ASTM E1171-15(2019)

(Test Method)Standard Test Methods for Photovoltaic Modules in Cyclic Temperature and Humidity Environments

Standard Test Methods for Photovoltaic Modules in Cyclic Temperature and Humidity Environments

SIGNIFICANCE AND USE

4.1 The useful life of photovoltaic modules may depend on their ability to withstand repeated temperature cycling with varying amounts of moisture in the air. These test methods provide procedures for simulating the effects of cyclic temperature and humidity environments. An extended duration damp heat procedure is provided to simulate the effects of long term exposure to high humidity.

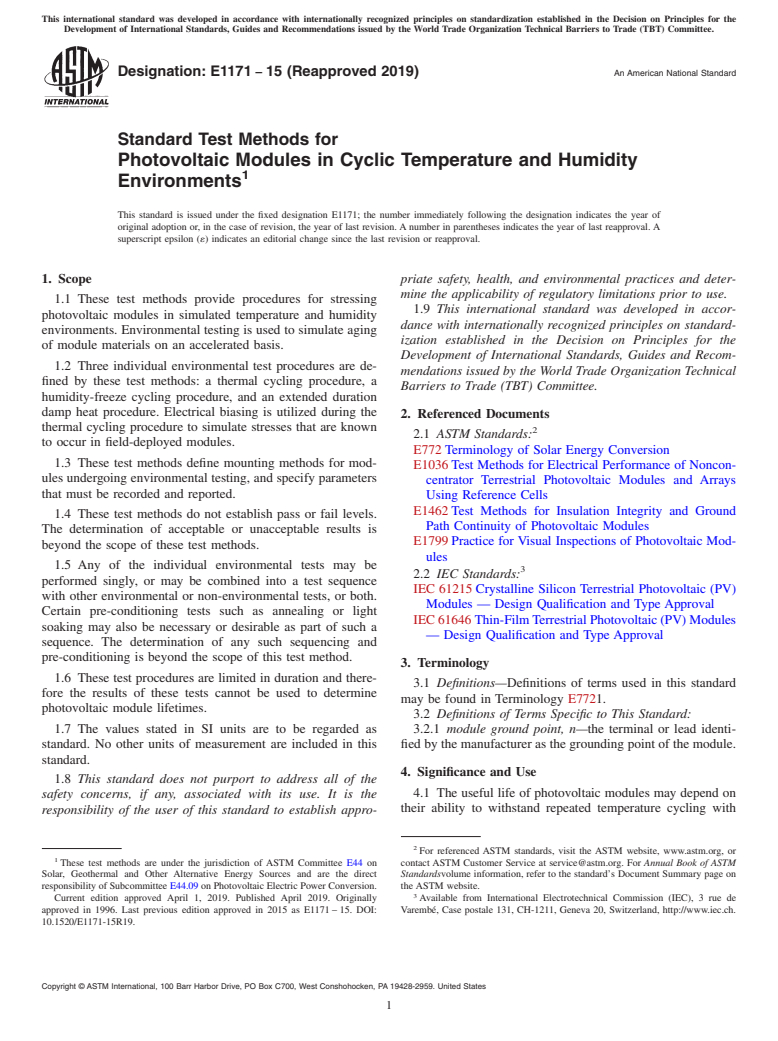

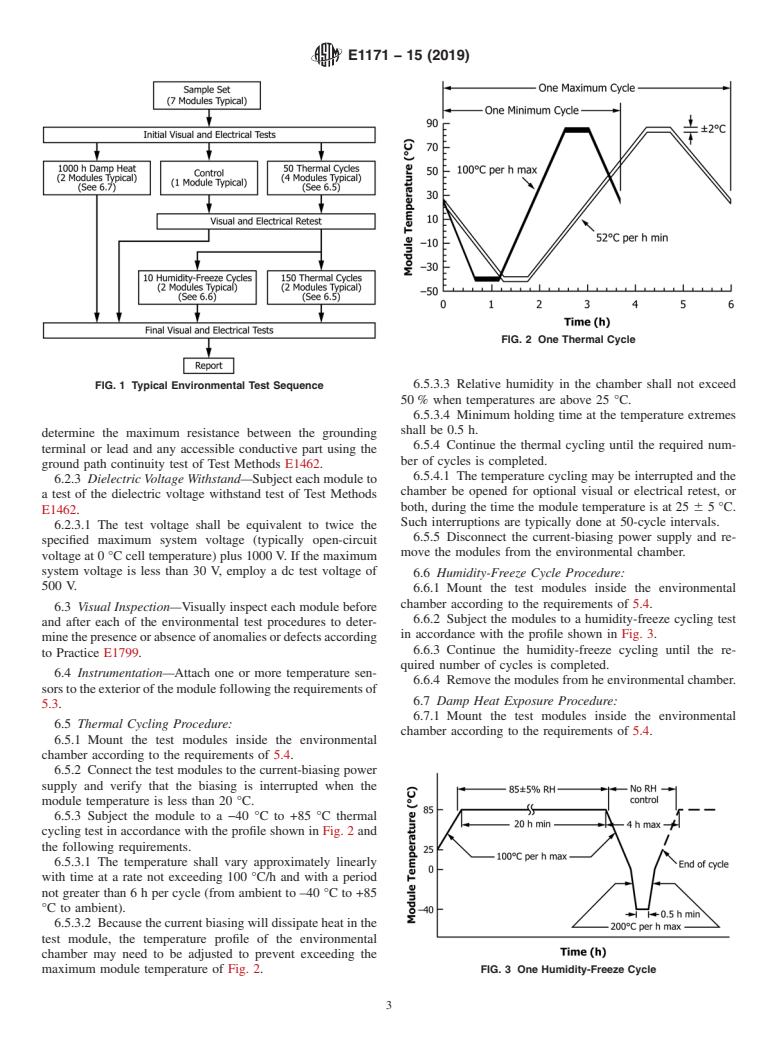

4.2 The durations of the individual environmental tests are specified by use of this test method; however, commonly used durations are 50 and 200 thermal cycles, 10 humidity-freeze cycles, and 1000 h of damp heat exposure, as specified by module qualification standards such as IEC 61215 and IEC 61646. Longer durations can also be specified for extended duration module stress testing.

4.3 Mounting—Test modules are mounted so that they are electrically isolated from each other, and in such a manner to allow free air circulation around the front and back surfaces of the modules.

4.4 Current Biasing:

4.4.1 During the thermal cycling procedure, test modules are operated without illumination and with a forward-bias current equal to the maximum power point current at standard reporting conditions (SRC, see Test Methods E1036) flowing through the module circuitry.

4.4.2 The current biasing is intended to stress the module interconnections and solder bonds in ways similar to those that are believed to be responsible for fill-factor degradation in field-deployed modules.

4.5 Effects of Test Procedures—Data generated using these test methods may be used to evaluate and compare the effects of simulated environment on test specimens. These test methods require determination of both visible effects and electrical performance effects.

4.5.1 Effects on modules may vary from none to significant changes. Some physical changes in the module may be visible when there are no apparent electrical changes in the module. Similarly, electrical changes may occur with no visible changes in...

SCOPE

1.1 These test methods provide procedures for stressing photovoltaic modules in simulated temperature and humidity environments. Environmental testing is used to simulate aging of module materials on an accelerated basis.

1.2 Three individual environmental test procedures are defined by these test methods: a thermal cycling procedure, a humidity-freeze cycling procedure, and an extended duration damp heat procedure. Electrical biasing is utilized during the thermal cycling procedure to simulate stresses that are known to occur in field-deployed modules.

1.3 These test methods define mounting methods for modules undergoing environmental testing, and specify parameters that must be recorded and reported.

