ASTM C1717-10

(Test Method)Standard Test Methods for Conducting Strength Tests of Masonry Wall Panels

Standard Test Methods for Conducting Strength Tests of Masonry Wall Panels

SIGNIFICANCE AND USE

The test methods described in this standard are intended for use as a starting point in developing specific testing protocols for masonry elements.

The testing protocols could be used for general research on the load-deflection behavior of masonry elements.

The testing protocols could be used for qualification of masonry elements and materials by evaluation services and other parties.

The test methods described in this standard are general, and are intended to be adaptable to address a wide range of anticipated support and loading conditions.

How the test results are interpreted will depend on the intended use of the masonry element being tested.

SCOPE

1.1 These test methods cover methods for determining the strength and load-deflection characteristics of masonry wall elements.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1717 − 10

StandardTest Methods for

1

Conducting Strength Tests of Masonry Wall Panels

This standard is issued under the fixed designation C1717; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Engineered design of masonry structures requires accurate technical data on the strength and

load-deflection behavior of masonry wall elements.These test methods provide a systematic basis for

obtaining such data.

1. Scope* 3.1.2 Thetestingprotocolscouldbeusedforqualificationof

masonry elements and materials by evaluation services and

1.1 These test methods cover methods for determining the

other parties.

strength and load-deflection characteristics of masonry wall

3.1.3 The test methods described in this standard are

elements.

general, and are intended to be adaptable to address a wide

1.2 The values stated in inch-pound units are to be regarded

range of anticipated support and loading conditions.

as standard. The values given in parentheses are mathematical

3.2 How the test results are interpreted will depend on the

conversions to SI units that are provided for information only

intended use of the masonry element being tested.

and are not considered standard.

1.3 This standard does not purport to address all of the

4. Test Specimens

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4.1 General Description—The specimens shall have mate-

priate safety and health practices and determine the applica-

rialsandworkmanshiprepresentativeofthestructuralelements

bility of regulatory limitations prior to use.

theyareintendedtorepresent,andbelargeenoughtobeuseful

in predicting the structural performance of those elements.

2. Referenced Documents

4.2 Length or Height—The specimen shall be long enough

2

2.1 ASTM Standards:

(for horizontal testing) or tall enough (for vertical testing) so

E2126Test Methods for Cyclic (Reversed) Load Test for

that its behavior under load will simulate that of the element

ShearResistanceofVerticalElementsoftheLateralForce

that the specimen is intended to represent.

Resisting Systems for Buildings

4.3 Width—The specimen shall be wide enough so that its

behavior under load will simulate that of the element the

3. Significance and Use

specimen is intended to represent.

3.1 The test methods described in this standard are intended

4.4 Laboratory Environment—Maintain the air in the labo-

for use as a starting point in developing specific testing

ratoryatatemperatureof75 615°F(24 68°C)andarelative

protocols for masonry elements.

humidity of 55 6 25%.

3.1.1 The testing protocols could be used for general re-

search on the load-deflection behavior of masonry elements.

4.5 Preconditioning of Masonry Materials—Precondition

materials by storing in the laboratory environment for at least

5 days before use.

1

These test methods are under the jurisdiction of ASTM Committee C15 on

4.6 Age—Test masonry construction at an age of at least 28

Manufactured Masonry Units and is the direct responsibility of Subcommittee

days after fabrication, unless specified otherwise.

C15.04 on Research.

Current edition approved Dec. 1, 2010. Published December 2010. Originally

approved in 2009. Last previous edition approved in 2009 as C1717–09. DOI:

5. General Requirements for Instrumentation

10.1520/C1717-10.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1 Load Measurement—Measure loads with a load cell or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

pressure transducer having a precision better than or equal to

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 1% of the expected maximum load.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

