ASTM D3997-97(2004)

(Practice)Standard Practice for Preparing Coke Samples for Microscopical Analysis by Reflected Light

Standard Practice for Preparing Coke Samples for Microscopical Analysis by Reflected Light

SIGNIFICANCE AND USE

Briquettes of granular coke prepared in accordance with the laboratory procedures of this practice will have flat, scratch-free surfaces suitable for examination with a microscope using reflected light illumination. The polished surface of briquettes prepared using this practice will contain particles representative of the original gross sample.

Samples prepared by this practice are used for microscopical determination of the textural components in coke (see Test Method D 5061).

SCOPE

1.1 This practice covers laboratory procedures for the preparation of granular samples of coke for examination with a reflected light microscope. The samples prepared are used for identifying and quantifying the textural components in coke. This practice does not apply to the preparation of oriented lump specimens of coke for structural analysis.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D3997 – 97 (Reapproved 2004)

Standard Practice for

Preparing Coke Samples for Microscopical Analysis by

Reflected Light

This standard is issued under the fixed designation D3997; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Practice

1.1 This practice covers laboratory procedures for the 4.1 Arepresentativesampleiscrushedtoaspecifiedparticle

preparation of granular samples of coke for examination with size, oven-dried, mixed with a binder, and formed into a block

areflectedlightmicroscope.Thesamplespreparedareusedfor specimen referred to as a briquette. The briquette is then

identifying and quantifying the textural components in coke. polished to a flat, scratch-free surface for microscopical ex-

Thispracticedoesnotapplytothepreparationoforientedlump amination under reflected light.

specimens of coke for structural analysis.

5. Significance and Use

1.2 The values stated in SI units are to be regarded as the

5.1 Briquettesofgranularcokepreparedinaccordancewith

standard. The values given in parentheses are for information

only. the laboratory procedures of this practice will have flat,

scratch-free surfaces suitable for examination with a micro-

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the scope using reflected light illumination. The polished surface

of briquettes prepared using this practice will contain particles

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- representative of the original gross sample.

5.2 Samples prepared by this practice are used for micro-

bility of regulatory limitations prior to use.

scopical determination of the textural components in coke (see

2. Referenced Documents

Test Method D5061).

2.1 ASTM Standards:

6. Apparatus

D121 Terminology of Coal and Coke

D346 Practice for Collection and Preparation of Coke 6.1 Grinder, Pulverizer, Mill, or Jaw Crusher, or other

suitable equipment for final crushing of the sample to pass a

Samples for Laboratory Analysis

D5061 TestMethodforMicroscopicalDeterminationofthe 2.36-mm (No. 8) sieve.

6.2 Coarse Riffle Sampler, with at least twelve divisions of

Textural Components of Metallurgical Coke

1 3

E11 SpecificationforWovenWireTestSieveClothandTest notlessthan12.7mm( ⁄2in.)andnotgreaterthan19.1mm( ⁄4

in.).

Sieves

6.3 Medium Riffle Sampler, with at least twelve divisions of

3. Terminology

1 1

not less than 6.4 mm ( ⁄4 in.) and not greater than 12.7 mm ( ⁄2

3.1 Definitions—For additional definitions of terms used in in.).

this practice, refer to Terminology D121. 6.4 Sieves—A6.4-mm ( ⁄4-in.) and 2.36-mm (No. 8) U.S.A.

3.1.1 briquette, n—a cylindrical block composed of granu- Standard Sieve (see Specification E11).

lated coal or coke particles compressed and embedded with an 6.5 Molds—Containers to hold the coke/binder mixture

