ASTM F109-21

(Terminology)Standard Terminology Relating to Surface Imperfections on Ceramics

Standard Terminology Relating to Surface Imperfections on Ceramics

SCOPE

1.1 This terminology describes and illustrates imperfections observed on whitewares and related products. For additional definitions of terms relating to whitewares and related products, refer to Terminology C242. To observe these defects, examination shall be performed visually, with or without the aid of a dye penetrant, as described in Test Method C949. Agreement by the manufacturer and the purchaser regarding specific techniques of observation is strongly recommended.

1.2 This terminology does not cover every defect or imperfection possible for whitewares or related products. The standard is not intended to be an all inclusive document for ceramic imperfections. New defect types may be created as ceramic processes, materials, and technology evolve.

1.3 Some of the imperfection photos utilize magnification for clarity in documentation. Unless otherwise noted, typical observation conditions for detection of tile imperfections/defects shall consist of current ANSI A137.1 viewing criteria for the specific defect type

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F109 − 21

Standard Terminology Relating to

1

Surface Imperfections on Ceramics

ThisstandardisissuedunderthefixeddesignationF109;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E165/E165M Practice for Liquid Penetrant Testing for Gen-

eral Industry

1.1 This terminology describes and illustrates imperfections

3

2.2 ANSI Standard:

observed on whitewares and related products. For additional

ANSI A137.1 American National Standards Specifications

definitions of terms relating to whitewares and related

For Ceramic Tile

products, refer to Terminology C242. To observe these defects,

examination shall be performed visually, with or without the

3. Terminology

aid of a dye penetrant, as described in Test Method C949.

Agreement by the manufacturer and the purchaser regarding

3.1 Definitions:

specific techniques of observation is strongly recommended.

blemish—strained or discolored area attributable to normal

composition or forming, or both; see Fig. 1 in addition to the

1.2 This terminology does not cover every defect or imper-

image below. (See also inclusion.)

fection possible for whitewares or related products. The

standard is not intended to be an all inclusive document for

ceramic imperfections. New defect types may be created as

ceramic processes, materials, and technology evolve.

