ASTM C849-88(2016)

(Test Method)Standard Test Method for Knoop Indentation Hardness of Ceramic Whitewares

Standard Test Method for Knoop Indentation Hardness of Ceramic Whitewares

SIGNIFICANCE AND USE

5.1 The Knoop indentation hardness is one of many properties that is used to characterize ceramic whitewares. Attempts have been made to relate Knoop indentation hardness to tensile strength, grinding speeds, and other hardness scales, but no generally accepted methods are available. Such conversions are limited in scope and should be used with caution, except for special cases where a reliable basis for the conversion has been obtained by comparison tests.

SCOPE

1.1 This test method covers the determination of the Knoop indentation hardness of ceramic whitewares and the verification of Knoop indentation hardness testing machines using standard glasses.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C849 − 88 (Reapproved 2016)

Standard Test Method for

1

Knoop Indentation Hardness of Ceramic Whitewares

This standard is issued under the fixed designation C849; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

NOTE 1—Ageneral description of the Knoop indentation hardness test

1. Scope

is given in Test Method E384. The present method differs from this

1.1 This test method covers the determination of the Knoop

description only in areas required by the special nature of ceramic

indentation hardness of ceramic whitewares and the verifica- whitewares.

tion of Knoop indentation hardness testing machines using

5. Significance and Use

standard glasses.

1.2 This standard does not purport to address all of the 5.1 The Knoop indentation hardness is one of many prop-

ertiesthatisusedtocharacterizeceramicwhitewares.Attempts

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- havebeenmadetorelateKnoopindentationhardnesstotensile

strength, grinding speeds, and other hardness scales, but no

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. generally accepted methods are available. Such conversions

arelimitedinscopeandshouldbeusedwithcaution,exceptfor

2. Referenced Documents

specialcaseswhereareliablebasisfortheconversionhasbeen

2

obtained by comparison tests.

2.1 ASTM Standards:

E4Practices for Force Verification of Testing Machines

6. Apparatus

E384Test Method for Microindentation Hardness of Mate-

rials 6.1 Testing Machines:

6.1.1 There are two general types of machines available for

3. Terminology

making this test. One type is a self-contained unit built for this

purpose,andtheothertypeisanaccessoryavailabletoexisting

3.1 Definitions:

microscopes. Usually, this second type is fitted on an inverted-

3.1.1 Knoop hardness number ( KHN)—a number obtained

stage microscope. Good descriptions of the various machines

by dividing the applied load in kilograms-force by the pro-

3,4

are available.

jected area of the indentation in square millimetres, computed

6.1.2 Designofthemachineshouldbesuchthattheloading

from the measured long diagonal of the indentation and the

rate, dwell time, and applied load can be standardized within

included edge angles of the diamond. It is assumed that the

the limits set forth in 3.1.1. It is an advantage to eliminate the

indentation is an imprint of the undeformed indenter.

human element whenever possible by appropriate machine

design. The machine should be designed so that vibrations

4. Summary of Test Method

induced at the beginning of a test will be damped out by the

4.1 This test method describes an indentation hardness test

time the indenter touches the sample.

using a calibrated machine to force a pointed, rhombic-base,

6.1.3 Thecalibrationofthebalancebeamshouldbechecked

pyramidal diamond indenter having specified face angles,

monthly or as needed. Indentations in standard glasses are also

under a predetermined load, into the surface of the material

used to check calibration when needed.

under test and to measure the long diagonal of the resulting

6.2 Indenter:

impression after removal of the load.

6.2.1 The indenter shall meet the specifications for Knoop

3

indenters. See Test Method E384.

