samples are used to determine compliance with the applicable commercial specifications C996 and C787. The quantities involved, physical properties, chemical reactivity, and hazardous nature of UF6 are such that for representative sampling, specially designed equipment must be used and operated in accordance with the most carefully controlled and stringent procedures. This practice can be used by UF6 converters, enrichers, and fuel fabricators to review the effectiveness of existing procedures or as a guide to the design of equipment and procedures for future use.

5.2 The intention of this practice is to avoid liquid UF6 sampling once the cylinder has been filled. For safety reasons, manipulation of large quantities of liquid UF6 should be avoided when possible.

5.3 It is emphasized that this practice is not meant to address conventional or nuclear criticality safety issues.

SCOPE

1.1 This practice covers methods for withdrawing representative sample(s) of uranium hexafluoride (UF6) during a transfer occurring in the gas phase. Such transfer in the gas phase can take place from a mother cylinder, for example in an autoclave to a receiving cylinder. It can also occur during the filling in the gas phase of a cylinder during a continuous production process, for example centrifuge enrichment facility or the distillation column in a conversion facility. Such sample(s) may be used for determining compliance with the applicable commercial specification, for example Specification C996 or Specification C787.

1.2 Since UF6 sampling is taken during the filling process, this practice does not address any special additional arrangements that may be agreed upon between the buyer and the seller when the sampled bulk material is being added to residues already present in a container (“heels recycle”). Such arrangements will be based on QA procedures such as traceability of cylinder origin (to prevent for example contamination with irradiated material).

1.3 If the receiving cylinder is purged after filling and sampling, special verifications must be performed by the user to verify the representativity of the sample(s). It is then expected that the results found on volatile impurities with gas phase sampling may be conservative.

1.4 This practice is only applicable when the transfer occurs in the gas phase. When the transfer is performed in the liquid phase, Practice C1052 should apply. This practice does not apply to gas sampling after the cylinder has been filled since the sample taken will not be representative of the cylinder.

1.5 The scope of this practice does not include provisions for preventing criticality incidents.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1703 −08 (Reapproved 2013)

Standard Practice for

1

Sampling of Gaseous Uranium Hexafluoride

This standard is issued under the fixed designation C1703; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This practice covers methods for withdrawing represen-

tative sample(s) of uranium hexafluoride (UF ) during a

6

2. Referenced Documents

transfer occurring in the gas phase. Such transfer in the gas

2

2.1 ASTM Standards:

phase can take place from a mother cylinder, for example in an

autoclave to a receiving cylinder. It can also occur during the C761 Test Methods for Chemical, Mass Spectrometric,

Spectrochemical, Nuclear, and RadiochemicalAnalysis of

filling in the gas phase of a cylinder during a continuous

production process, for example centrifuge enrichment facility Uranium Hexafluoride

C787 Specification for Uranium Hexafluoride for Enrich-

or the distillation column in a conversion facility. Such

ment

sample(s) may be used for determining compliance with the

C996 Specification for Uranium Hexafluoride Enriched to

applicable commercial specification, for example Specification

235

Less Than 5 % U

C996 or Specification C787.

C1052 Practice for Bulk Sampling of Liquid Uranium

1.2 Since UF sampling is taken during the filling process,

6

Hexafluoride

this practice does not address any special additional arrange-

2.2 Other Document:

ments that may be agreed upon between the buyer and the

ISO/DIS 7195 Packaging of Uranium Hexafluoride (UF )

seller when the sampled bulk material is being added to 6

3

for Transport

residues already present in a container (“heels recycle”). Such

arrangements will be based on QA procedures such as trace-

3. Terminology

abilityofcylinderorigin(topreventforexamplecontamination

with irradiated material).

3.1 Definitions of Terms Specific to This Standard:

3.1.1 container—a vessel either holding or receiving by

1.3 If the receiving cylinder is purged after filling and

transfer, the UF to be sampled; it may consist of, for example,

6

sampling, special verifications must be performed by the user

a fixed vessel in a UF handling plant or a cylinder to be used

to verify the representativity of the sample(s). It is then 6

for the transport of UF .