1.3 Some of the imperfection photos utilize magnification

for clarity in documentation. Unless otherwise noted, typical

observation conditions for detection of tile imperfections/

defects shall consist of current ANSI A137.1 viewing criteria

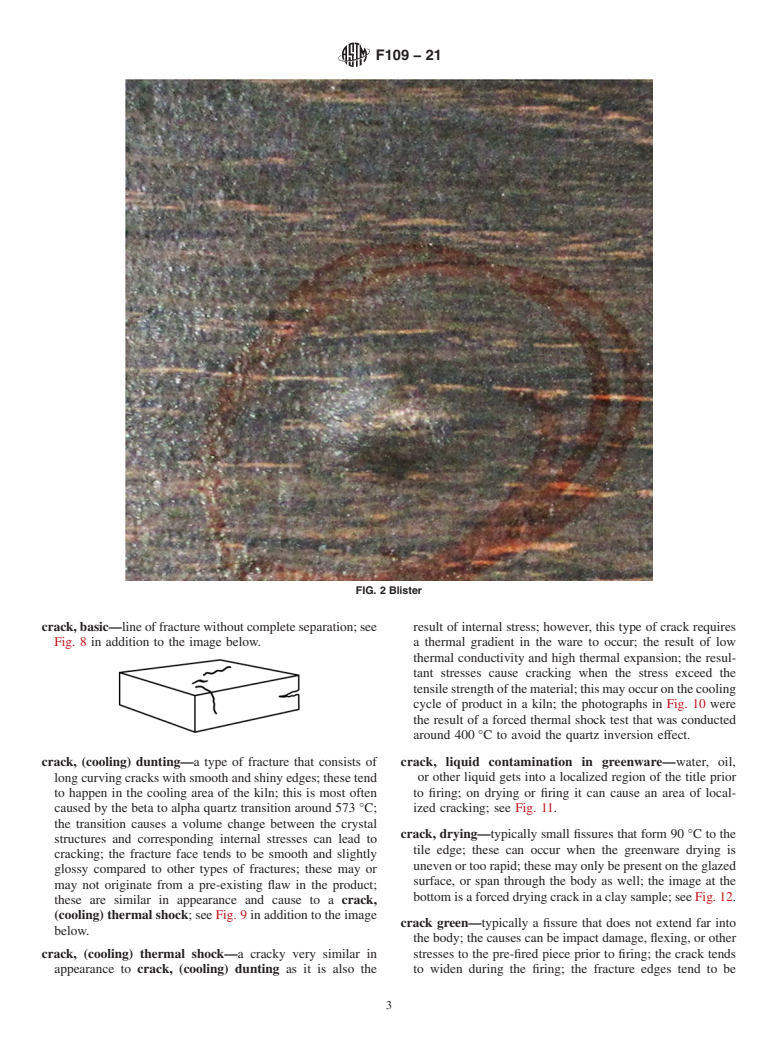

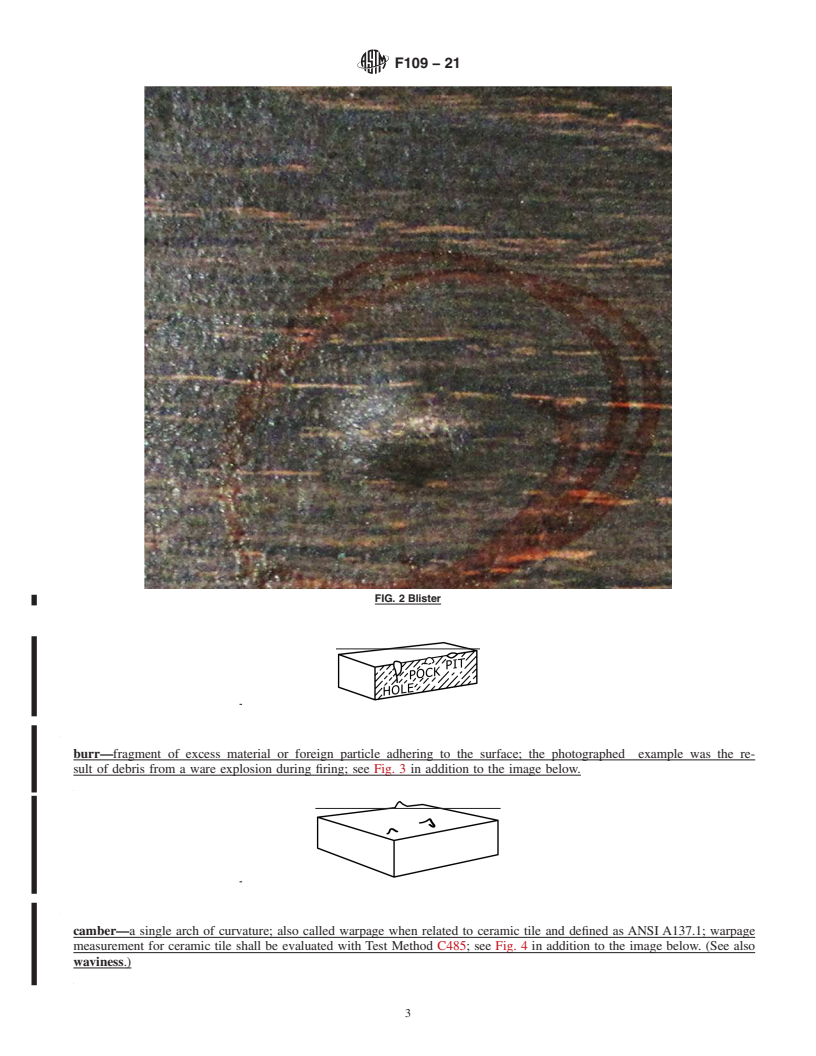

blister—bubble or gaseous inclusion at the surface which if

for the specific defect type

broken could form a pit, pock, or hole; see Fig. 2 in addition

1.4 This international standard was developed in accor-

to the image below.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

2. Referenced Documents

burr—fragment of excess material or foreign particle adhering

2

to the surface; the photographed example was the re-

2.1 ASTM Standards:

sult of debris from a ware explosion during firing; see Fig. 3

C242 Terminology of Ceramic Whitewares and Related

in addition to the image below.