1

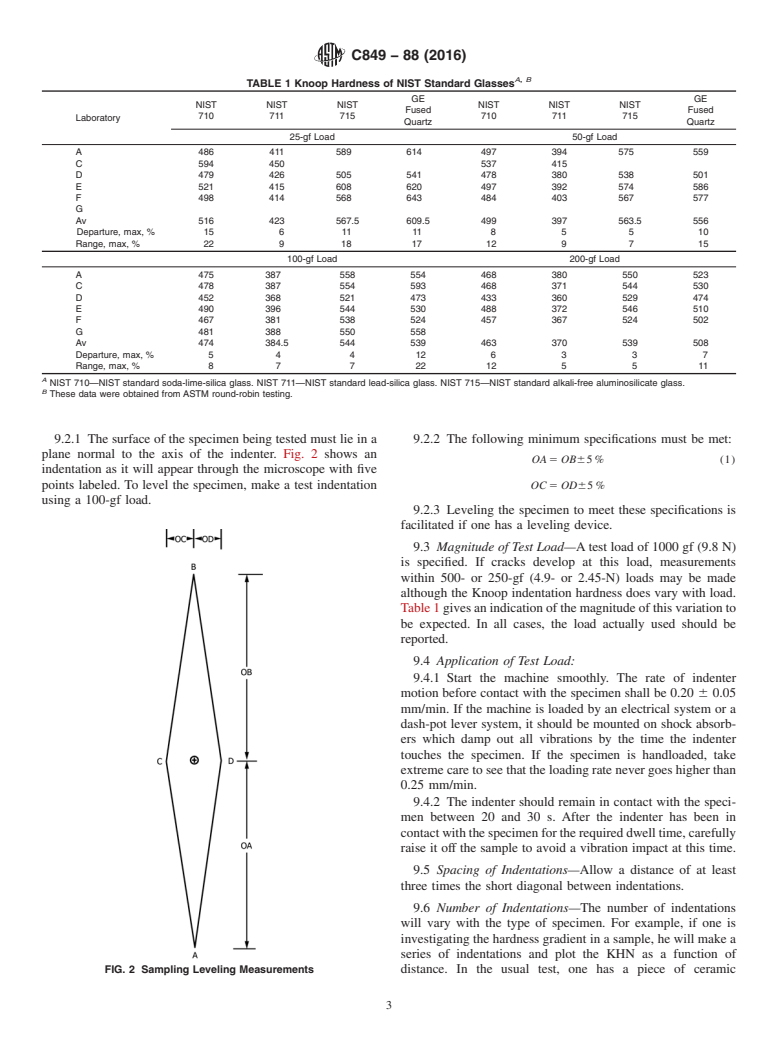

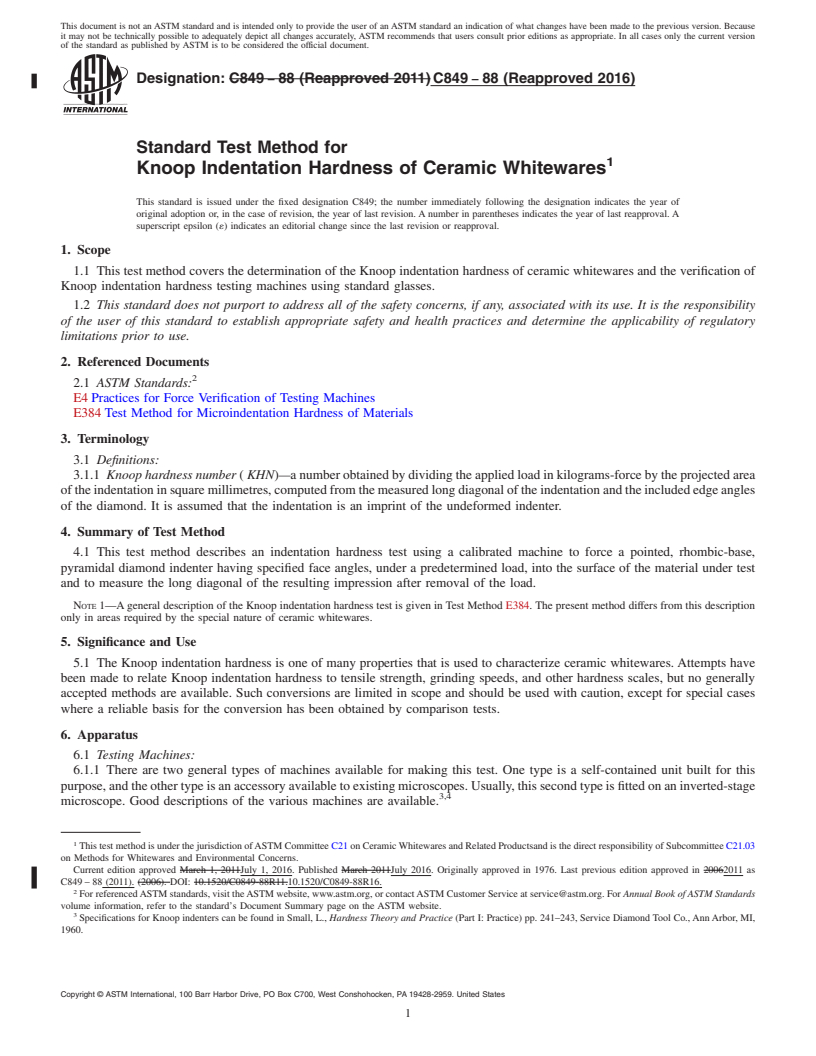

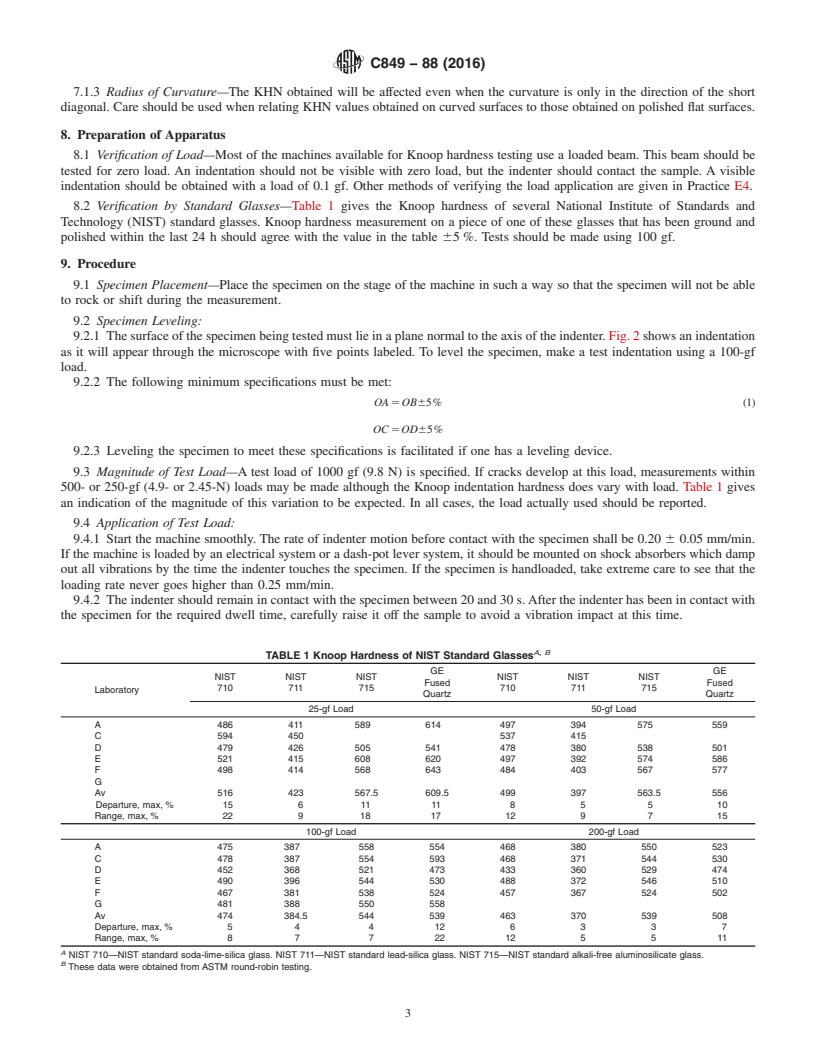

6.2.2 Fig. 1 shows the indenter and its maximum usable

ThistestmethodisunderthejurisdictionofASTMCommitteeC21onCeramic

Whitewares and Related Productsand is the direct responsibility of Subcommittee

dimensions. The diagonals have an approximate ratio of 7:1,

C21.03 on Methods for Whitewares and Environmental Concerns.

