ASTM D3641-02

(Practice)Standard Practice for Injection Molding Test Specimens of Thermoplastic Molding and Extrusion Materials

Standard Practice for Injection Molding Test Specimens of Thermoplastic Molding and Extrusion Materials

SIGNIFICANCE AND USE

It is well known that plastic test specimens molded under different conditions can have significantly different properties. This practice is designed to minimize those differences by establishing operating protocols without being unnecessarily restrictive.

Always refer to the ASTM material specification or ISO designation for the material for recommended molding conditions. If not available, consult the material supplier.

This practice requires the use of adequate quantities of plastic material to find desirable operating conditions and to make the desired test specimens.

SCOPE

1.1 This practice covers the general principles to be followed when injection molding test specimens of thermoplastic molding and extrusion materials. This practice is to be used to obtain uniformity in methods of describing the various steps of the injection molding process and to set up uniform methods of reporting these conditions. The exact conditions required to prepare suitable specimens will vary for each plastic material. Those conditions should become a part of the specification for the material, or be agreed upon between the purchaser and the supplier. Any requirements or recommendations in the material specification which differ from this standard take precedence over those in this standard.

1.2 The methodology presented assumes the use of reciprocating screw injection molding machines.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—This practice is equivalent to the following parts of ISO 294: Plastics-Injection Moulding of Test Specimens of Thermoplastic Materials; 294-1: Part 1-General Principles and Multipurpose Test Specimens (ISO Type A Mould) and Bars (ISO Type B Mould); ISO 294-2: Part 2-Small Tensile Bars (ISO Type C Mould); ISO 294-3: Part 3-Plates (ISO Type D Moulds).

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3641–02

Standard Practice for

Injection Molding Test Specimens of Thermoplastic Molding

1

and Extrusion Materials

This standard is issued under the fixed designation D3641; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D256 Test Methods for Determining the Izod Pendulum

Impact Resistance of Plastics

1.1 This practice covers the general principles to be fol-

D570 Test Method for Water Absorption of Plastics

lowed when injection molding test specimens of thermoplastic

D638 Test Method for Tensile Properties of Plastics

molding and extrusion materials. This practice is to be used to

D648 Test Method for Deflection Temperature of Plastics

obtain uniformity in methods of describing the various steps of

Under Flexural Load in the Edgewise Position

theinjectionmoldingprocessandtosetupuniformmethodsof

D790 Test Methods for Flexural Properties of Unreinforced

reporting these conditions. The exact conditions required to

and Reinforced Plastics and Electrical Insulating Materials

prepare suitable specimens will vary for each plastic material.

D883 Terminology Relating to Plastics

Those conditions should become a part of the specification for

D955 Test Method of Measuring Shrinkage from Mold

the material, or be agreed upon between the purchaser and the

Dimensions of Thermoplastics

supplier.Any requirements or recommendations in the material

D957 Practice for Determining Surface Temperature of

specification which differ from this standard take precedence

Molds for Plastics

over those in this standard.

2.2 ISO Standards:

1.2 The methodology presented assumes the use of recipro-

ISO 3167 Plastics—Preparation and Use of Multipurpose

cating screw injection molding machines.

2

Test Specimens

1.3 The values stated in SI units are to be regarded as the

ISO294-1: Plastics—InjectionMouldingofTestSpecimens

standard. The values given in parentheses are for information

of Thermoplastic Materials—Part 1: General Principles

only.

and Multipurpose Test Specimens (ISO Type A Mould)

1.4 This standard does not purport to address all of the

2

and Bars (ISO Type B Mould)

safety concerns, if any, associated with its use. It is the

ISO294-2: Plastics—InjectionMouldingofTestSpecimens

responsibility of the user of this standard to establish appro-

of Thermoplastic Materials—Part 2: Small Tensile Bars

priate safety and health practices and determine the applica-

2

(ISO Type C Mould)

bility of regulatory limitations prior to use.

ISO294-3: Plastics—InjectionMouldingofTestSpecimens

NOTE 1—This practice is equivalent to the following parts of ISO 294:

of Thermoplastic Materials—Part 3: Plates (ISO Type D

Plastics—Injection Moulding of Test Specimens of Thermoplastic Mate-

2

Moulds)

2

rials ; 294-1: Part 1—General Principles and Multipurpose Test Speci-

2

mens (ISO Type A Mould) and Bars (ISO Type B Mould) ; ISO 294-2:

3. Terminology

Part 2—Small Tensile Bars (ISO Type C Mould); ISO 294-3: Part

3.1 Definitions—Definitions of terms applying to this prac-

3—Plates (ISO Type D Moulds).

tice appear in Terminology D883.

