ASTM D1601-99(2004)

(Test Method)Standard Test Method for Dilute Solution Viscosity of Ethylene Polymers

Standard Test Method for Dilute Solution Viscosity of Ethylene Polymers

SIGNIFICANCE AND USE

The knowledge of dilute solution viscosity serves as an additional tool in characterizing ethylene polymers. Viscosity data alone may be of limited value in predicting the processing behavior of the polymer. However, when used in conjunction with other flow and physical property values, the solution viscosity of ethylene polymers may contribute to their characterizations.

Satisfactory correlation between solution viscosity and certain other properties is possible from polymers of a single manufacturing process. The solution viscosity test is not sensitive to some molecular configurational patterns that may occur among polymers from different manufacturing processes. Hence, its correlation with other properties of polymers produced by different processes, by even one manufacturer, may be limited.

The viscosity of polymer solutions may be drastically affected by the presence of known or unknown additives in the sample. The use of solution viscosity may be of questionable value where ethylene polymers are known or suspected to contain colorants, carbon black, low molecular weight hydrocarbons, fillers, or other additives.

The measurement of dilute solution viscosity of ethylene polymers presents problems not ordinarily encountered in viscosimetry. Ethylene polymers are not soluble at room temperature in any known solvent. Some of the higher density materials are insoluble below 100°C. Extreme care must be exercised in transferring the solution to the viscometer for the test if the correct solution concentration is to be maintained. This test has no significance unless the sample is completely soluble.

The solution viscosity is a function of the root-mean-square size of the polymer molecules in solution. It is known that the solvent selected and the temperature of the determination have an effect on the root-mean-square size of the particles. Hence, where a viscometer, solvent, or temperature other than specified is used, data may not be comparable to that obtai...

SCOPE

1.1 This test method covers the determination of the dilute solution viscosity of ethylene polymers at 135°C. It is applicable to a reasonably wide spectrum of ethylene polymers having densities from 0.910 to 0.970 g/cm2. Directions are given for the determination of relative viscosity (viscosity ratio), inherent viscosity (logarithmic viscosity number), and intrinsic viscosity (limiting viscosity number) (see Appendix X4).

1.2 The values as stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—This test method is technically equivalent to ISO 1628-3.

Note 2—Appendix X1-Appendix X3 contain material from the previous version of Test Method D 1601 and are included for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1601 − 99(Reapproved 2004)

Standard Test Method for

Dilute Solution Viscosity of Ethylene Polymers

This standard is issued under the fixed designation D1601; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* IEEE/ASTM SI-10 Standard for Use of the International

System of Units (SI): The Modern Metric System

1.1 This test method covers the determination of the dilute

2.2 ISO Standards:

solution viscosity of ethylene polymers at 135°C. It is appli-

ISO 1628-3 Plastics—Determination of Viscosity Number

cable to a reasonably wide spectrum of ethylene polymers

2 and Limiting Viscosity Number—Part 3: Polyethylenes

having densities from 0.910 to 0.970 g/cm . Directions are

and Polypropylenes

given for the determination of relative viscosity (viscosity

ratio), inherent viscosity (logarithmic viscosity number), and

3. Terminology

intrinsic viscosity (limiting viscosity number) (see Appendix

3.1 Units, symbols, and abbreviations used in this test

X4).

method are those recommended in IEEE/ASTM SI-10 and

1.2 The values as stated in SI units are to be regarded as the

Terminologies D883 and D1600 (see also Appendix X4).

standard.

4. Significance and Use

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4.1 The knowledge of dilute solution viscosity serves as an

responsibility of the user of this standard to establish appro-

additional tool in characterizing ethylene polymers. Viscosity

priate safety and health practices and determine the applica-

data alone may be of limited value in predicting the processing

bility of regulatory limitations prior to use.

behavior of the polymer. However, when used in conjunction

with other flow and physical property values, the solution

NOTE 1—This test method is technically equivalent to ISO 1628-3.

viscosity of ethylene polymers may contribute to their charac-

NOTE 2—Appendix X1-Appendix X3 contain material from the previ-

ous version of Test Method D1601 and are included for information only. terizations.

4.2 Satisfactory correlation between solution viscosity and

2. Referenced Documents

certain other properties is possible from polymers of a single

2.1 ASTM Standards:

manufacturing process. The solution viscosity test is not

D86 Test Method for Distillation of Petroleum Products at

sensitive to some molecular configurational patterns that may

Atmospheric Pressure

occur among polymers from different manufacturing pro-

D445 Test Method for Kinematic Viscosity of Transparent

cesses. Hence, its correlation with other properties of polymers

and Opaque Liquids (and Calculation of Dynamic Viscos-

produced by different processes, by even one manufacturer,

ity)

may be limited.

