ASTM F641-09

(Specification)Standard Specification for Implantable Epoxy Electronic Encapsulants

Standard Specification for Implantable Epoxy Electronic Encapsulants

ABSTRACT

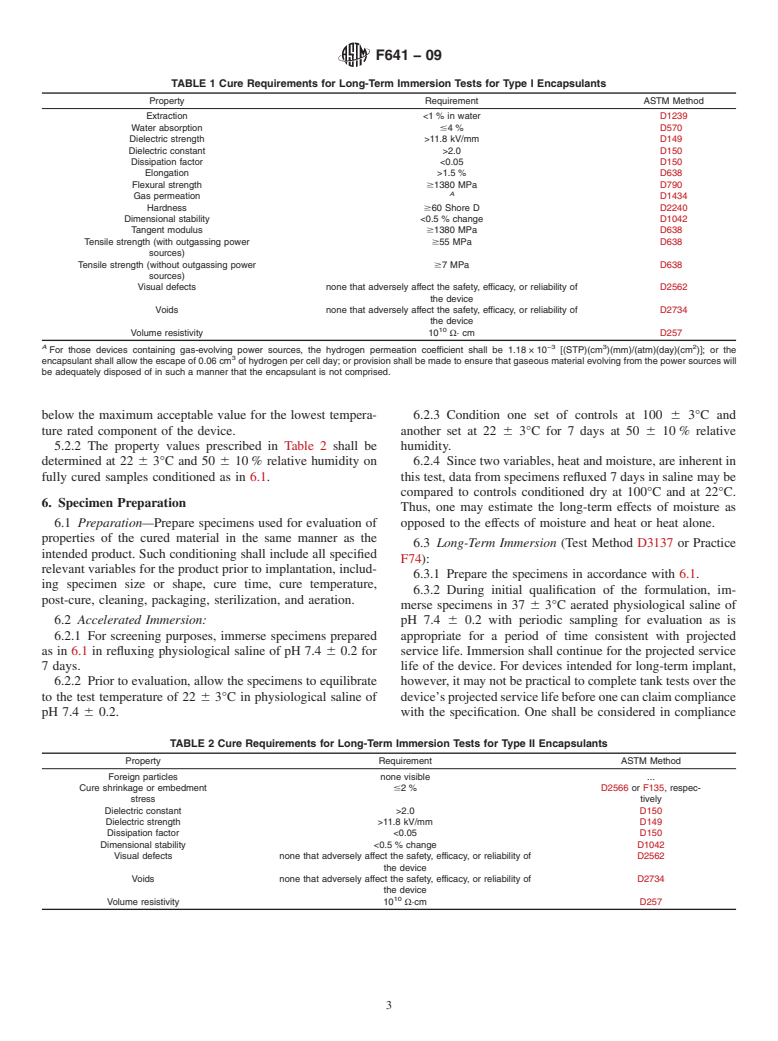

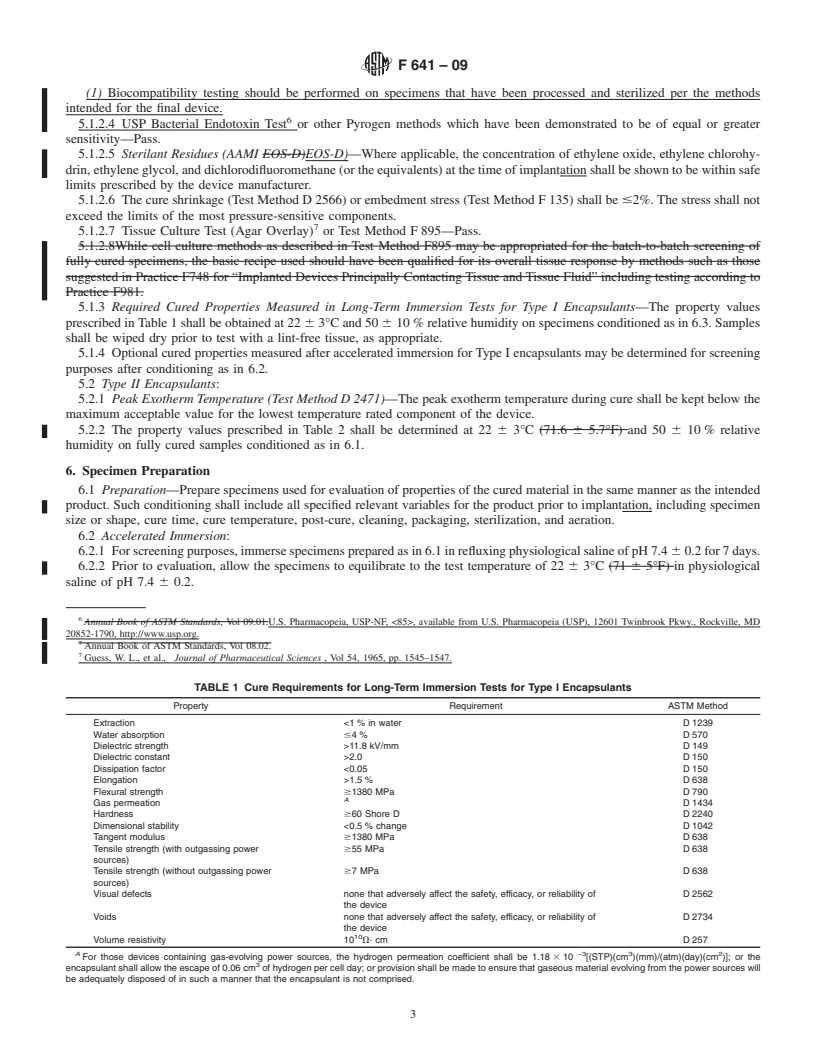

This specification covers thermoset plastics based on diglycidyl ethers of bisphenol A and amino functional curing agents or amine catalysts for implantable epoxy electronic encapsulants. Encapsulants shall be classified depending on contact with tissues or physiological fluids. Chemical composition requirements may include additives, phthalate esters, amines, catalysts, and carbonates. The material shall be tested for the following physical properties: peak exotherm temperature, transparency, foreign particles, USP biological test plastic containers, USP pyrogen test, sterilant residues, cure shrinkage, embedment stress, tissue culture test, long-term immersion test, and accelerated immersion test. The material shall also be inspected with infrared spectroscopy, amine number, epoxide equivalent weight, spectrographic analysis, and total nitrogen.

SCOPE

1.1 This specification covers thermoset plastics based on diglycidyl ethers of bisphenol A and amino functional curing agents or amine catalysts.

1.2 The epoxy encapsulants covered by this specification are intended to provide a tissue-compatible protective covering for implantable medical devices such as pulse generators, telemetry devices and RF receivers. The biocompatibility of epoxy plastics has not been established. Epoxy plastic is a generic term relating to the class of polymers formed from epoxy resins, certain curing agents or catalysts and various additives. Since many compositions and formulations fall under this category, it is essential that the fabricator assure safety of implantability of the specific composition or formulation for the intended use by current state-of-the-art test methods. This specification can be used as a basis for standardized evaluation of biocompatibility for such implantable encapsulants.

1.3 The encapsulants covered by this specification are for use in devices intended as long-term implants.