6

expected that the results found on volatile impurities with gas

phase sampling may be conservative. 3.1.2 sample vessel—the small vessel into which the sample

of UF is withdrawn for analysis in the laboratory for charac-

6

1.4 This practice is only applicable when the transfer occurs

terization. It can be a 1S or 2S bottle or a PCTFE

in the gas phase. When the transfer is performed in the liquid

(polydifluorodichloroethylene)/ PTFE (polytetrafluoroethyl-

phase, Practice C1052 should apply. This practice does not

ene) pot or tube or any other type of cylinder compatible with

apply to gas sampling after the cylinder has been filled since

UF .

6

the sample taken will not be representative of the cylinder.

1.5 The scope of this practice does not include provisions

4. Summary of Practices

for preventing criticality incidents.

4.1 Two methods of withdrawing gas UF for sampling are

6

1.6 This standard does not purport to address all of the

possible, namely: (1) continuous withdrawal using for example

safety concerns, if any, associated with its use. It is the

a capillary and producing only one sample, or (2) sequential

responsibility of the user of this standard to establish appro-

withdrawals producing a composite sample. Depending on the

1 2

This practice is under the jurisdiction of ASTM Committee C26 on Nuclear For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Fuel Cycle and is the direct responsibility of Subcommittee C26.02 on Fuel and contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Fertile Material Specifications. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Jan. 1, 2013. Published January 2013. Originally the ASTM website.

3

approved in 2008. Last previous edition approved in 2008 as C1703 – 08. DOI: Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/C1703-08R13. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1703−08 (2013)

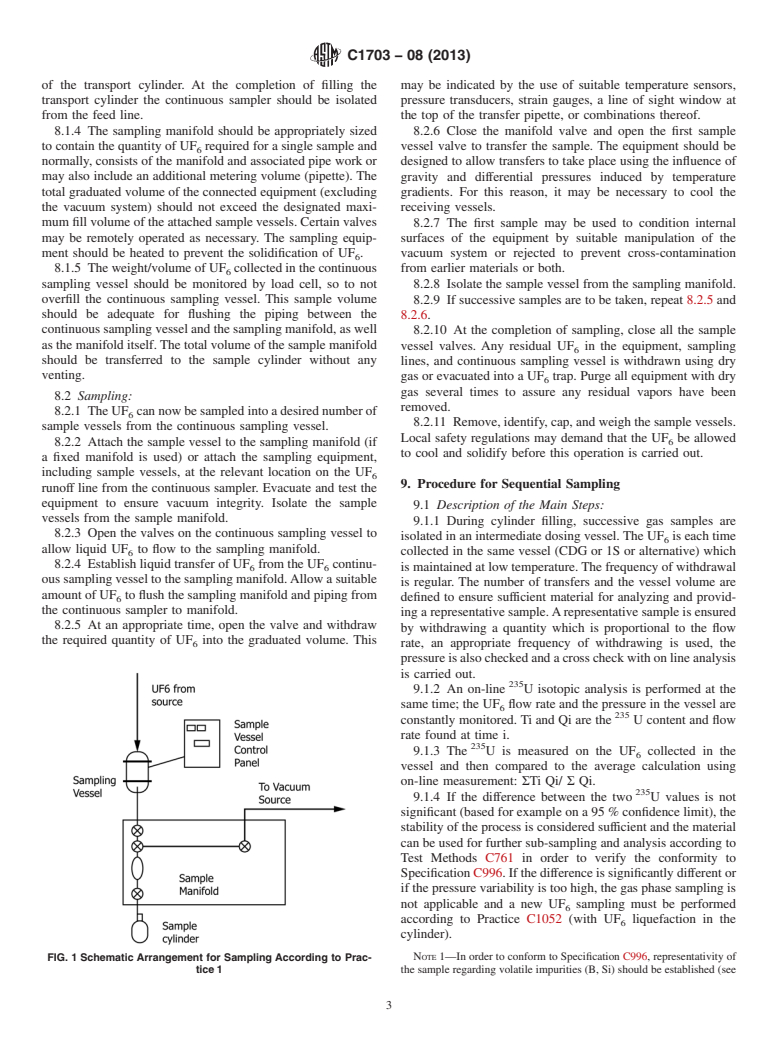

pressure and temperature conditions during the transfer, the 7.1.1 It is recommended to va

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.