D883 Terminology Relating to Plastics

4.3 The viscosity of polymer solutions may be drastically

D1600 Terminology forAbbreviatedTerms Relating to Plas-

affected by the presence of known or unknown additives in the

tics

sample. The use of solution viscosity may be of questionable

D4020 Specification for Ultra-High-Molecular-Weight Poly-

value where ethylene polymers are known or suspected to

ethylene Molding and Extrusion Materials

contain colorants, carbon black, low molecular weight

E1 Specification for ASTM Liquid-in-Glass Thermometers

hydrocarbons, fillers, or other additives.

4.4 The measurement of dilute solution viscosity of ethyl-

ene polymers presents problems not ordinarily encountered in

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.70 on Analytical Methods

viscosimetry. Ethylene polymers are not soluble at room

(Section D20.70.05).

temperature in any known solvent. Some of the higher density

Current edition approved July 1, 2004. Published July 2004. Originally approved

materials are insoluble below 100°C. Extreme care must be

in 1958. Last previous edition approved in 1999 as D1601 - 99. DOI: 10.1520/

D1601-99R04. exercised in transferring the solution to the viscometer for the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1601 − 99 (2004)

test if the correct solution concentration is to be maintained. may be used. Care should be exercised in using fluids that

This test has no significance unless the sample is completely discolor or smoke with prolonged heating.

soluble.

NOTE 5—Silicone heat-transfer fluids are adequate for this use .

4.5 The solution viscosity is a function of the root-mean-

7. Procedure

square size of the polymer molecules in solution. It is known

7.1 Decahydronaphthalene Preparation—Add 0.2 %

that the solvent selected and the temperature of the determina-

tion have an effect on the root-mean-square size of the weight/volume stabilizer (Irganox 1010 or equivalent), to the

decahydronaphthalene, stir to dissolve, filter through fast filter

particles. Hence, where a viscometer, solvent, or temperature

otherthanspecifiedisused,datamaynotbecomparabletothat paper, and store in a clean amber bottle.

obtained by this procedure.

7.2 Cleaning the Viscometer—Clean the viscometer thor-

oughly as follows: fill with cleaning solution, let stand over-

5. Apparatus

night, empty and rinse several times with distilled water, then

5.1 Volumetric Flasks, 100-mL, grade EXAX or better.

rinse with acetone and purge with dry nitrogen.

5.2 Transfer Pipets, Grade EXAX or better.

7.3 Solution Preparation—Weigh 20 to 30 mg of the UH-

MWPE (see Note 6) into the Erlenmeyer flask. Add the

5.3 Constant Temperature Bath, capable of maintaining 135

decahydronaphthalene at room temperature, using a burette to

6 l0.1°C.

measure in milliliters a volume equal to 4.5 times the UHM-

5.4 Viscometer, Ubbelohde No. 1, calibrated for kinetic

WPE weight in milligrams (for example, 26 mg of UHMWPE

energy correction constant.

and 117 ml of decahydronaphthalene). Heat the flask, with

NOTE 3—Other types of viscometers may be used provided they can be stirring, to 150°C 6 2°C. Continue stirring at 150°C 6 2°C for

shown to agree with the type specified.

1 h, with the flask lightly stoppered. Examine the flask to see

5.5 Oven, maintained at 140 6 5°C. if undissolved UHMWPE remains. If so, heat an additional 15

minandreexamine.Heatforanadditional15min,ifnecessary,

5.6 Timer, as specified in 4.5 of Test Method D445.

but do not heat longer than 2 h total.

5.7 Thermometer—An ASTM High Softening Point Ther-

7.4 Viscosity Measurement:

mometer having a range from 30 to 200°C, and conforming to

7.4.1 Place the clean viscometer into the constant-

the requirements for Thermometer 16C in Specification E1.

temperature bath. Fill the viscometer with decahydronaphtha-

lene,andallowitandthesolventtoequilibrateat135 60.1°C.

6. Reagents and Materials

Measure the flow time of the solvent, t , three times, and

o

6.1 Solvent—Decahydronaphthalene, practical grade, puri-

average the results. The viscometer may have to be cleaned if

fied and redistilled, as follows:

replicate measurements of flow time differ by more than 0.3 s

6.1.1 The solvent shall be purified by percolation through

(see 7.4.3). Remove the decahydronaphthalene from the vis-

100 to 200 mesh commercial grade silica gel. This treatment

cometerwithvacuumandthoroughlyrinsetheviscometerwith

removes naphthalene, tetrahydronaphthalene, and oxy com-

xylene at 110 to 120°C or decahydronaphthalene at 135°C.

pounds, particularly peroxides.