1.4 These test methods do not establish pass or fail levels. The determination of acceptable or unacceptable results is beyond the scope of these test methods.

1.5 Any of the individual environmental tests may be performed singly, or may be combined into a test sequence with other environmental or non-environmental tests, or both. Certain pre-conditioning tests such as annealing or light soaking may also be necessary or desirable as part of such a sequence. The determination of any such sequencing and pre-conditioning is beyond the scope of this test method.

1.6 These test procedures are limited in duration and therefore the results of these tests cannot be used to determine photovoltaic module lifetimes.

1.7 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internati...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E1171 − 15 (Reapproved 2019) An American National Standard

Standard Test Methods for

Photovoltaic Modules in Cyclic Temperature and Humidity

Environments

This standard is issued under the fixed designation E1171; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

1.1 These test methods provide procedures for stressing

1.9 This international standard was developed in accor-

photovoltaic modules in simulated temperature and humidity

dance with internationally recognized principles on standard-

environments. Environmental testing is used to simulate aging

ization established in the Decision on Principles for the

of module materials on an accelerated basis.

Development of International Standards, Guides and Recom-

1.2 Three individual environmental test procedures are de-

mendations issued by the World Trade Organization Technical

fined by these test methods: a thermal cycling procedure, a

Barriers to Trade (TBT) Committee.

humidity-freeze cycling procedure, and an extended duration

damp heat procedure. Electrical biasing is utilized during the

2. Referenced Documents

thermal cycling procedure to simulate stresses that are known

2.1 ASTM Standards:

to occur in field-deployed modules.

E772Terminology of Solar Energy Conversion

1.3 These test methods define mounting methods for mod-

E1036Test Methods for Electrical Performance of Noncon-

ules undergoing environmental testing, and specify parameters

centrator Terrestrial Photovoltaic Modules and Arrays

that must be recorded and reported.

Using Reference Cells

E1462Test Methods for Insulation Integrity and Ground

1.4 These test methods do not establish pass or fail levels.

Path Continuity of Photovoltaic Modules

The determination of acceptable or unacceptable results is

E1799Practice for Visual Inspections of Photovoltaic Mod-

beyond the scope of these test methods.

ules

1.5 Any of the individual environmental tests may be

2.2 IEC Standards:

performed singly, or may be combined into a test sequence

IEC 61215Crystalline Silicon Terrestrial Photovoltaic (PV)

with other environmental or non-environmental tests, or both.