1.4 Limitations—This specification covers only the initial qualification of epoxy encapsulants for implantable electronic circuitry. Some of the requirements are not applicable to routine lot-to-lot quality control.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F641 −09

StandardSpecification for

1

Implantable Epoxy Electronic Encapsulants

ThisstandardisissuedunderthefixeddesignationF641;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This specification covers thermoset plastics based on 2.1 ASTM Standards:

diglycidyl ethers of bisphenol A and amino functional curing D149Test Method for Dielectric Breakdown Voltage and

agents or amine catalysts. DielectricStrengthofSolidElectricalInsulatingMaterials

at Commercial Power Frequencies

1.2 The epoxy encapsulants covered by this specification

D150Test Methods forAC Loss Characteristics and Permit-

areintendedtoprovideatissue-compatibleprotectivecovering

tivity (Dielectric Constant) of Solid Electrical Insulation

for implantable medical devices such as pulse generators,

D257Test Methods for DC Resistance or Conductance of

telemetry devices and RF receivers. The biocompatibility of

Insulating Materials

epoxy plastics has not been established. Epoxy plastic is a

D570Test Method for Water Absorption of Plastics

generic term relating to the class of polymers formed from

D638Test Method for Tensile Properties of Plastics

epoxy resins, certain curing agents or catalysts and various

D790Test Methods for Flexural Properties of Unreinforced

additives. Since many compositions and formulations fall

and Reinforced Plastics and Electrical Insulating Materi-

under this category, it is essential that the fabricator assure

als

safety of implantability of the specific composition or formu-

D1042Test Method for Linear Dimensional Changes of

lation for the intended use by current state-of-the-art test

Plastics Under Accelerated Service Conditions

methods. This specification can be used as a basis for stan-

D1239Test Method for Resistance of Plastic Films to

dardized evaluation of biocompatibility for such implantable

Extraction by Chemicals

encapsulants.

D1434TestMethodforDeterminingGasPermeabilityChar-

1.3 The encapsulants covered by this specification are for

acteristics of Plastic Film and Sheeting

use in devices intended as long-term implants.

