ASTM F2191/F2191M-13

(Specification)Standard Specification for Packing Material, Graphitic or Carbon Braided Yarn

Standard Specification for Packing Material, Graphitic or Carbon Braided Yarn

SCOPE

1.1 This specification covers staple or continuous filament carbon/graphite yarn valve stem compression packing, suitable for use as end-rings on packing systems for valves. Intended services include steam, hydrocarbons, water and non-oxidizing chemicals. Where this specification is invoked as ASTM F2191, Sections 1 – 18 apply. Where this specification is invoked as ASTM/DoD F2191, Sections 1 – 18 and the Supplementary Requirements shall be applicable.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2191/F2191M −13 An American National Standard

Standard Specification for

1

Packing Material, Graphitic or Carbon Braided Yarn

ThisstandardisissuedunderthefixeddesignationF2191/F2191M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C816 Test Method for Sulfur Content in Graphite by

Combustion-Iodometric Titration Method

1.1 This specification covers staple or continuous filament

C889Test Methods for Chemical and Mass Spectrometric

carbon/graphiteyarnvalvestemcompressionpacking,suitable

Analysis of Nuclear-Grade Gadolinium Oxide (Gd O )

2 3

for use as end-rings on packing systems for valves. Intended

Powder

servicesincludesteam,hydrocarbons,waterandnon-oxidizing

D129Test Method for Sulfur in Petroleum Products (Gen-

chemicals. Where this specification is invoked as ASTM

eral High Pressure Decomposition Device Method)

F2191, Sections 1–18 apply. Where this specification is

D512Test Methods for Chloride Ion In Water

invoked as ASTM/DoD F2191, Sections 1–18 and the

D1179Test Methods for Fluoride Ion in Water

Supplementary Requirements shall be applicable.

D1246Test Method for Bromide Ion in Water

1.2 The values stated in either SI units or inch-pound units

D3178Test Methods for Carbon and Hydrogen in the

3

are to be regarded separately as standard. The values stated in

Analysis Sample of Coal and Coke (Withdrawn 2007)

each system may not be exact equivalents; therefore, each

D3684Test Method for Total Mercury in Coal by the

system shall be used independently of the other. Combining

Oxygen Bomb Combustion/Atomic Absorption Method

values from the two systems may result in non-conformance

D3761Test Method for Total Fluorine in Coal by the

with the standard.

Oxygen Bomb Combustion/Ion Selective Electrode

1.3 This standard does not purport to address all of the

Method

safety concerns, if any, associated with its use. It is the D3951Practice for Commercial Packaging

responsibility of the user of this standard to establish appro-

D4239Test Method for Sulfur in the Analysis Sample of

priate safety, health, and environmental practices and deter- Coal and Coke Using High-Temperature Tube Furnace

mine the applicability of regulatory limitations prior to use.

Combustion

4

1.4 This international standard was developed in accor- 2.2 Military Standards:

dance with internationally recognized principles on standard- MIL-STD-129Marking for Shipment and Storage

ization established in the Decision on Principles for the

MIL-P-24583 Packing Material, Graphitic or Carbon

Development of International Standards, Guides and Recom- Braided Yarn

mendations issued by the World Trade Organization Technical

MIL-P-24503Packing Material, Graphitic, Corrugated Rib-

Barriers to Trade (TBT) Committee. bon or Textured Tape and Preformed Ring

5

2.3 Fluid Sealing Association Handbook:

2. Referenced Documents

Guidelines for the Use of Compression Packings, Copyright

2

1997

2.1 ASTM Standards:

C135Test Method for True Specific Gravity of Refractory

3. Terminology

Materials by Water Immersion

3.1 base fiber density—bulk density of the base fiber before

C561Test Method for Ash in a Graphite Sample

being coated or impregnated and braided into packing.

C562Test Method for Moisture in a Graphite Sample

3.2 braided flexible graphite—a braid constructed of con-

tinuous strands or strips of expanded flexible graphite tape or

1 ribbons, which have been overwrapped or have imbedded

This specification is under the jurisdiction ofASTM Committee F25 on Ships

and Marine Technology and is the direct responsibility of Subcommittee F25.02 on

reinforcing fibers.

Insulation/Processes.