Products

C485 Test Method for Measuring Warpage of Ceramic Tile

C949 Test Method for Porosity in Vitreous Whitewares by

Dye Penetration

1

This terminology is under the jurisdiction of ASTM Committee C21 on

Ceramic Whitewares and Related Products and is the direct responsibility of

C21.01Editorial and Terminology on Nomenclature.

camber—a single arch of curvature; also called warpage when

Current edition approved Feb. 1, 2021. Published March 2021. Originally

approved in 1969. Last previous edition approved 2018 as F109 – 12 (2018). DOI:

related to ceramic tile and defined asANSIA137.1; warpage

10.1520/F0109-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F109 − 21

FIG. 1 Blemish

measurement for ceramic tile shall be evaluated with Test chip, closed —fractured area on the edge or corner when the

MethodC485;seeFig.4inadditiontotheimagebelow.(See material has not broken off; see Fig. 6 in addition to the

also waviness.)

image below. (Syn. potential chip)

where:

W = width

l = length, and

chip, basic—area along an edge or corner where the material

d = depth.

has broken off; see Fig. 5 in addition to the image below.

chip, pre-print or pre-glaze—Surface damage that occurs

prior to decorative glazing or printing; these may occur

before or after the base color; the photographed examples in

Fig. 7 show chips that were printed over with graphic,

making them more difficult to detect; the upper picture of in

Fig. 7 is a tile that was chipped after the base glaze, but prior

to printing; the lower picture in Fig. 7 is a tile that was

where:

chipped prior to th

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F109 − 12 (Reapproved 2018) F109 − 21

Standard Terminology Relating to

1

Surface Imperfections on Ceramics

This standard is issued under the fixed designation F109; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This terminology describes and illustrates imperfections observed on whitewares and related products. For additional

definitions of terms relating to whitewares and related products, refer to Terminology C242. To observe these defects, examination

shall be performed visually, with or without the aid of a dye penetrant, as described in Test Method C949. Agreement by the

manufacturer and the purchaser regarding specific techniques of observation is strongly recommended.

1.2 This terminology does not cover every defect or imperfection possible for whitewares or related products. The standard is not

intended to be an all inclusive document for ceramic imperfections. New defect types may be created as ceramic processes,

materials, and technology evolve.

1.3 Some of the imperfection photos utilize magnification for clarity in documentation. Unless otherwise noted, typical

observation conditions for detection of tile imperfections/defects shall consist of current ANSI A137.1 viewing criteria for the

specific defect type

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C242 Terminology of Ceramic Whitewares and Related Products

C485 Test Method for Measuring Warpage of Ceramic Tile

C949 Test Method for Porosity in Vitreous Whitewares by Dye Penetration

E165E165/E165M Practice for Liquid Penetrant Testing for General Industry

3

2.2 ANSI Standard:

ANSI A137.1 American National Standards Specifications For Ceramic Tile

3. Terminology

blemish—strained or discolored area attributable to normal composition or forming, or both. (See also inclusion.

1

This terminology is under the jurisdiction of ASTM Committee C21 on Ceramic Whitewares and Related Products and is the direct responsibility of C21.01Editorial

and Terminology on Nomenclature.

Current edition approved Feb. 1, 2018Feb. 1, 2021. Published February 2018March 2021. Originally approved in 1969. Last previous edition approved 20122018 as

F109 – 12.F109 – 12 (2018). DOI: 10.1520/F0109-12R18.10.1520/F0109-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F109 − 21

)

3.1 Definitions:

blemish—strained or discolored area attributable to normal composition or forming, or both; see Fig. 1 in addition to the image

below. (See also inclusion.)

blister—bubble or gaseous inclusion at the surface which if broken could form a pit, pock, or hole; see Fig. 2 in addition to the

image below.

FIG. 1 Blemish

2

---------------------- Page: 2 ----------------------

F109 − 21

FIG. 2 Blister

burr—fragment of excess material or foreign particle adhering to the surface; the photographed example was the re-

sult of debris from a ware explosion during firing; see Fig. 3 in addition to the image below.

camber—a single arch of curvature; also called warpage when related to ceramic tile and defined as ANSI A137.1; warpage

measurement for ceramic tile shall be evaluated with Test Method C485; see Fig. 4 in addition to the image below. (See also

waviness.)

3

---------------------- Page: 3 ----------------------

F109 − 21

FIG. 3 Burr

chip, basic—area along an edge or corner where the material has broken off; see Fig. 5 in addition to the image below.

4

---------------------- Page: 4 ----------------------

F109 − 21

FIG. 4 Camber

where:

w = width

l = length, and

d =

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.