ASTM C752-03

(Specification)Standard Specification for Nuclear-Grade Silver-Indium-Cadmium Alloy

Standard Specification for Nuclear-Grade Silver-Indium-Cadmium Alloy

ABSTRACT

This specification covers silver-indium-cadmium alloy for use as a control material in light-water nuclear reactors. The use of this material in applications is excluded where material strength of this alloy is a prime requisite. Also, this material must be protected from the primary water by a corrosion and wear resistant cladding. The identity of each lot by melt number shall be maintained at all stages of manufacture. Parts produced to this specification shall be made from billets by hot working and cold finishing to size. The cold-finished parts shall be produced to the finish condition and dimensions as specified. The surface of the cold-finished part shall be free of oxides, grease, oil, residual lubricants, inclusions, and other extraneous materials. Surface defects such as folds, cracks, seams, slivers, and blisters shall be cause for rejection.

SCOPE

1.1 This specification covers silver-indium-cadmium alloy for use as a control material in light-water nuclear reactors.

1.2 The scope of this specification excludes the use of this material in applications where material strength of this alloy is a prime requisite. Also, this material must be protected from the primary water by a corrosion and wear resistant cladding.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C752 – 03

Standard Specification for

1

Nuclear-Grade Silver-Indium-Cadmium Alloy

This standard is issued under the fixed designation C752; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.3 A lot shall be defined as all parts produced from the

same melt by the same process.

1.1 This specification covers silver-indium-cadmium alloy

for use as a control material in light-water nuclear reactors.

4. Ordering Information

1.2 The scope of this specification excludes the use of this

4.1 Thebuyershallspecifythefollowinginformationonthe

material in applications where material strength of this alloy is

order:

a prime requisite. Also, this material must be protected from

4.1.1 Quantity,

the primary water by a corrosion and wear resistant cladding.

4.1.2 Lot size, and

2. Referenced Documents 4.1.3 Dimensions and tolerances.

2

2.1 ASTM Standards:

5. Materials and Manufacture

C760 Test Methods for Chemical and Spectrochemical

5.1 The identity of each lot by melt number shall be

Analysis of Nuclear-Grade Silver-Indium-Cadmium Al-

maintained at all stages of manufacture.

loys

5.2 Parts produced to this specification shall be made from

C859 Terminology Relating to Nuclear Materials

billets by hot working and cold finishing to size.

E105 Practice for Probability Sampling Of Materials

5.3 The cold-finished parts shall be produced to the finish

2.2 ANSI Standard:

3

condition and dimensions as specified in the purchase order.

