ASTM D788-16

(Classification)Standard Classification System for Poly(Methyl Methacrylate) (PMMA) Molding and Extrusion Compounds

Standard Classification System for Poly(Methyl Methacrylate) (PMMA) Molding and Extrusion Compounds

ABSTRACT

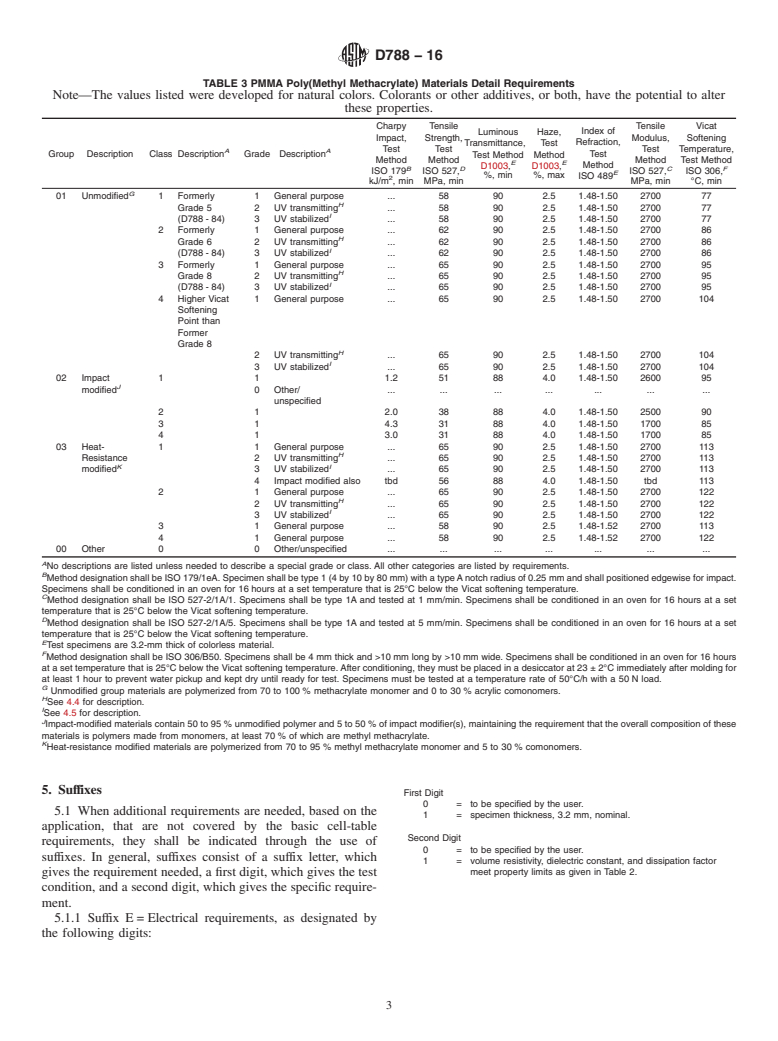

The purpose of this classification system is to provide a method of adequately identifying poly(methyl methacrylate) (PMMA) molding and extrusion compounds. These compounds are polymers based on methyl methacrylate, and at least 70 % of the polymer shall be polymerized from methyl methacrylate. Poly(methyl methacrylate) molding and extrusion compounds are classified into groups in accordance with their composition. These groups are subdivided into classes and grades: class 1, 2, 3, and 4; grade 1 - materials used where special ultraviolet transmission, filtering, or stabilization characteristics are not required, grade 2 - materials used for those specialized applications in which the greatest amount of transmission of UV light is required, and grade 3 - materials (transparent UV stabilized or transparent UV absorbing) used when either special resistance to slight color change over long exposure times or high-intensity UV radiation is required, or when the material is required to filter out ultraviolet light. The plastics composition shall be uniform and shall conform to the requirements specified.

SCOPE

1.1 The purpose of this classification system is to provide a method of adequately identifying PMMA materials using a system consistent with that of Classification System D4000. It further provides a means for specifying these materials by the use of a simple line callout designation.

1.2 This classification system covers poly(methyl methacrylate) molding and extrusion compounds. These compounds are polymers based on methyl methacrylate, and at least 70 % of the polymer shall be polymerized from methyl methacrylate.

1.3 The properties in this classification system are those required to identify the compositions covered. Other requirements necessary to identify particular characteristics important to specific applications shall be described by using the suffixes as given in Section 5.