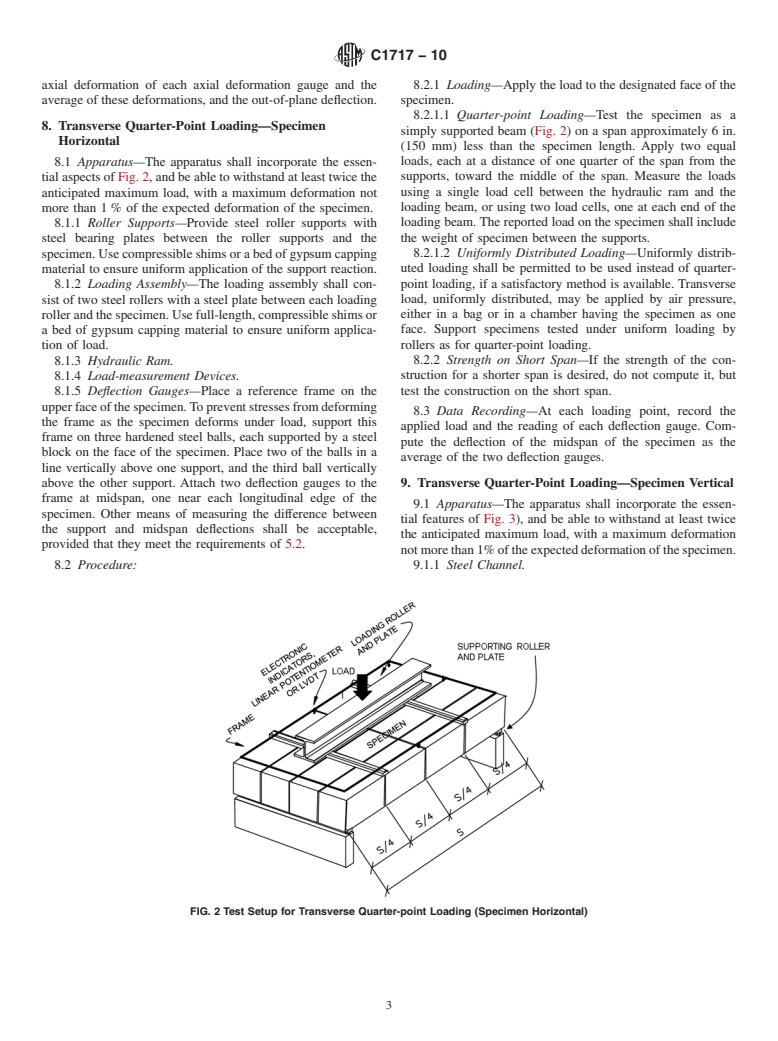

C1717 − 10

5.2 Displacement Measurement—Measure displacements the maximum anticipated load. Design the test setup so its

with a linear potentiometer, linear variable displacement trans- stiffness parallel to the axis of the specimen is at least 10× the

former (LVDT), or dial gauge having a precision equal to or anticipated axial stiffness of the specimen itself.The bottom of

better than the lesser of 61% of the expected maximum the specimen shall be simply supported (with a zero or

displacement, or 60.02 in. (60.5 mm). non-zero eccentricity) or restrained. The top of the specimen

shallbesimplysupported(

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1717–09 Designation:C1717–10

Standard Test Methods for

1

Conducting Strength Tests of Masonry Wall Panels

This standard is issued under the fixed designation C1717; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Engineered design of masonry structures requires accurate technical data on the strength and

load-deflection behavior of masonry wall elements. These test methods provide a systematic basis for

obtaining such data.

1. Scope*

1.1 Thesetestmethodscovermethodsfordeterminingthestrengthandload-deflectioncharacteristicsofmasonrywallelements.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E2126 Test Methods for Cyclic (Reversed) Load Test for Shear Resistance of Vertical Elements of the Lateral Force Resisting

Systems for Buildings

3. Significance and Use

3.1 The test methods described in this standard are intended for use as a starting point in developing specific testing protocols

for masonry elements.

3.1.1 The testing protocols could be used for general research on the load-deflection behavior of masonry elements.

3.1.2 The testing protocols could be used for qualification of masonry elements and materials by evaluation services and other

parties.

3.1.3 The test methods described in this standard are general, and are intended to be adaptable to address a wide range of

anticipated support and loading conditions.

3.2 How the test results are interpreted will depend on the intended use of the masonry element being tested.

4. Test Specimens

4.1 General Description—The specimens shall have materials and workmanship representative of the structural elements they

are intended to represent, and be large enough to be useful in predicting the structural performance of those elements.

4.2 Length or Height—The specimen shall be long enough (for horizontal testing) or tall enough (for vertical testing) so that

its behavior under load will simulate that of the element that the specimen is intended to represent.