Current edition approved Dec. 15, 2013. Published January 2014. Originally

3

approved in 2002. Last previous edition approved in 2008 as F2191–02 (2008). The last approved version of this historical standard is referenced on

DOI: 10.1520/F2191_F2191M-13. www.astm.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

5

Standards volume information, refer to the standard’s Document Summary page on Available from the Fluid Sealing Association, 994 Old Eagle School Road,

the ASTM website. Suite 1019, Wayne, PA 19087-1866.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

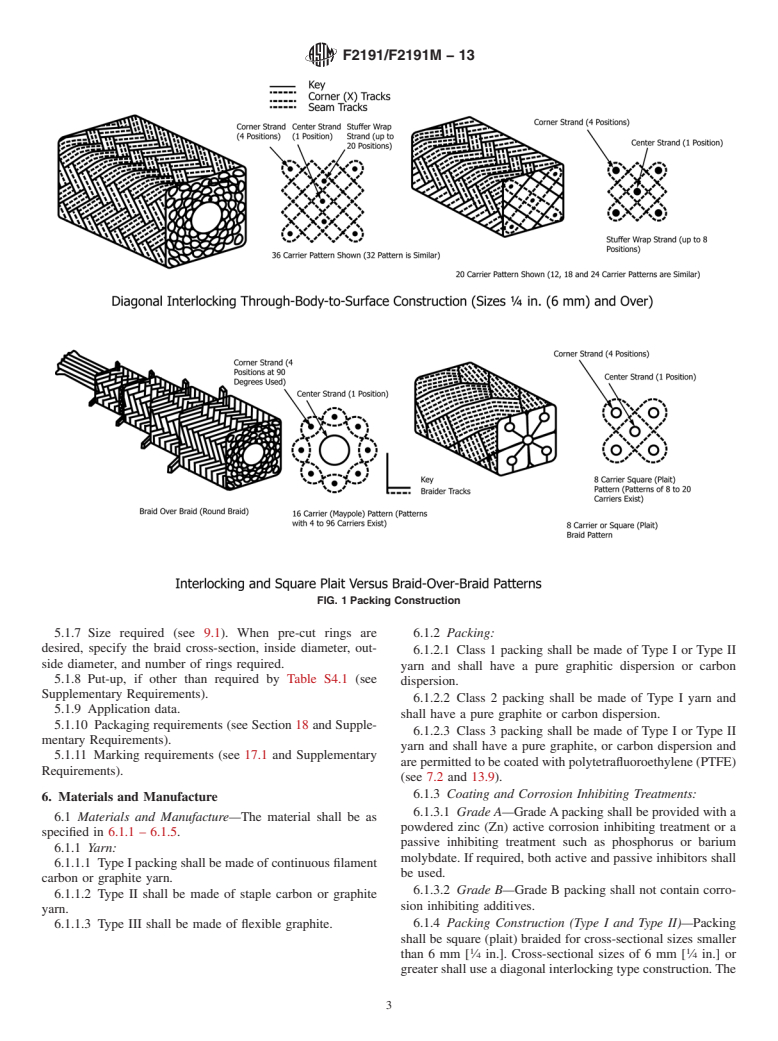

F2191/F2191M−13

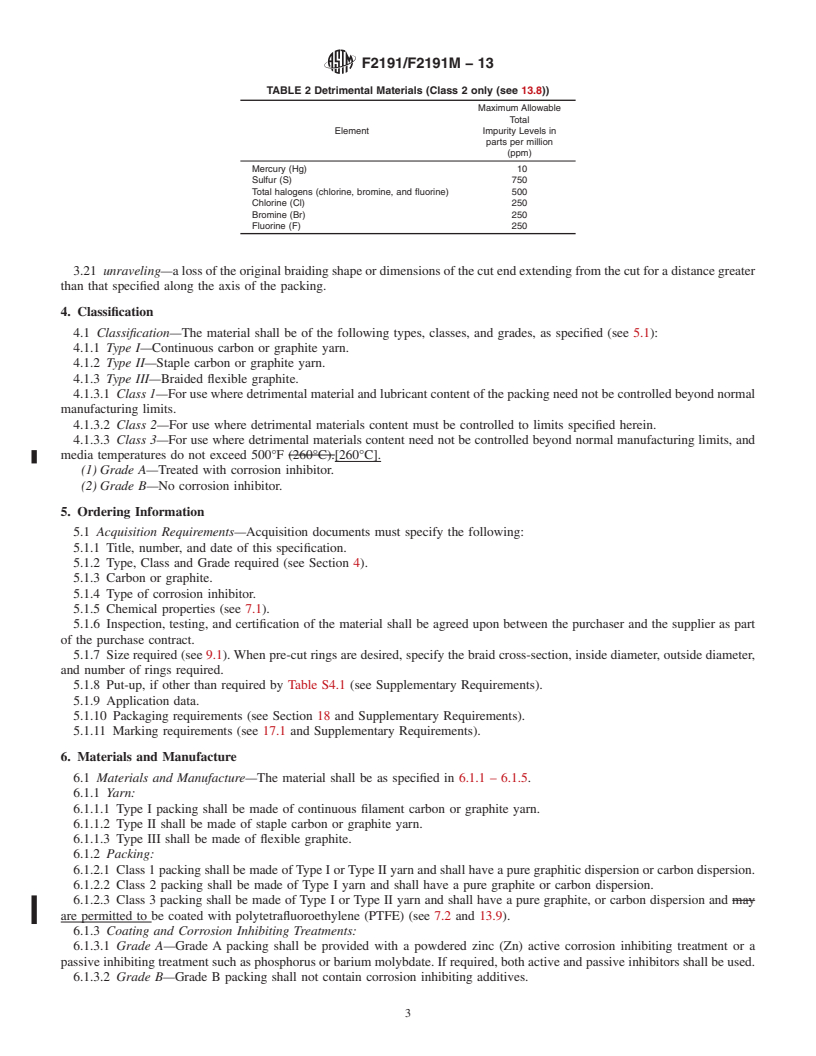

TABLE 2 Detrimental Materials (Class 2 only (see 13

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2191 − 02 (Reapproved 2008) F2191/F2191M − 13 An American National Standard

Standard Specification for

1

Packing Material, Graphitic or Carbon Braided Yarn

This standard is issued under the fixed designation F2191;F2191/F2191M; the number immediately following the designation indicates

the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers staple or continuous filament carbon/graphite yarn valve stem compression packing, suitable for

use as end-rings on packing systems for valves. Intended services include steam, hydrocarbons, water and non-oxidizing

chemicals. Where this specification is invoked as ASTM F2191, Sections 1 – 18 apply. Where this specification is invoked as

ASTM/DoD F2191, Sections 1 – 18 and the Supplementary Requirements are shall be applicable.

1.2 The values stated in either SI units or inch-pound units are to be regarded as the separately as standard. The values stated

in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values

from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C135 Test Method for True Specific Gravity of Refractory Materials by Water Immersion

C561 Test Method for Ash in a Graphite Sample

C562 Test Method for Moisture in a Graphite Sample

C816 Test Method for Sulfur in Graphite by Combustion-Iodometric Titration Method

C889 Test Methods for Chemical and Mass Spectrometric Analysis of Nuclear-Grade Gadolinium Oxide (Gd O ) Powder