1.4 Acrylic molding and extrusion compounds are used frequently in applications where extreme clarity and the ability to retain that clarity and color under severe weathering and other environmental exposures are of primary significance. While the test specimen properties of this document extend to the evaluation of nonvirgin materials, the user must take precautions to ensure that parts made from these materials meet the desired end-use requirements. Accordingly, this specification allows for the use of those acrylic plastic materials that can be recycled, reconstituted, and reground provided the following:

1.4.1 The requirements as stated in this specification are met, and

1.4.2 The requirements of the particular end-use application are met.

1.5 This classification system and subsequent line callout (specification) are not intended for the selection of materials, but only as a means to call out plastic materials to be used for the manufacture of parts. The selection of these materials is to be made by personnel with expertise in the plastics field in which the environment, inherent properties of the materials, performance of the parts, part design, manufacturing process, and economics are considered.

Note 1: This classification system is similar to ISO 8257-1:1987 in title only. The technical content is significantly different.

1.6 The values stated in SI units are to be regarded as standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D788 −16

Standard Classification System for

Poly(Methyl Methacrylate) (PMMA) Molding and Extrusion

1

Compounds

This standard is issued under the fixed designation D788; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* the manufacture of parts. The selection of these materials is to

be made by personnel with expertise in the plastics field in

1.1 The purpose of this classification system is to provide a

which the environment, inherent properties of the materials,

method of adequately identifying PMMA materials using a

performance of the parts, part design, manufacturing process,

system consistent with that of Classification System D4000.It

and economics are considered.

further provides a means for specifying these materials by the

use of a simple line callout designation.

NOTE 1—This classification system is similar to ISO 8257-1:1987 in

title only. The technical content is significantly different.

1.2 Thisclassificationsystemcoverspoly(methylmethacry-

1.6 The values stated in SI units are to be regarded as

late) molding and extrusion compounds.These compounds are

standard.

polymers based on methyl methacrylate, and at least 70% of

the polymer shall be polymerized from methyl methacrylate.

1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.3 The properties in this classification system are those

responsibility of the user of this standard to establish appro-

required to identify the compositions covered. Other require-

priate safety and health practices and determine the applica-

ments necessary to identify particular characteristics important

bility of regulatory limitations prior to use.

to specific applications shall be described by using the suffixes

as given in Section 5.

2. Referenced Documents

1.4 Acrylic molding and extrusion compounds are used

2

2.1 ASTM Standards:

frequentlyinapplicationswhereextremeclarityandtheability

D149Test Method for Dielectric Breakdown Voltage and

to retain that clarity and color under severe weathering and

DielectricStrengthofSolidElectricalInsulatingMaterials

other environmental exposures are of primary significance.

at Commercial Power Frequencies

While the test specimen properties of this document extend to

D150Test Methods forAC Loss Characteristics and Permit-

the evaluation of nonvirgin materials, the user must take

tivity (Dielectric Constant) of Solid Electrical Insulation

precautionstoensurethatpartsmadefromthesematerialsmeet

D257Test Methods for DC Resistance or Conductance of

the desired end-use requirements. Accordingly, this specifica-

Insulating Materials

tionallowsfortheuseofthoseacrylicplasticmaterialsthatcan

D618Practice for Conditioning Plastics for Testing

be recycled, reconstituted, and reground provided the follow-

D883Terminology Relating to Plastics

ing:

D1003Test Method for Haze and Luminous Transmittance

1.4.1 The requirements as stated in this specification are

of Transparent Plastics

met, and

D1238Test Method for Melt Flow Rates of Thermoplastics

1.4.2 Therequirementsoftheparticularend-useapplication

by Extrusion Plastometer

are met.

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

1.5 This classification system and subsequent line callout

tics

(specification) are not intended for the selection of materials,

D3641Practice for Injection Molding Test Specimens of

but only as a means to call out plastic materials to be used for

Thermoplastic Molding and Extrusion Materials

D3892Practice for Packaging/Packing of Plastics

1

ThisclassificationsystemisunderthejurisdictionofASTMCommitteeD20on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

2

Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2016. Published September 2016. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1944. Last previous edition approved in 2014 as D788–14. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D0788–16. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D788−1

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D788 − 14 D788 − 16

Standard Classification System for

Poly(Methyl Methacrylate) (PMMA) Molding and Extrusion

1

Compounds

This standard is issued under the fixed designation D788; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 The purpose of this classification system is to provide a method of adequately identifying PMMA materials using a system

consistent with that of Classification System D4000. It further provides a means for specifying these materials by the use of a

simple line callout designation.

1.2 This classification system covers poly(methyl methacrylate) molding and extrusion compounds. These compounds are

polymers based on methyl methacrylate, and at least 70 % of the polymer shall be polymerized from methyl methacrylate.

1.3 The properties in this classification system are those required to identify the compositions covered. Other requirements

necessary to identify particular characteristics important to specific applications shall be described by using the suffixes as given

in Section 5.

