ASTM C208-12(2017)e1

(Specification)Standard Specification for Cellulosic Fiber Insulating Board

Standard Specification for Cellulosic Fiber Insulating Board

ABSTRACT

This specification covers the principal cellulosic fiber insulating board types, grades, and sizes. Insulating board covered by this specification consists of six types: Types I, II (Grades 1 and 2), III (Grades 1 and 2), IV (Grades 1 and 2), V, and VI. Cellulosic fiber insulating board shall be manufactured from refined or partially refined ligno-cellulosic (wood or cane) fibers, by felting or molding process, into homogeneous panels. The insulating board shall conform to the physical properties specified.

SCOPE

1.1 This specification covers the principal cellulosic fiber insulating board types, grades, and sizes. Requirements are specified for composition, construction, physical properties, tolerances, sampling procedures, and test methods.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 When the installation or use of thermal insulation materials, accessories, and systems may pose safety or health problems, the manufacturer shall provide the user appropriate current information regarding any known problems associated with the recommended use of the company's products and shall also recommend protective measures to be employed in their safe utilization. The user shall establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:C208 −12 (Reapproved 2017)

Standard Specification for

Cellulosic Fiber Insulating Board

This standard is issued under the fixed designation C208; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Editorially added missing SI conversions in September 2017.

1. Scope C209Test Methods for Cellulosic Fiber Insulating Board

C390Practice for Sampling and Acceptance of Thermal

1.1 This specification covers the principal cellulosic fiber

Insulation Lots

insulating board types, grades, and sizes. Requirements are

C846Practice forApplication of Cellulosic Fiber Insulating

specified for composition, construction, physical properties,

Board for Wall Sheathing

tolerances, sampling procedures, and test methods.

D1037Test Methods for Evaluating Properties of Wood-

1.2 The values stated in inch-pound units are to be regarded

Base Fiber and Particle Panel Materials

as standard. The values given in parentheses are mathematical

D1554Terminology Relating to Wood-Base Fiber and Par-

conversions to SI units that are provided for information only

ticle Panel Materials

and are not considered standard.

D2164Methods of Testing Structural Insulating Roof Deck

1.3 When the installation or use of thermal insulation (Withdrawn 2005)

E72Test Methods of Conducting Strength Tests of Panels

materials, accessories, and systems may pose safety or health

problems, the manufacturer shall provide the user appropriate for Building Construction

2.2 Federal Standard:

current information regarding any known problems associated

withtherecommendeduseofthecompany’sproductsandshall 4900.1Rev-1 U.S. Dept. of Housing and Urban Develop-

ment Minimum Property Standards, One and Two Family

also recommend protective measures to be employed in their

safe utilization. The user shall establish appropriate safety and Dwellings

health practices and determine the applicability of regulatory

3. Terminology

requirements prior to use.

3.1 For definitions of terms used in this specification, see

1.4 This international standard was developed in accor-

Terminology C168 and Definitions D1554.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

3.2 Definitions of Terms Specific to This Standard:

Development of International Standards, Guides and Recom-

3.2.1 cellulosic fiber insulating board—a fibrous-felted, ho-

mendations issued by the World Trade Organization Technical

mogeneous panel made from ligno-cellulosic fibers (usually

3 3

Barriers to Trade (TBT) Committee.

wood) and having a density of less than 31 lb/ft (497 kg/m )

3 3

but more than 10 lb/ft (160 kg/m ).

2. Referenced Documents

3.2.1.1 Discussion—Cellulosic fiber insulating board is

2.1 ASTM Standards: characterized by an integral bond which is produced by

interfelting of the fibers, but which has not been consolidated

C165TestMethodforMeasuringCompressivePropertiesof

Thermal Insulations under heat and pressure as a separate stage in manufacture.

Other materials may be added during manufacture to improve

C168Terminology Relating to Thermal Insulation

certain properties.