B46.1 Surface Roughness

ANSI/ASME NQA-1 Quality Assurance Program Require-

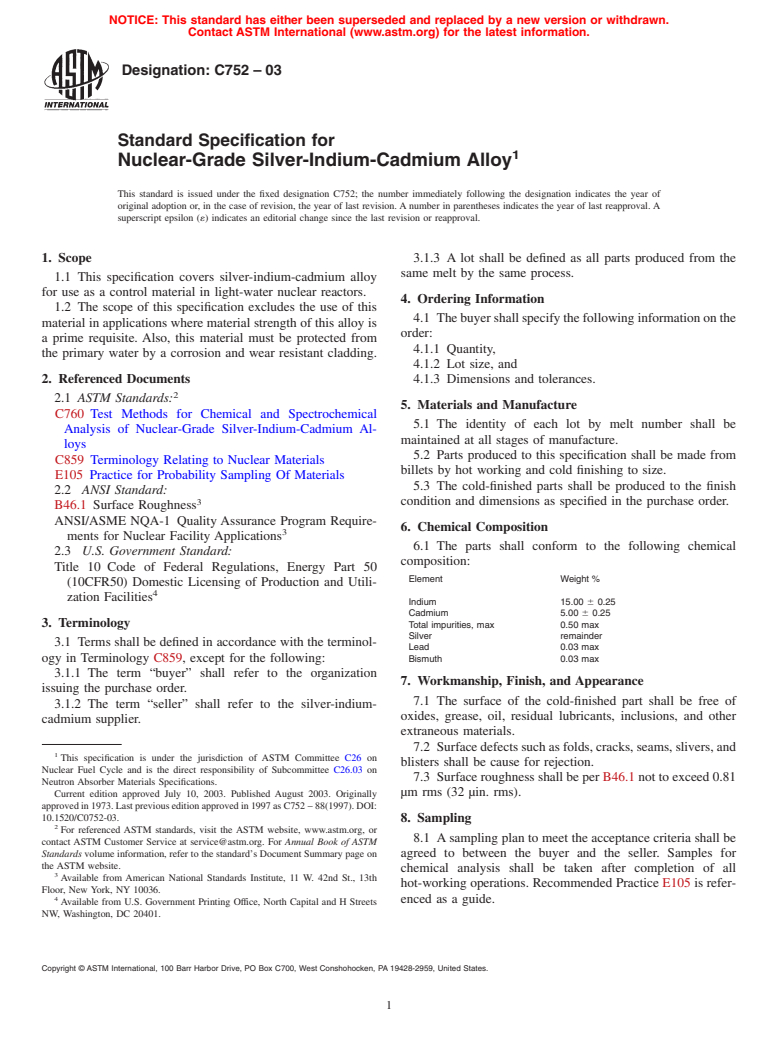

6. Chemical Composition

3

ments for Nuclear Facility Applications

6.1 The parts shall conform to the following chemical

2.3 U.S. Government Standard:

composition:

Title 10 Code of Federal Regulations, Energy Part 50

Element Weight %

(10CFR50) Domestic Licensing of Production and Utili-

4

zation Facilities

Indium 15.00 6 0.25

Cadmium 5.00 6 0.25

3. Terminology

Total impurities, max 0.50 max

Silver remainder

3.1 Terms shall be defined in accordance with the terminol-

Lead 0.03 max

ogy in Terminology C859, except for the following: Bismuth 0.03 max

3.1.1 The term “buyer” shall refer to the organization

7. Workmanship, Finish, and Appearance

issuing the purchase order.

7.1 The surface of the cold-finished part shall be free of

3.1.2 The term “seller” shall refer to the silver-indium-

oxides, grease, oil, residual lubricants, inclusions, and other

cadmium supplier.

extraneous materials.

7.2 Surface defects such as folds, cracks, seams, slivers, and

1

This specification is under the jurisdiction of ASTM Committee C26 on

blisters shall be cause for rejection.

Nuclear Fuel Cycle and is the direct responsibility of Subcommittee C26.03 on

7.3 Surface roughness shall be per B46.1 not to exceed 0.81

Neutron Absorber Materials Specifications.

µm rms (32 µin. rms).

Current edition approved July 10, 2003. Published August 2003. Originally

approvedin1973.Lastpreviouseditionapprovedin1997asC752 – 88(1997).DOI:

10.1520/C0752-03.

8. Sampling

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

8.1 Asampling plan to meet the acceptance criteria shall be

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on agreed to between the buyer and the seller. Samples for

the ASTM website.

chemical analysis shall be taken after completion of all

3

Available from American National Standards Institute, 11 W. 42nd St., 13th

hot-working operations. Recommended Practice E105 is refer-

Floor, New York, NY 10036.

4

enced as a guide.

Available from U.S. Government Printing Office, North Capital and H Streets

NW, Washington, DC 20401.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C752 – 03

8.2 The sample shall be sufficient to perform quality control 60 calendar days. Rejected material may be returned to the

tests, acceptance tests and referee tests, as necessary. seller at the seller’s expense, unless the buyer receives, within

8.2.1 Quality control tests, 3 weeks of notice of rejection, other instructions for disposi-

8.2.2 Acceptance tests, and tion.

8.2.3 Referee tests.

12. Packaging and Package Marking

9. Methods of Chemical Analysis

12.1 Each part shall be individually wrapped or bagged and

9.1 Use analytical chemistry methods in accordance with packed in suitable containers to prevent damage and contami-

Test Method C760 or demonstrated equivalent methods agreed nation during shipment and storage

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.