Modules — Design Qualification and Type Approval

Certain pre-conditioning tests such as annealing or light

IEC61646Thin-FilmTerrestrialPhotovoltaic(PV)Modules

soaking may also be necessary or desirable as part of such a

— Design Qualification and Type Approval

sequence. The determination of any such sequencing and

pre-conditioning is beyond the scope of this test method.

3. Terminology

1.6 These test procedures are limited in duration and there-

3.1 Definitions—Definitions of terms used in this standard

fore the results of these tests cannot be used to determine

may be found in Terminology E7721.

photovoltaic module lifetimes.

3.2 Definitions of Terms Specific to This Standard:

1.7 The values stated in SI units are to be regarded as 3.2.1 module ground point, n—the terminal or lead identi-

standard. No other units of measurement are included in this fied by the manufacturer as the grounding point of the module.

standard.

4. Significance and Use

1.8 This standard does not purport to address all of the

4.1 The useful life of photovoltaic modules may depend on

safety concerns, if any, associated with its use. It is the

their ability to withstand repeated temperature cycling with

responsibility of the user of this standard to establish appro-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

These test methods are under the jurisdiction of ASTM Committee E44 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Solar, Geothermal and Other Alternative Energy Sources and are the direct Standardsvolume information, refer to the standard’s Document Summary page on

responsibility of Subcommittee E44.09 on Photovoltaic Electric Power Conversion. the ASTM website.

Current edition approved April 1, 2019. Published April 2019. Originally Available from International Electrotechnical Commission (IEC), 3 rue de

approved in 1996. Last previous edition approved in 2015 as E1171–15. DOI: Varembé, Case postale 131, CH-1211, Geneva 20, Switzerland, http://www.iec.ch.

10.1520/E1171-15R19.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1171 − 15 (2019)

varying amounts of moisture in the air. These test methods 5.2.3 Provisions for monitoring and recording the chamber

provide procedures for simulating the effects of cyclic tem- temperature and relative humidity throughout the environmen-

perature and humidity environments. An extended duration tal testing shall be provided.

dampheatprocedureisprovidedtosimulatetheeffectsoflong

5.3 Temperature Measurement Equipment—An instrument

term exposure to high humidity.

or instruments used to measure module temperature during the

4.2 The durations of the individual environmental tests are environmental testing with a resolution of at least 0.1 °C, and

specified by use of this test method; however, commonly used a total error of less than 62 °C of reading.

durations are 50 and 200 thermal cycles, 10 humidity-freeze 5.3.1 Temperature sensors suitable for the test temperature

cycles, and 1000 h of damp heat exposure, as specified by range, such as thermocouples or thermistors, shall be attached

module qualification standards such as IEC 61215 and IEC to the portions of the modules likely to exhibit the longest

61646. Longer durations can also be specified for extended thermal time constant. For flat-plate modules, attach the

duration module stress testing.

sensors near the middle of the front or back surfaces of the

modules.

4.3 Mounting—Test modules are mounted so that they are

5.3.2 If more than one module of identical design and

electrically isolated from each other, and in such a manner to

construction is tested simultaneously, it is not necessary to

allow free air circulation around the front and back surfaces of

monitor the temperature of all identical modules.

the modules.

5.4 Test Frame—Aframeinsidetheenvironmentalchamber

4.4 Current Biasing:

which supports the test modules during the test procedures.

4.4.1 During the thermal cycling procedure, test modules

5.4.1 Itisnotrequiredtomountthetestmodulesatanangle

are operated without illumination and with a forward-bias

such as when modules are installed as part of an array; they

current equal to the maximum power point current at standard

may be mounted vertically to facilitate testing multiple mod-

reporting conditions (SRC, see Test Methods E1036) flowing

ules inside the environmental chamber.

through the module circuitry.

5.4.2 The test modules shall be mounted in a manner that

4.4.2 The current biasing is intended to stress the module

allows free air circulation around the modules.

interconnectionsandsolderbondsinwayssimilartothosethat

5.4.3 The test frame should be constructed such that corro-

are believed to be responsible for fill-factor degradation in

sionofthetestframeduringtheenvironmentaltestingdoesnot

field-deployed modules.

adversely affect the test modules.

4.5 Effects of Test Procedures—Data generated using these

5.5 Current-Biasing Power Supply—A dc power supply

test methods may be used to evaluate and compare the effects

capable of operating a test module at a point on the dark

of simulated environment on test specimens. These test meth-

forward current-voltage curve equal to the maximum power

ods require determination of both visible effects and electrical

current at SRC during the thermal cycling procedure.

performance effects.

5.5.1 Provisionsmustbemadeforremovingthecurrentbias

4.5.1 Effects on modules may vary from none to significant

when the module temperature is less than 20 °C.

changes. Some physical changes in the module may be visible

5.5.2 Thecurrentbiasingpowersupplyshouldbecapableof

when there are no apparent electrical changes in the module.

setting a voltage compliance limit equal to 1.25 times the

Similarl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.