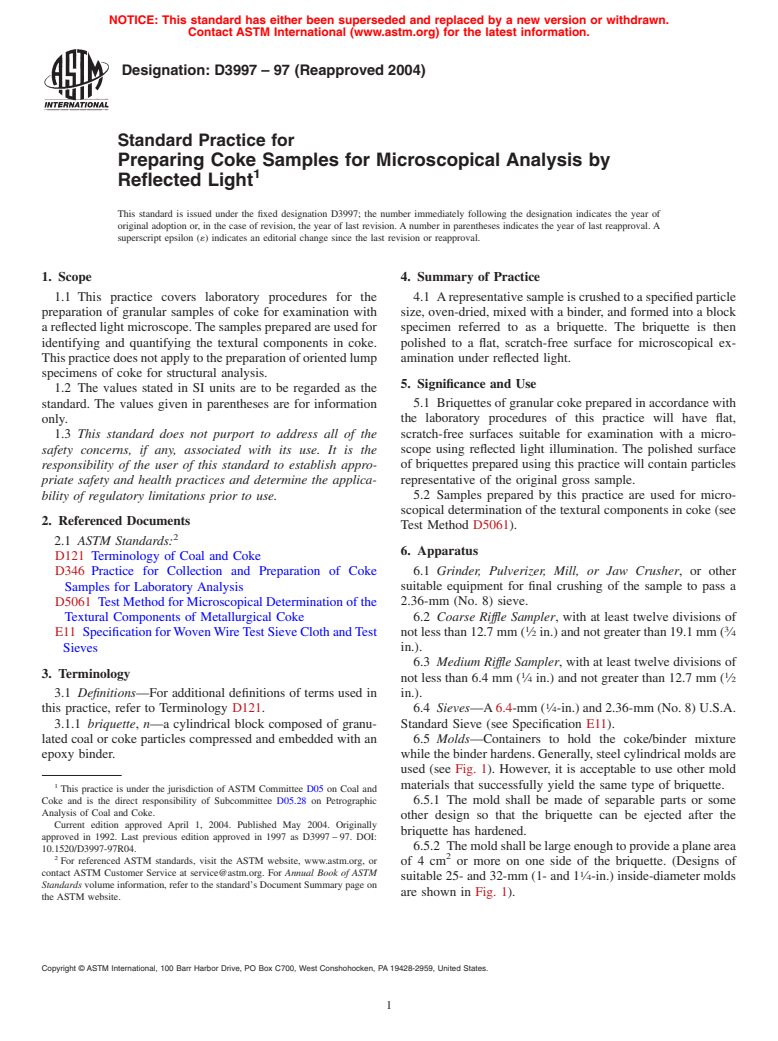

epoxy binder. whilethebinderhardens.Generally,steelcylindricalmoldsare

used (see Fig. 1). However, it is acceptable to use other mold

materials that successfully yield the same type of briquette.

This practice is under the jurisdiction of ASTM Committee D05 on Coal and

Coke and is the direct responsibility of Subcommittee D05.28 on Petrographic 6.5.1 The mold shall be made of separable parts or some

Analysis of Coal and Coke.

other design so that the briquette can be ejected after the

Current edition approved April 1, 2004. Published May 2004. Originally

briquette has hardened.

approved in 1992. Last previous edition approved in 1997 as D3997–97. DOI:

6.5.2 Themoldshallbelargeenoughtoprovideaplanearea

10.1520/D3997-97R04.

2 2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

of4cm or more on one side of the briquette. (Designs of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

suitable 25- and 32-mm (1- and 1 ⁄4-in.) inside-diameter molds

Standards volume information, refer to the standard’s Document Summary page on

are shown in Fig. 1).

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3997 – 97 (2004)

7.1.4 The binder shall be such that a substantially flat and

scratch-free surface can be obtained as a result of the grinding

and polishing procedure.

NOTE 2—Relief, or difference in level, particularly between the coke

andthebinder,isundesirableformicroscopicobservation.Reliefdepends

a great deal on the polishing technique.

7.2 Release Agent—Any preparation that does not damage

the molds or adversely affect the coke or mounting medium

may be used to coat the inside of the mold and facilitate

ejection of the briquette.

7.3 Grinding Abrasives—Water-resistant, adhesive-backed

silicon carbide papers of grit Nos. 120, 240, 400, and 600.The

grinding and polishing sequences recommended are listed in

Table 1.

NOTE 3—It is acceptable to use commercially available diamond

impregnated wheels as substitutes particularly for the coarse grinding

abrasive papers if the same polish quality requirements are met as

specified in Section 10.

7.4 Polishing Abrasives—Aluminum oxide slurries in 0.3-

and 0.05-µm sizes. The grinding and polishing sequences

recommended are listed in Table 1.

NOTE 4—It is acceptable to use commercially available colloidal silica

asasubstituteforaluminumoxideifthesamepolishqualityrequirements

NOTE 1—Material: cold rolled or stainless steel. Dimensions a and b

are met as specified in Section 10.

(inside diameters) are nominally 32 and 25 mm. If an automatic polishing

attachment is to be used, these dimensions should be specified to yield a

7.5 Lap Coverings—Nap-free cloths or chemotextile mate-

briquette fitting snugly in the briquette holder.

rial backed with water-resistant adhesive.

FIG. 1 Molds Suitable for Briquetting Coke Samples

7.6 Detergent—Any nonoxidizing detergent may be used

for cleaning briquettes after each grinding or polishing stage.

6.6 Hydraulic Press, capable of producing a pressure up to

28 MPa (4000 psi) on the briquette with an attachment to eject

8. Sampling

the briquette after hardening of the binder.

6.7 Grinding and Polishing Equipment, having one or 8.1 Obtain gross samples of coke in accordance

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.