ASTM D1601-99

(Test Method)Standard Test Method for Dilute Solution Viscosity of Ethylene Polymers

Standard Test Method for Dilute Solution Viscosity of Ethylene Polymers

SCOPE

1.1 This test method covers the determination of the dilute solution viscosity of ethylene polymers at 135°C. It is applicable to a reasonably wide spectrum of ethylene polymers having densities from 0.910 to 0.970 g/cm . Directions are given for the determination of relative viscosity (viscosity ratio), inherent viscosity (logarithmic viscosity number), and intrinsic viscosity (limiting viscosity number).

1.2 The values as stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 1601 – 99

Standard Test Method for

1

Dilute Solution Viscosity of Ethylene Polymers

This standard is issued under the fixed designation D 1601; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

7

1. Scope * 2.2 ISO Standards:

ISO 1628-3 Plastics—Determination of Viscosity Number

1.1 This test method covers the determination of the dilute

and Limiting Viscosity Number—Part 3: Polyethylenes

solution viscosity of ethylene polymers at 135°C. It is appli-

and Polypropylenes

cable to a reasonably wide spectrum of ethylene polymers

2

having densities from 0.910 to 0.970 g/cm . Directions are

3. Terminology

given for the determination of relative viscosity (viscosity

3.1 Units, symbols, and abbreviations used in this test

ratio), inherent viscosity (logarithmic viscosity number), and

method are those recommended in IEEE/ASTM SI 10 and

intrinsic viscosity (limiting viscosity number) (see Appendix

Terminologies D 883 and D 1600 (see also Appendix X4).

X4).

1.2 The values as stated in SI units are to be regarded as the

4. Significance and Use

standard.

4.1 The knowledge of dilute solution viscosity serves as an

1.3 This standard does not purport to address all of the

additional tool in characterizing ethylene polymers. Viscosity

safety concerns, if any, associated with its use. It is the

data alone may be of limited value in predicting the processing

responsibility of the user of this standard to establish appro-

behavior of the polymer. However, when used in conjunction

priate safety and health practices and determine the applica-

with other flow and physical property values, the solution

bility of regulatory limitations prior to use.

viscosity of ethylene polymers may contribute to their charac-

NOTE 1—This test method is technically equivalent to ISO 1628-3.

terizations.

NOTE 2—Appendix X1-Appendix X3 contain material from the previ-

4.2 Satisfactory correlation between solution viscosity and

ous version of Test Method D 1601 and are included for information only.

certain other properties is possible from polymers of a single

manufacturing process. The solution viscosity test is not

2. Referenced Documents

sensitive to some molecular configurational patterns that may

2.1 ASTM Standards:

occur among polymers from different manufacturing pro-

D 86 Method for Distillation of Petroleum Products at

cesses. Hence, its correlation with other properties of polymers

2

Atmospheric Pressure

produced by different processes, by even one manufacturer,

D 445 Test Method for Kinematic Viscosity of Transparent

may be limited.

2

and Opaque Liquids

4.3 The viscosity of polymer solutions may be drastically

3

D 883 Terminology Relating to Plastics

affected by the presence of known or unknown additives in the

D 1600 Terminology for Abbreviated Terms Relating to

sample. The use of solution viscosity may be of questionable

3

Plastics

value where ethylene polymers are known or suspected to

D 4020 Specification for Ultra-High-Molecular Weight

contain colorants, carbon black, low molecular weight hydro-

4

Polyethylene Molding and Extrusion Materials

carbons, fillers, or other additives.

5

E 1 Specification for ASTM Thermometers

4.4 The measurement of dilute solution viscosity of ethyl-

IEEE/ASTM SI-10 Standard for Use of the International

ene polymers presents problems not ordinarily encountered in

6

System of Units (SI): The Modern Metric System

viscosimetry. Ethylene polymers are not soluble at room

temperature in any known solvent. Some of the higher density

materials are insoluble below 100°C. Extreme care must be

1

This test method is under the jurisdiction of ASTM Committee D-20 on Plastics

exercised in transferring the solution to the viscometer for the

and is the direct responsibility of Subcommittee D20.70 on Analytical Methods

test if the correct solution concentration is to be maintained.

(Section D20.70.05).

This test has no significance unless the sample is completely

Current edition approved Sept. 10, 1999. Published January 2000. Originally

e1

soluble.

published as D 1601 – 58. Last previous edition D 1601 – 86 (1991) .

2

Annual Book of ASTM Standards, Vol 05.01.

3

Annual Book of ASTM Standards, Vol 08.01.

4

Annual Book of ASTM Standards, Vol 08.03.

5 7

Annual Book of ASTM Standards, Vol 14.03. Available from American National Standards Institute, 11 W. 42nd St., 13th

6

Annual Book of ASTM Standards, Vol 14.04. Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United S

...

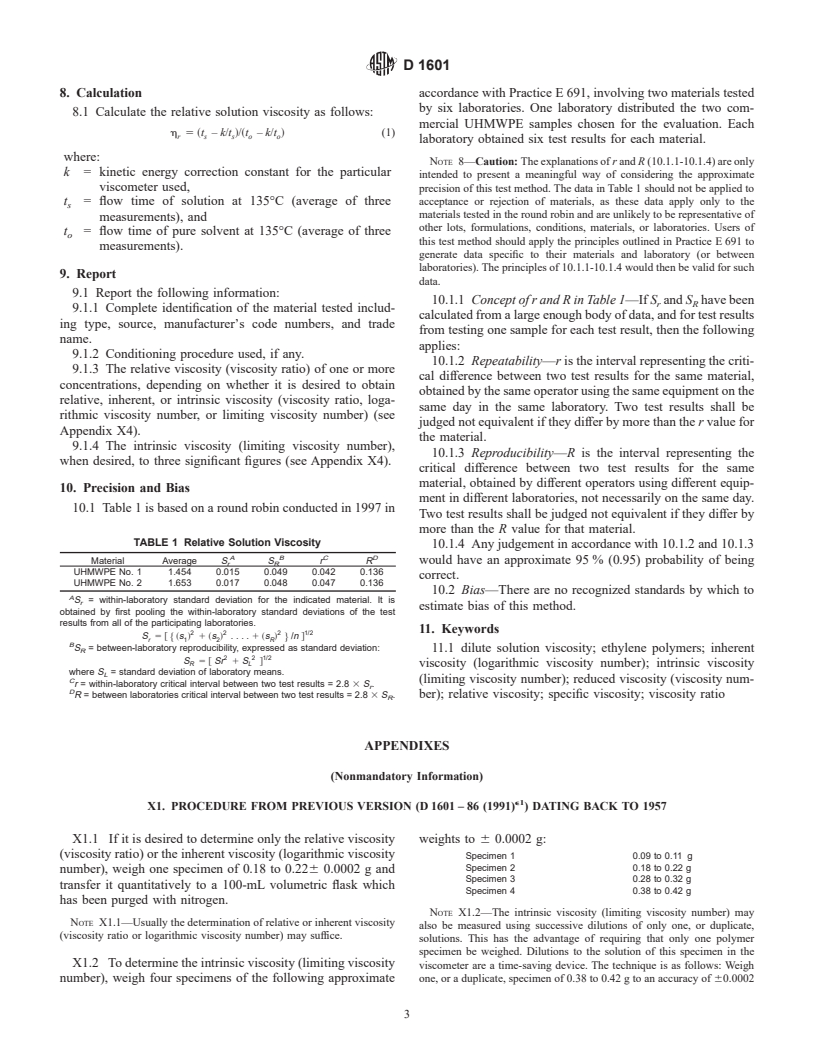

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.