ASTM E519/E519M-10

(Test Method)Standard Test Method for Diagonal Tension (Shear) in Masonry Assemblages

Standard Test Method for Diagonal Tension (Shear) in Masonry Assemblages

SIGNIFICANCE AND USE

This test method was developed to measure more accurately the diagonal tensile (shear) strength of masonry than was possible with other available methods. The specimen size was selected as being the smallest that would be reasonably representative of a full-size masonry assemblage and that would permit the use of testing machines such as are used by many laboratories.

Note 1—As a research test method used only for the purpose of evaluating the effects of variables such as type of masonry unit, mortar, workmanship, etc., a smaller size specimen could be used if the available testing equipment will not accommodate a 1.2-m [4-ft] square specimen. However, there is a lack of experimental data that would permit an evaluation of the effect of specimen size on the shear strength or to permit a correlation between the results of small-scale specimen tests and larger specimens.

SCOPE

1.1 This test method covers determination of the diagonal tensile or shear strength of masonry assemblages by loading them in compression along one diagonal (see Fig. 1), thus causing a diagonal tension failure with the specimen splitting apart parallel to the direction of load.

1.2 Annex A1 provides requirements regarding the determination of the diagonal-tension strength of masonry under combined diagonal-tension and compressive loading.

1.3 These test methods cover the application of the tests using either inch-pound or SI units. The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the inch-pound units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.4 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E519/E519M − 10

StandardTest Method for

1

Diagonal Tension (Shear) in Masonry Assemblages

This standard is issued under the fixed designation E519/E519M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* C1019 Test Method for Sampling and Testing Grout

E4 Practices for Force Verification of Testing Machines

1.1 This test method covers determination of the diagonal

E575 Practice for Reporting Data from Structural Tests of

tensile or shear strength of masonry assemblages by loading

Building Constructions, Elements, Connections, and As-

them in compression along one diagonal (see Fig. 1), thus

semblies

causing a diagonal tension failure with the specimen splitting

apart parallel to the direction of load.

3. Significance and Use

1.2 AnnexA1 provides requirements regarding the determi-

3.1 This test method was developed to measure more

nation of the diagonal-tension strength of masonry under

accuratelythediagonaltensile(shear)strengthofmasonrythan

combined diagonal-tension and compressive loading.

was possible with other available methods. The specimen size

was selected as being the smallest that would be reasonably

1.3 These test methods cover the application of the tests

representative of a full-size masonry assemblage and that

using either inch-pound or SI units. The values stated in either

would permit the use of testing machines such as are used by

SI units or inch-pound units are to be regarded separately as

many laboratories.

standard. Within the text, the inch-pound units are shown in

brackets. The values stated in each system may not be exact

NOTE 1—As a research test method used only for the purpose of

equivalents;therefore,eachsystemshallbeusedindependently

evaluating the effects of variables such as type of masonry unit, mortar,

of the other. Combining values from the two systems may workmanship, etc., a smaller size specimen could be used if the available

testing equipment will not accommodate a 1.2-m [4-ft] square specimen.

result in nonconformance with the standard.

However, there is a lack of experimental data that would permit an

1.4 This standard may involve hazardous materials,

evaluation of the effect of specimen size on the shear strength or to permit

operations, and equipment. This standard does not purport to a correlation between the results of small-scale specimen tests and larger

specimens.

address all of the safety problems, if any, associated with its

use. It is the responsibility of the user of this standard to

4. Apparatus

establish appropriate safety and health practices and deter-

4.1 Testing Machine—The testing machine shall have suffi-

mine the applicability of regulatory limitations prior to use.

cient compressive load capacity and provide the rate of loading

prescribed in 6.4. It shall be power-operated and capable of

2. Referenced Documents

applying the load continuously, rather than intermittently, and

2

2.1 ASTM Standards:

without shock. It shall conform to the requirements of the

C67 Test Methods for Sampling and Testing Brick and

Calculation and Report sections of Practices E4.

Structural Clay Tile

C109/C109M Test Method for Compressive Strength of NOTE 2—In order to accommodate a 1.2-m [4-ft] square specimen

placed in the machine so that its diagonal is in a vertical position, the

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

machine should have a clear opening height of at least 2.13 m [7 ft].

Specimens)