1.4 Acrylic molding and extrusion compounds are used frequently in applications where extreme clarity and the ability to retain

that clarity and color under severe weathering and other environmental exposures are of primary significance. While the test

specimen properties of this document extend to the evaluation of nonvirgin materials, the user must take precautions to ensure that

parts made from these materials meet the desired end-use requirements. Accordingly, this specification allows for the use of those

acrylic plastic materials that can be recycled, reconstituted, and reground provided the following:

1.4.1 The requirements as stated in this specification are met, and

1.4.2 The material has not been modified in any way to alter its conformance to food contact regulations or similar requirements,

and

1.4.2 The requirements of the particular end-use application are met.

1.5 This classification system and subsequent line callout (specification) are not intended for the selection of materials, but only

as a means to call out plastic materials to be used for the manufacture of parts. The selection of these materials is to be made by

personnel with expertise in the plastics field in which the environment, inherent properties of the materials, performance of the

parts, part design, manufacturing process, and economics are considered.

NOTE 1—This classification system is similar to ISO 8257-1:1987 in title only. The technical content is significantly different.

1.6 The values stated in SI units are to be regarded as standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D149 Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at

Commercial Power Frequencies

D150 Test Methods for AC Loss Characteristics and Permittivity (Dielectric Constant) of Solid Electrical Insulation

1

This classification system is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

Materials.

Current edition approved Aug. 1, 2014Sept. 1, 2016. Published September 2014September 2016. Originally approved in 1944. Last previous edition approved in 20122014

as D788 – 12.D788 – 14. DOI: 10.1520/D0788–14.10.1520/D0788–16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

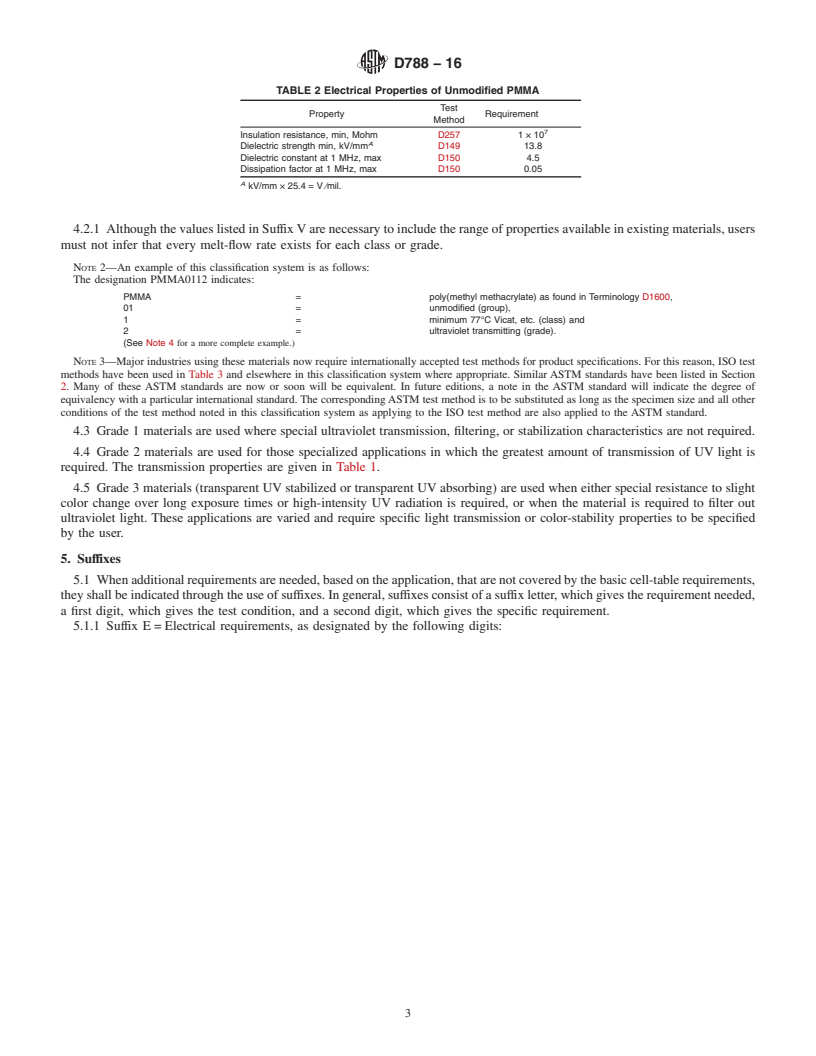

D788 − 16

TABLE 1 Transmission of Grade 2 Materials at Various

A,B

Wavelengths

Wavelength, nm Transmission, min, %

400 86

340 85

310 70

290 50

280 26

27

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.