4.3 Width—The specimen shall be wide enough so that its behavior under load will simulate that of the element the specimen

is intended to represent.

4.4 Laboratory Environment—Maintain the air in the laboratory at a temperature of 75 6 15°F (24 6 8°C) and a relative

humidity of 55 6 25 %.

1

These test methods are under the jurisdiction of ASTM Committee C15 on Manufactured Masonry Units and is the direct responsibility of Subcommittee C15.04 on

Research.

Current edition approved June 1, 2009. Published July 2009. DOI: 10.1520/C1717-09.

Current edition approved Dec. 1, 2010. Published December 2010. Originally approved in 2009. Last previous edition approved in 2009 as C1717 – 09. DOI:

10.1520/C1717-10.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

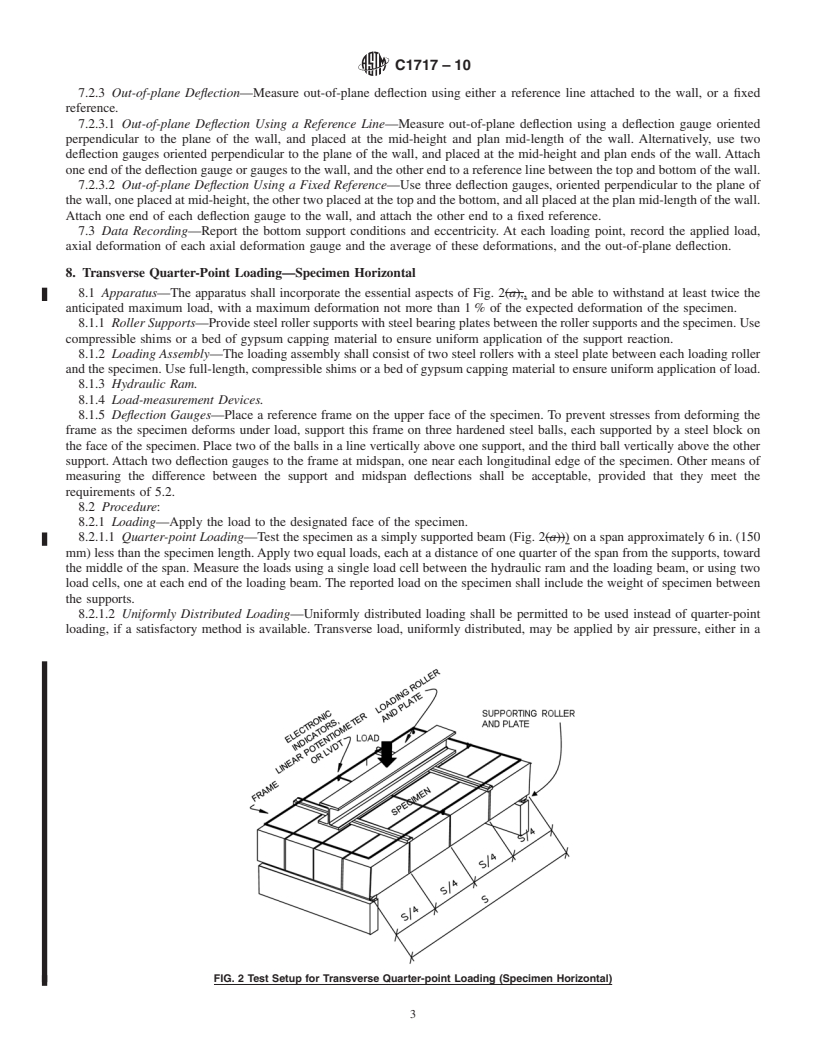

C1717–10

4.5 Preconditioning of Masonry Materials—Precondition materials by storing in the laboratory environment for at least 5 days

before use.

4.6 Age—Test masonry construction at an age of at least 28 days after fabrication, unless specified otherwise.

5. General Requirements for Instrumentation

5.1 Load Measurement—Measure loads with a load cell or pressure transducer having a precision better than or equal to 1 %

of the expected maximum load.

5.2 Displacement Measurement—Measure displacements with a linear potentiometer, linear variable displacement transformer

(LVDT), or dial gauge having a precision equal to or better than the le

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.