4. Classification

This specification is under the jurisdiction of ASTM Committee C16 on

Thermal Insulation and is the direct responsibility of Subcommittee C16.22 on

4.1 Insulatingboardcoveredbythisspecificationconsistsof

Organic and Nonhomogeneous Inorganic Thermal Insulations.

six types:

Current edition approved Sept. 1, 2017. Published December 2017. Originally

approved in 1946. Last previous edition approved in 2012 as C208–12. DOI:

10.1520/C0208-12R17E01.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

Standards volume information, refer to the standard’s Document Summary page on Available from the U.S. Department of Housing and Urban Development,

the ASTM website. Construction Standards Division, HUD Building, Washington, DC 20410.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

C208−12 (2017)

4.1.1 Type I—Sound deadening board, for use in wall fibers, by a felting or molding process, into homogeneous

assemblies to control sound transmissions. panels. Other ingredients may be added to provide or improve

4.1.2 Type II—Roof insulation board, for use in various certain properties such as strength and water resistance, in

roofing systems. addition to surface finishes for decorative products and special

4.1.2.1 Grade 1—Primarily for use under built-up, and coatings which impart resistance to flame spread. The material

modified bitumen roof systems. is subjected to such drying temperatures as to effect complete

4.1.2.2 Grade 2—Primarily for use under single-ply, built- destruction of rot producing fungi.

up, and modified bitumen roofing systems.

5.2 The finished board may be either single or multiple ply.

4.1.3 Type III—Ceiling tiles and panels.

When multiple-ply boards are supplied, a suitable moisture-

4.1.3.1 Grade 1—Nonacoustical, for use as decorative wall

resistant adhesive shall be used to join the plies.

and ceiling coverings.

4.1.3.2 Grade 2—Acoustical, for use as decorative, sound 6. Physical Properties

absorbing wall and ceiling coverings.