D2240TestMethodforRubberProperty—DurometerHard-

1.4 Limitations—This specification covers only the initial ness

D2471PracticeforGelTimeandPeakExothermicTempera-

qualification of epoxy encapsulants for implantable electronic

3

circuitry. Some of the requirements are not applicable to tureofReactingThermosettingResins(Withdrawn2008)

D2562Practice for Classifying Visual Defects in Parts

routine lot-to-lot quality control.

Molded from Reinforced Thermosetting Plastics

1.5 The values stated in SI units are to be regarded as

D2566Test Method for Linear Shrinkage of CuredThermo-

standard. No other units of measurement are included in this

3

setting Casting Resins During Cure (Withdrawn 1993)

standard.

D2734TestMethodsforVoidContentofReinforcedPlastics

1.6 This standard does not purport to address all of the

D3137Test Method for Rubber Property—Hydrolytic Sta-

safety concerns, if any, associated with its use. It is the

bility

responsibility of the user of this standard to establish appro-

F74Practice for Determining Hydrolytic Stability of Plastic

priate safety and health practices and determine the applica- 3

Encapsulants for Electronic Devices (Withdrawn 1994)

bility of regulatory limitations prior to use.

1 2

This specification is under the jurisdiction of ASTM Committee F04 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Medical and Surgical Materials and Devices and is the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee F04.11 on Polymeric Materials. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Aug. 1, 2009. Published September 2009. Originally the ASTM website.

3

approved in 1979. Last previous edition approved in 2003 as F641–98a(2003). The last approved version of this historical standard is referenced on

DOI: 10.1520/F0641-09. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F641−09

F135TestMethodforEmbedmentStressCausedbyCasting 5. Physical Properties

Compounds on Glass-Encased Electronic (Withdrawn

5.1 Type I Encapsulants:

3

1997)

5.1.1 Peak Exotherm Temperature (Test Method D2471)—

F602Criteria for Implantable Thermoset Epoxy Plastics

The peak exotherm temperature during cure shall be kept

F748PracticeforSelectingGenericBiologicalTestMethods

below the maximum acceptable value for the lowes

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F641–98a (Reapproved 2003) Designation: F 641 – 09

Standard Specification for

1

Implantable Epoxy Electronic Encapsulants

This standard is issued under the fixed designation F 641; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers thermoset plastics based on diglycidyl ethers of bisphenol A and amino functional curing agents

or amine catalysts.

1.2 The epoxy encapsulants covered by this specification are intended to provide a tissue-compatible protective covering for

implantable medical devices such as pulse generators, telemetry devices and RF receivers. The biocompatibility of epoxy plastics

has not been established. Epoxy plastic is a generic term relating to the class of polymers formed from epoxy resins, certain curing

agents or catalysts and various additives. Since many compositions and formulations fall under this category, it is essential that

the fabricator assure safety of implantability of the specific composition or formulation for the intended use by current

state-of-the-art test methods. This specification can be used as a basis for standardized evaluation of biocompatibility for such

implantable encapsulants.

1.3 The encapsulants covered by this specification are for use in devices intended as long-term implants.

1.4 Limitations— This specification covers only the initial qualification of epoxy encapsulants for implantable electronic

circuitry. Some of the requirements are not applicable to routine lot to lot quality control.

1.5—This specification covers only the initial qualification of epoxy encapsulants for implantable electronic circuitry. Some of

the requirements are not applicable to routine lot-to-lot quality control.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 149 Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at

Commercial Power Frequencies

D 150 Test Methods for acAC Loss Characteristics and Permittivity (Dielectric Constant) of Solid Electrical Insulating

2

Materials Insulation

D 257 Test Methods for dcDC Resistance or Conductance of Insulating Materials

D 570 Test Method for Water Absorption of Plastics

D 638 Test Method for Tensile Properties of Plastics

D 790 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

3

D883Terminology Relating to Plastics 1042

D1042 Test Method for Linear Dimensional Changes of Plastics Under Accelerated Service Conditions

D 1239 Test Method for Resistance of Plastic Films to Extraction by Chemicals

D 1434 Test Method for Determining Gas Permeability Characteristics of Plastic Film and Sheeting

3

D1763Specification for Epoxy Resins 2240

D1898Practice for Sampling of Plastics

D2240 Test Method for Rubber Property—Durometer Hardness

D 2471 Test Method Practice for Gel Time and Peak Exothermic Temperature of Reacting Thermosetting Resins

D 2562 Practice for Classifying Visual Defects in Parts Molded from Reinforced Thermosetting Plastics

1

This specification is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.11 on Polymeric Materials.

Current edition approved Apr. 10, 2003. Published May 2003. Originally approved in 1979. Last previous edition approved in 1998 as F641–98a.

Current edition approved Aug. 1, 2009. Published September 2009. Originally approved in 1979. Last previous edition approved in 2003 as F 641 – 98a(2003).

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 10.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

-----------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.