2. Referenced Documents

3.2 Definitions of Terms Specific to This Standard:

3

2.1 ASTM Standards: 3.2.1 average injection velocity, n—the mean value of the

velocity of the molten plastic flow front within a cavity during

the injection time that is calculated from the shot volume and

1 injection time. (See Terminology D883.)

ThispracticeisunderthejurisdictionofASTMCommitteeD20onPlasticsand

3.2.1.1 Discussion—The average injection velocity is cal-

is the direct responsibility of Subcommittee D20.09 on Specimen Preparation.

Current edition approved April 10, 2002. Published June 2002. Originally

culated as follows:

published as D3641 – 91. Last previous edition D3641 – 97. DOI: 10.1520/D3641-

V

02. s

V 5

2 av

Available from American National Standards Institute, 25 W. 43rd St., 4th T 3 A 3 n

i c

Floor, New York, NY 10036.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

where:

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

V = average injection velocity, mm/s,

av

Standards volume information, refer to the standard’s Document Summary page on 3

V = shot volume, mm ,

s

the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

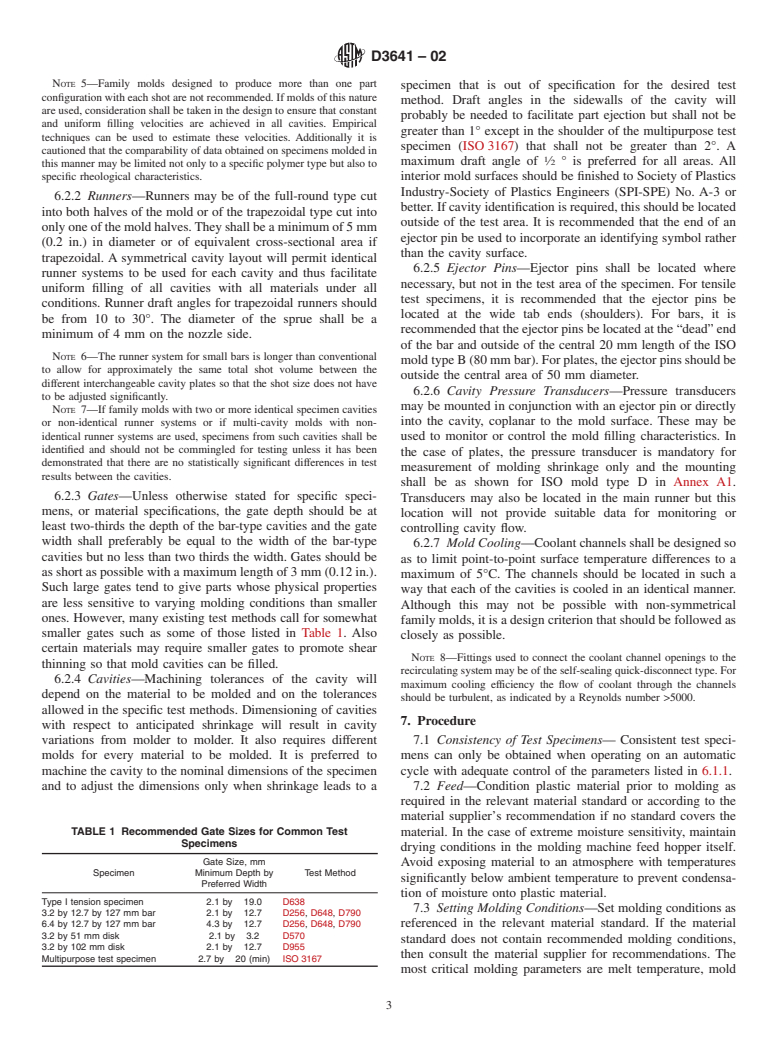

---------------------- Page: 1 ----------------------

D3641–02

and measurement of hydraulic pressure, all relevant tempera-

T = injection time, s,

i

2

tures, and the timing of certain cycle elemen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.