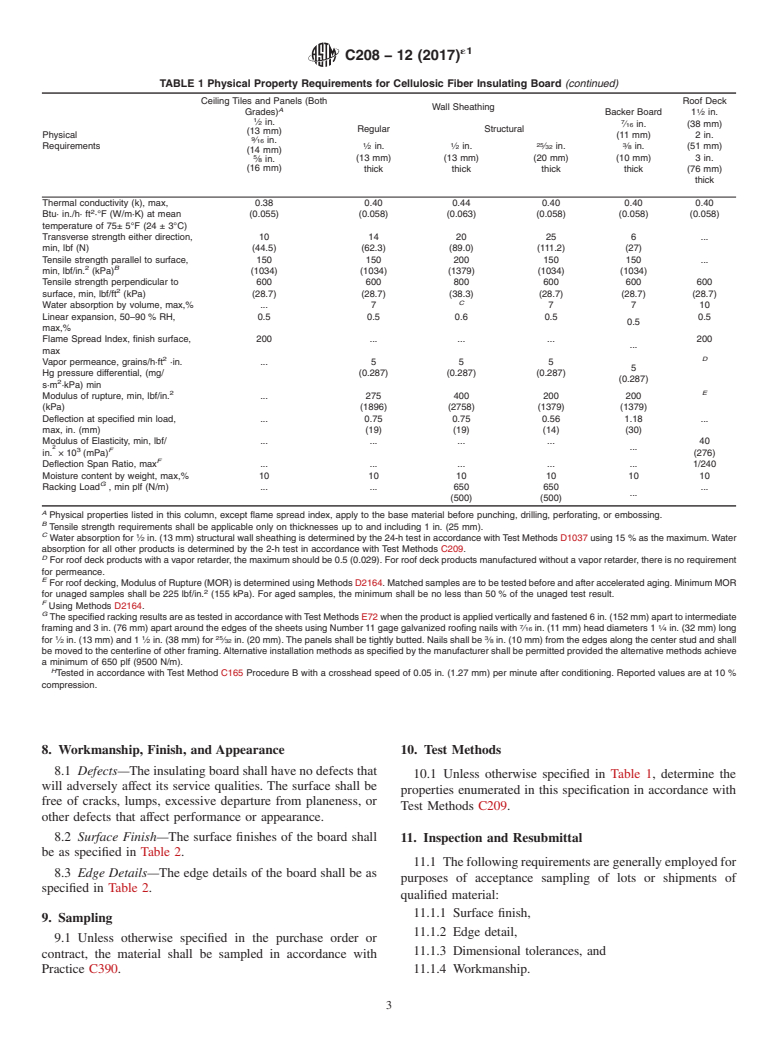

6.1 The insulating board shall conform to the physical

4.1.4 Type IV—Wall Sheathing.

properties in Table 1.

4.1.4.1 Grade 1—Regular, for use as wall sheathing in

1 1

6.2 Roof products with a thickness of 1 in., 1 ⁄2 in., 2 ⁄2 in.

frame construction.

(25 mm, 38 mm, 64 mm), or greater, are post-laminated using

4.1.4.2 Grade 2—Structural, for use as wall sheathing in

thinner board stock whose properties are covered in Table 1.

frameconstruction.WheninstalledinaccordancewithPractice

When laminated, tests shall be performed on the thin board

C846, structural wall sheathing provides adequate racking

stock.

resistance for use as exterior wall bracing.

4.1.5 Type V—Backer board, for use behind exterior finish

7. Dimensions, Mass, and Permissible Variations

in wall assemblies where there are no structural requirements.

7.1 The materials covered by this specification are available

4.1.6 Type VI—Roof deck, for use as roof decking for flat,

in the sizes shown in Table 2.

pitched, or shed-type, open-beamed, ceiling-roof construction.

7.2 Length and Width Tolerances—Unless otherwise

4.2 On occasion these products are used for other applica-

specified, the tolerance for length and width of any size panel

tions.Themanufacturerandthepurchasershallagreeuponany

shall by+0,− ⁄16 in. per ft (+0,−5.2 mm⁄m), but the total

special requirements for such end uses.

tolerance in any dimension shall not exceed+0,− ⁄8 in. (+0

5. Materials and Manufacture mm,−10 mm).

5.1 Cellulosic fiber insulating board shall be manufactured 7.3 Thickness Tolerance—The thickness tolerances are

fromrefinedorpartiallyrefinedligno-cellulosic(usuallywood) shown in Table 3.

TABLE 1 Physical Property Requirements for Cellulosic Fiber Insulating Board

Sound Deadening Roof Insulation Board

Board

Grade 1 Grade 2

Physical 1

⁄2 in.

7 1 1

⁄16 in. ⁄2 in. 1in. 2in. ⁄2 in. 1in. 2in.

Requirements

(13 mm)

(11 mm) (13 mm) (25 mm) (51 mm) (13 mm) (25 mm) (51 mm)

thick

thick thick thick thick thick thick thick

Thermal conductivity (k), max, 0.38 0.38 0.38 0.38 0.38 0.50 0.40 0.40

Btu· in./h· ft ·°F (W/m·K) at mean (0.055) (0.055) (0.055) (0.055) (0.055) (0.072) (0.058) (0.058)

temperature of 75± 5°F (24 ± 3°C)

Transverse strength either direction, 12 7 7 14 28 12 24 36

min, lbf (N) (53.4) (31.1) (31.1) (62.3) (124.6) (53.4) (107) (160)

Tensile strength parallel to surface, min, 150 50 50 50 . 150 150 .

B

lbf/in. (kPa) (1034) (345) (345) (345) (1034) (1034)

Tensile strength perpendicular to 600 500 500 500 500 600 600 600

surface, min, lbf/ft (kPa) (28.7) (23.9) (23.9) (23.9) (23.9) (28.7) (28.7) (28.7)

Water absorption by volume, max,% 7 10 10 10 10 7 7 7

Linear expansion, 50–90 % RH, max,% 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5

Flame Spread Index, finish surface, . . . . . . . .

max

Vapor permeance, grains/h·ft ·in. Hg 5 . . . . . . .

pressure differential, (mg/s·m ·kPa) min (0.287)

Modulus of rupture, min, lbf/in. (kPa) 240 140 140 80 40 275 140 70

(1655) (965) (965) (552) (276) (1896) (965) (483)

Deflection at specified min load, max, 0.85 1.25 1.25 0.62 0.31 0.75 0.42 0.21

in. (mm) (22) (32) (32) (16) (8) (19) (11) (5)

2 3

Modulus of Elasticity, min, lbf/in. ×10 . . . . . . . .