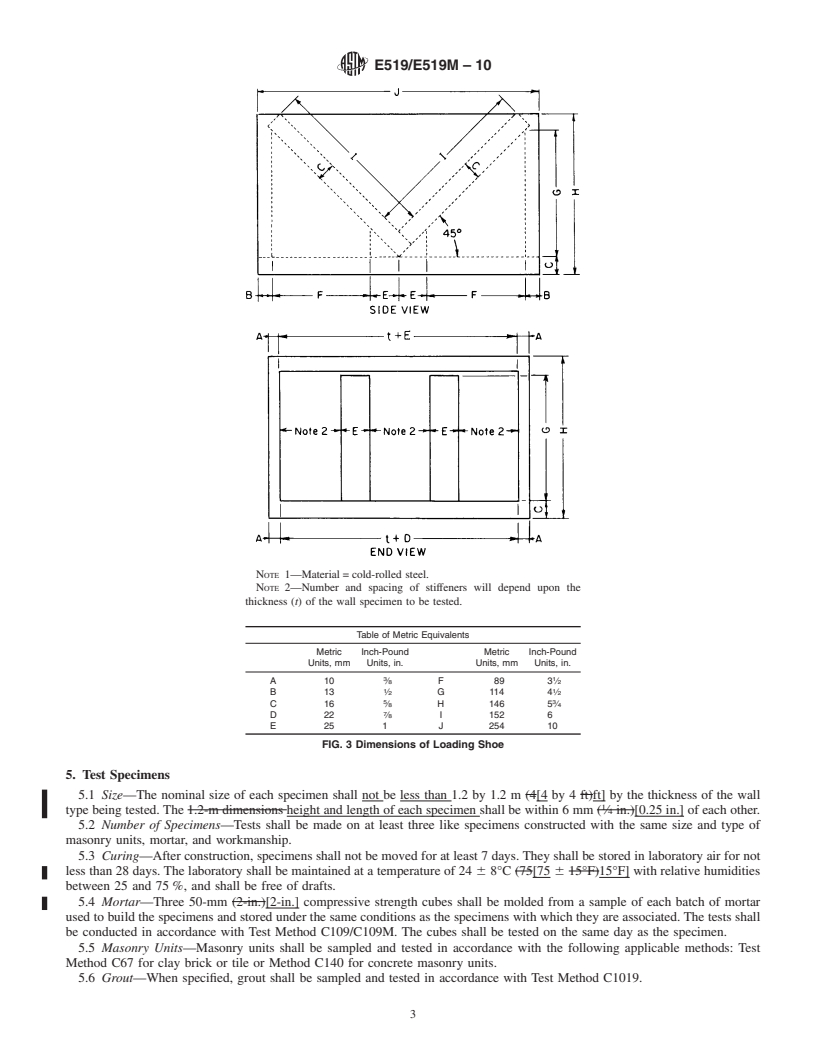

4.2 LoadingShoes—Two steel loading shoes (see Fig. 2 and

C140 Test Methods for Sampling and Testing Concrete

Fig.3)shallbeusedtoapplythemachineloadtothespecimen.

Masonry Units and Related Units

The length of bearing of the shoe shall be 150 mm [6 in.].

NOTE 3—Experimental work has indicated that the maximum length of

1

This test method is under the jurisdiction of ASTM Committee C15 on

1

bearing of the shoe should be approximately ⁄8 the length of the edge of

Manufactured Masonry Units and is the direct responsibility of Subcommittee

the specimen to avoid excessive bearing stress.

C15.04 on Research.

CurrenteditionapprovedJune1,2010.PublishedJuly2010.Originallyapproved

5. Test Specimens

1974. Last previous edition approved in 2007 as E519 – 07. DOI: 10.1520/E0519

_E0519M-10.

5.1 Size—The nominal size of each specimen shall not be

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

less than 1.2 by 1.2 m [4 by 4 ft] by the thickness of the wall

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

type being tested.The height and length of each specimen shall

Standards volume information, refe

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E519–07 Designation: E519/E519M – 10

Standard Test Method for

1

Diagonal Tension (Shear) in Masonry Assemblages

This standard is issued under the fixed designation E519/E519M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This test method covers determination of the diagonal tensile or shear strength of 1.2 by 1.2-m (4 by 4-ft) masonry

assemblages by loading them in compression along one diagonal (see Fig. 1), thus causing a diagonal tension failure with the

specimen splitting apart parallel to the direction of load.

1.2 AnnexA1 provides requirements regarding the determination of the diagonal-tension strength of masonry under combined

diagonal-tension and compressive loading.

1.3The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information

only.

1.3 These test methods cover the application of the tests using either inch-pound or SI units. The values stated in either SI units

or inch-pound units are to be regarded separately as standard. Within the text, the inch-pound units are shown in brackets. The

values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other.

Combining values from the two systems may result in nonconformance with the standard.

1.4 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all

of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate

safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C67 Test Methods for Sampling and Testing Brick and Structural Clay Tile

C109/C109M Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens)

C140 Test Methods for Sampling and Testing Concrete Masonry Units and Related Units

C1019 Test Method for Sampling and Testing Grout

E4 Practices for Force Verification of Testing Machines

E575 Practice for Reporting Data from Structural Tests of Building Constructions, Elements, Connections, and Assemblies

3. Significance and Use

3.1 This test method was developed to measure more accurately the diagonal tensile (shear) strength of masonry than was

possible with other available methods. The specimen size was selected as being the smallest that would be reasonably

representative of a full-size masonry assemblage and that would permit the use of testing machines such as are used by many

laboratories.

NOTE 1—As a research test method used only for the purpose of evaluating the effects of variables such as type of masonry unit, mortar, workmanship,

etc., a smaller size specimen could be used if the available testing equipment will not accommodate a 1.2-m (4-ft)[4-ft] square specimen. However, there

is a lack of experimental data that would permit an evaluation of the effect of specimen size on the shear strength or to permit a correlation between the

results of small-scale specimen tests and larger specimens.

4. Apparatus

4.1 Testing Machine—The testing machine shall have sufficient compressive load capacity and provide the rate of loading

prescribed in 6.4. It shall be power-operated and capable of applying the load continuously, rather than intermittently, and without

shock. It shall conform to the requirements of the Calculation and Report sections of Practices E4.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC15onManufacturedMasonryUnitsandisthedirectresponsibilityofSubcommitteeC15.04onResearch.

Current edition approved June 1, 2007.2010. Published July 2007.2010. Originally approved 1974. Last previous edition approved in 20022007 as E519 – 027. DOI:

10.1520/E0519_E0519M-107.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.