2 3

D129 Test Method for Sulfur in Petroleum Products (General High Pressure Decomposition Device Method)

D512 Test Methods for Chloride Ion In Water

D1179 Test Methods for Fluoride Ion in Water

D1246 Test Method for Bromide Ion in Water

3

D3178 Test Methods for Carbon and Hydrogen in the Analysis Sample of Coal and Coke (Withdrawn 2007)

D3684 Test Method for Total Mercury in Coal by the Oxygen BombCombustion/Atomic Absorption Method

D3761 Test Method for Total Fluorine in Coal by the Oxygen Bomb Combustion/Ion Selective Electrode Method

D3951 Practice for Commercial Packaging

D4239 Test Method for Sulfur in the Analysis Sample of Coal and Coke Using High-Temperature Tube Furnace Combustion

2.2 Military Standards:

4

MIL-STD-129 Marking for Shipment and Storage

4

MIL-P-24583 Packing Material, Graphitic or Carbon Braided Yarn

4

MIL-P-24503 Packing Material, Graphitic, Corrugated Ribbon or Textured Tape and Preformed Ring

2.3 Fluid Sealing Association Handbook:

5

Guidelines for the Use of Compression Packings, Copyright 1997

1

This specification is under the jurisdiction of ASTM Committee F25 on Ships and Marine Technology and is the direct responsibility of Subcommittee F25.02 on

Insulation/Processes.

Current edition approved May 1, 2008Dec. 15, 2013. Published July 2008January 2014. Originally approved in 2002. Last previous edition approved in 20022008 as

F2191 - 02.F2191 - 02(2008). DOI: 10.1520/F2191-02R08.10.1520/F2191_F2191M-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

4

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://www.dodssp.daps.mil.

5

Available from the Fluid Sealing Association, 994 Old Eagle School Road, Suite 1019, Wayne, PA 19087-1866.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2191/F2191M − 13

3. Terminology

3.1 base fiber density—bulk density of the base fiber before being coated or impregnated and braided into packing; expressed

3

as lb/ftpacking. .

3.2 braided flexible graphite—a braid constructed of continuous strands or strips of expanded flexible graph

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.