F

(mPa)

F

Deflection Span Ratio, max . . . . . . . .

Moisture content by weight, max,% 10 10 10 10 10 10 10 10

G

Racking Load , min plf (N/m) . . . . . . . .

H 2

Compressive Strength , min, lbf/in. . 14.5 14.5 14.5 14.5 15 15 15

(kPa) (100) (100) (100) (100) (105) (105) (105)

´1

C208−12 (2017)

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: C208 − 12 C208 − 12 (Reapproved 2017)

Standard Specification for

Cellulosic Fiber Insulating Board

This standard is issued under the fixed designation C208; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Editorially added missing SI conversions in September 2017.

1. Scope

1.1 This specification covers the principal cellulosic fiber insulating board types, grades, and sizes. Requirements are specified

for composition, construction, physical properties, tolerances, sampling procedures, and test methods.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 When the installation or use of thermal insulation materials, accessories, and systems may pose safety or health problems,

the manufacturer shall provide the user appropriate current information regarding any known problems associated with the

recommended use of the company’s products and shall also recommend protective measures to be employed in their safe

utilization. The user shall establish appropriate safety and health practices and determine the applicability of regulatory

requirements prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

C165 Test Method for Measuring Compressive Properties of Thermal Insulations

C168 Terminology Relating to Thermal Insulation

C209 Test Methods for Cellulosic Fiber Insulating Board

C390 Practice for Sampling and Acceptance of Thermal Insulation Lots

C846 Practice for Application of Cellulosic Fiber Insulating Board for Wall Sheathing

D1037 Test Methods for Evaluating Properties of Wood-Base Fiber and Particle Panel Materials

D1554 Terminology Relating to Wood-Base Fiber and Particle Panel Materials

D2164 Methods of Testing Structural Insulating Roof Deck (Withdrawn 2005)

E72 Test Methods of Conducting Strength Tests of Panels for Building Construction

2.2 Federal Standard:

4900.1 Rev-1 U.S. Dept. of Housing and Urban Development Minimum Property Standards, One and Two Family Dwellings

3. Terminology

3.1 For definitions of terms used in this specification, see Terminology C168 and Definitions D1554.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 cellulosic fiber insulating board—a fibrous-felted, homogeneous panel made from ligno-cellulosic fibers (usually wood)

3 3 3 3

and having a density of less than 31 lb/ft (497 kg/m ) but more than 10 lb/ft (160 kg/m ).

This specification is under the jurisdiction of ASTM Committee C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.22 on Organic and

Nonhomogeneous Inorganic Thermal Insulations.

Current edition approved Sept. 1, 2012Sept. 1, 2017. Published October 2012December 2017. Originally approved in 1946 . Last previous edition approved in 20082012

as C208C208 – 12.– 08a. DOI: 10.1520/C0208-12.10.1520/C0208-12R17E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Available from the U.S. Department of Housing and Urban Development, Construction Standards Division, HUD Building, Washington, DC 20410.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

C208 − 12 (2017)

3.2.1.1 Discussion—

Cellulosic fiber insulating board is characterized by an integral bond which is produced by interfelting of the fibers, but which has

not been consolidated under heat and pressure as a separate stage in manufacture. Other materials may be added during

manufacture to improve certain properties.