CurrenteditionapprovedJuly1,2016.PublishedJuly2016.Originallyapproved

in 1976. Last previous edition approved in 2011 as C849–88(2011). DOI:

3

10.1520/C0849-88R16. SpecificationsforKnoopindenterscanbefoundinSmall,L., Hardness Theory

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or and Practice (Part I: Practice) pp. 241–243, Service DiamondTool Co.,AnnArbor,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM MI, 1960.

4

Standards volume information, refer to the standard’s Document Summary page on Mott, B. W., Micro-Indentation Hardness Testing, Butterworth’s Scientific

the ASTM website. Publications, London, 1956.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

1

---------------------- Page: 1 ----------------------

C849 − 88 (2016)

FIG. 1 Knoop Indenter Showing Maximum Usable Dimension

1

and the depth of the indentation is about ⁄30 t

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C849 − 88 (Reapproved 2011) C849 − 88 (Reapproved 2016)

Standard Test Method for

1

Knoop Indentation Hardness of Ceramic Whitewares

This standard is issued under the fixed designation C849; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the Knoop indentation hardness of ceramic whitewares and the verification of

Knoop indentation hardness testing machines using standard glasses.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E4 Practices for Force Verification of Testing Machines

E384 Test Method for Microindentation Hardness of Materials

3. Terminology

3.1 Definitions:

3.1.1 Knoop hardness number ( KHN)—a number obtained by dividing the applied load in kilograms-force by the projected area

of the indentation in square millimetres, computed from the measured long diagonal of the indentation and the included edge angles

of the diamond. It is assumed that the indentation is an imprint of the undeformed indenter.

4. Summary of Test Method

4.1 This test method describes an indentation hardness test using a calibrated machine to force a pointed, rhombic-base,

pyramidal diamond indenter having specified face angles, under a predetermined load, into the surface of the material under test

and to measure the long diagonal of the resulting impression after removal of the load.

NOTE 1—A general description of the Knoop indentation hardness test is given in Test Method E384. The present method differs from this description

only in areas required by the special nature of ceramic whitewares.

5. Significance and Use

5.1 The Knoop indentation hardness is one of many properties that is used to characterize ceramic whitewares. Attempts have

been made to relate Knoop indentation hardness to tensile strength, grinding speeds, and other hardness scales, but no generally

accepted methods are available. Such conversions are limited in scope and should be used with caution, except for special cases

where a reliable basis for the conversion has been obtained by comparison tests.

6. Apparatus

6.1 Testing Machines:

6.1.1 There are two general types of machines available for making this test. One type is a self-contained unit built for this

purpose, and the other type is an accessory available to existing microscopes. Usually, this second type is fitted on an inverted-stage

3,4

microscope. Good descriptions of the various machines are available.

1

This test method is under the jurisdiction of ASTM Committee C21 on Ceramic Whitewares and Related Productsand is the direct responsibility of Subcommittee C21.03

on Methods for Whitewares and Environmental Concerns.

Current edition approved March 1, 2011July 1, 2016. Published March 2011July 2016. Originally approved in 1976. Last previous edition approved in 20062011 as

C849 – 88 (2011). (2006). DOI: 10.1520/C0849-88R11.10.1520/C0849-88R16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Specifications for Knoop indenters can be found in Small, L., Hardness Theory and Practice (Part I: Practice) pp. 241–243, Service Diamond Tool Co., Ann Arbor, MI,

1960.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C849 − 88 (2016)

6.1.2 Design of the machine should be such that the loading rate, dwell time, and applied load can be standardized within the

limits set forth in 3.1.1. It is an advantage to eliminate the human element whenever possible by appropriate machine design. The

machine should be designed so that vibrations induced at the beginning of a test will be damped out by the time the indenter

touches the sample.

6.1.3 The calibration of the balance beam should be checked monthly or as needed. Indentations in standard glasses are also

used to c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.