Remove the xylene or decahydronaphthalene with vacuum and

6.1.2 The redistilled product shall conform to the following

aspirate dry air or nitrogen to dry the viscometer (2 or 3 min).

requirements when tested in accordance with Method D86:

It is essential that the viscometer be completely dry.

ASTM

7.4.2 Transfer the hot (150°C) polymer solution to the

Standard Distillation

Method D86

viscometer with sufficient quantity to fill to the mark (see Note

Initial boiling point 190°C min

10 mL 191°C min 7), allow to equilibrate at 135°C 6 0.1°C, and measure the

20 mL 192°C min

flow time of the solution, t , in triplicate, and average the

s

80 mL 194°C max

results.

90 mL 195°C max

Dry point 196°C max

7.4.3 Between uses, clean the viscometer by rinsing with

hot xylene or decahydronaphthalene, drying with air or nitro-

NOTE 4—While use of other solvents, such as tetrahydronaphthalene or

xylene, may sometimes be advantageous, they will generally yield gen, and storing filled with hot decahydronaphthalene. If

different values for solution viscosities.

solvent flow time changes by more than 0.3 s, or if difficulty is

encountered in obtaining reproducible flow times with any

6.1.3 Immediately after redistillation of the decahydronaph-

solution or solvent, clean the viscometer with cleaning solution

thalene, add 0.2 % Tetrakis [methylene 3-(3',5'-di-tert-butyl-4'-

as described in 7.2.

hydroxphenyl) propionate] methane to inhibit oxidation during

the viscosity determination.

NOTE 6—If the UHMWPE is suspected to contain moisture or other

volatiles, it shall first be dried in a vacuum oven at 60°C for 2 h.

6.2 Heat Transfer Medium—Any liquid heat transfer me-

NOTE 7—Filling of the viscometer is made easier by the use of a glass

dium that will not appreciably affect the accuracy of the test

funnelwarmedwithaheatingmantle.ThishelpstopreventtheUHMWPE

solution from precipitating.

Glassware used in this test method should be tested in accordance with the

procedures described in the National Institute of Standards andTechnology Circular The silicone fluids available from the Dow Corning Corp., Midland, MI, or

No. C-434, “Testing of Glass Volumetric Apparatus,” and should not exceed the from the Union Carbide Corp., Linde Silicones Div., New York, NY, have been

limits of accuracy set forth in the circular. found satisfactory for this purpose.

D1601 − 99 (2004)

TABLE 1 Relative Solution Viscosity

8. Calculation

A B C D

Material Average S S r R

r R

8.1 Calculate the relative solution viscosity as follows:

UHMWPE No. 1 1.454 0.015 0.049 0.042 0.136

UHMWPE No. 2 1.653 0.017 0.048 0.047 0.136

h 5 t 2 k/t / t 2 k/t (1)

~ ! ~ !

r s s o o

A

S = within-laboratory standard deviation for the indicated material. It is obtained

r

where:

by first pooling the within-laboratory standard deviations of the test results from all

of the participating laboratories.

k = kinetic energy correction constant for the particular

2 2 2 1/2

S 5 f h ss d 1ss d .1ss d j/n g

viscometer used, r 1 2 R

B

t = flow time of solution at 135°C (average of three

s S = between-laboratory reproducibility, expressed as standard deviation:

R

measurements), and

2 2 1/2

S 5 Sr 1S

f g

R L

t = flow time of pure solvent at 135°C (average of three

o

where S = standard deviation of laboratory means.

L

measurements).

C

r = within-laboratory critical interval between two test results = 2.8 × S .

r

D

R = between laboratories critical interval between two test results = 2.8 × S .