4. Classification

4.1 Insulating board covered by this specification consists of six types:

4.1.1 Type I—Sound deadening board, for use in wall assemblies to control sound transmissions.

4.1.2 Type II—Roof insulation board, for use in various roofing systems.

4.1.2.1 Grade 1—Primarily for use under built-up, and modified bitumen roof systems.

4.1.2.2 Grade 2—Primarily for use under single-ply, built-up, and modified bitumen roofing systems.

4.1.3 Type III—Ceiling tiles and panels.

4.1.3.1 Grade 1—Nonacoustical, for use as decorative wall and ceiling coverings.

4.1.3.2 Grade 2—Acoustical, for use as decorative, sound absorbing wall and ceiling coverings.

4.1.4 Type IV—Wall Sheathing.

4.1.4.1 Grade 1—Regular, for use as wall sheathing in frame construction.

4.1.4.2 Grade 2—Structural, for use as wall sheathing in frame construction. When installed in accordance with Practice C846,

structural wall sheathing provides adequate racking resistance for use as exterior wall bracing.

4.1.5 Type V—Backer board, for use behind exterior finish in wall assemblies where there are no structural requirements.

4.1.6 Type VI—Roof deck, for use as roof decking for flat, pitched, or shed-type, open-beamed, ceiling-roof construction.

4.2 On occasion these products are used for other applications. The manufacturer and the purchaser shall agree upon any special

requirements for such end uses.

5. Materials and Manufacture

5.1 Cellulosic fiber insulating board shall be manufactured from refined or partially refined ligno-cellulosic (usually wood)

fibers, by a felting or molding process, into homogeneous panels. Other ingredients may be added to provide or improve certain

properties such as strength and water resistance, in addition to surface finishes for decorative products and special coatings which

impart resistance to flame spread. The material is subjected to such drying temperatures as to effect complete destruction of rot

producing fungi.

5.2 The finished board may be either single or multiple ply. When multiple-ply boards are supplied, a suitable moisture-resistant

adhesive shall be used to join the plies.

