ASTM D5766/D5766M-11

(Test Method)Standard Test Method for Open-Hole Tensile Strength of Polymer Matrix Composite Laminates

Standard Test Method for Open-Hole Tensile Strength of Polymer Matrix Composite Laminates

SIGNIFICANCE AND USE

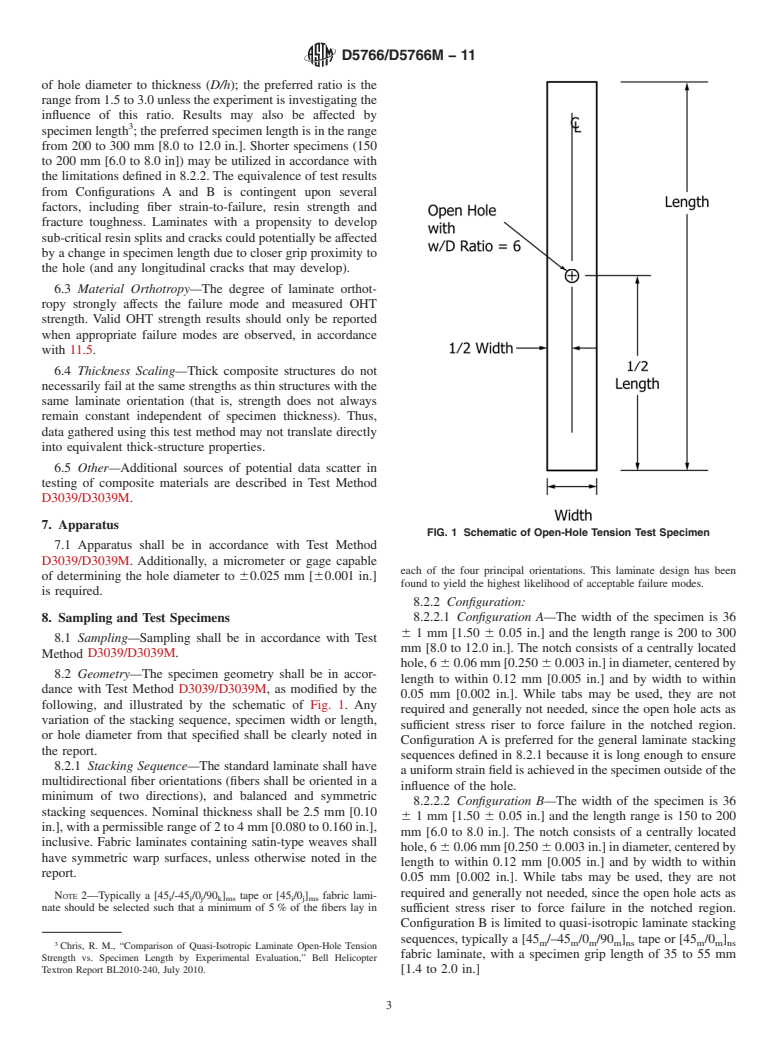

This test method is designed to produce notched tensile strength data for structural design allowables, material specifications, research and development, and quality assurance. Factors that influence the notched tensile strength and should therefore be reported include the following: material, methods of material fabrication, accuracy of lay-up, laminate stacking sequence and overall thickness, specimen geometry (including hole diameter, diameter-to-thickness ratio, and width-to-diameter ratio), specimen preparation (especially of the hole), specimen conditioning, environment of testing, specimen alignment and gripping, speed of testing, time at temperature, void content, and volume percent reinforcement. Properties that may be derived from this test method include the following:

Open-hole (notched) tensile strength (OHT).

SCOPE

1.1 This test method determines the open-hole tensile strength of multidirectional polymer matrix composite laminates reinforced by high-modulus fibers. The composite material forms are limited to continuous-fiber or discontinuous-fiber (tape or fabric, or both) reinforced composites in which the laminate is balanced and symmetric with respect to the test direction. The range of acceptable test laminates and thicknesses are described in 8.2.1.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.2.1 Within the text the inch-pound units are shown in brackets.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5766/D5766M − 11

Standard Test Method for

Open-Hole Tensile Strength of Polymer Matrix Composite

1

Laminates

This standard is issued under the fixed designation D5766/D5766M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mer Matrix Composite Materials

D3171Test Methods for Constituent Content of Composite

1.1 This test method determines the open-hole tensile

Materials

strength of multidirectional polymer matrix composite lami-

D3878Terminology for Composite Materials

nates reinforced by high-modulus fibers. The composite mate-

D5229/D5229MTestMethodforMoistureAbsorptionProp-

rialformsarelimitedtocontinuous-fiberordiscontinuous-fiber

erties and Equilibrium Conditioning of Polymer Matrix

(tape or fabric, or both) reinforced composites in which the

Composite Materials

laminate is balanced and symmetric with respect to the test

E6Terminology Relating to Methods of Mechanical Testing

direction. The range of acceptable test laminates and thick-

E177Practice for Use of the Terms Precision and Bias in

nesses are described in 8.2.1.

ASTM Test Methods

1.2 The values stated in either SI units or inch-pound units

E456Terminology Relating to Quality and Statistics

are to be regarded separately as standard. The values stated in

E691Practice for Conducting an Interlaboratory Study to

each system may not be exact equivalents; therefore, each

Determine the Precision of a Test Method

system shall be used independently of the other. Combining

E1309 Guide for Identification of Fiber-Reinforced

values from the two systems may result in non-conformance

Polymer-Matrix Composite Materials in Databases

with the standard.