R

9. Report

9.1 Report the following information:

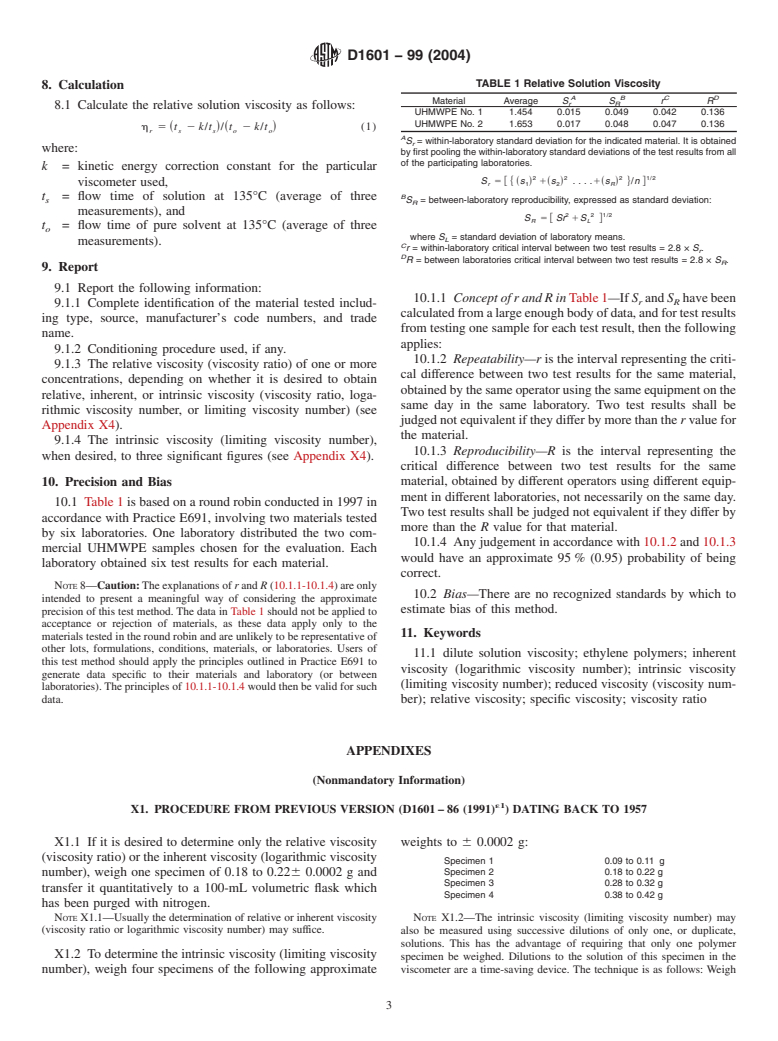

10.1.1 Concept of r and R inTable1—If S and S havebeen

r R

9.1.1 Complete identification of the material tested includ-

calculatedfromalargeenoughbodyofdata,andfortestresults

ing type, source, manufacturer’s code numbers, and trade

from testing one sample for each test result, then the following

name.

applies:

9.1.2 Conditioning procedure used, if any.

10.1.2 Repeatability—r is the interval representing the criti-

9.1.3 The relative viscosity (viscosity ratio) of one or more

cal difference between two test results for the same material,

concentrations, depending on whether it is desired to obtain

obtainedbythesameoperatorusingthesameequipmentonthe

relative, inherent, or intrinsic viscosity (viscosity ratio, loga-

same day in the same laboratory. Two test results shall be

rithmic viscosity number, or limiting viscosity number) (see

judgednotequivalentiftheydifferbymorethanthe rvaluefor

Appendix X4).

the material.

9.1.4 The intrinsic viscosity (limiting viscosity number),

10.1.3 Reproducibility—R is the interval representing the

when desired, to three significant figures (see Appendix X4).

critical difference between two test results for the same

10. Precision and Bias material, obtained by different operators using different equip-

ment in different laboratories, not necessarily on the same day.

10.1 Table 1 is based on a round robin conducted in 1997 in

Two test results shall be judged not equivalent if they differ by

accordance with Practice E691, involving two materials tested

more than the R value for that material.

by six laboratories. One laboratory distributed the two com-

10.1.4 Any judgement in accordance with 10.1.2 and 10.1.3

mercial UHMWPE samples chosen for the evaluation. Each

would have an approximate 95 % (0.95) probability of being

laboratory obtained six test results for each material.

correct.

NOTE8—Caution:Theexplanationsof rand R(10.1.1-10.1.4)areonly

10.2 Bias—There are no recognized standards by which to

intended to present a meaningful way of considering the approximate

estimate bias of this method.

precision of this test method. The data in Table 1 should not be applied to

acceptance or rejection of materials, as these data apply only to the

11. Keywords

materials tested in the round robin and are unlikely to be representative of

other lots, formulations, conditions, materials, or laboratories. Users of

11.1 dilute solution viscosity; ethylene polymers; inherent

this test method should apply the principles outlined in Practice E691 to

viscosity (logarithmic viscosity number); intrinsic viscosity

generate data specific to their materials and laboratory (or between

(limiting viscosity number); reduced viscosity (viscosity num-

laboratories).The principles of 10.1.1-10.1.4 would then be valid for such

data. ber); relative viscosity; specific viscosity; viscosity ratio

APPENDIXES

(Nonmandatory Information)

´1

X1. PROCEDURE FROM PREVIOUS VERSION (D1601 – 86 (1991) ) DATING BACK TO 1957

X1.1 If it is desired to determine only the relative viscosity weights to 6 0.0002 g:

(viscosity ratio) or the inherent viscosity (logarithmic viscosity

Specimen 1 0.0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.