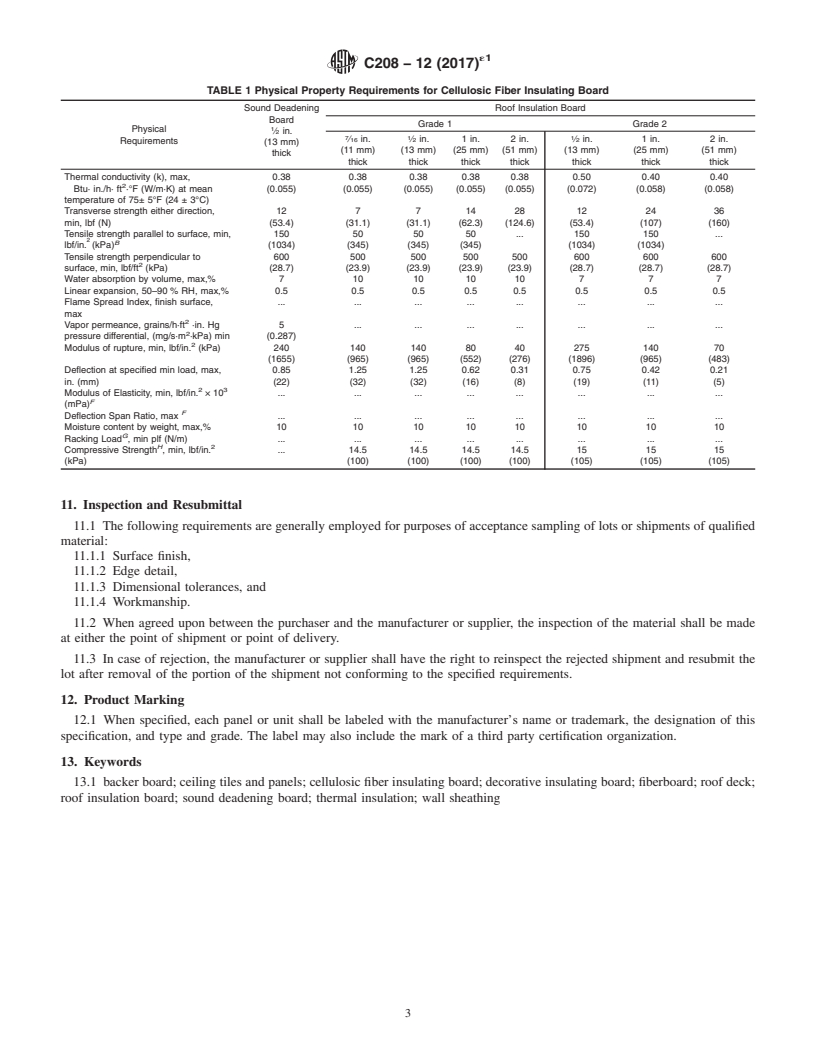

6. Physical Properties

6.1 The insulating board shall conform to the physical properties in Table 1.

1 1

6.2 Roof products with a thickness of 1 in., 1 ⁄2 in., 2 ⁄2 in., in. (25 mm, 38 mm, 64 mm), or greater, are post-laminated using

thinner board stock whose properties are covered in Table 1. When laminated, tests shall be performed on the thin board stock.

7. Dimensions, Mass, and Permissible Variations

7.1 The materials covered by this specification are available in the sizes shown in Table 2.

7.2 Length and Width Tolerances—Unless otherwise specified, the tolerance for length and width of any size panel shall

1 3

by + 0, − ⁄16 in. per ft ( + 0, − 5.2 mm/m),mm ⁄m), but the total tolerance in any dimension shall not exceed + 0, − ⁄8 in. ( + 0

mm, − 10 mm).

7.3 Thickness Tolerance—The thickness tolerances are shown in Table 3.

8. Workmanship, Finish, and Appearance

8.1 Defects—The insulating board shall have no defects that will adversely affect its service qualities. The surface shall be free

of cracks, lumps, excessive departure from planeness, or other defects that affect performance or appearance.

8.2 Surface Finish—The surface finishes of the board shall be as specified in Table 2.

8.3 Edge Details—The edge details of the board shall be as specified in Table 2.

9. Sampling

9.1 Unless otherwise specified in the purchase order or contract, the material shall be sampled in accordance with Practice C390.

10. Test Methods

10.1 Unless otherwise specified in Table 1, determine the properties enumerated in this specification in accordance with Test

Methods C209.

´1

C208 − 12 (2017)

TABLE 1 Physical Property Requirements for Cellulosic Fiber Insulating Board

Sound Deadening Roof Insulation Board

Board

Grade 1 Grade 2

Physical

⁄2 in.

7 1 1

⁄16 in. ⁄2 in. 1 in. 2 in. ⁄2 in. 1 in. 2 in.

Requirements

(13 mm)

(11 mm) (13 mm) (25 mm) (51 mm) (13 mm) (25 mm) (51 mm)

thick

thick thick thick thick thick thick thick

Thermal conductivity (k), max, 0.38 0.38 0.38 0.38 0.38 0.50 0.40 0.40

Btu· in./h· ft ·°F (W/m·K) at mean (0.055) (0.055) (0.055) (0.055) (0.055) (0.072) (0.058) (0.058)

temperature of 75± 5°F (24 ± 3°C)

Transverse strength either direction, 12 7 7 14 28 12 24 36

min, lbf (N) (53.4) (31.1) (31.1) (62.3) (124.6) (53.4) (107) (160)

Tensile strength parallel to surface, min, 150 50 50 50 . 150 150 .

B

lbf/in. (kPa) (1034) (345) (345) (345) (1034) (1034)

Tensile strength perpendicular to 600 500 500 500 500 600 600 600

surface, min, lbf/ft (kPa) (28.7) (23.9) (23.9) (23.9) (23.9) (28.7) (28.7) (28.7)

Water absorption by volume, max,% 7 10 10 10 10 7 7 7

Linear expansion, 50–90 % RH, max,% 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5

Flame Sp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.