E1434Guide for Recording Mechanical Test Data of Fiber-

1.2.1 Within the text the inch-pound units are shown in

Reinforced Composite Materials in Databases

brackets.

1.3 This standard does not purport to address all of the

3. Terminology

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.1 Definitions—Terminology D3878 defines terms relating

priate safety and health practices and determine the applica-

to high-modulus fibers and their composites. Terminology

bility of regulatory limitations prior to use.

D883definestermsrelatingtoplastics.TerminologyE6defines

terms relating to mechanical testing. Terminology E456 and

2. Referenced Documents

Practice E177 define terms relating to statistics. In the event of

2

2.1 ASTM Standards:

a conflict between terms, Terminology D3878 shall have

D792Test Methods for Density and Specific Gravity (Rela-

precedence over the other standards.

tive Density) of Plastics by Displacement

3.2 Definitions of Terms Specific to This Standard:

D883Terminology Relating to Plastics

D2584Test Method for Ignition Loss of Cured Reinforced NOTE 1—If the term represents a physical quantity, its analytical

dimensionsarestatedimmediatelyfollowingtheterm(orlettersymbol)in

Resins

fundamental dimension form, using the following ASTM standard sym-

D2734TestMethodsforVoidContentofReinforcedPlastics

bology for fundamental dimensions, shown within square brackets: [M]

D3039/D3039MTestMethodforTensilePropertiesofPoly-

for mass, [L] for length, [T] for time, [θ] for thermodynamic temperature,

and[nd]fornon-dimensionalquantities.Useofthesesymbolsisrestricted

to analytical dimensions when used with square brackets, as the symbols

1

This test method is under the jurisdiction of ASTM Committee D30 on

may have other definitions when used without the brackets.

Composite Materials and is the direct responsibility of Subcommittee D30.05 on

Structural Test Methods.

3.2.1 diameter-to-thickness ratio, D/h [nd], n—in an open-

Current edition approved Jan. 1, 2011. Published February 2011. Originally

hole specimen, the ratio of the hole diameter to the specimen

approved in 1995. Last previous edition approved in 2007 as D5766/D5766M–07.

thickness.

DOI: 10.1520/D5766_D5766M-11.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.2.1.1 Discussion—Thediameter-to-thicknessratiomaybe

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

eitheranominalvaluedeterminedfromnominaldimensionsor

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. an actual value determined from measured dimensions.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5766/D5766M − 11

3.2.2 nominal value, n—a value, existing in name only, x =test res

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5766/D5766M–07 Designation: D5766/D5766M – 11

Standard Test Method for

Open-Hole Tensile Strength of Polymer Matrix Composite

1

Laminates

This standard is issued under the fixed designation D5766/D5766M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method determines the open-hole tensile strength of multidirectional polymer matrix composite laminates

reinforced by high-modulus fibers. The composite material forms are limited to continuous-fiber or discontinuous-fiber (tape or

fabric,orboth)reinforcedcompositesinwhichthelaminateisbalancedandsymmetricwithrespecttothetestdirection.Therange

of acceptable test laminates and thicknesses are described in 8.2.1.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text the

inch-pound units are shown in brackets.The values stated in each system aremay not be exact equivalents; therefore, each system

mustshall be used independently of the other. Combining values from the two systems may result in non-conformance with the

standard.

1.2.1 Within the text the inch-pound units are shown in brackets.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

D883 Terminology Relating to Plastics

D2584 Test Method for Ignition Loss of Cured Reinforced Resins

D2734 Test Methods for Void Content of Reinforced Plastics

D3039/D3039M Test Method for Tensile Properties of Polymer Matrix Composite Materials

D3171 Test Methods for Constituent Content of Composite Materials

D3878 Terminology for Composite Materials

D5229/D5229M Test Method for MoistureAbsorption Properties and Equilibrium Conditioning of Polymer Matrix Composite

Materials

E6 Terminology Relating to Methods of Mechanical Testing

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E456 Terminology Relating to Quality and Statistics

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E1309 Guide for Identification of Fiber-Reinforced Polymer-Matrix Composite Materials in Databases

E1434 Guide for Recording Mechanical Test Data of Fiber-Reinforced Composite Materials in Databases

3. Terminology

3.1 Definitions—Terminology D3878 defines terms relating to high-modulus fibers and their composites. Terminology D883

defines terms relating to plastics. Terminology E6 defines terms relating to mechanical testing. Terminology E456 and Practice

E177 define terms relating to statistics. In the event of a conflict between terms, Terminology D3878 shall have precedence over

the other standards.

3.2 Definitions of Terms Specific to This Standard:

1

This test method is under the jurisdiction ofASTM Committee D30 on Composite Materials and is the direct responsibility of Subcommittee D30.05 on Structural Test

Methods.

Current edition approved Oct. 15, 2007.Jan. 1, 2011. Published November 2007.February 2011. Originally approved in 1995. Last previous edition approved in 2007 as

D5766/D5766M–02a(2007).D5766/D5766M–07. DOI: 10.1520/D5766_D5766M-0711.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5766/D5766M – 11

NOTE 1—If the term represents a physical quantity, its analytical dimensions are stated immediately following the term (or letter symbol) in

fundamental dimension form, using the followingASTM standard symbology for fundamental dimensions, shown within square brackets: [M] for mass,

[L] for length, [T] for time, [u] for thermodynamic temperature, and [ nd] for non-dimensional quantities. Use of these symbols is restricted to analytical

dimensions when used with square bracket

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.